Self-compaction enrockment concrete gravity dam structure and construction method thereof

A rockfill concrete and construction method technology, applied in gravity dams, foundation structure engineering, dams, etc., can solve the problems of large concrete pouring volume, achieve the effects of shortening the construction period, simplifying temperature control measures, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

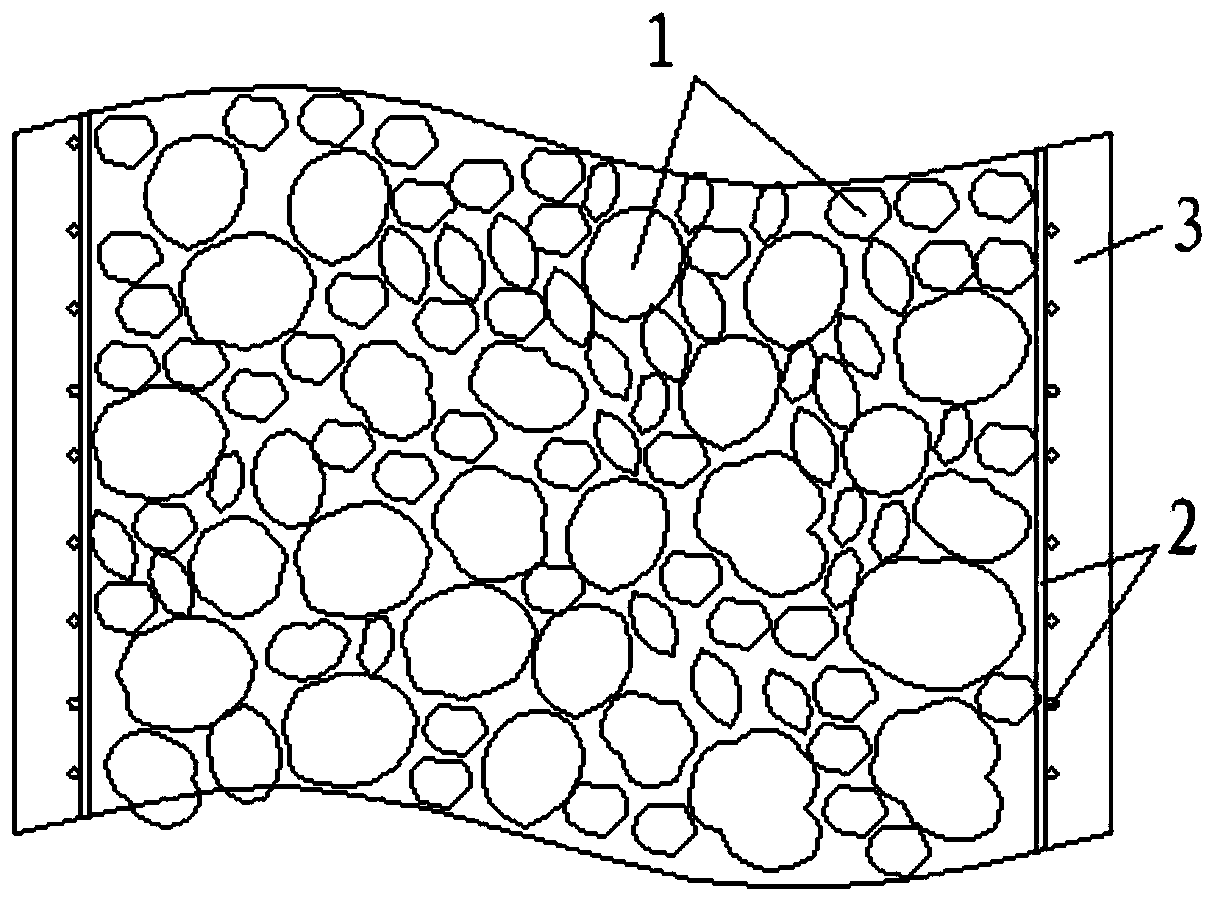

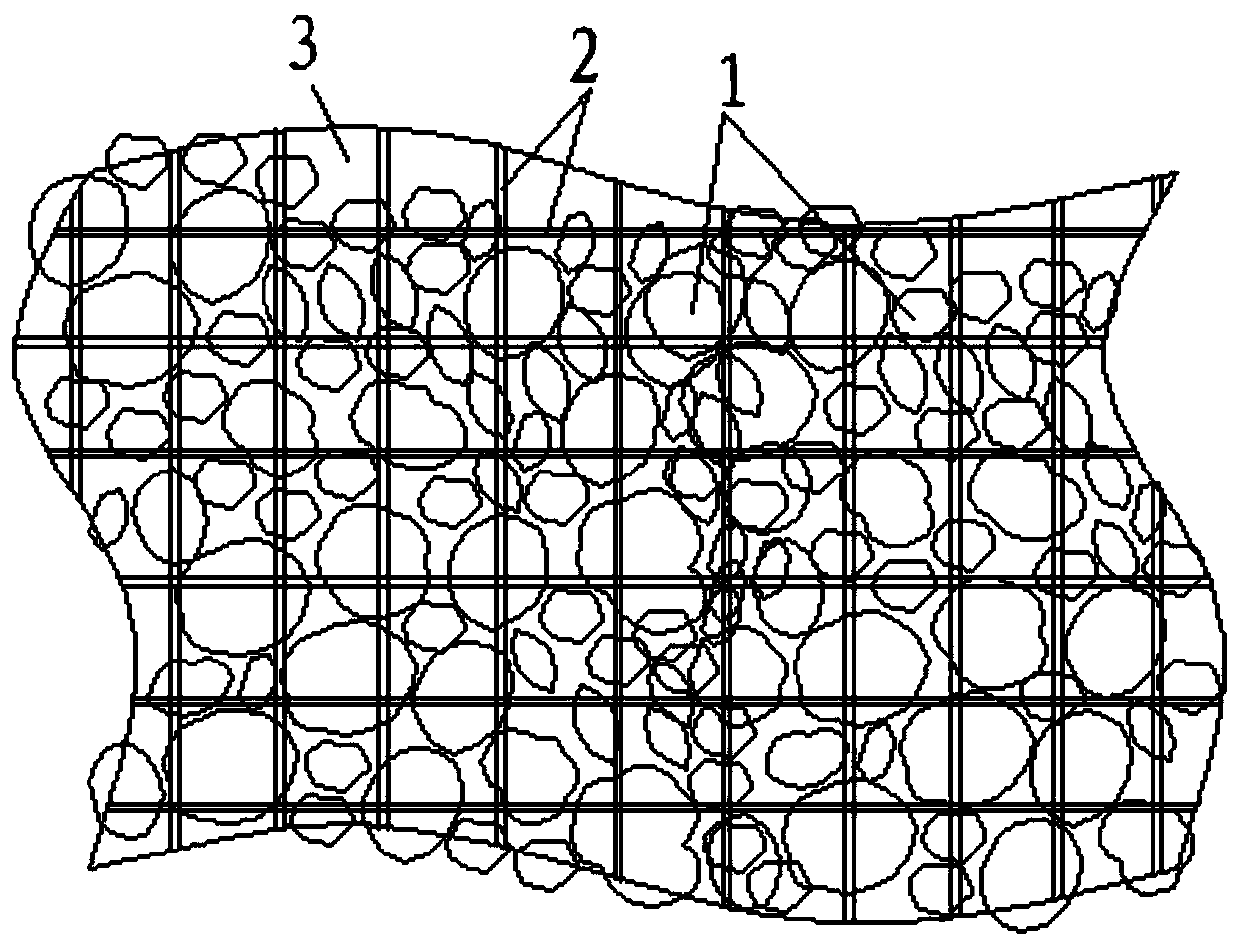

[0016] Embodiment 1: as attached Figure 1~2 Shown, a kind of self-compacting rockfill concrete gravity dam structure, it comprises steel bar layer 2, rockfill material layer 1 and concrete material 3, and described rockfill material layer 1 is positioned at the middle of dam body and is arranged vertically, in rockfill material layer The two sides of 1 are arranged with vertically arranged steel bar layers 2, and the concrete material (3) covers the rockfill material layer 1 and the steel bar layer 2 inside.

[0017] Further, the reinforcing bar layer 2 includes horizontal and vertical reinforcing bars that are uniformly arranged.

[0018] Further, the rockfill particle size of the rockfill material layer 1 is 300-1000 mm, and the maximum particle size of the rockfill should not exceed 1 / 4 of the minimum side length of the dam structure section.

[0019] A construction method for a self-compacting rockfill concrete gravity dam structure, the steps of the method are: 1. clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com