Cooling structure and manufacturing method thereof

A technology of heat dissipation structure and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of material damage, high production cost, spillage, etc., and achieve the effect of preventing leakage and saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

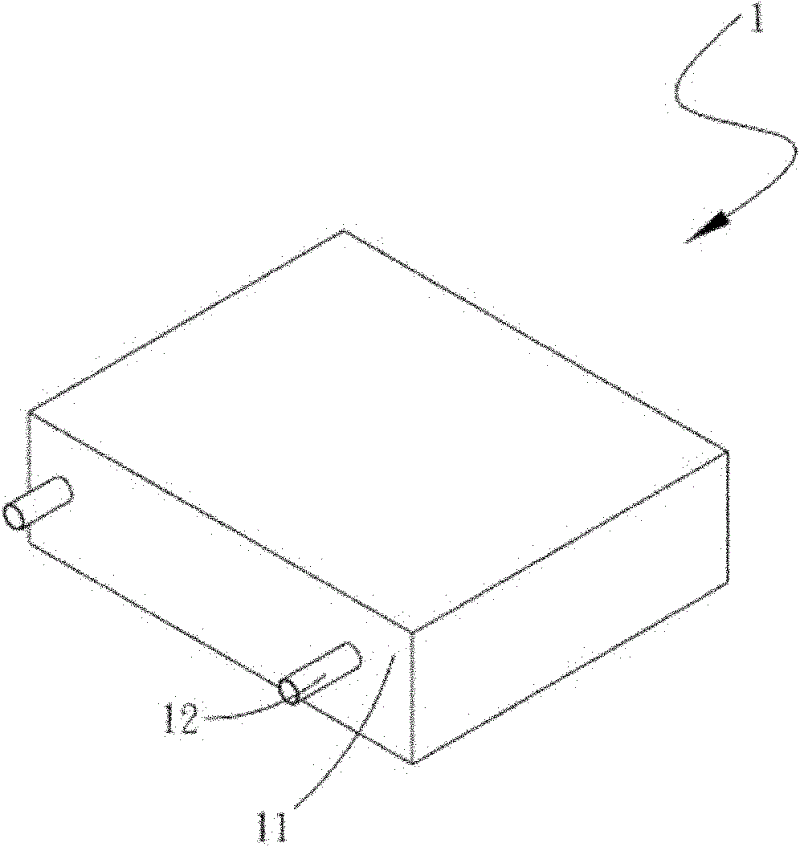

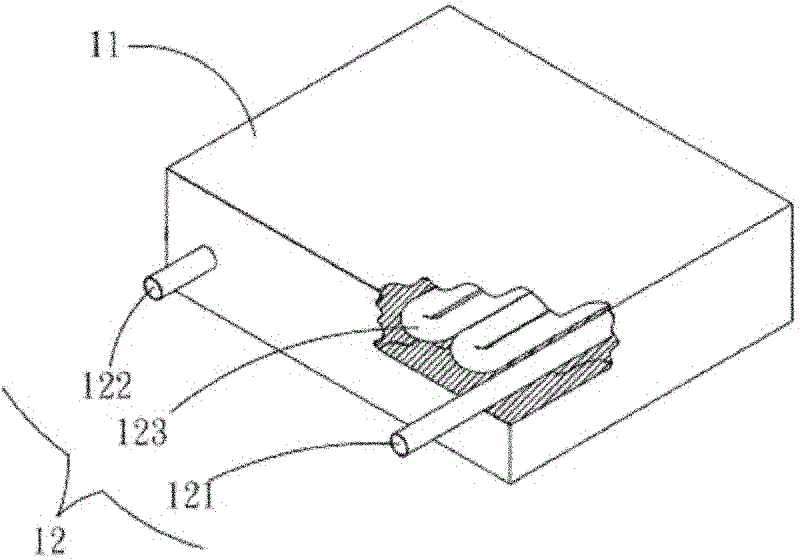

[0063] see figure 1 , 2 , is a perspective view and an exploded view of the first embodiment of the heat dissipation structure of the present invention. As shown in the figure, the heat dissipation structure includes: a base 1; the base 1 has a body 11 and at least one tube body 12, so The pipe body 12 has an inlet end 121 , an outlet end 122 and a pipe body 123 , the pipe body 123 is correspondingly disposed in the body 11 , and the outlet end 122 and the inlet end 121 protrude outside the body 11 .

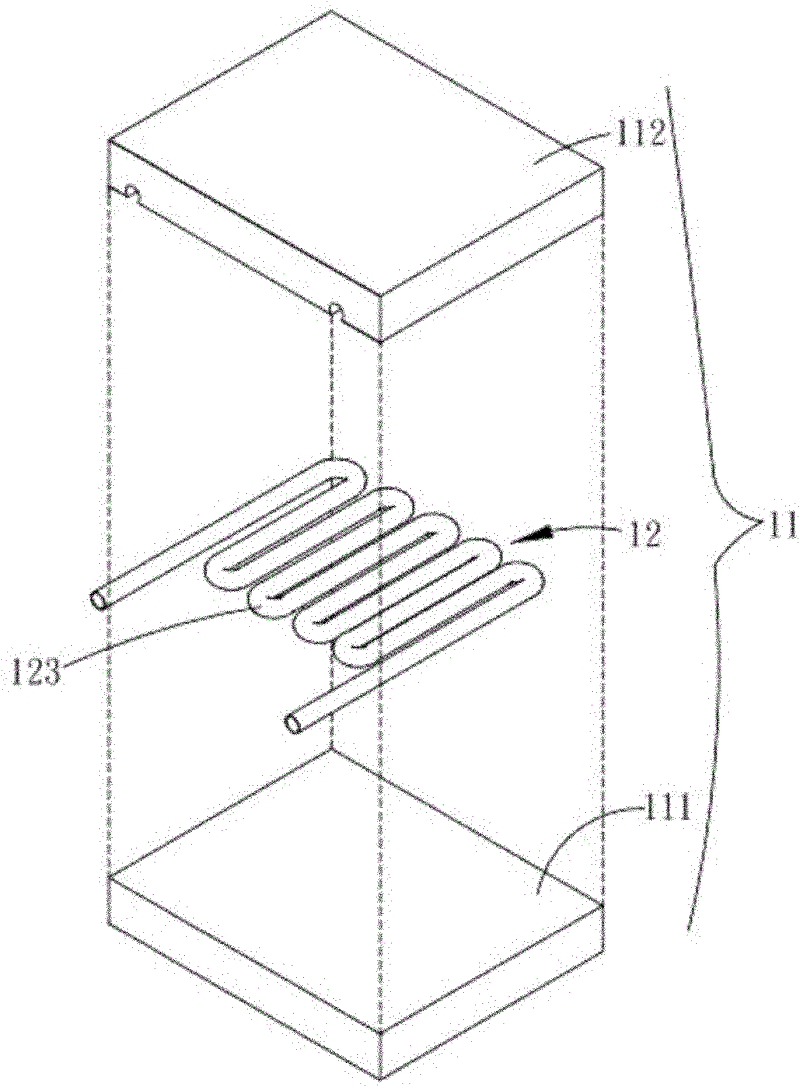

[0064] see image 3 , is a three-dimensional exploded view of the second embodiment of the heat dissipation structure of the present invention. As shown in the figure, part of the structure of this embodiment is the same as that of the aforementioned first embodiment, so it will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com