Overflow dam with dam face cantilever sills for current diversion and energy dissipation

An overflow dam and energy dissipation technology, which is applied in the direction of dams, gravity dams, water conservancy projects, etc., can solve the problems of increased impact on the front end of the stilling pool, poor energy dissipation effect, and damage to the bottom plate of the stilling pool. The effect of energy dissipating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

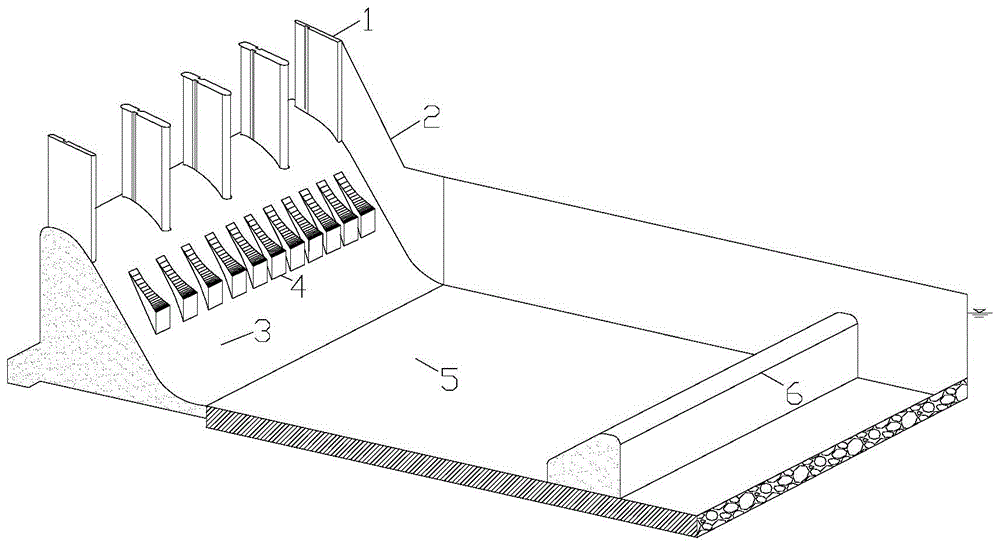

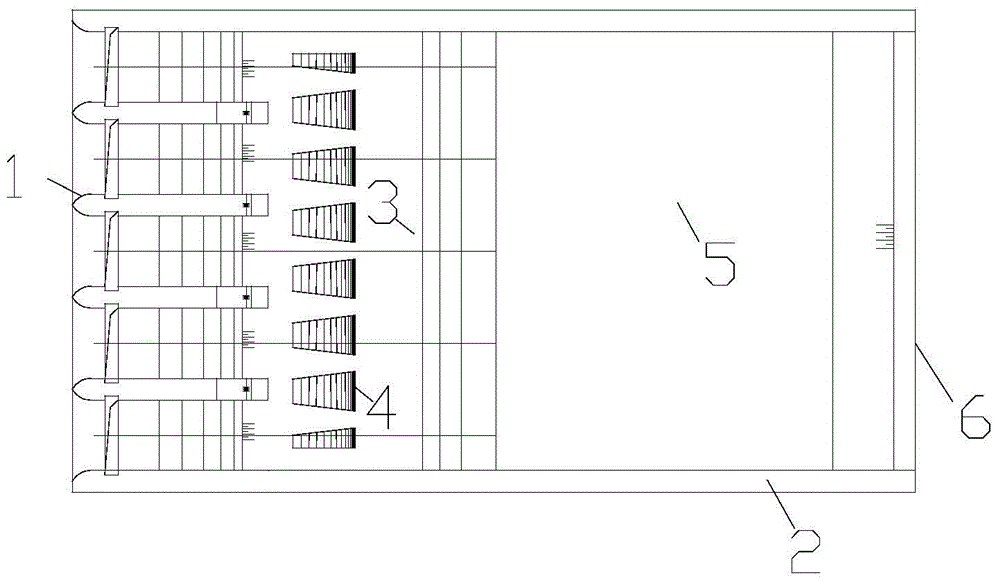

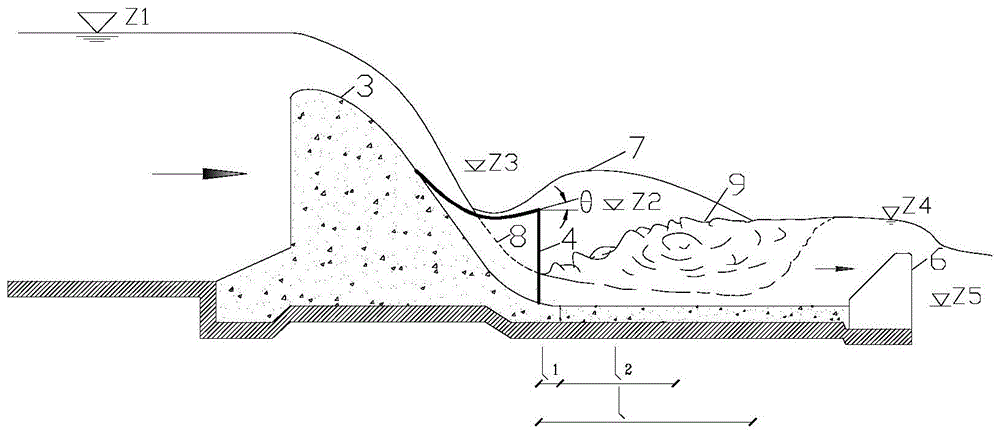

[0026] The overflow dam of the dam surface of the present embodiment is raised to divert and dissipate energy, and its structure is as attached figure 1 And attached figure 2 As shown, the discharge slope surface 3 of the overflow dam is connected straightly with the bottom of the stilling tank 5, and the side wall 2 of the discharge slope surface is connected to the protective side wall of the stilling tank behind. The crest of the overflow dam is designed with several The water body flow area is divided into several gate piers 1 with surface holes, and the discharge slope of the overflow dam is provided with a number of anti-arc shunt ridges 4 distributed at intervals, so that part of the water flow from the surface holes passes through the anti-arc ridges to lift The form of water flow enters the second half area of the stilling pool, while another part of the water flows into the front half area of the stilling pool through the flow channel between the two ridges. Am...

Embodiment 2

[0028] In the overflow dam of the present embodiment, the dam face lifts the ridge to divert flow and dissipate energy. The discharge slope surface 3 of the overflow dam is connected to the bottom of the stilling basin 5 through a drop ridge, and the side wall 2 of the discharge slope surface is connected to the stilling basin behind. The protective side wall and the crest of the overflow dam are designed with a number of gate piers 1 that divide the water body flow area into a number of surface holes, and the discharge slope of the overflow dam is provided with a number of anti-arc diversion risers 4 that are distributed at intervals, so that from Part of the water flow from the surface hole enters the second half of the stilling pool in the form of deflected flow through the anti-arc ridge, while the other part of the water flows into the front half of the stilling pool through the flow channel between the two ridges. Among them, the distance between the central axes of two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com