Continuous honeycomb core manufacturing process and manufacturing device thereof

A manufacturing process and honeycomb core technology, applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve the problems of inaccurate control of cutting accuracy, low bonding efficiency, poor flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

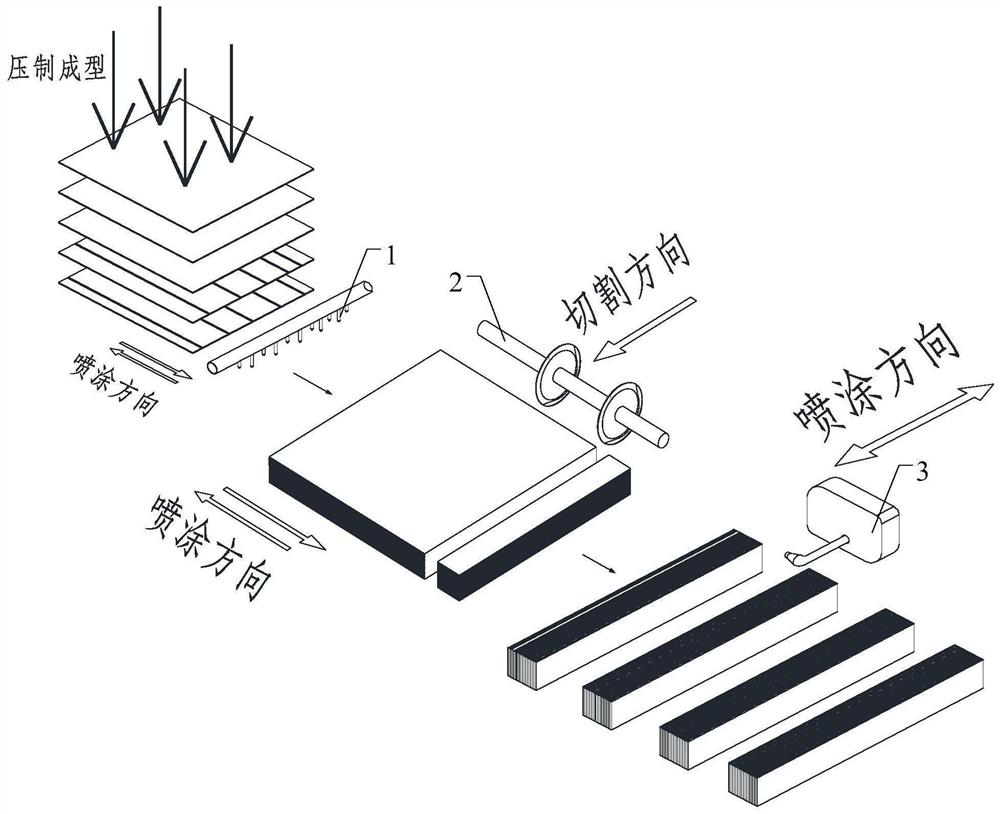

[0022] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution and provides detailed implementation and specific operation procedures, but the scope of protection of the present invention is not limited to this Examples.

[0023] figure 1 This is a flowchart of a continuous honeycomb core manufacturing process according to an embodiment of the present invention, such as figure 1 As shown, the structure of the present invention includes the following steps:

[0024] S1. Spray adhesive on the laminated surfaces of multiple honeycomb core materials of the same size; in step S1, the adhesive sprayed on two adjacent layers of honeycomb core materials are arranged in a staggered manner. After the spraying is completed, a diamond shape can be formed by pulling vertically honeycomb.

[0025] S2. Lay the sprayed multiple honeycomb core materials one by one on top of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com