Eddy-current vertical-well energy dissipation structure of water discharging hole for ditchwater treatment and water discharging method

A technology for ditch water treatment and whirlpool shafts, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as hidden safety hazards, long tunnel lines, and large amount of water outlet protection works, so as to facilitate construction and save engineering investment. Good effect, energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

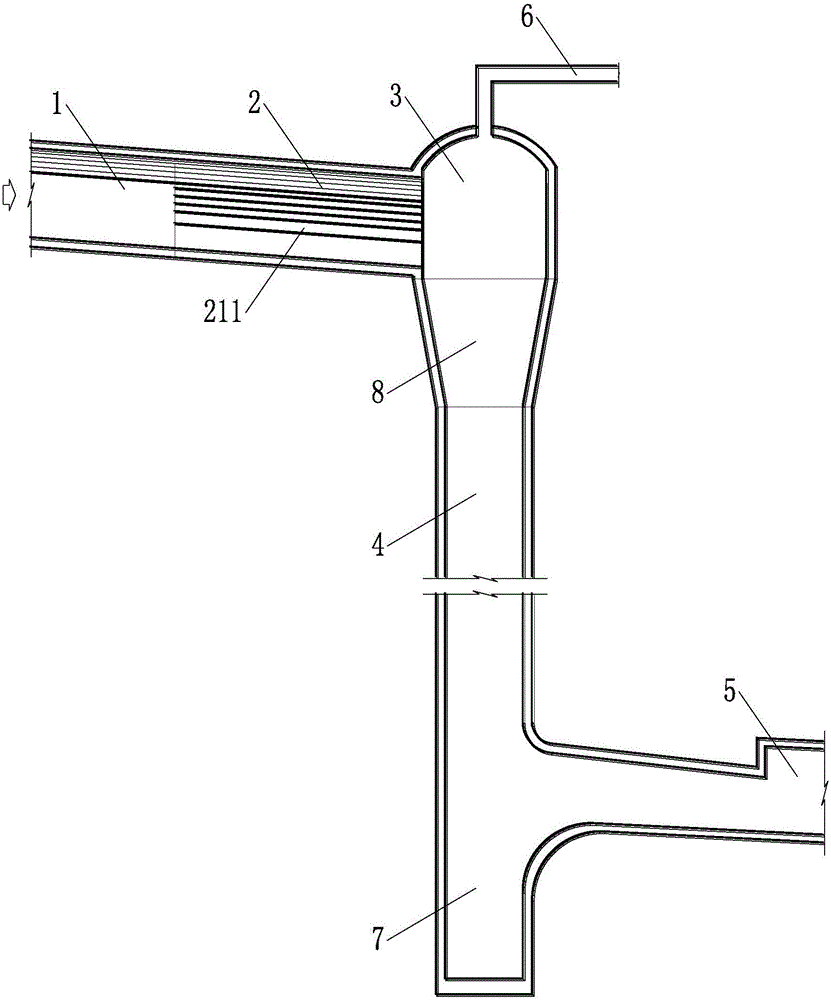

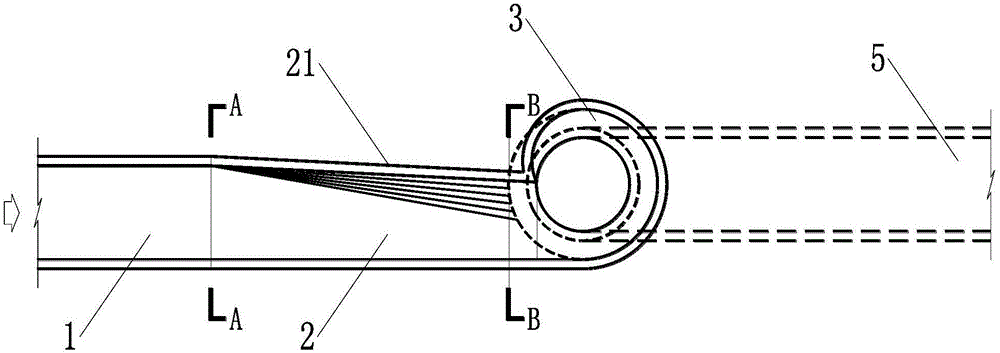

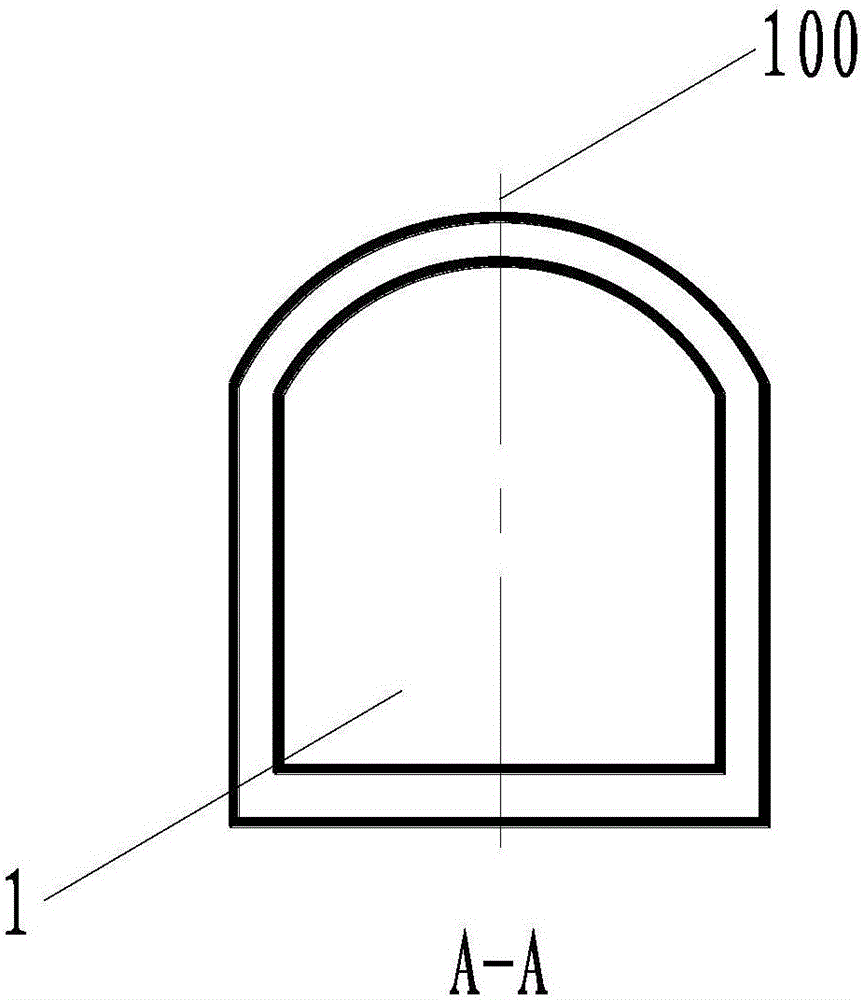

[0025] The present invention will be further described below in conjunction with accompanying drawing, and the direction of the arrow in the figure is the direction of water flow.

[0026] Such as Figure 1 to Figure 5 As shown, the drain hole swirl shaft energy dissipation structure for ditch water treatment of the present invention includes a high drain hole 1, a side contraction hole 2, a swirl vortex chamber 3, a vertical shaft 4, a low drain hole 5 and a ventilation hole 6. The side contraction hole 2 is arranged between the high drainage hole 1 and the vortex vortex chamber 3, the top of the vertical shaft 4 communicates with the vortex vortex chamber 3, and the bottom end of the vertical shaft 4 communicates with the low drainage hole 5. The ventilation hole 6 is arranged on the top of the vortex chamber 3, and the side contraction hole 2 has an inclined contraction side wall 21, and the inclined contraction side wall 21 is arranged obliquely, and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com