Gravity reverse-supporting debris flow protective retaining wall and construction method thereof

An anti-support, debris flow technology, applied in gravity dams, hydraulic engineering, marine engineering and other directions, can solve the problems of not providing spring performance materials, not obtaining reasonable debris flow protection facilities, and inability to prove, and achieves good durability and ease of use. Promotion and application, simple effect of construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

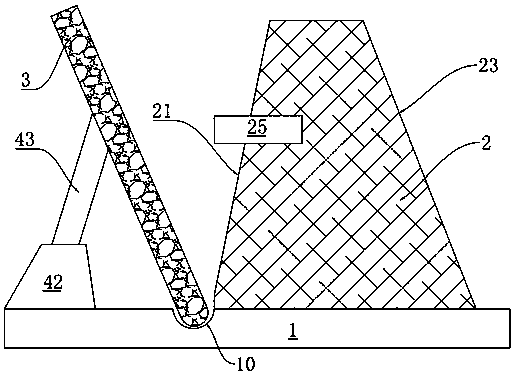

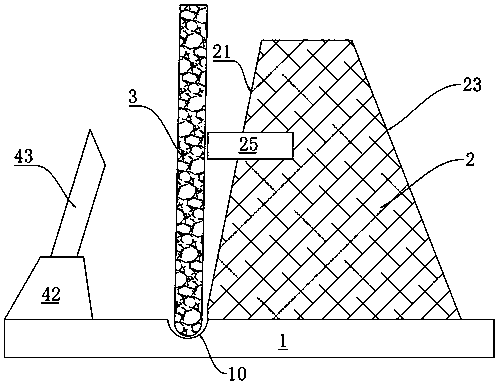

[0044] Such as figure 1 and figure 2 As shown, the gravity anti-supporting debris flow protective retaining wall of embodiment 1 includes a base 1, a dam body 2, a gravity plate 3 and a corner fixing seat arranged on the base 1.

[0045] Specifically, the base 1 is a bottom plate made of concrete with a strength grade not less than C40. The middle part of the base 1 is provided with a straight arc-shaped groove 10, the gravity plate 3 is placed upright on the groove 10, the dam body 2 is arranged on one side of the groove 10, and the angular position is fixed on the other side of the groove 10. seat.

[0046] The dam body 2 is provided with a water-facing slope 21 and a back-water slope 23 corresponding to each other. The facing slope 21 of the dam body 2 is located at the outermost part of the entire dam body 2, that is, the debris flow impact surface side, and is made of concrete with a strength grade not less than C40; the backwater slope 23 of the dam body 2 is located...

Embodiment 2

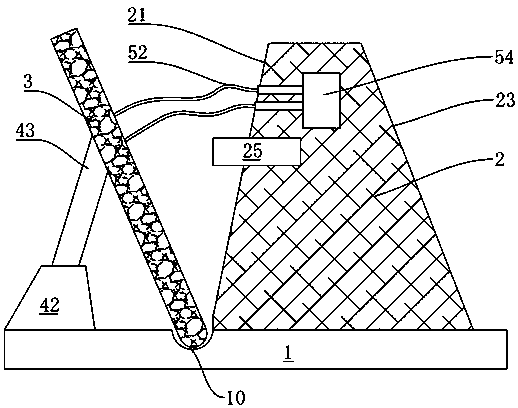

[0058] Such as image 3 and Figure 4 As shown, the gravity anti-supporting debris flow protective retaining wall of embodiment 2 is similar to the structure of embodiment 1, the difference is that embodiment 2 is also provided with a protection mechanism for connecting the gravity plate 3 and the dam body 2 .

[0059] Specifically, the protection mechanism includes a protection rope 52 with a certain strength and a protection rope fixing stake 54 . The protection rope fixing stake 54 is embedded in the middle and upper part of the dam body 2 . One end of the protection rope 52 is connected to the protection rope fixing stake 54 , and the other end of the protection rope 52 is connected to the middle and upper part of the gravity plate 3 . The protection rope 52 is in an unstressed state under normal conditions.

[0060] Preferably, in Embodiment 2, more than two protection ropes 52 are provided to ensure that the force on the protection ropes 52 is even. Moreover, even if...

Embodiment 3

[0071] Such as Figure 5 and Figure 6 As shown, the gravity anti-supporting debris flow protective retaining wall of embodiment 3 is similar to the structure of embodiment 2, the difference is that embodiment 3 is also provided with a trigger mechanism for connecting the corner fixing seat and the gravity plate 3 .

[0072] Specifically, the surface of the gravity plate 3 is perforated to form a safety installation hole 30 , and the end of the diagonal support rod 43 of the corner fixing seat is provided with a trigger screw 45 , and a safety washer 46 is provided on the trigger screw 45 . The trigger screw 45 is sleeved with a nut 47 , and the safety washer 46 is limited on the trigger screw 45 by the nut 47 . The safety installation hole 30 of the gravity plate 3 is mated with the trigger screw 45 of the inclined support rod 43 , and the safety gasket 46 is arranged in the safety installation hole 30 of the gravity plate 3 . The gravity plate 3 leans firmly against the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com