Adjustable guiding tension device of steel wire ring wrapping and winding machine

A technology of winding machine and bead ring, applied in the field of bead wrap wrapping machine, can solve the problems that affect the quality of tire manufacturing, cannot be completely solved, and the tension is inconvenient to adjust, so as to reduce the phenomenon of bead bursting, and the wrapping cloth is tight and consistent. , high tension and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

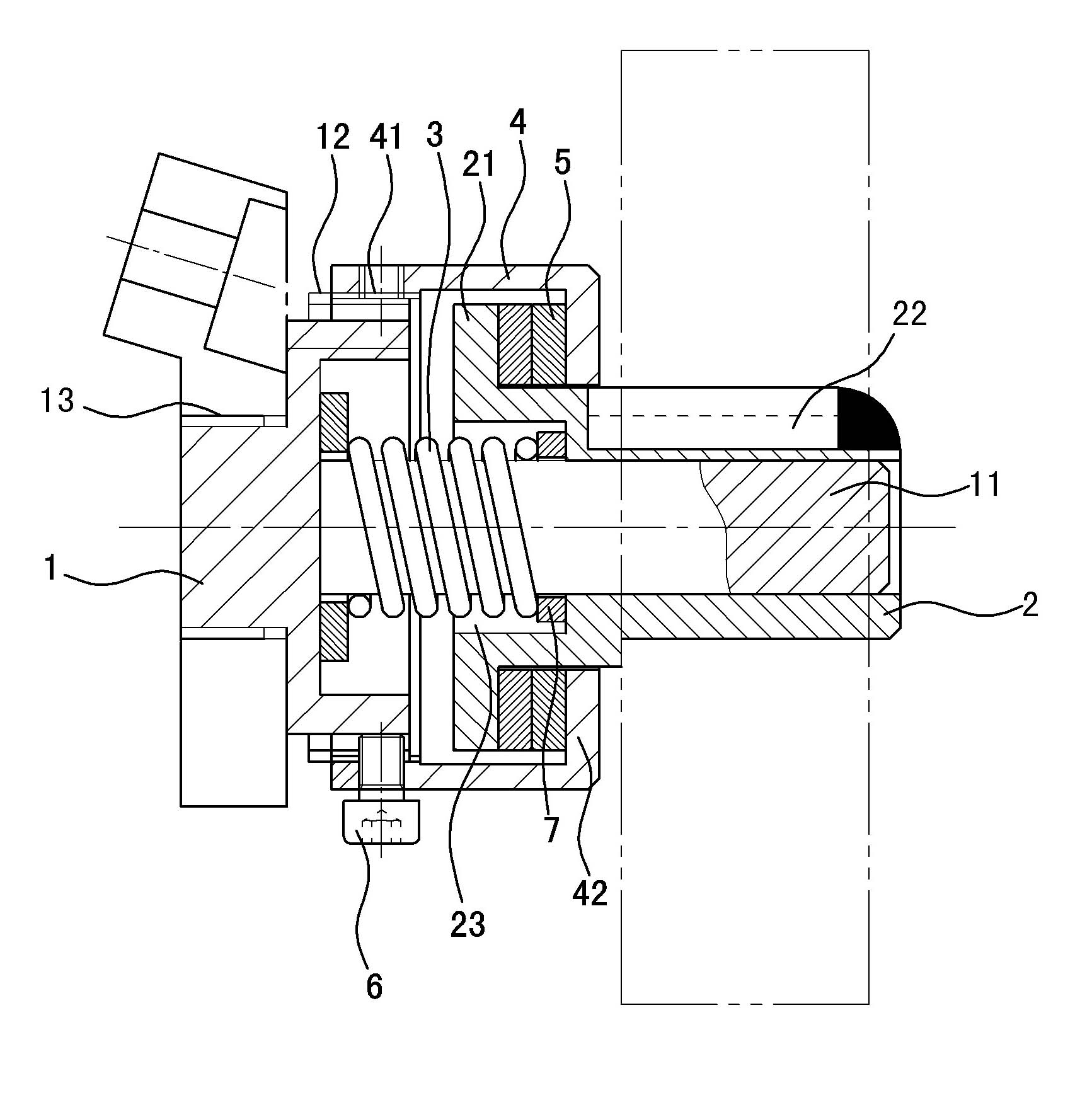

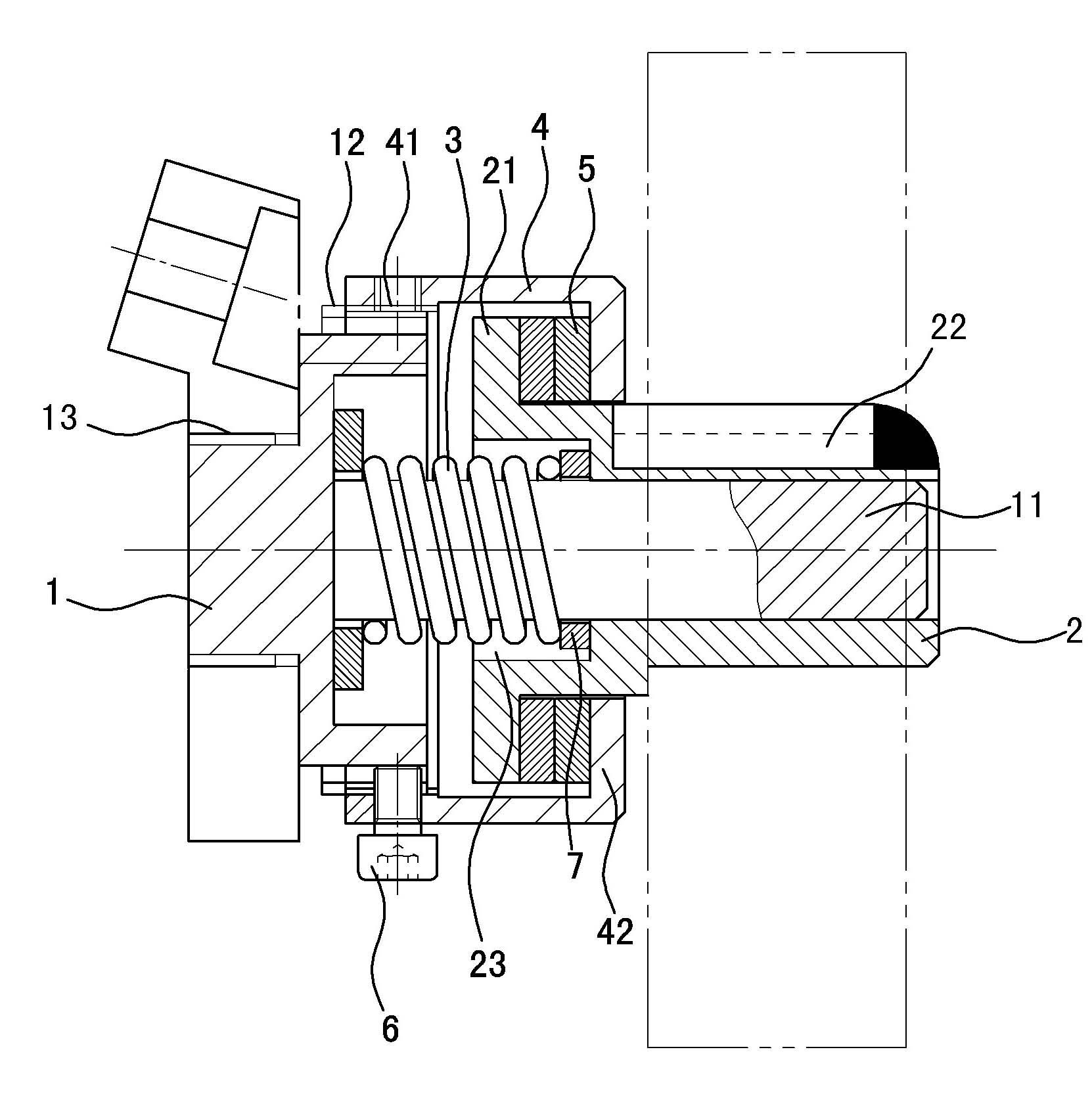

[0008] As shown in the drawings, it includes a fixed shaft seat 1 installed on the base of the traveler cloth winding machine during use, and a rotating seat 2 that is rotatably mounted on the central axis 11 of the fixed shaft seat 1 and used to install and unwind the traveler cloth roll. , it also includes a pressure spring 3, a threaded lock cap 4 and two friction plates 5, the pressure spring 3 is located between the fixed shaft seat 1 and the rotating seat 2 and is sleeved on the central axis 11 of the fixed shaft seat 1, and each friction plate 5 is respectively The shaft end side of the central axis 11 of the fixed shaft seat is sleeved on the rotary seat 2 and pressed axially on the rotary seat 2, and the thread lock cap 4 is sleeved on the rotary seat 2 and each friction plate 5 from the axial end side of the central shaft 11 of the fixed shaft seat and axially press on the friction plate 5 in contact with it, and the end of the threaded lock cap 4 that passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com