A kind of high-density polyethylene oil-water separation material and preparation method thereof

A technology of high-density polyethylene and oil-water separation, which is applied in the field of high-density polyethylene oil-water separation materials and its preparation, and the preparation of three-dimensional porous oil-water separation materials, which can solve the problems of low applicability, environmental pollution, and easy crushing and damage. Achieve safety and environmental protection in the processing process, high-efficiency oil-water separation effect, and good oil-water separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

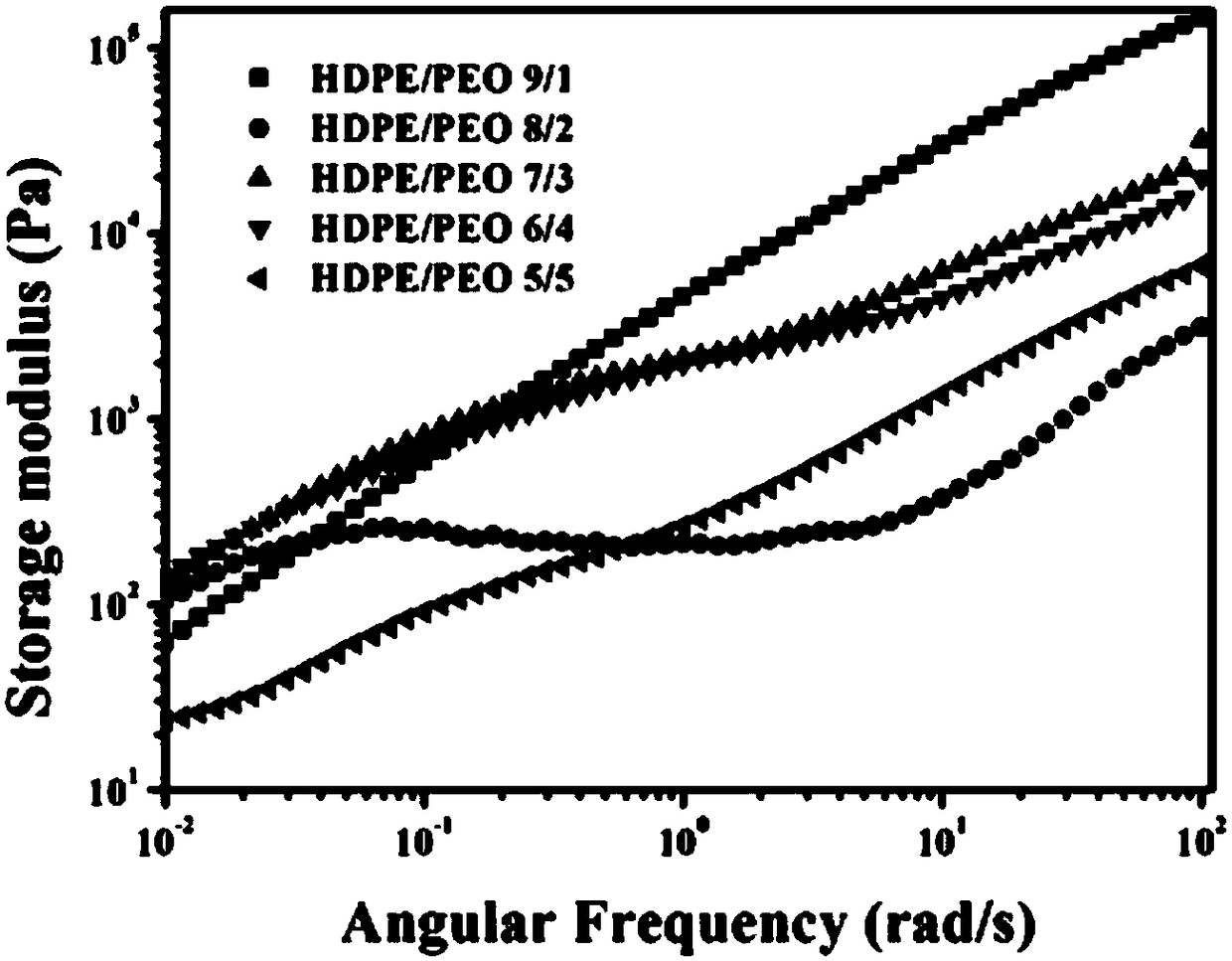

[0043] The rheological experiment of samples prepared with different mass ratios of polyethylene oxide and high-density polyethylene comprises the following steps:

[0044] (1) Mix the polyethylene oxide powder with deionized water to form a paste (the mass fraction of polyethylene oxide is 40~50%), and then put the paste mixture in an oven at 30 Dry at ~40°C for 2~3 days until its quality no longer changes, and then crush it into polyethylene oxide pellets after cooling to room temperature;

[0045] (2) The polyethylene oxide pellets obtained in step (1) and the high-density polyethylene pellets are respectively in mass ratios of 1:9, 1:4, 1:2.3, 1:1.5, and 1:1. Add it into a micro-twin-screw extruder for melt extrusion, the temperature of melt extrusion is 140~160°C, and the speed of the screw is 8~12rpm;

[0046] (3) Breaking the continuous rope-shaped strips melted and extruded in step (2) into pellets respectively, and set aside;

[0047] (4) Press the pellets obtained ...

Embodiment 2

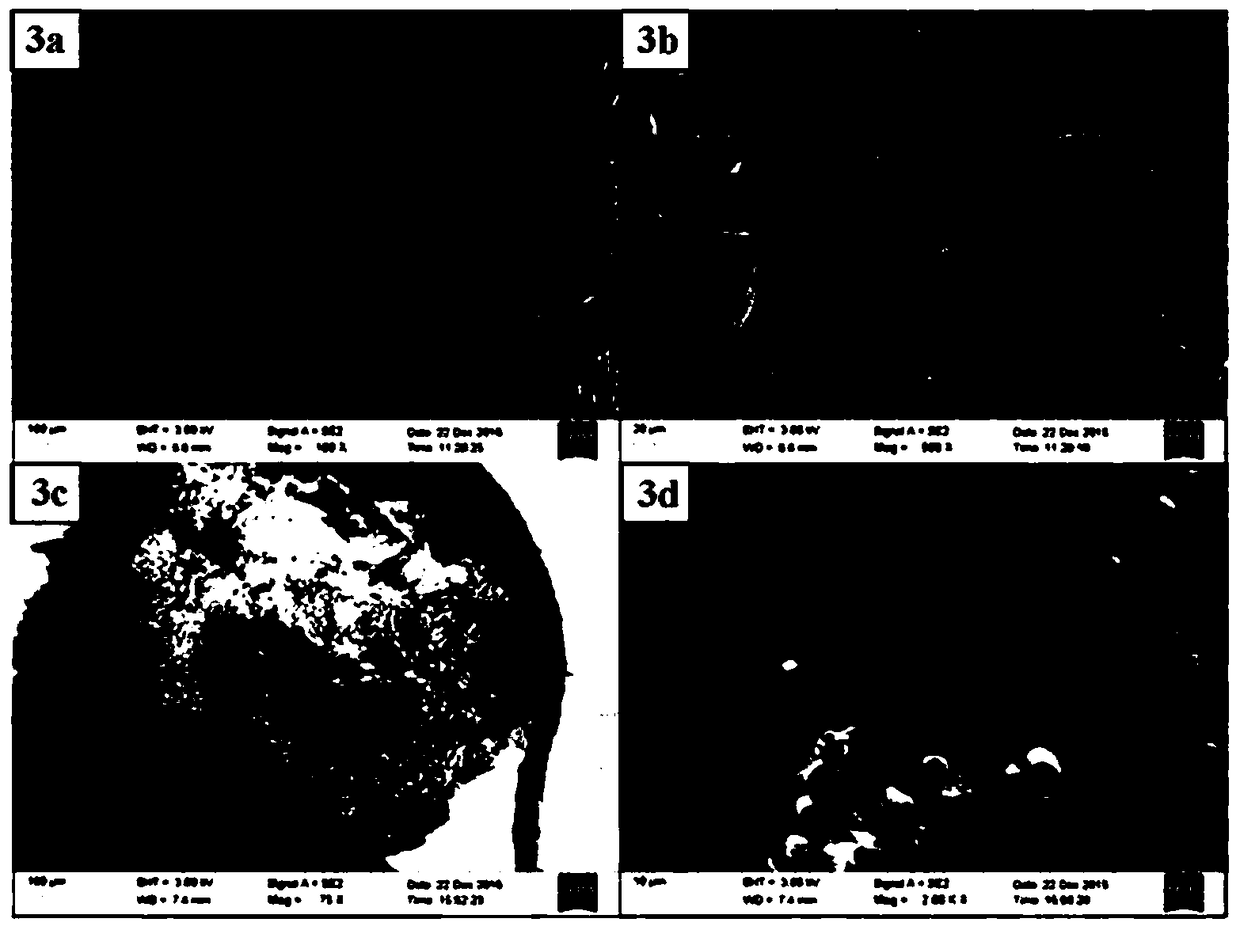

[0051] One of the preparation methods of high-density polyethylene oil-water separation material, comprising the following steps:

[0052] (1) Mix polyethylene oxide powder with deionized water to form a paste (the mass fraction of polyethylene oxide is 40~50%), and then put the mixture in an oven at 35±5 Dry at ℃ for 2~3 until its quality no longer changes, and then break it into polyethylene oxide pellets after cooling to room temperature;

[0053] (2) Add the polyethylene oxide pellets and high-density polyethylene pellets obtained in step (1) to a micro-twin-screw extruder at a mass ratio of 1:1 for melt extrusion, and the melt-extruded The temperature is 140~160°C, and the rotation speed of the screw is 8~12rpm;

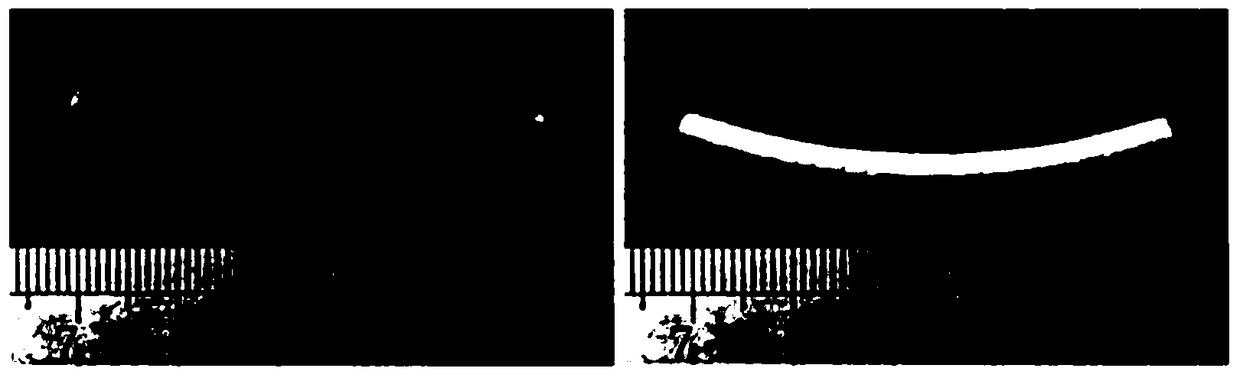

[0054] (3) Collect the continuous rope-shaped material strips melted and extruded in step (2) in a non-stretched state with a coiler. The collection rate of the coiler is 20±2cm / min, and then the collected continuous The rope-like strips are cut into small con...

Embodiment 3

[0061] The second preparation method of high-density polyethylene continuous fiber bundle comprises the following steps:

[0062] (1) Mix polyethylene oxide powder with deionized water to form a paste (the mass fraction of polyethylene oxide is 40~50%), and then put the mixture in an oven at 35±5 Dry at ℃ for 2~3 days until its quality no longer changes, and then break it into polyethylene oxide pellets after cooling to room temperature;

[0063] (2) Add the polyethylene oxide pellets and high-density polyethylene pellets obtained in step (1) to a micro-twin-screw extruder with a mass ratio of 1:9 for melt extrusion, and the melt-extruded The temperature is 140~160°C, and the rotation speed of the screw is 8~12rpm;

[0064] (3) Collect the continuous rope-shaped material strips melted and extruded in step (2) in a non-stretched state with a coiler. The collection rate of the coiler is 20±2cm / min, and then the collected continuous The rope-like strips are cut into small conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com