Roadbed protective system in debris flow gully and implementation method for roadbed protective system

A technology of debris flow ditch and protection system, applied in dikes, road bottom, coastline protection, etc., can solve problems such as reducing maintenance costs and blockage risks during tunnel drainage, uneven stress on drainage structures, and long drainage tunnel lines. , to achieve the effect of low maintenance cost and blockage risk, ensuring stability and durability, and low engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] A method for implementing a subgrade protection system in a debris flow ditch, comprising the following steps;

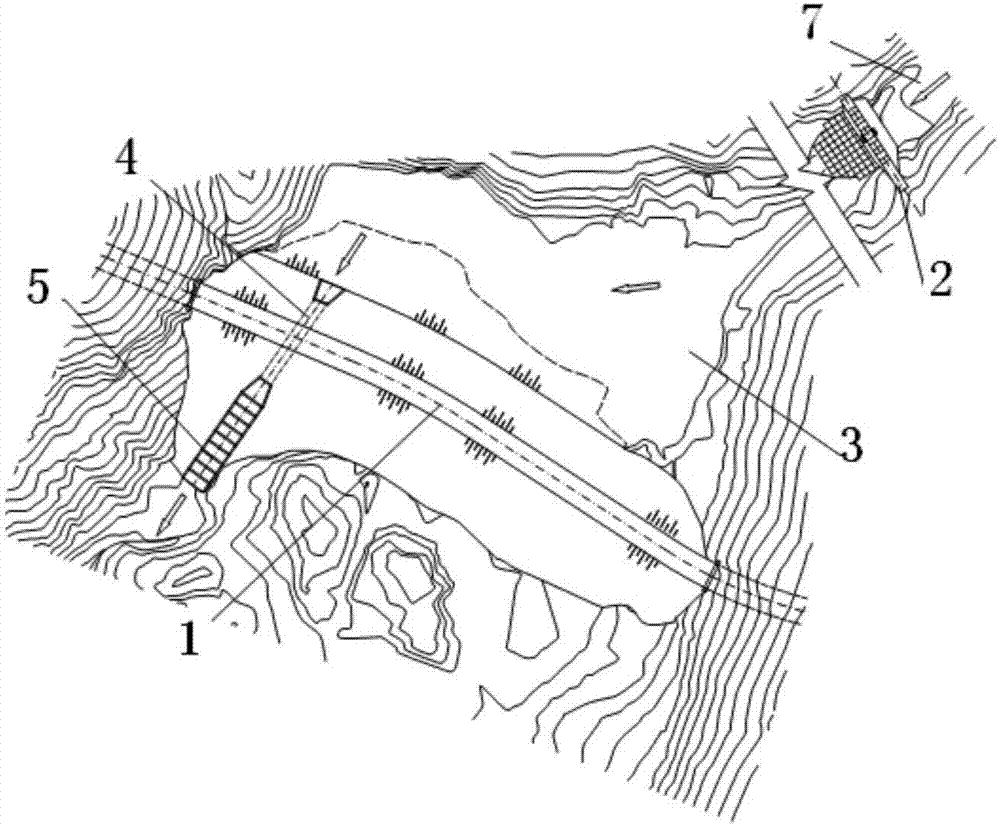

[0042] ①. Determine the formation area and circulation area of the debris flow through on-site investigation of the quantity and distribution of loose materials in the debris flow ditch;

[0043] 2. In the debris flow formation area and circulation area determined in step 1., select a location with good geological conditions and a large storage capacity in front of the dam as the dam site of the retaining dam 2, and the number of the dam sites of the retaining dam 2 is based on loose The distribution of substances is determined;

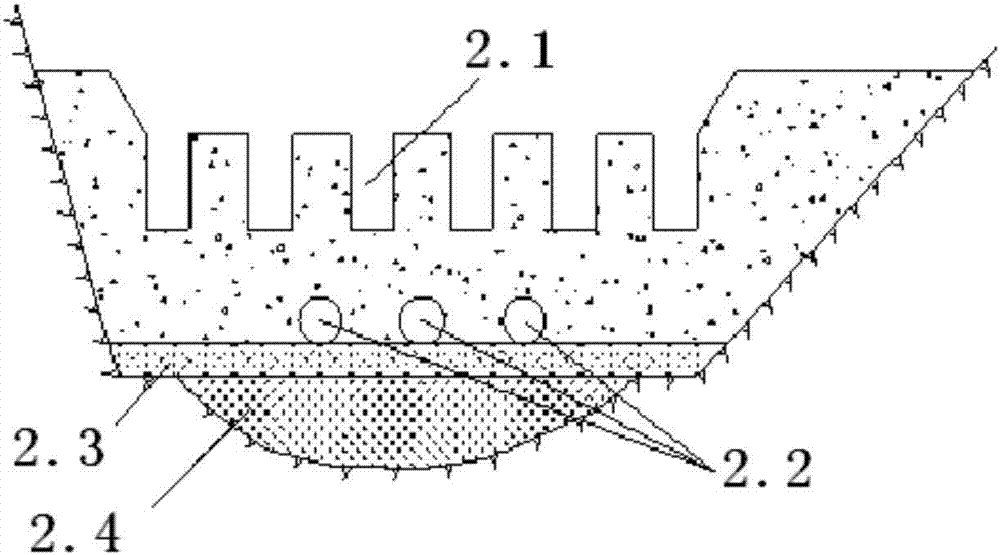

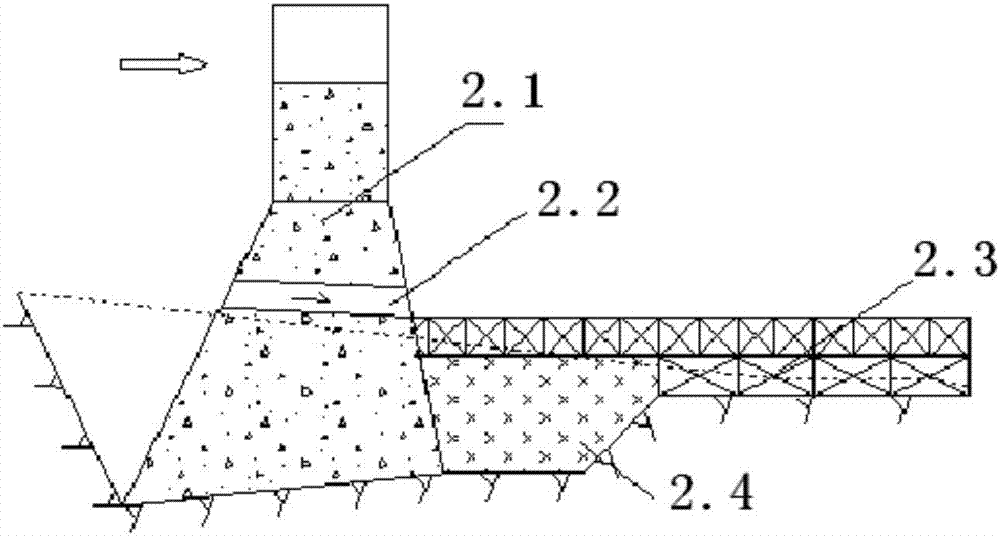

[0044] 3. Excavate the foundation of the retaining dam 2 at the dam site determined in step 2 until the anti-sliding stability requirements of the dam body are met, and the bank slope of the abutment is excavated into grooves so that the dam body of the retaining dam 2 is embedded in the bank slope bedrock;

[0045] 4. The retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com