Differential current sensor

A differential current and sensor technology, applied in the direction of measuring current/voltage, parts and instruments of electrical measuring instruments, etc., can solve the problems of impossible calibration and connection, and achieve the effect of preventing temperature difference and improving the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

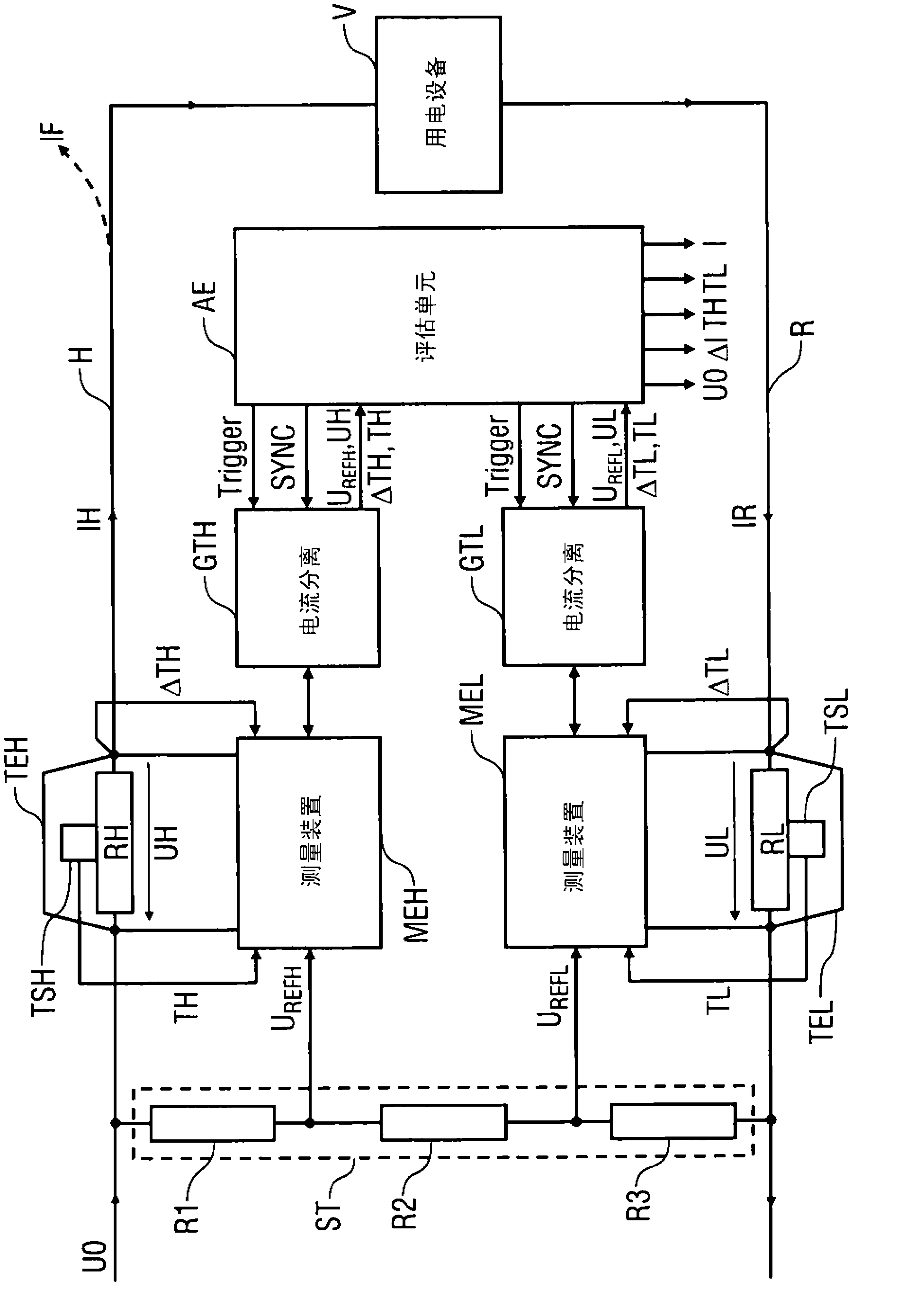

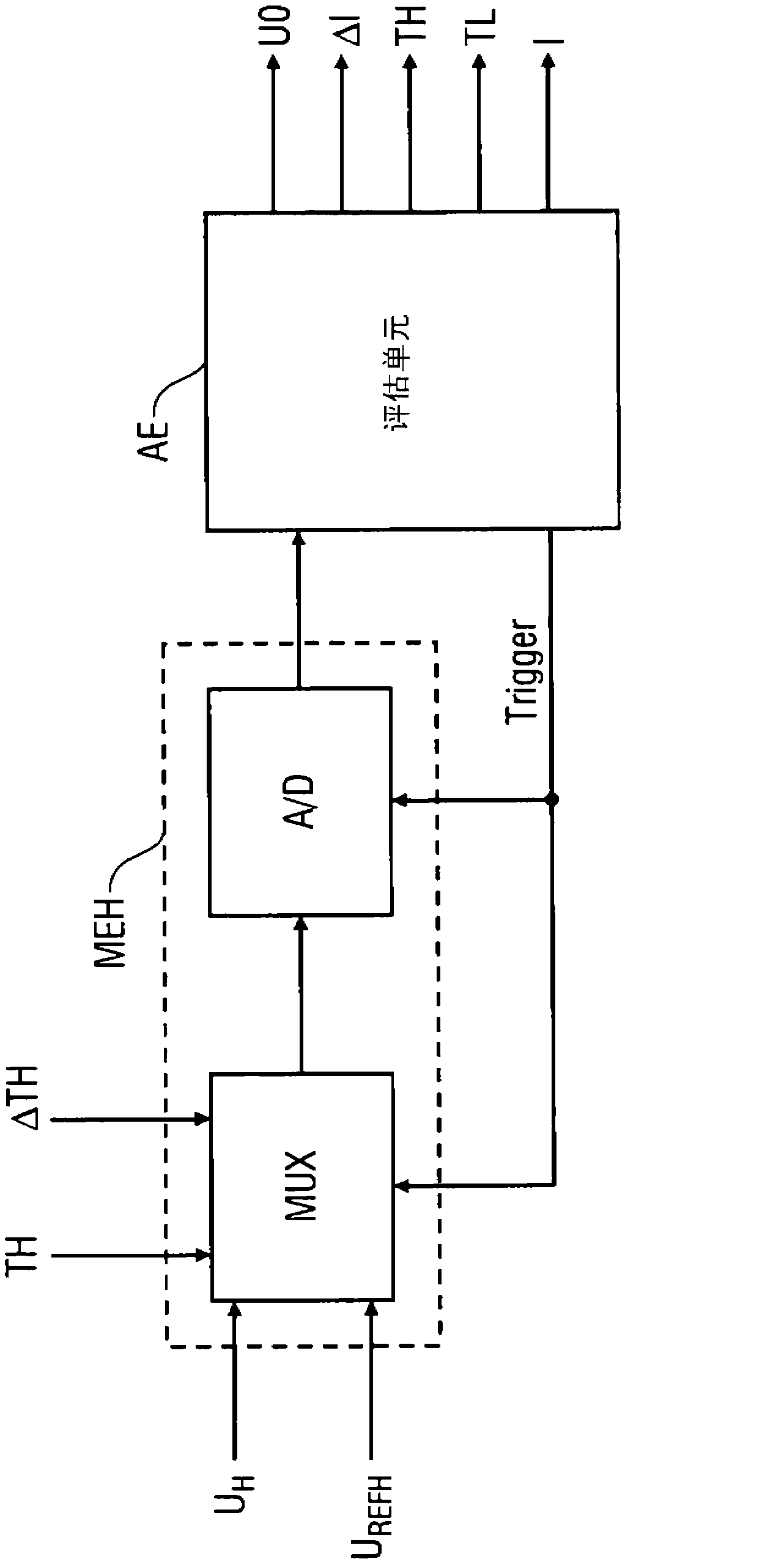

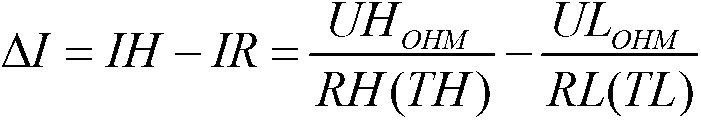

[0030] The drawing shows a schematic diagram of a differential current sensor according to the invention, which can be used, for example, in a single-phase DC power supply network in order to measure the differential current ΔI.

[0031]The DC power supply network is only schematically shown here. In essence, the DC power supply network is composed of a transmission wire H, a loop wire R and a schematically shown electrical device V, wherein the current IH flows through the transmission wire H to reach the user The electrical equipment V, while the corresponding current IR flows back through the loop wire R.

[0032] In the case of fault-free operation, the current IH through the supply conductor H corresponds exactly to the current IR through the return conductor R.

[0033] In the event of a fault, however, for example in the event of a short circuit to ground or a leakage current to ground, a fault current IR may flow away from the feed conductor H. In the event of such a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com