Water storage tank type steel structural dam

A technology for steel dams and water storage tanks, applied in dams, gravity dams, etc., can solve the problems of high terrain and geological requirements, high cost of steel dams, and large sand and gravel materials, and achieve low cost, increased self-weight, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

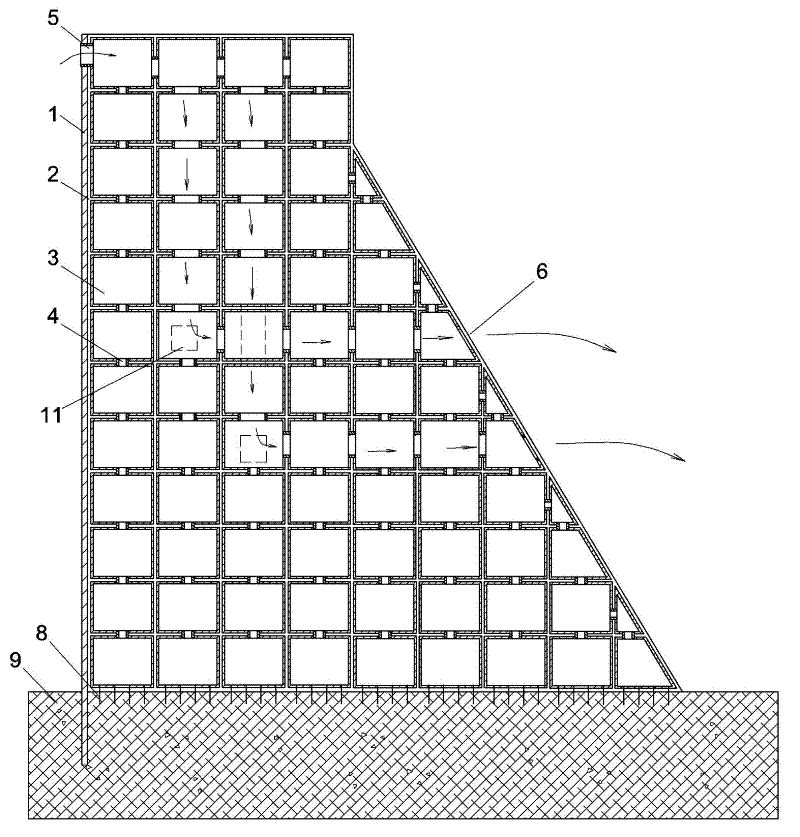

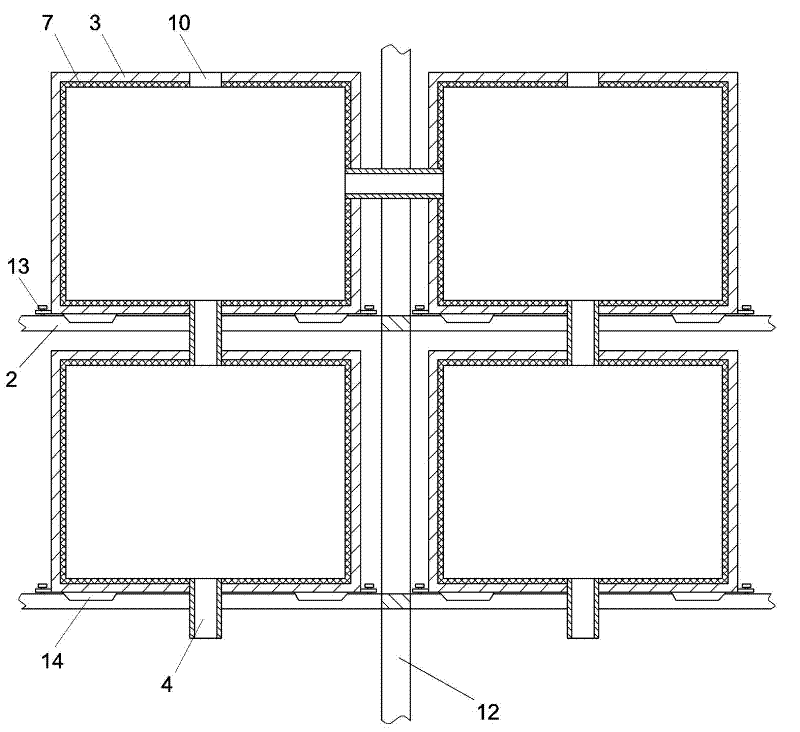

[0018] A water storage tank type steel structure dam comprises a truss structure dam body 2 and a steel structure water retaining panel 1 . The lower end of the truss structure dam. Each unit cell of the truss structure siege is fixedly installed with matching water 3 respectively, and each water tank on the same vertical line is connected to each other, and all adjacent water tanks can also be connected to each other. The water tank at the upper end of the truss structure is provided with a water inlet 5, and a water pump for injecting water into the water tank is installed at the upper end of the truss structure. The truss structure dam 2, the steel structure panel 1, the water tank 3 and the connecting bolts are supplemented with a layer of anti-corrosion coating polyurea material.

[0019] figure 2 Among them, a plastic plate 7 is also set and sealed inside each water tank.

[0020] figure 1 There are multiple rows (on the same vertical line) of water tanks connected ...

Embodiment 2

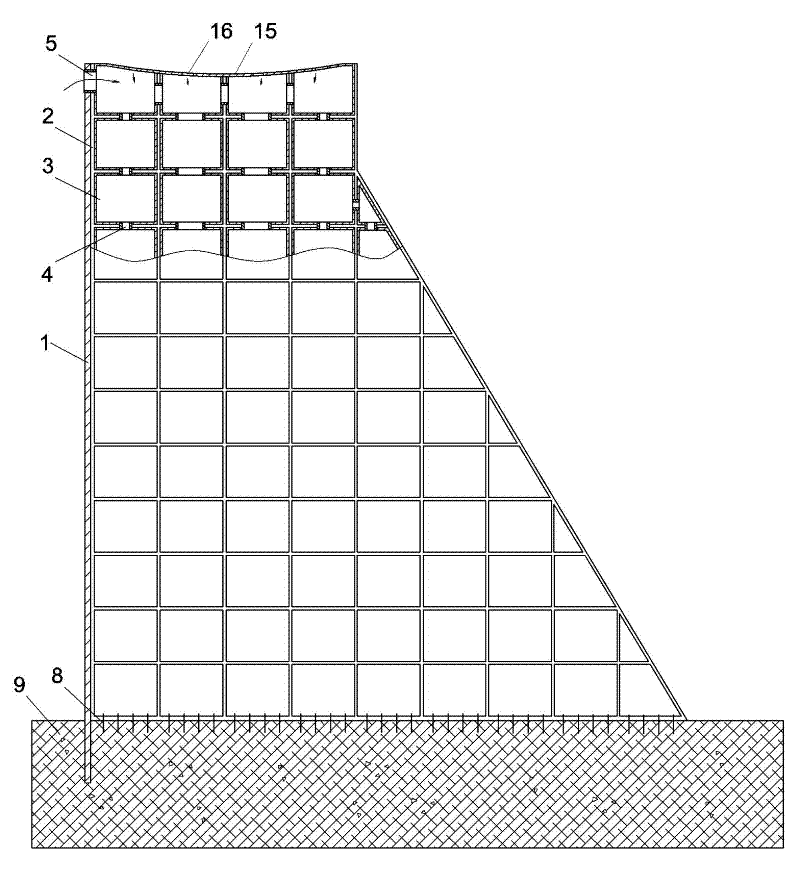

[0022] Embodiment three: see Figure 4 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that a steel plate 1' is fixed on the back water surface of the truss structure dam body, and the distribution of the water retaining surface steel plate 1 and the back water surface steel plate 1' is consistent with the concrete bearings on both sides. The platform is sealed to form a water-accommodating cavity. The cavity is filled with water so that part of the truss is located in the water injection cavity and is aided by a layer of anti-corrosion polyurea material on the truss and all steel structural panels.

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com