Anti-crack concrete suitable for large stations and construction method

A construction method and concrete technology, applied in artificial islands, water conservancy projects, building types, etc., can solve the problems of concrete volume shrinkage, cracks, shrinkage deformation, etc., and achieve the effect of reducing the number of shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the anti-crack concrete construction method suitable for large stations described in the embodiments of the present invention, the method comprises the following steps:

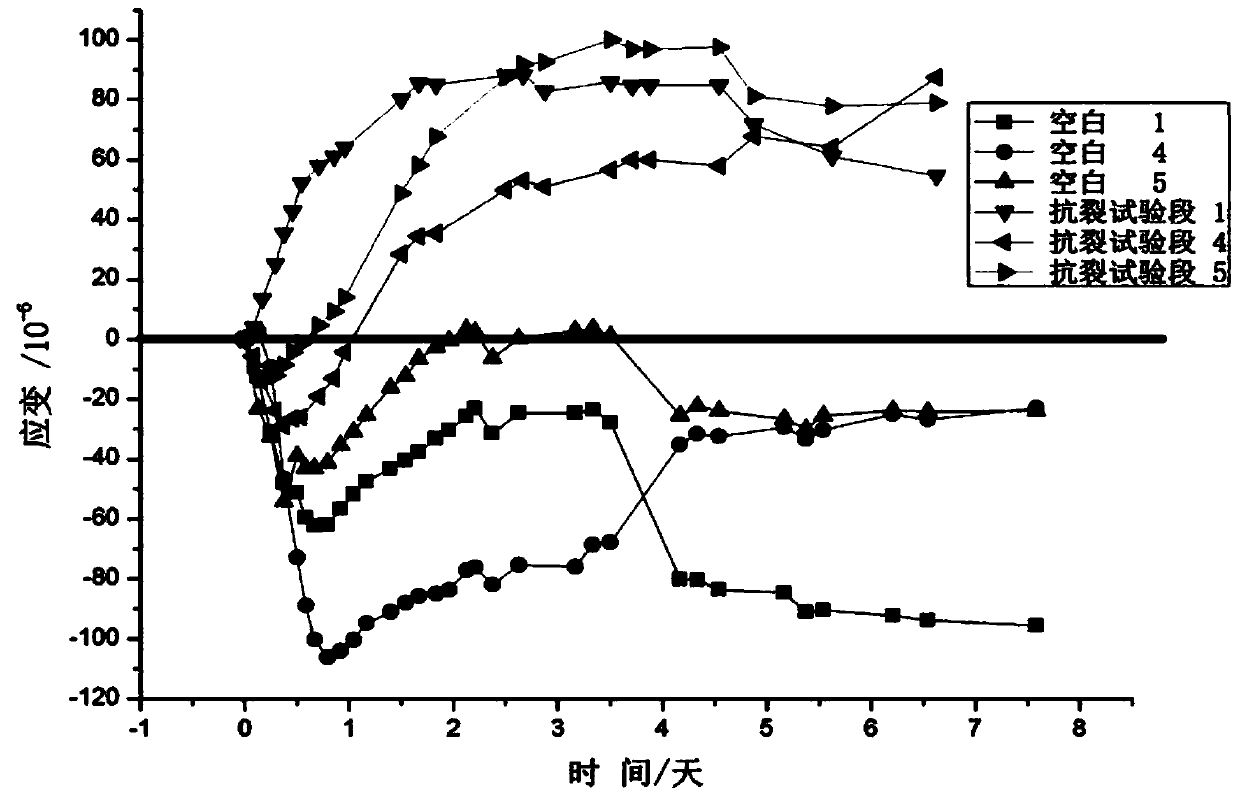

[0033] (1) After the steel bars are bound and before the formwork is installed, embedded vibrating wire strain gauges are embedded to monitor the strain and temperature changes inside the concrete in real time, and to control the temperature difference between the inside and outside of the allowable value; the strain gauges are embedded in the side walls 1 / 2 of the height direction, 1 / 4, 1 / 2 and 3 / 4 of the side wall in the horizontal direction, a total of 3 wires are embedded, and the embedding depth is 1 / 2 of the thickness of the side wall. After the embedding is completed, the test line Lead to the post-pouring belt or other places that are convenient for testing after concrete pouring, and protect the measuring head of the strain gauge to prevent damage or water ingress from affecting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com