Hydraulic power acceleration equipment

A hydraulic power and equipment technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high cost, limited output power of electric motors, unbalanced pressure, etc., and achieve a wide range of applications, good operation stability and smooth The effect of load equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

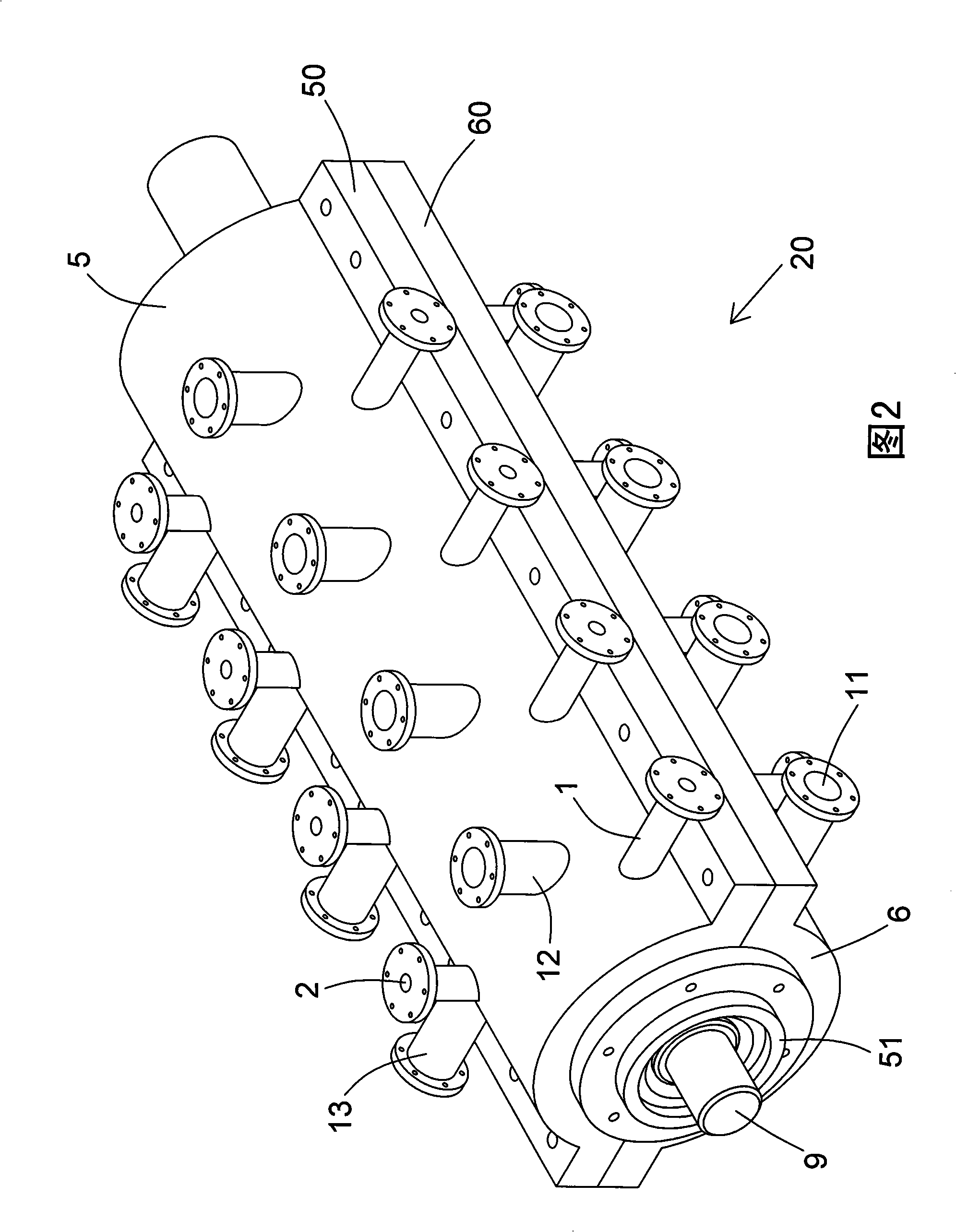

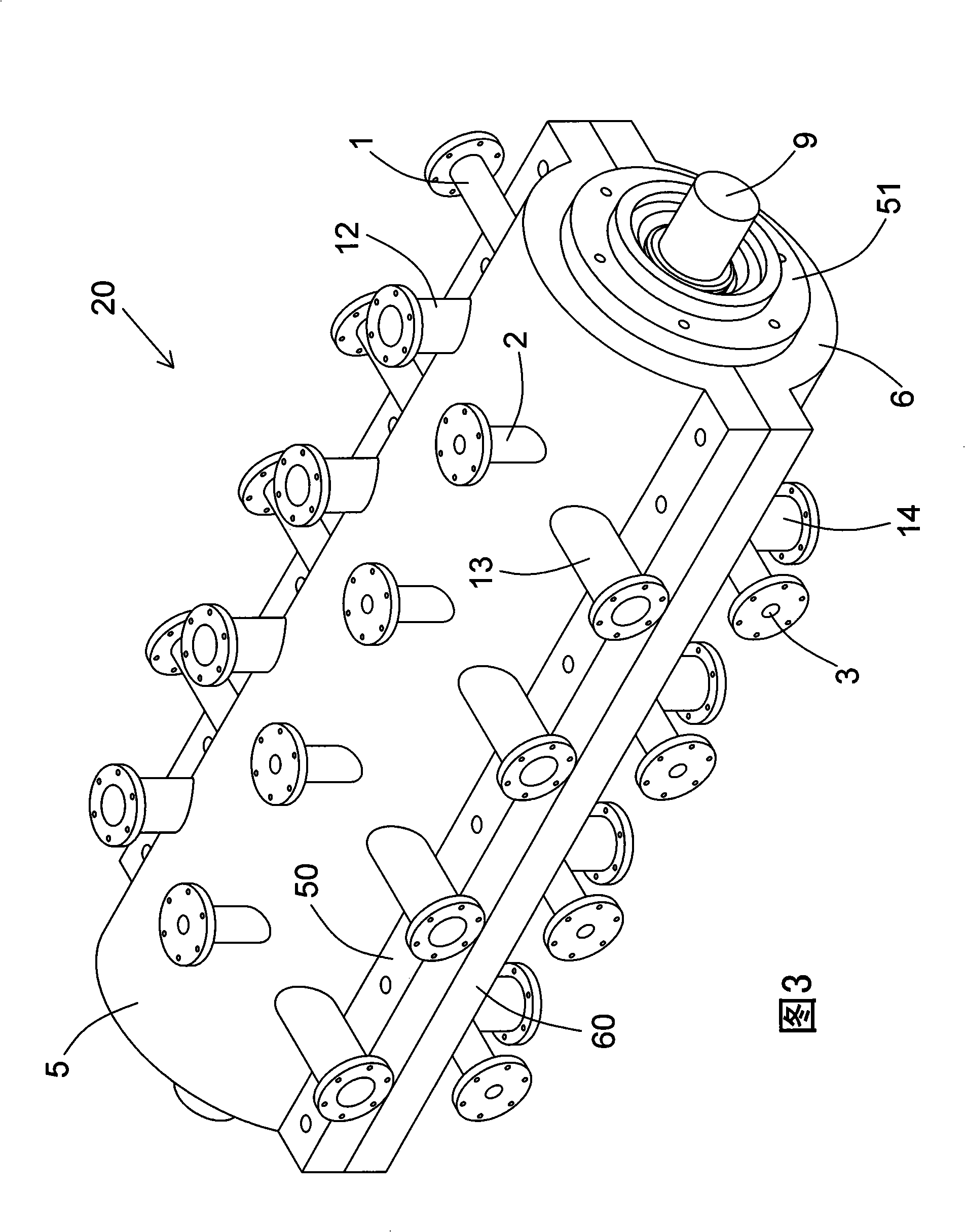

[0027] Label in the figure

[0028] 1 No. 1 oil inlet channel 2 No. 2 oil inlet channel 3 No. 3 oil inlet channel

[0029] 4 No. 4 oil inlet channel 5 Upper cover 6 Lower cover

[0030] 7 rotor 8 impeller 9 power shaft 10 hydraulic oil circuit system

[0031] 11 No. 1 oil outlet channel 12 No. 2 oil outlet channel

[0032] 13 No. 3 oil outlet channel 14 No. 4 oil outlet channel

[0033] 15 upper groove 16 lower groove 17 ring groove 18 teeth

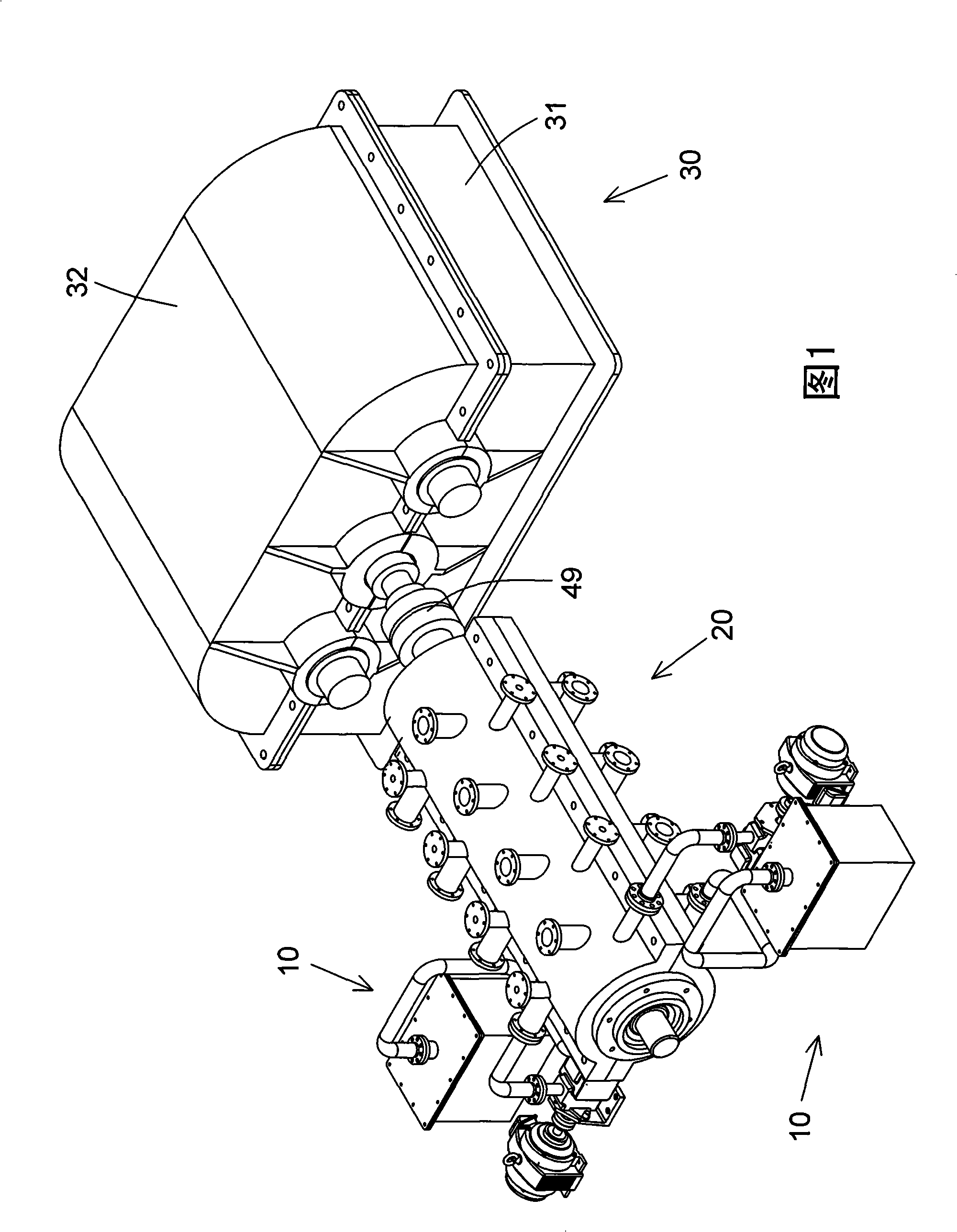

[0034] 19 spacer ring 20 hydraulic power machine

[0035] 21 No. 1 cylinder 22 No. 2 cylinder 23 No. 3 cylinder 24 No. 4 cylinder

[0036] 25 electric motor 26 oil pump 27 oil tank 28 oil inlet pipe

[0037] 29 oil return pipe 30 speed increase box 31 box body 32 box cover

[0038] 33 Input shaft 34 Output shaft 35 Left drive shaft 36 Right drive shaft

[0039] 37 Support seat 38 Left front bearing 39 Left rear bearing 40 Gear set

[0040] 41 Right front bearing 42 Right rear bearing 43 Input gear 44 Output gear

[0041] 45 lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com