Electroplating groove

A technology of electroplating tank and tank body, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve problems such as easy overflow and temperature difference of electroplating solution, and achieve the effect of avoiding temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

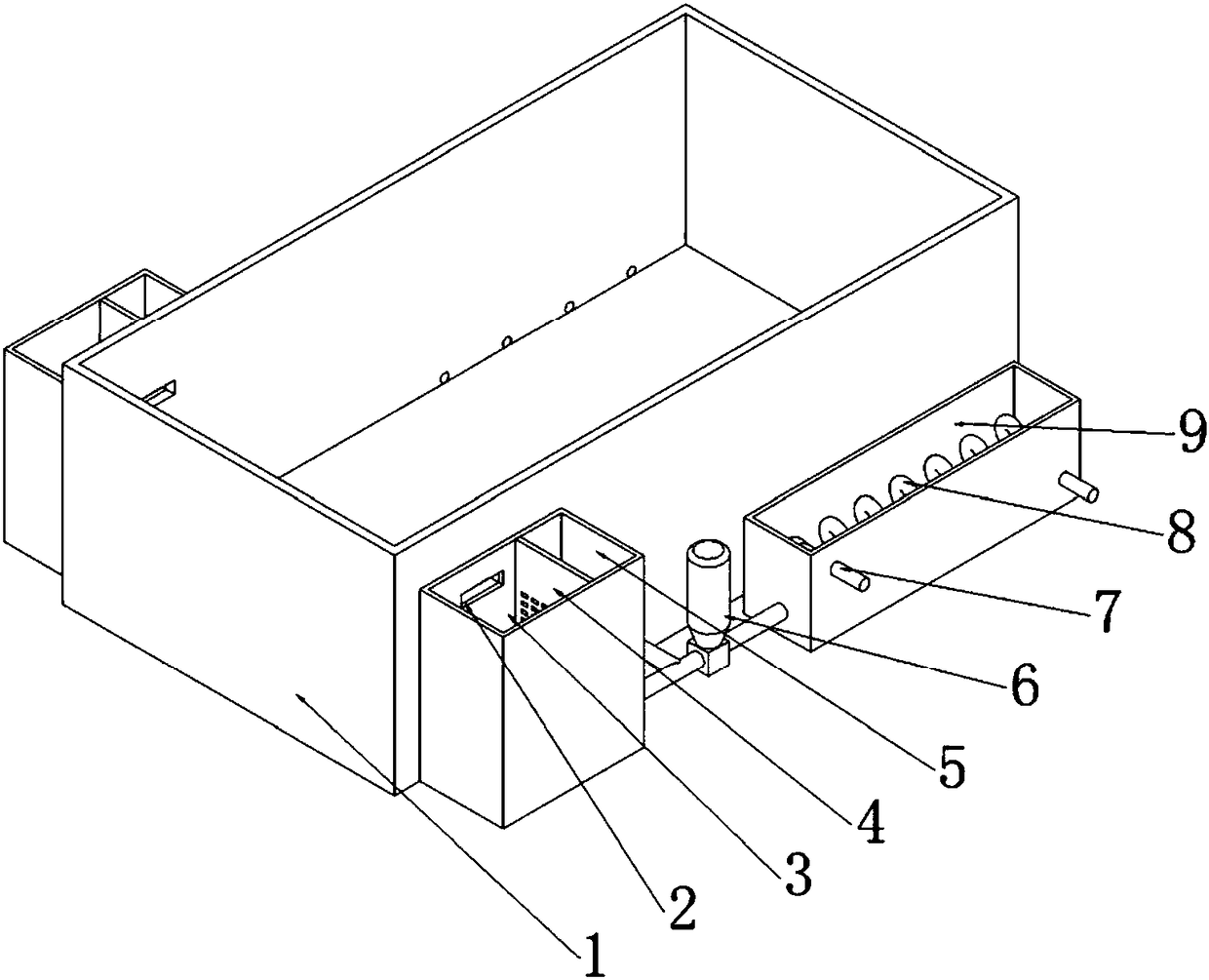

[0017] Example 1 as figure 1 Shown: the electroplating tank of the present invention comprises a main tank body 1 and two sets of overflow tanks and temperature-variable tanks 9 that are matched with each other. A temperature-variable pump 6 is arranged between the overflow tank and the temperature-variable tank 9. The overflow tank and the temperature-variable tank 9 are It is connected with the variable temperature pump 6 through pipelines, wherein an overflow port 2 is provided on the outer walls of the two sides of the main tank body, and the overflow port 2 is connected to the overflow tank, and the overflow tank is composed of the settling chamber 3 and the clear liquid The settling chamber 3 and the clear liquid chamber 5 are separated by a filter screen 4. This filter screen 4 is used to isolate impurities and sediments. In order to ensure the settling effect and filtering effect, the inner bottom of the settling chamber 3 is low. On the inner bottom surface of the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com