Mixed constructing method of high concrete gravity dam and high concrete gravity dam

A concrete and gravity dam technology, applied in the field of high concrete gravity dams, can solve the problems of slow construction progress and achieve the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

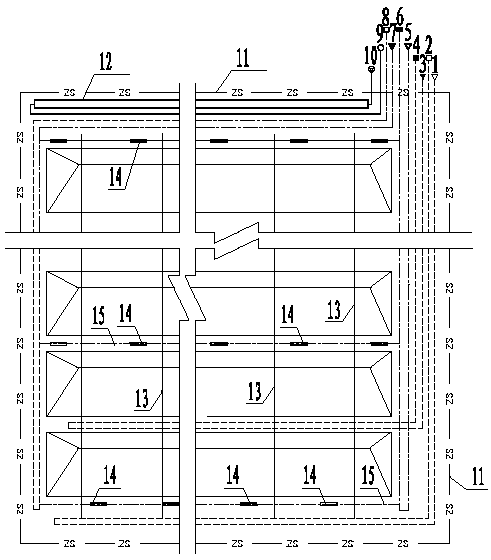

[0055] A kind of high concrete gravity dam hybrid dam construction method, comprises the steps:

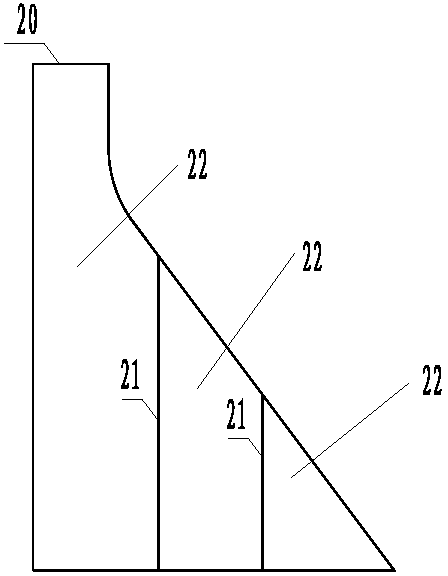

[0056] 1) Set longitudinal joints to divide the dam body into multiple dam blocks;

[0057] 2) For some dam blocks that must be poured with normal concrete, use normal concrete for pouring, while for the rest of the dam blocks that must not be poured with normal concrete and need to speed up the construction progress, use roller compacted concrete for pouring;

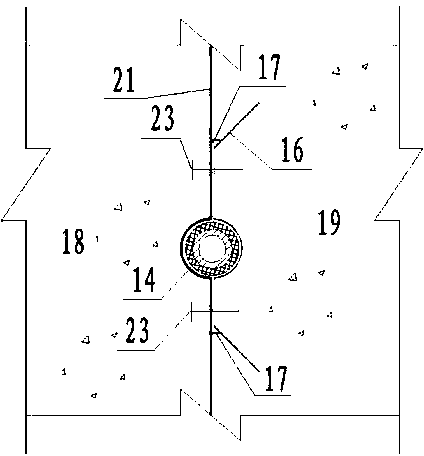

[0058] 3) For the longitudinal joints between the dam blocks poured by roller compacted concrete and the dam blocks poured by normal concrete, a conventional grouting system and a repeated grouting system are set;

[0059] 4) Grout the longitudinal joints between the dam blocks using a conventional grouting system;

[0060] 5) Use the repeated grouting system to grout the re-opened longitudinal joints multiple times.

[0061] Such as Figure 4 As shown, a high concrete gravity dam is built by the above-mentioned dam bui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com