Large area sawed joint cutting construction method of concrete gravity dam cross joint

A construction method and gravity dam technology, applied in gravity dams, earthwork drilling, drilling equipment and methods, etc., can solve problems such as failure to repair defects, and achieve fast construction speed, low cost, and high construction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

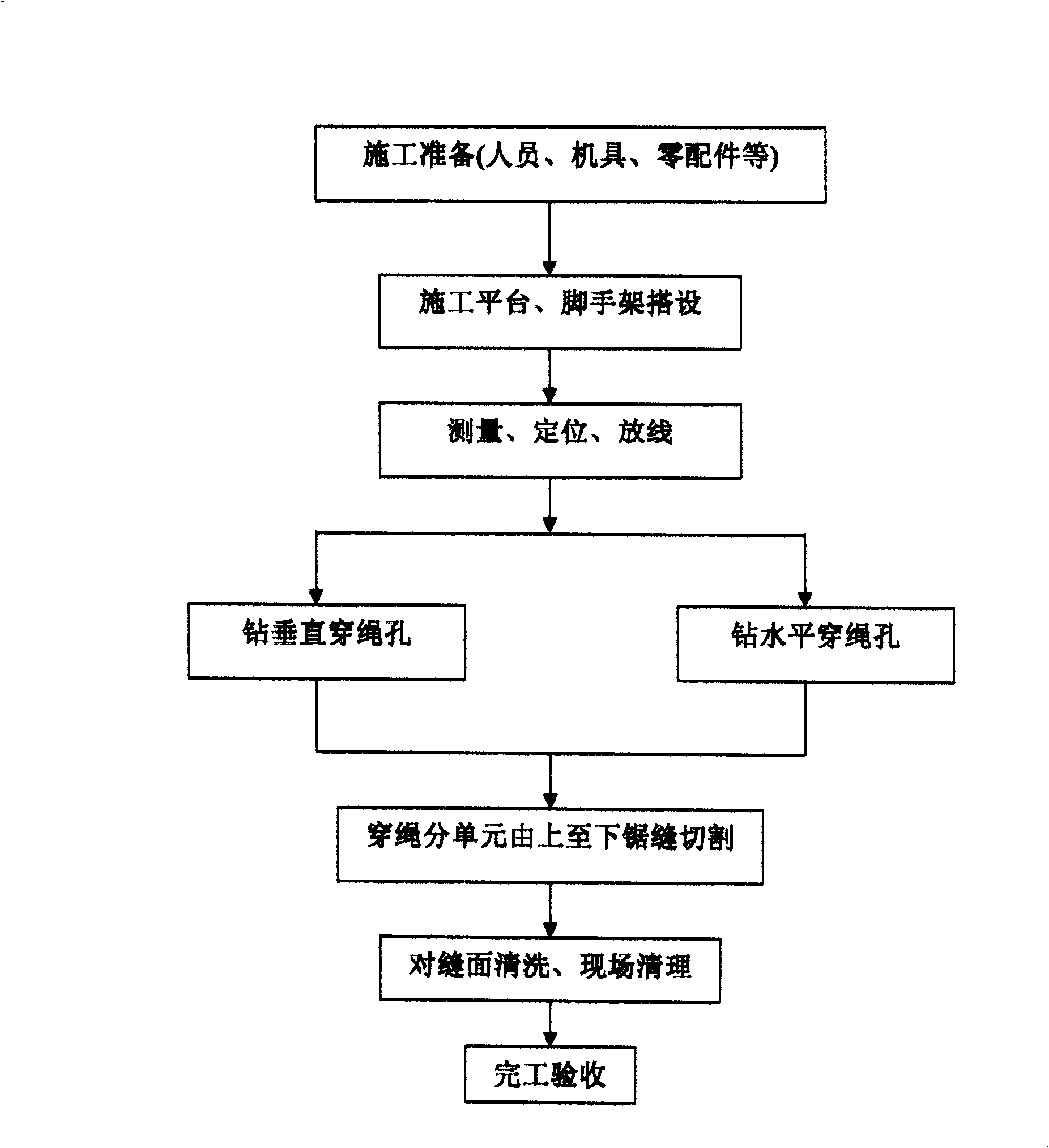

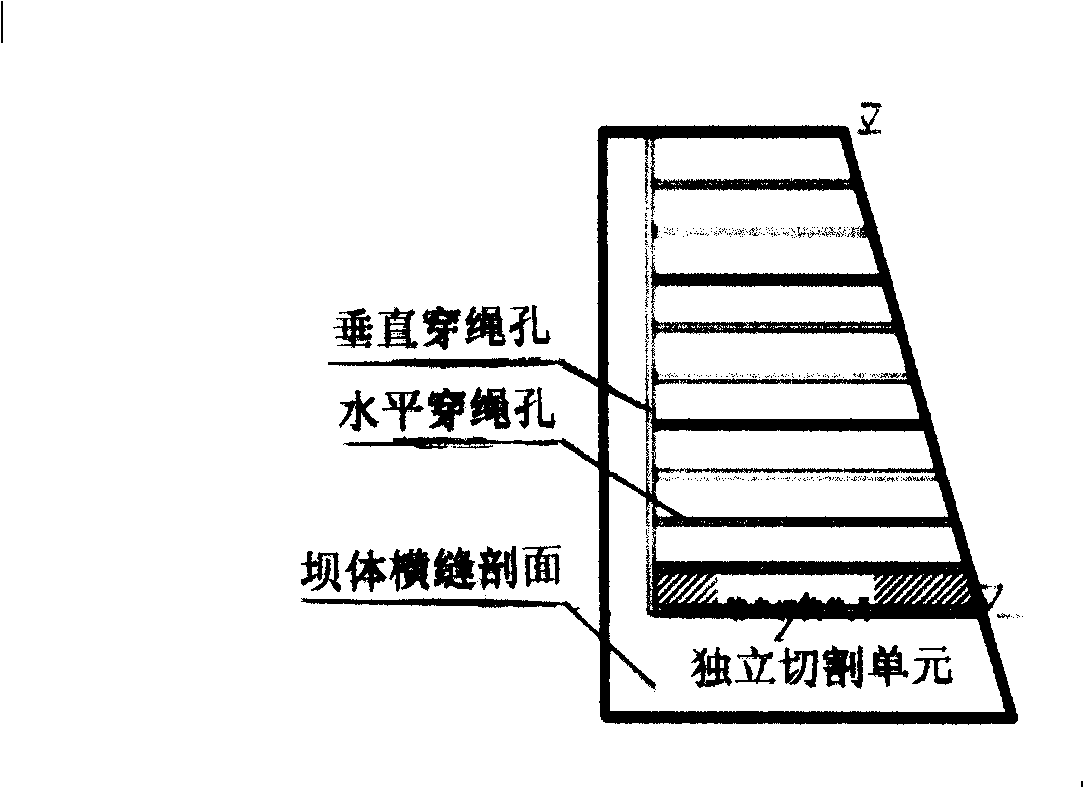

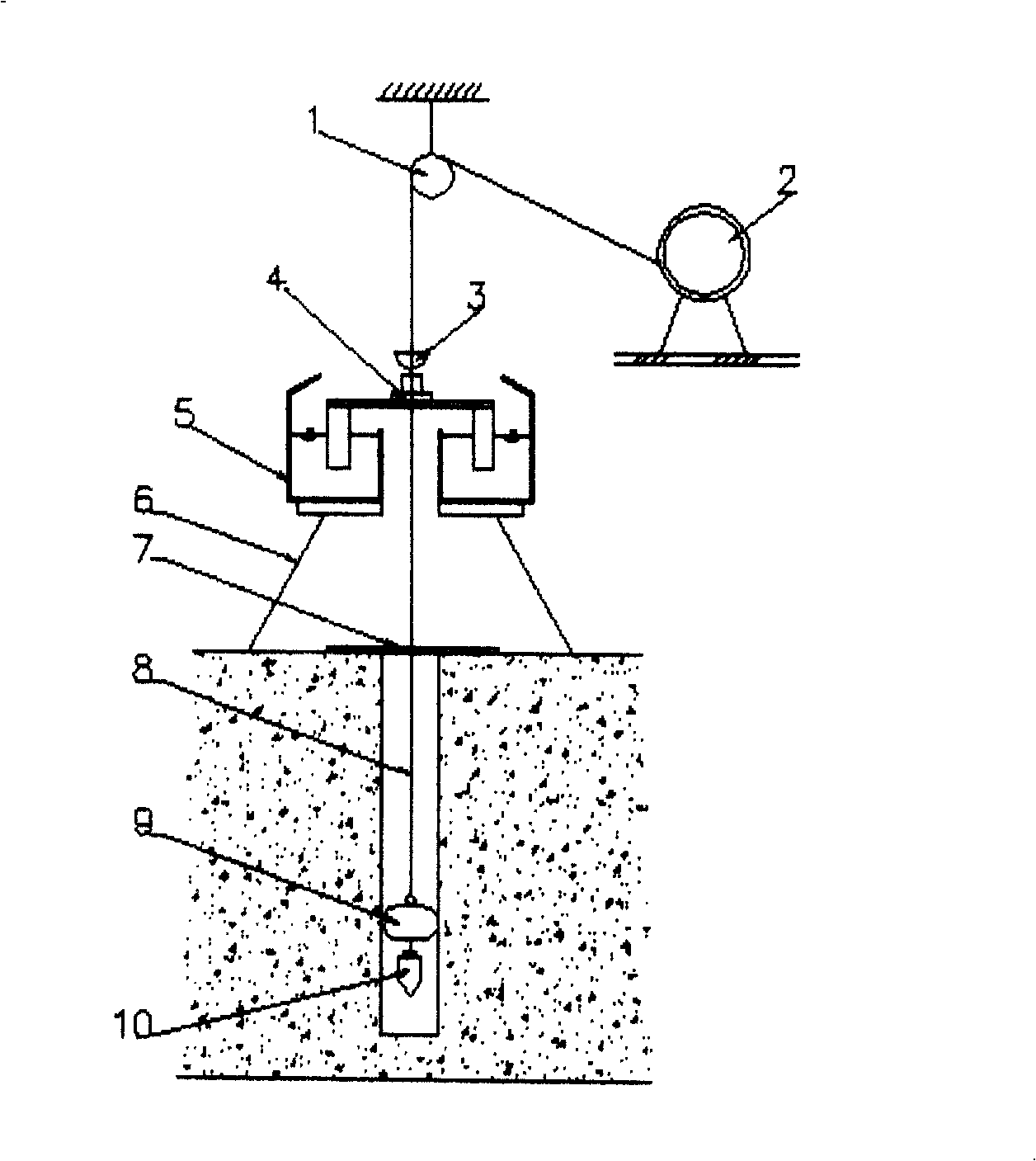

Method used

Image

Examples

Embodiment

[0053] The heightening of a certain dam is one of the important components of the water source project of the South-to-North Water Diversion Middle Route. It is located about 800m downstream of the confluence of the main stream and the tributaries, and the controlled drainage area is 95,200km 2 . The water conservancy complex is composed of earth-rock dams on both banks, concrete dams, ship lifts, power stations and other buildings. The initial project was completed in 1973. The normal water storage level is 157m and the dam crest elevation is 162m. The dam body below the elevation of 100m in the riverbed section has been built according to the normal water storage level of 170m after the heightening of the dam. After the dam is heightened, the main tasks of the reservoir are flood control, water supply, power generation and shipping. After the heightening of the dam, the normal storage level of the reservoir is 170m, the elevation of the dam crest is 176.6m, and the total st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com