Patents

Literature

68results about How to "Avoid taking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

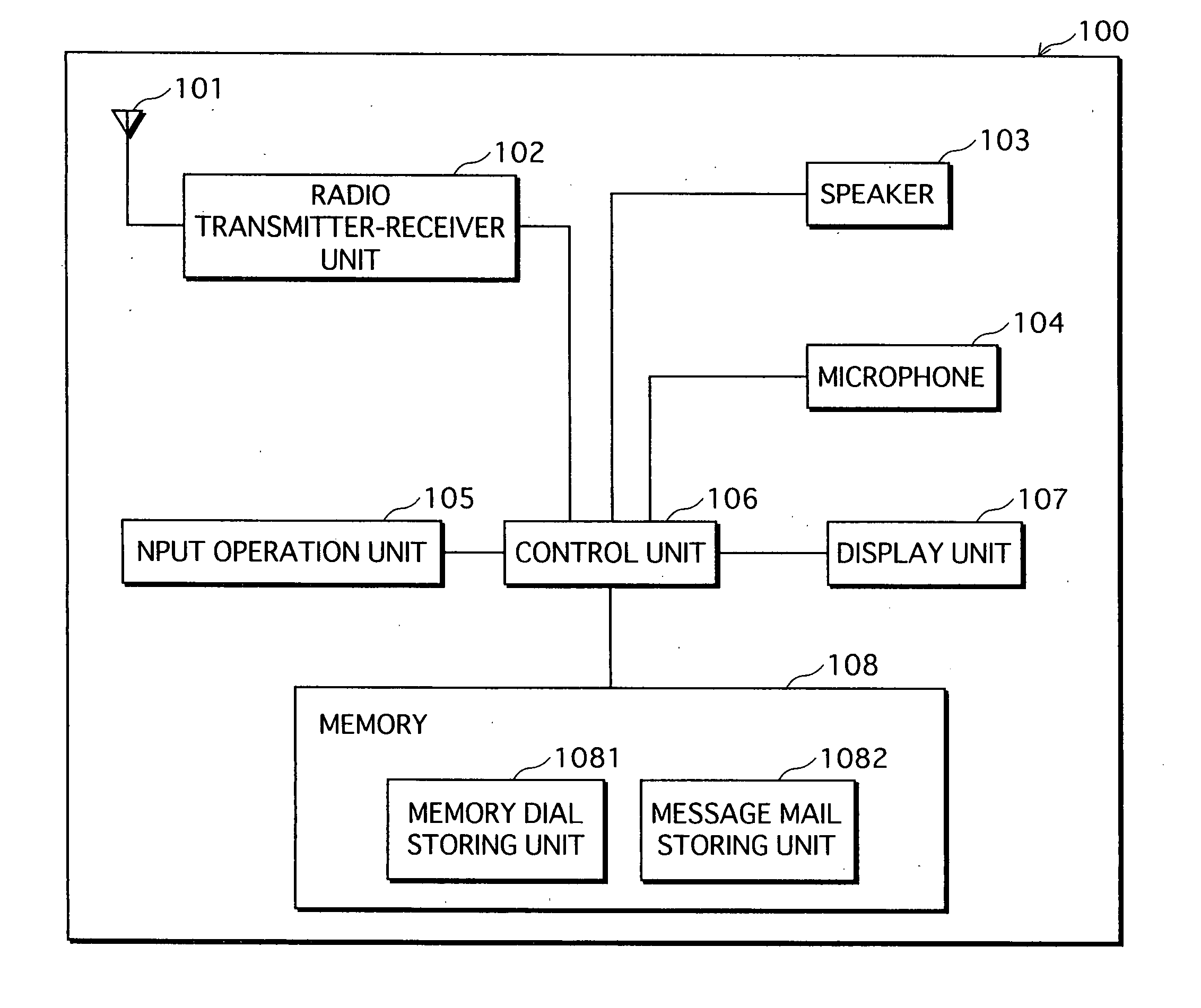

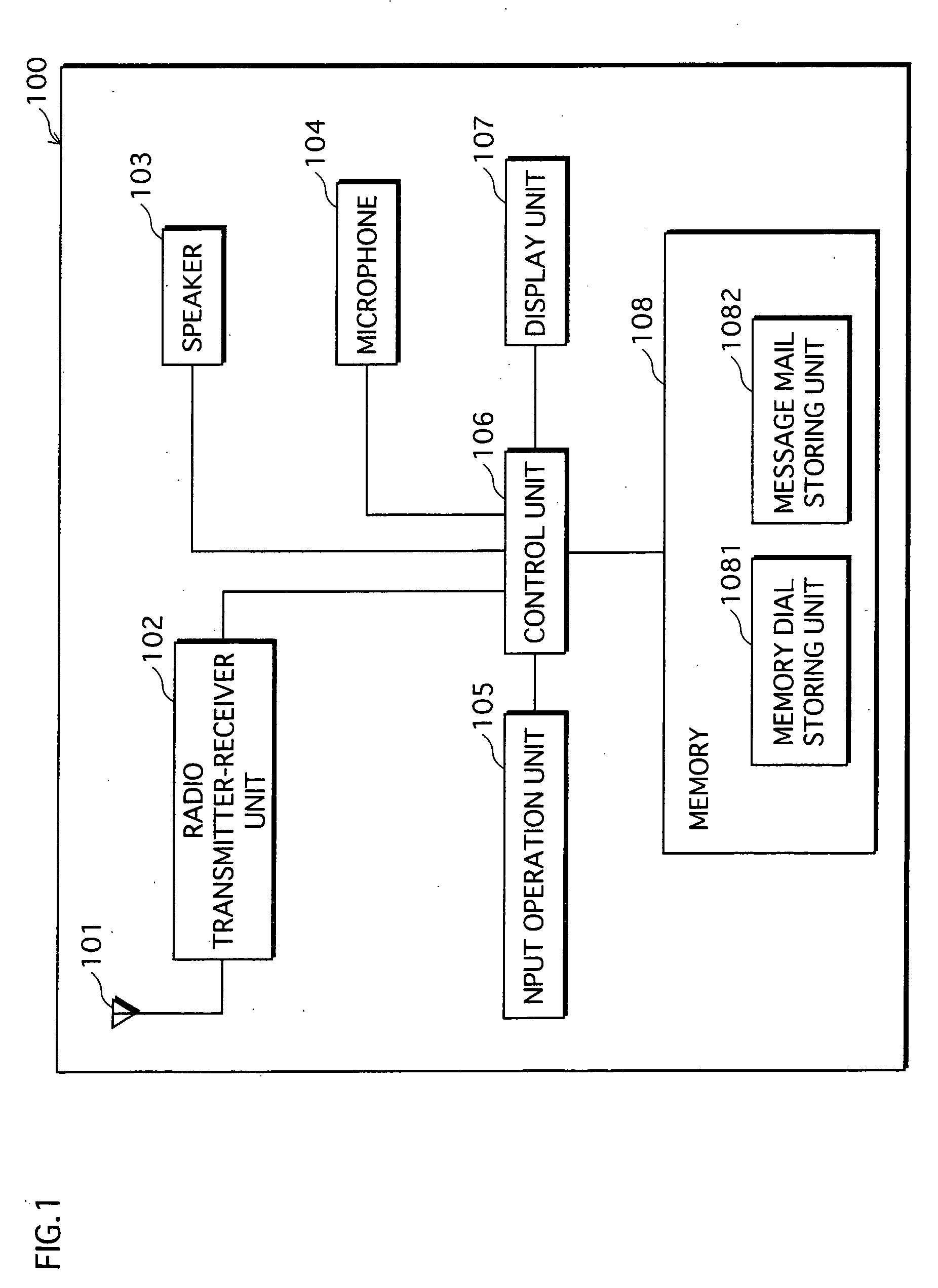

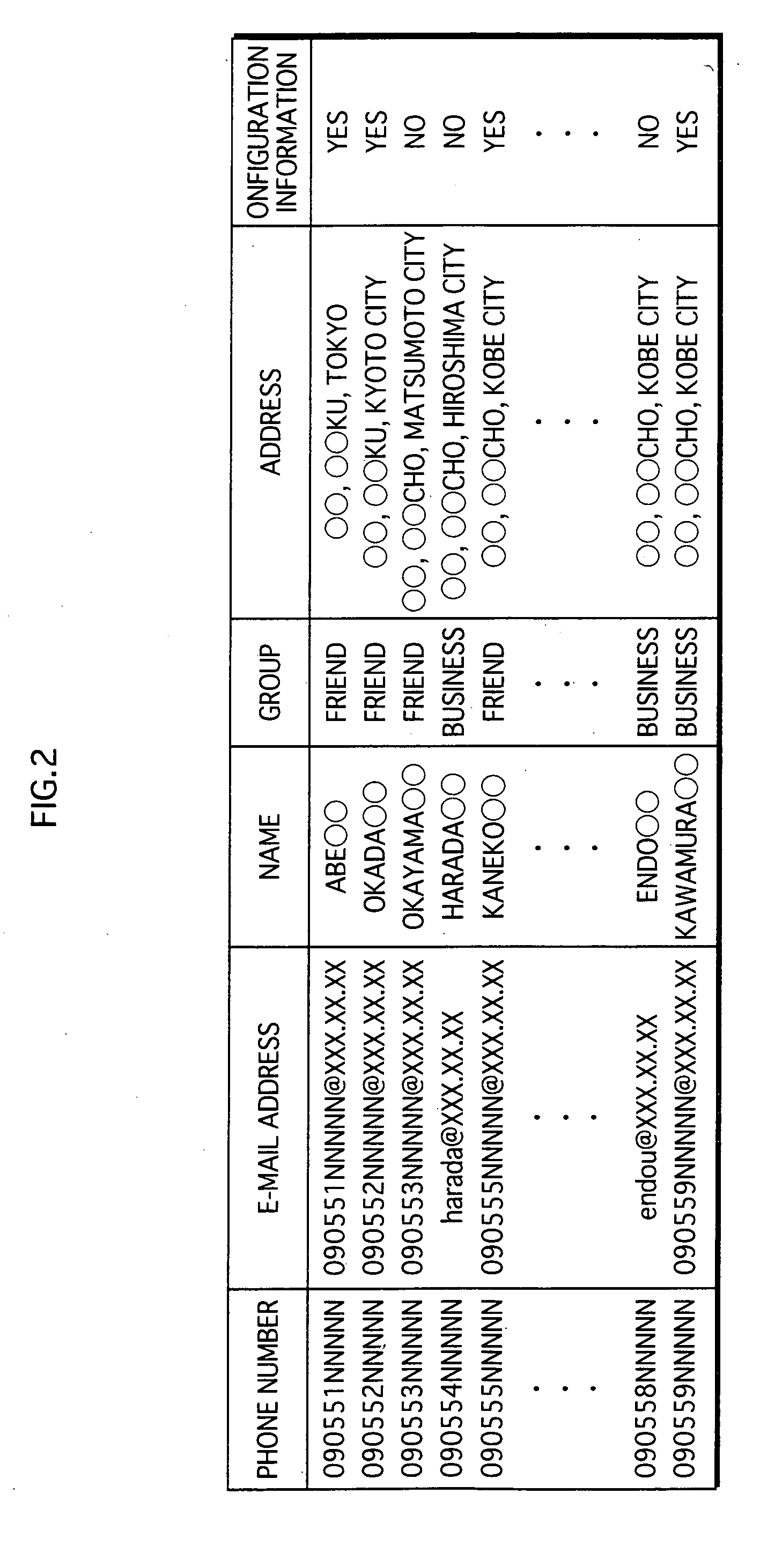

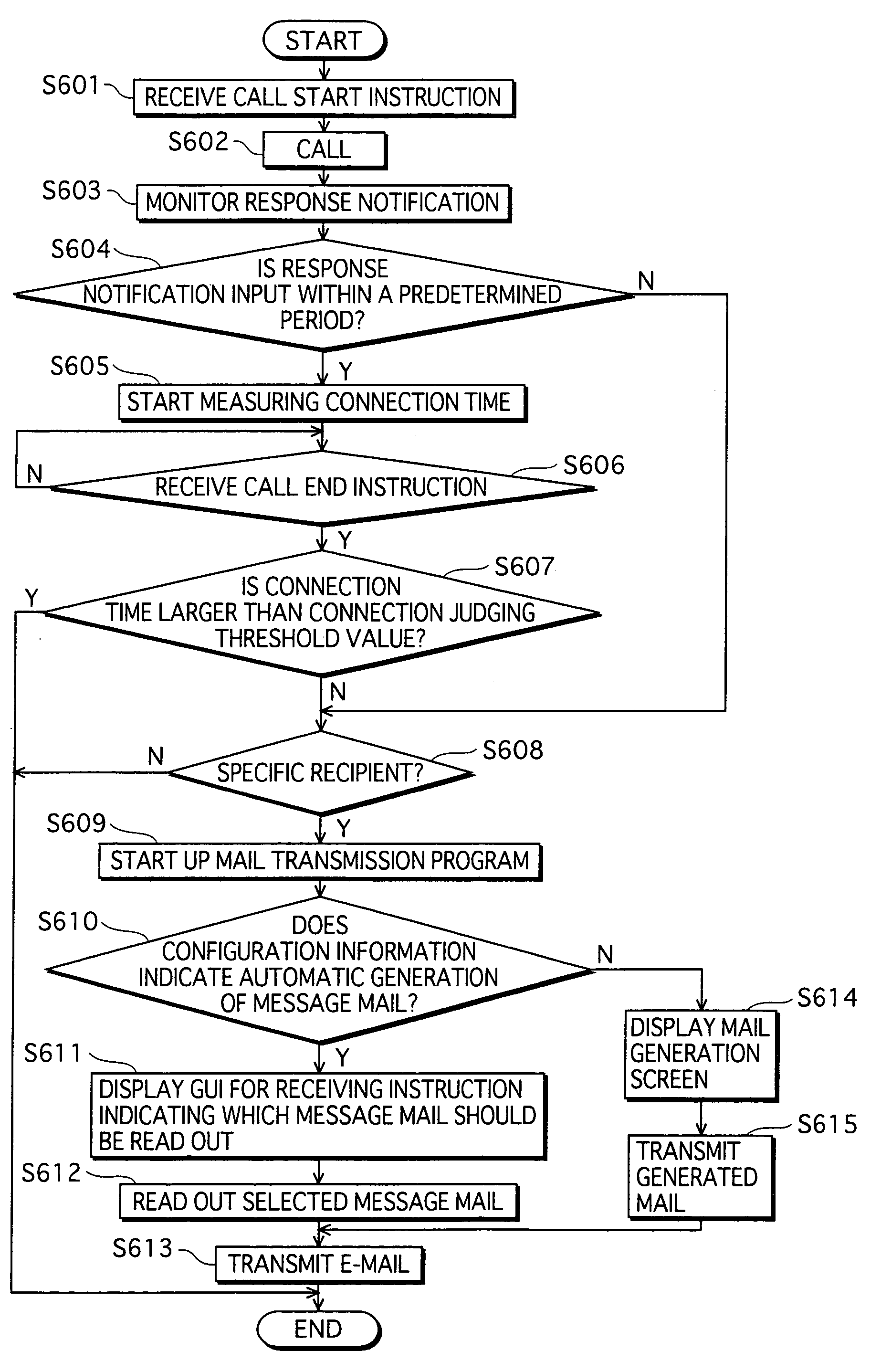

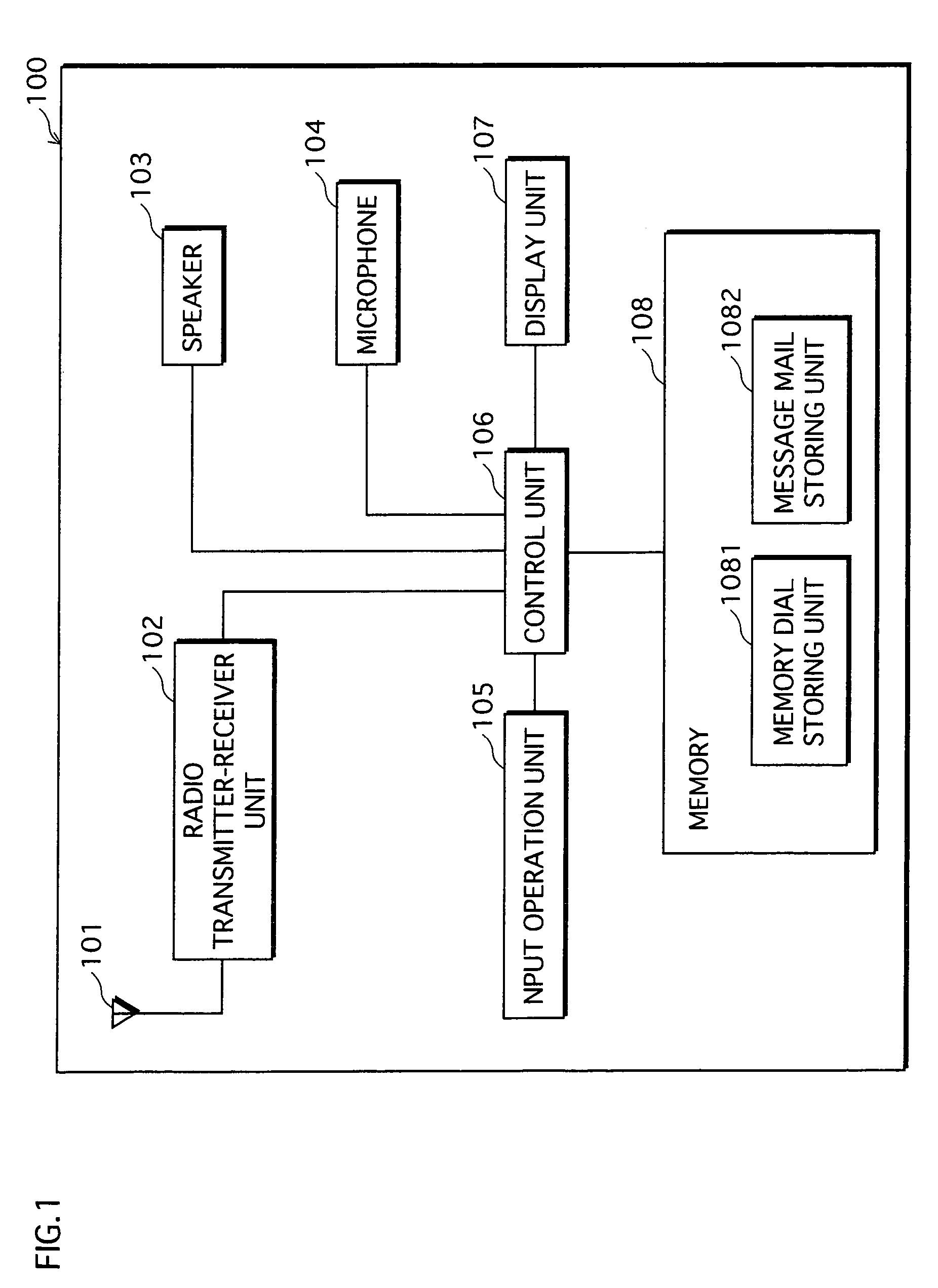

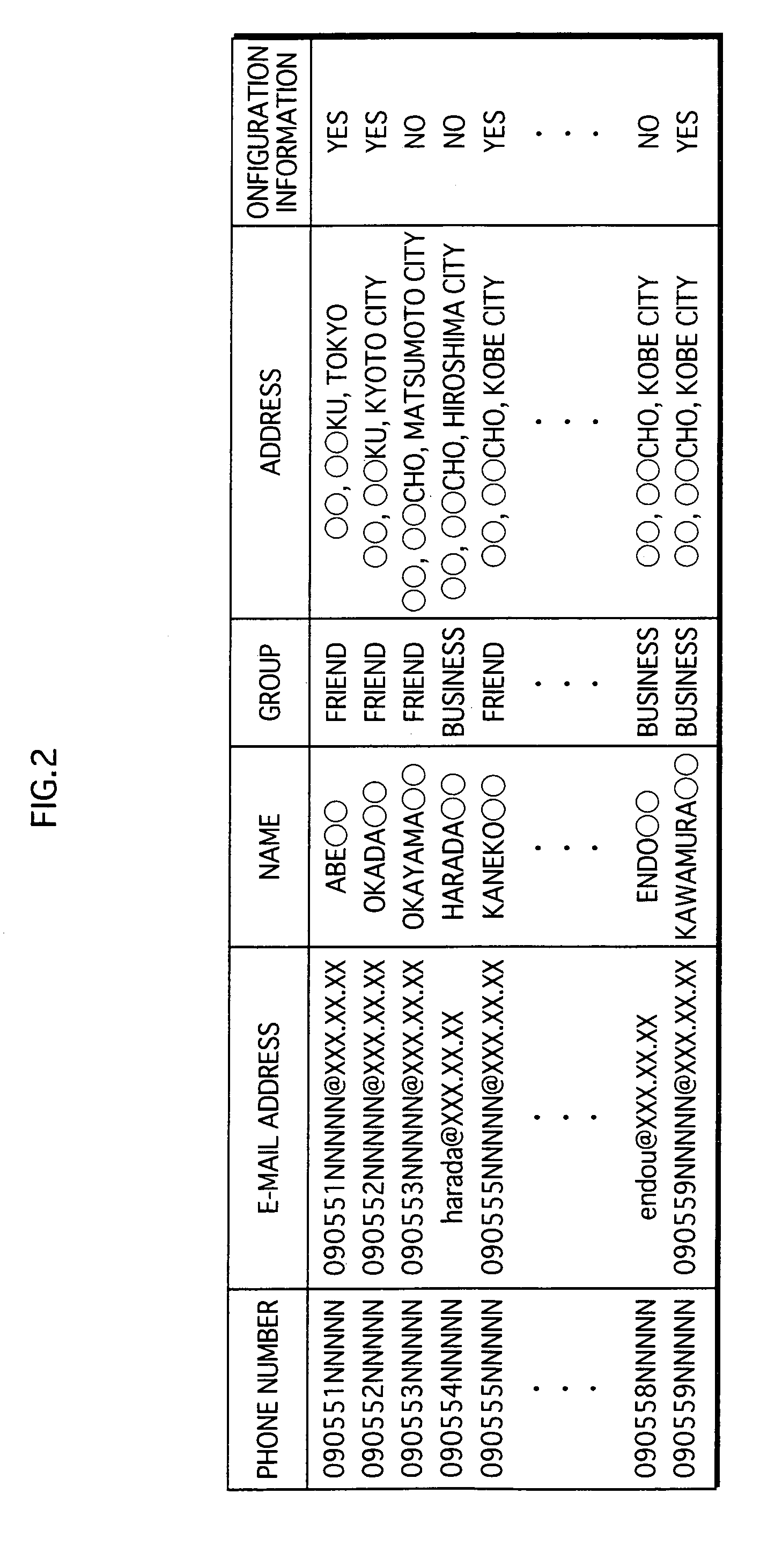

Telephone apparatus having e-mail transmitting function

InactiveUS20060245552A1Easy to operatePromote disseminationAutomatic call-answering/message-recording/conversation-recordingData switching networksElectronic mailStart up

A telephone apparatus 100 having a mail transmitting function, comprising: a calling unit operable to originate a call to a phone number of a recipient; a response judging unit operable to judge whether a response to the call is returned; and a mail program control unit operable to start up a mail transmission program if the response judging unit judges in the negative.

Owner:KYOCERA CORP

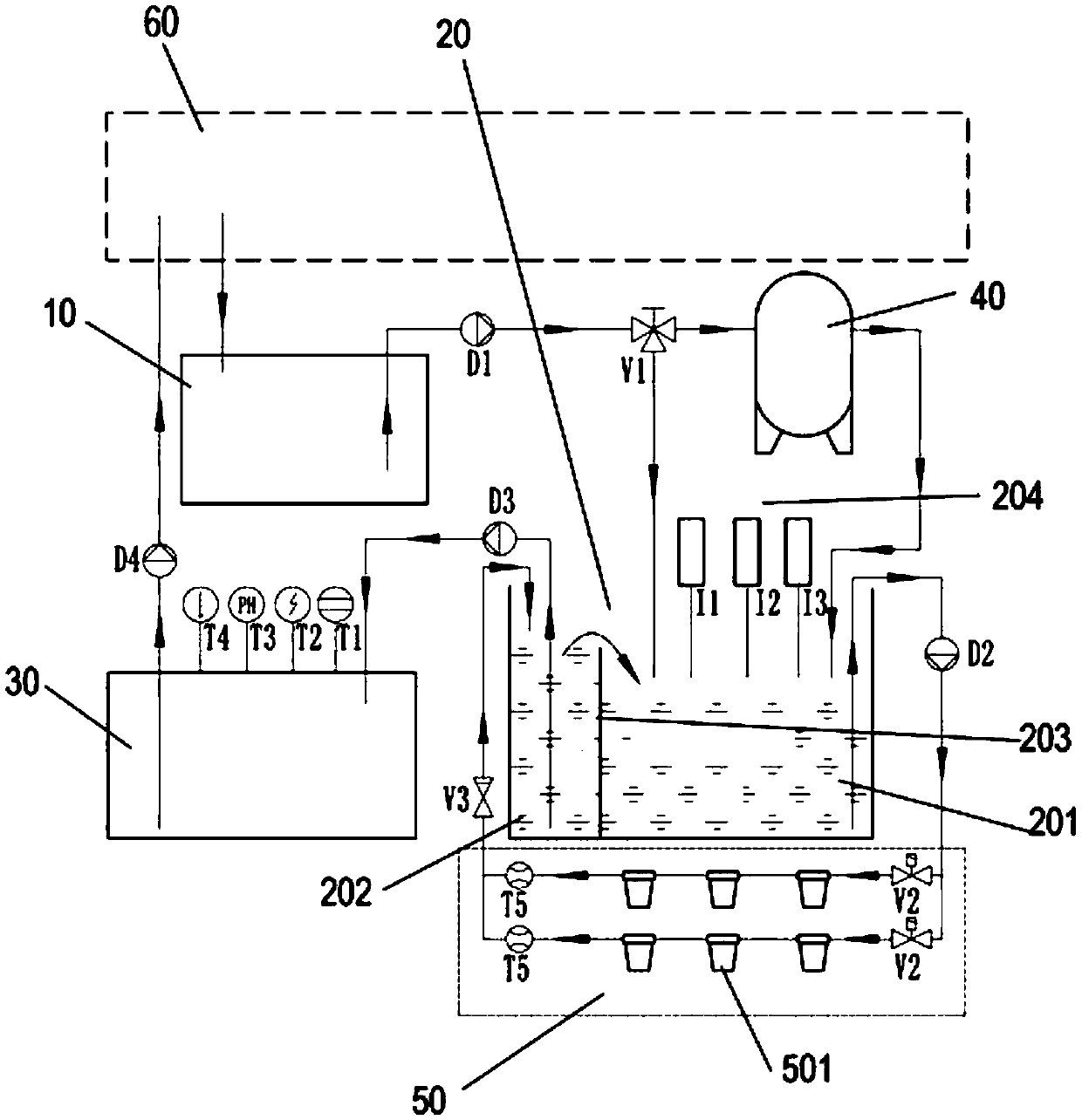

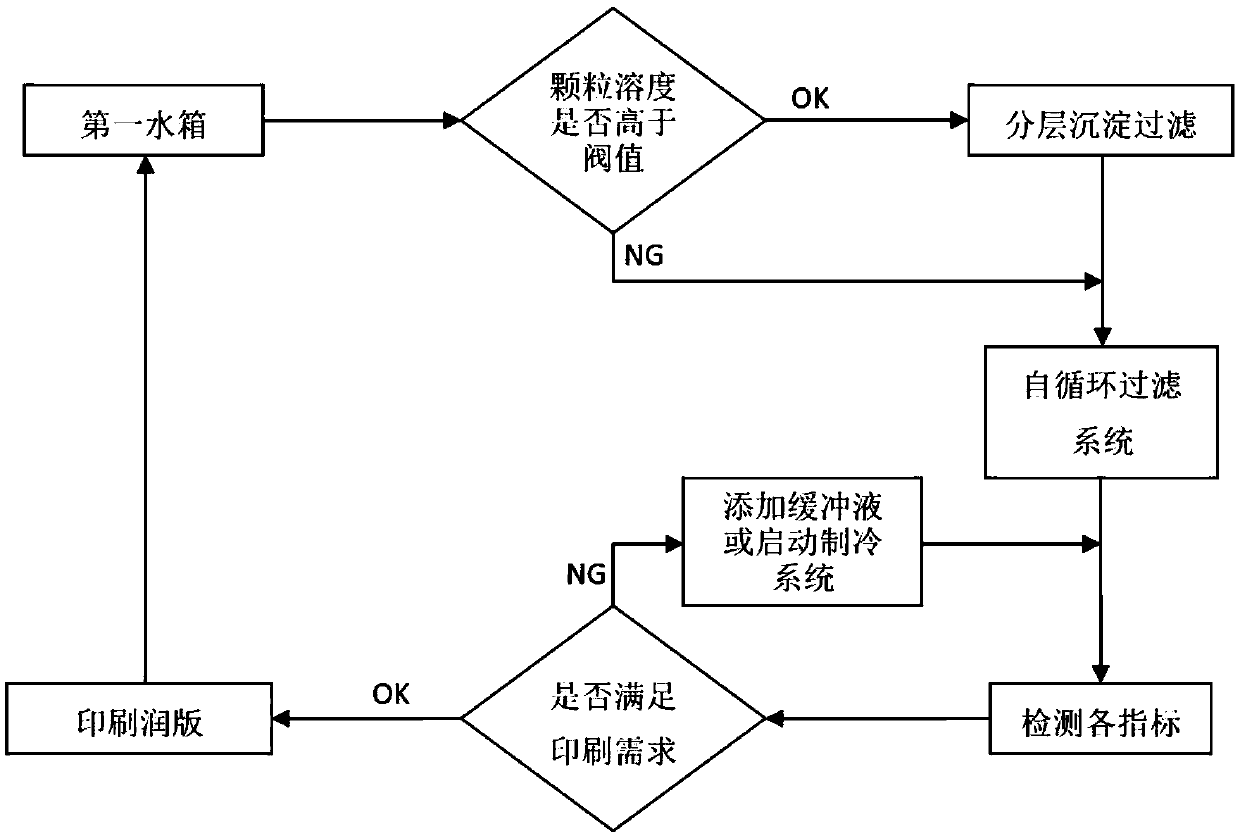

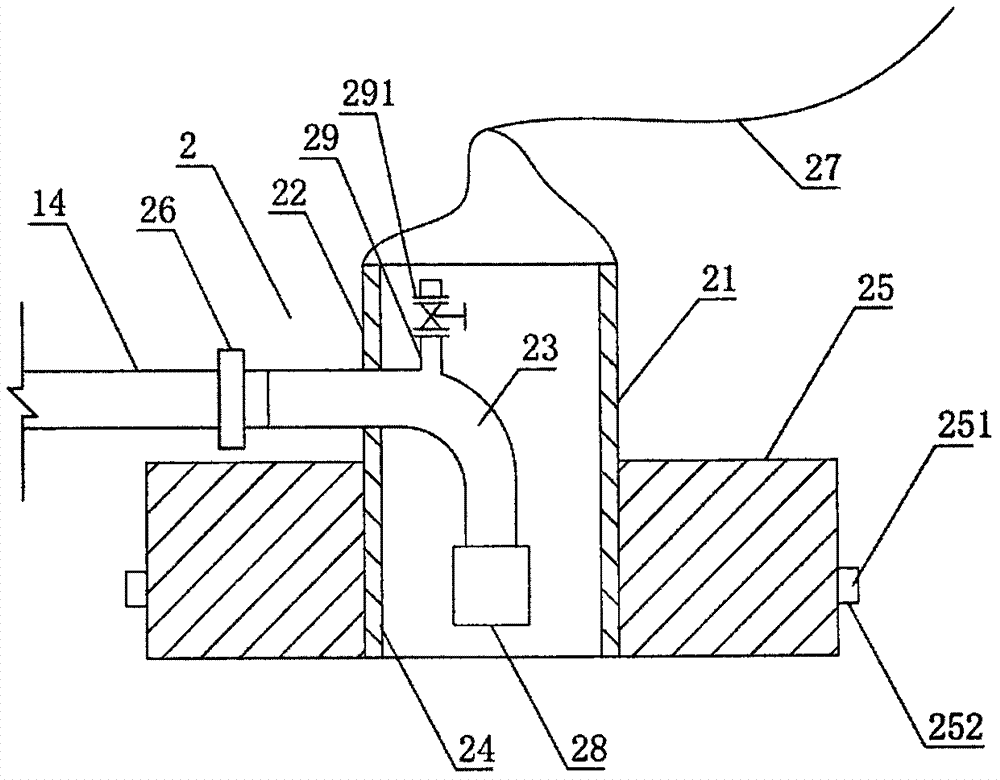

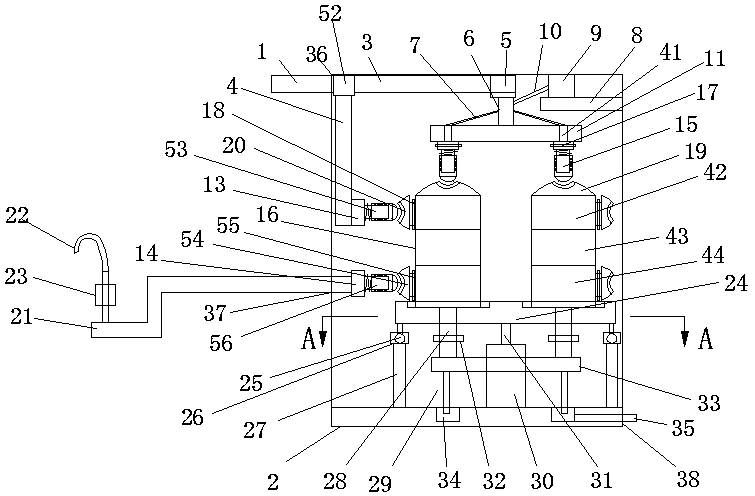

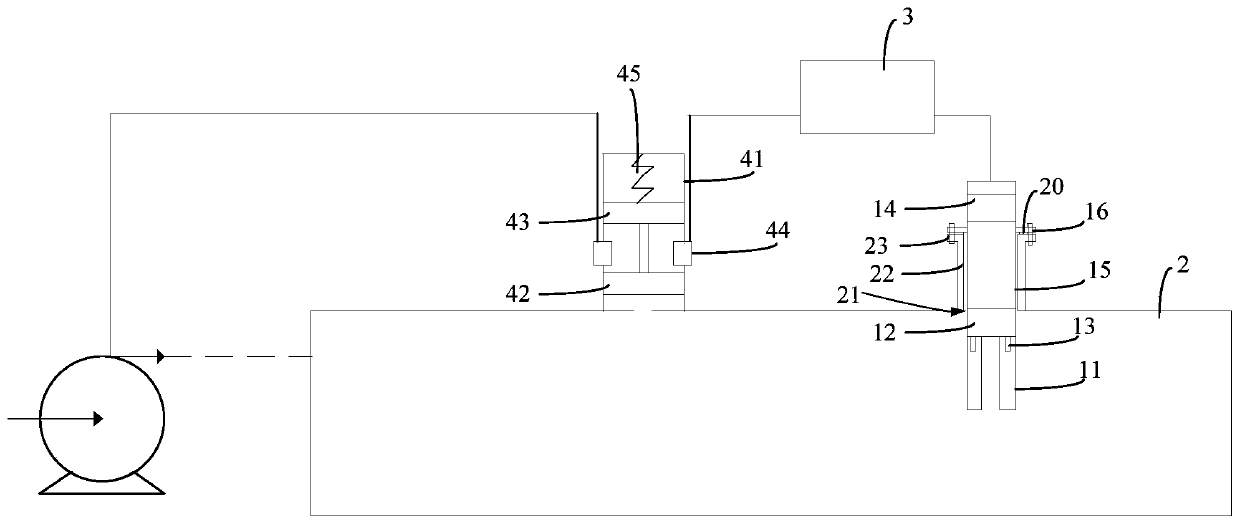

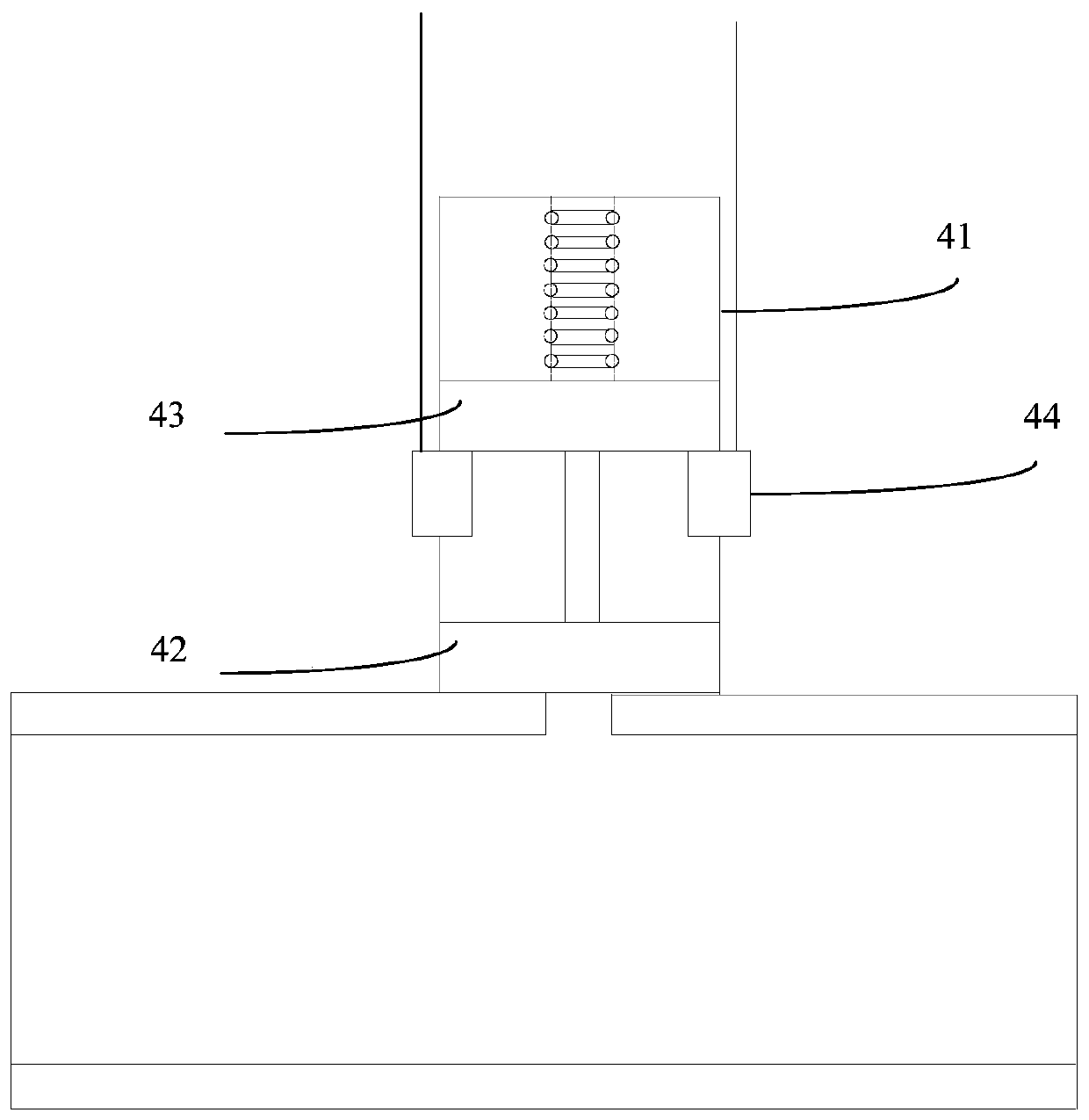

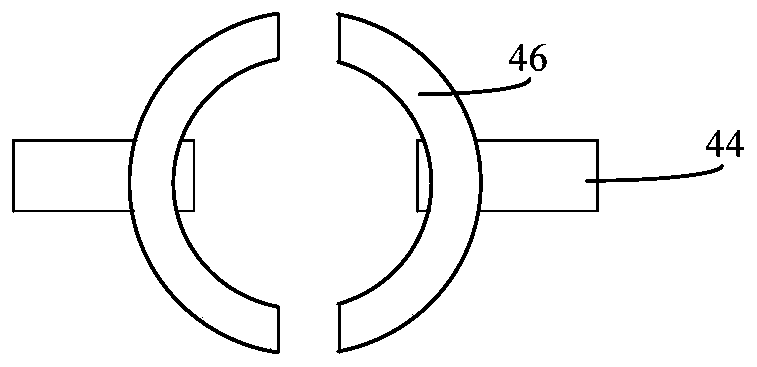

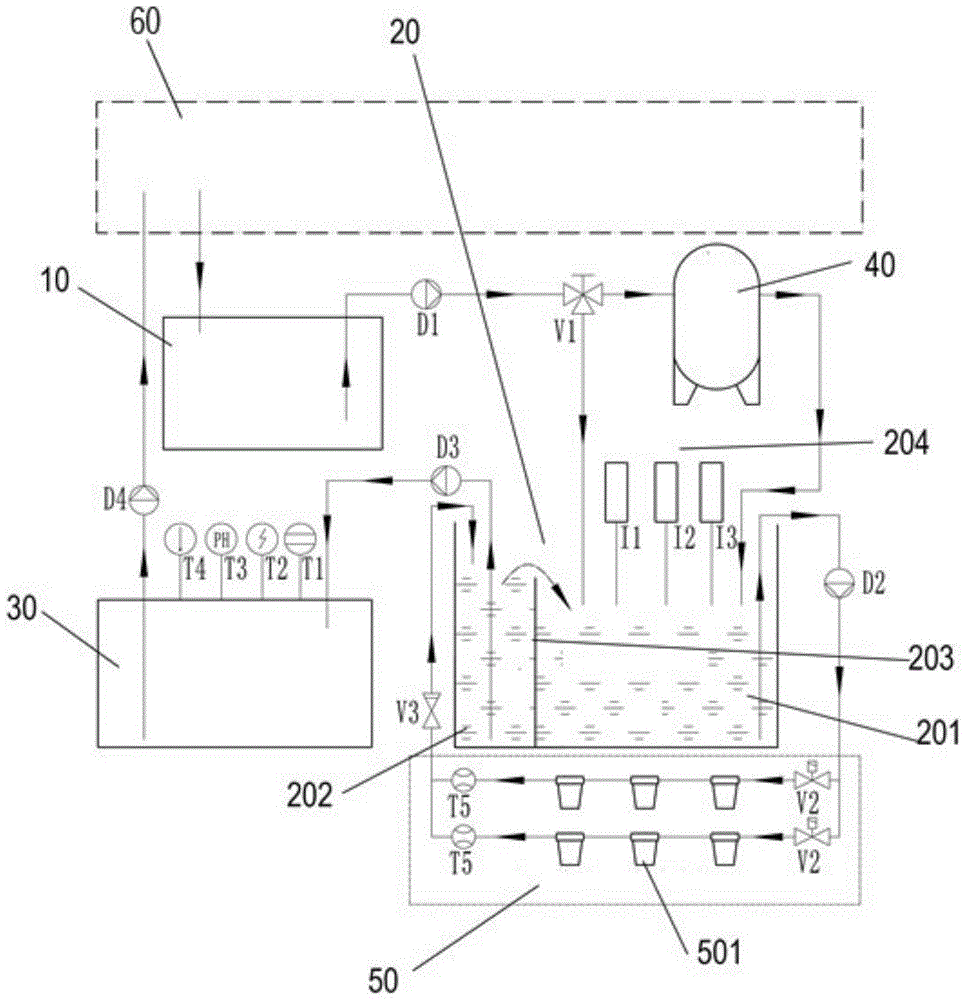

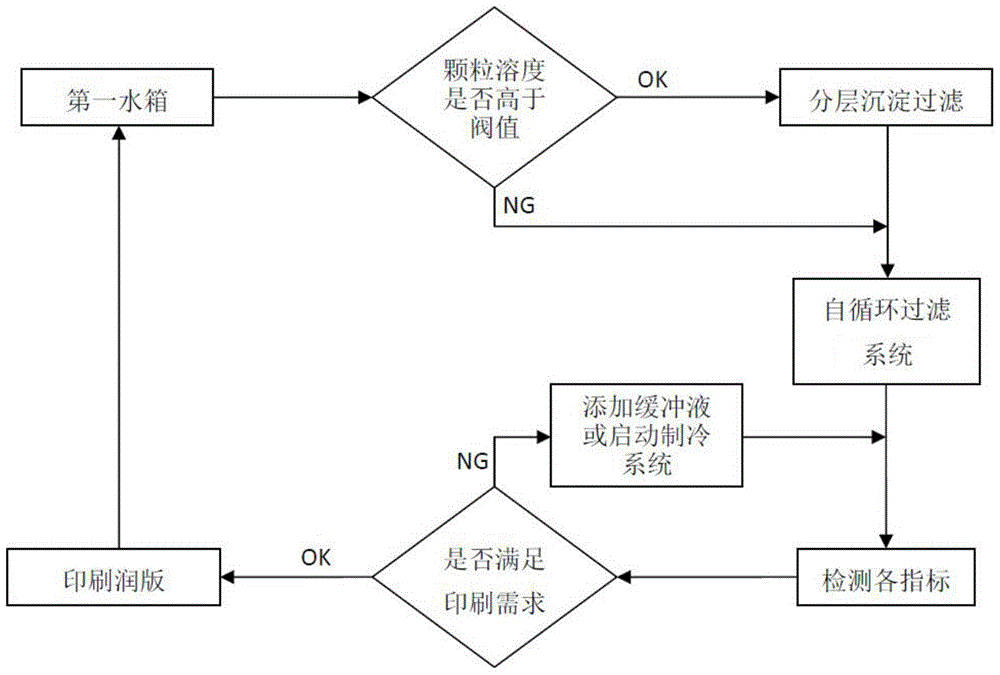

Offset printing fountain solution self-circulation purification system and method

ActiveCN105363277AImprove filtering effectAvoid taking timePrinting pre-treatmentFiltration circuitsSolubilityAqueous alcohol

The invention discloses an offset printing fountain solution self-circulation purification system and method. The system comprises a first water tank, a second water tank, a layered deposition filter, a filter, a third water tank and a control circuit. When through the control circuit, it is found that particle solubility of a fountain solution in the first water tank is less than a preset value, the control circuit controls a 3-way shift switch so that the fountain solution flows into a first chamber, when through the control circuit, it is found that particle solubility of the fountain solution in the first water tank is greater than the preset value, the control circuit controls the 3-way shift switch so that the fountain solution goes through the layered deposition filter, flows into the first chamber, then enters a self-circulation filter system and is subjected to cyclic purification, the control circuit receives signals of a thermometer, a pH detector and a conductivity detector, and when the pH and the conductivity are higher than a corresponding pH threshold and a conductivity threshold, alcohol and water are added into the primary fountain solution according to a certain ratio. The system and method have high fountain solution purification efficiency, realize real-time accurate detection of indexes of the fountain solution, make the fountain solution quality stable and guarantee printing quality.

Owner:力嘉包装(东莞)有限公司 +2

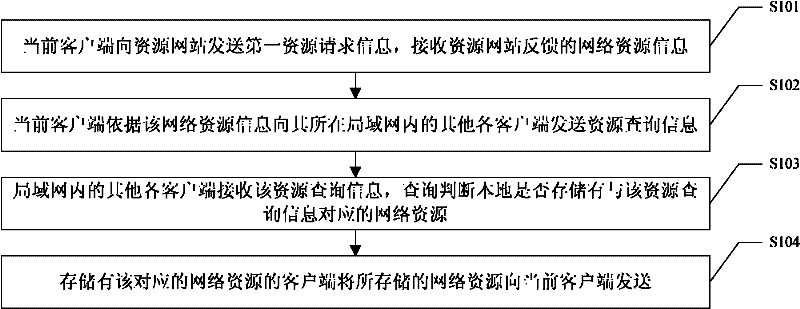

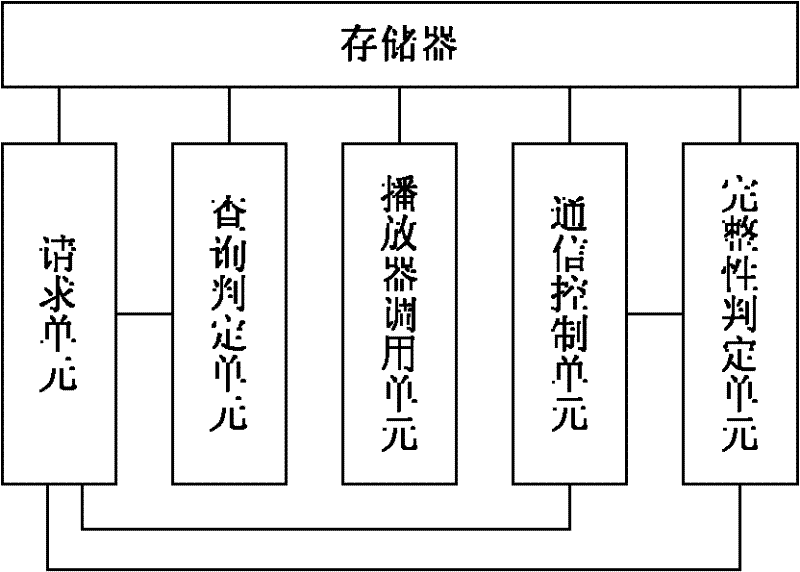

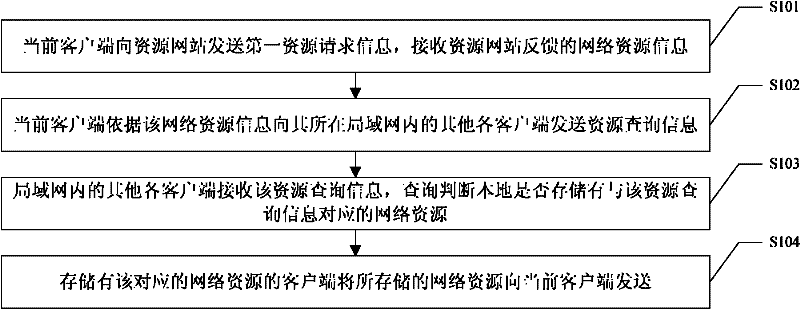

Network information sharing method, device and client

InactiveCN102291432AImprove user experienceAvoid duplicate downloadsTransmissionSpecial data processing applicationsInformation sharingResource information

A network information sharing method, device, and client, the method comprising steps: the current client sends first resource request information to a resource website, and receives network resource information fed back by the resource website, the network resource information including link information and / or network Resource name; the current client sends resource query information to other clients in the local area network according to the network resource information; other clients in the LAN receive the resource query information, and check to determine whether there is a local storage corresponding to the resource query information If yes, send the stored network resource corresponding to the resource query information to the current client. According to the solution of the present invention, repeated downloading of network resources from the resource website is avoided, repeated occupation of network bandwidth is avoided, users can obtain and view network resources in time, avoiding the time taken for re-downloading resources from the website, and improving the user experience. use experience.

Owner:GUANGDONG VTRON TECH CO LTD

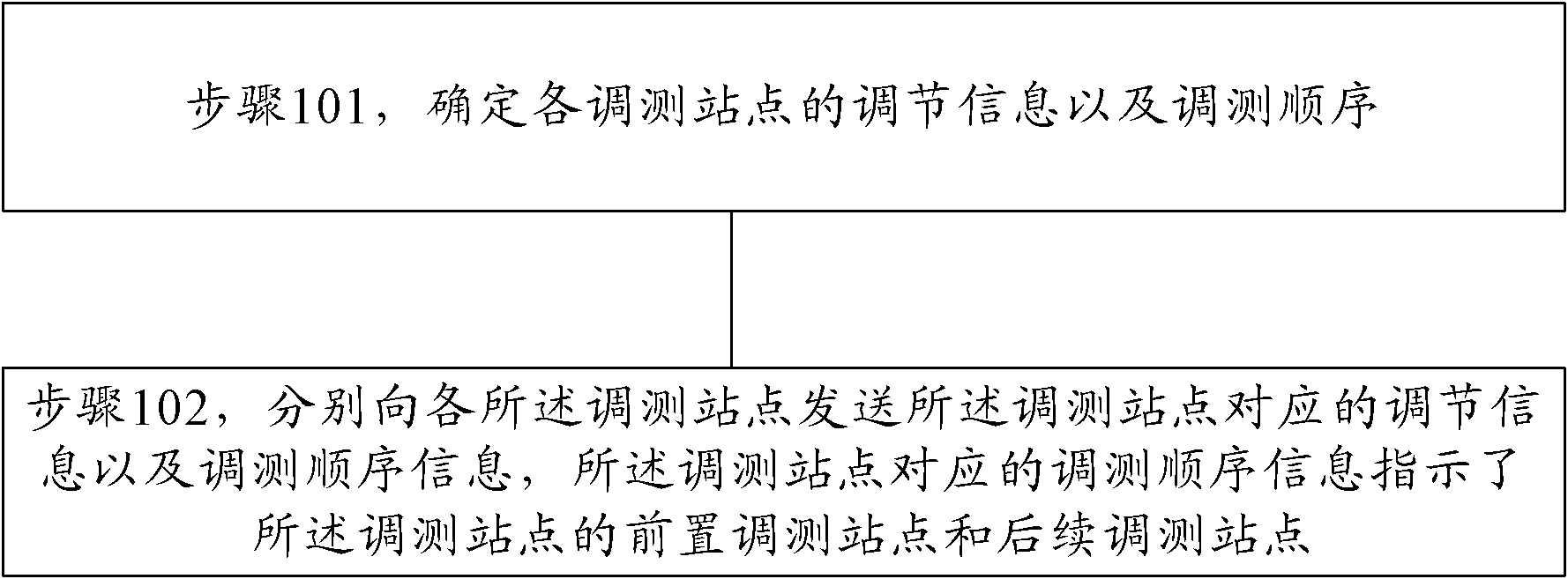

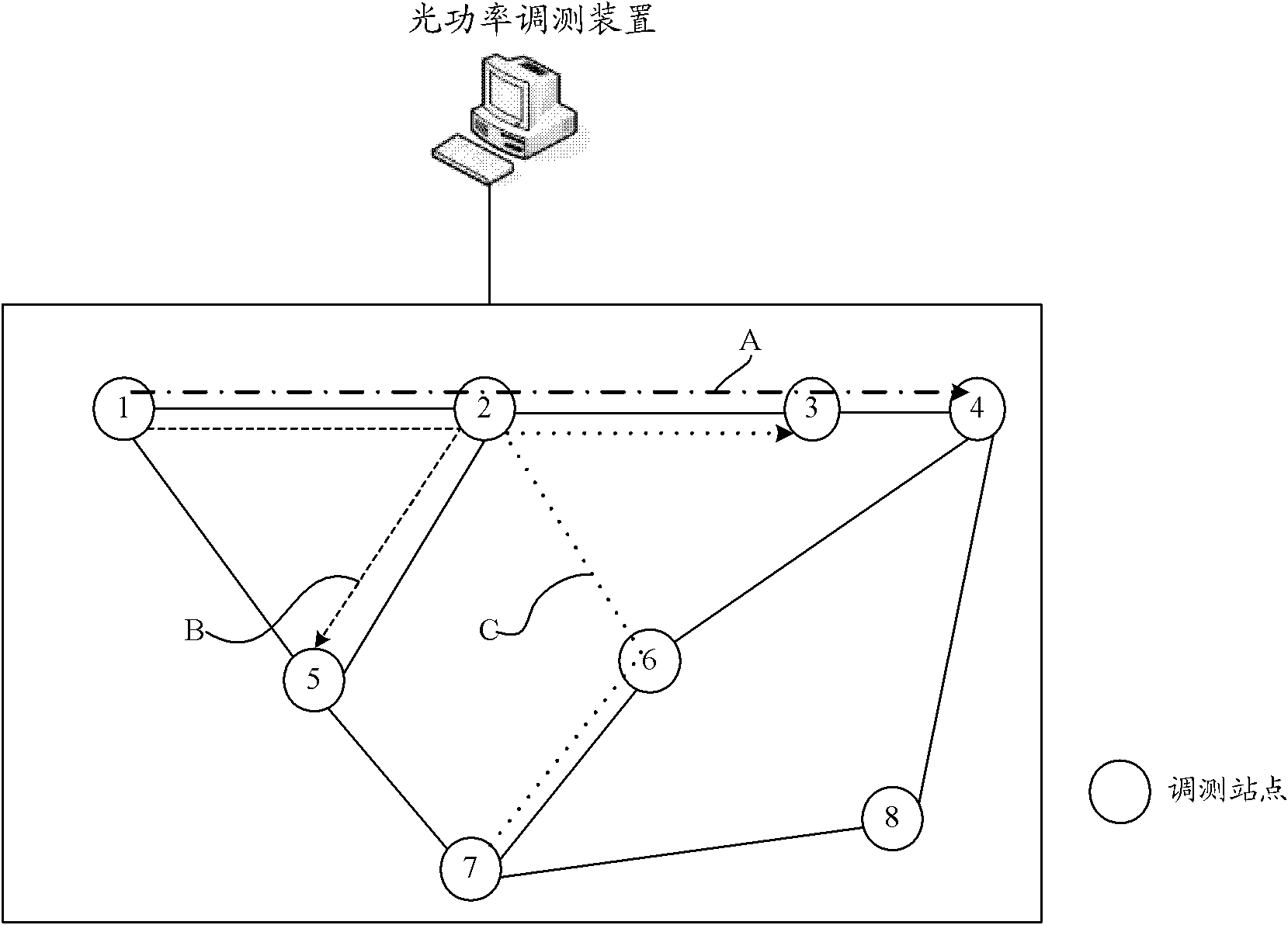

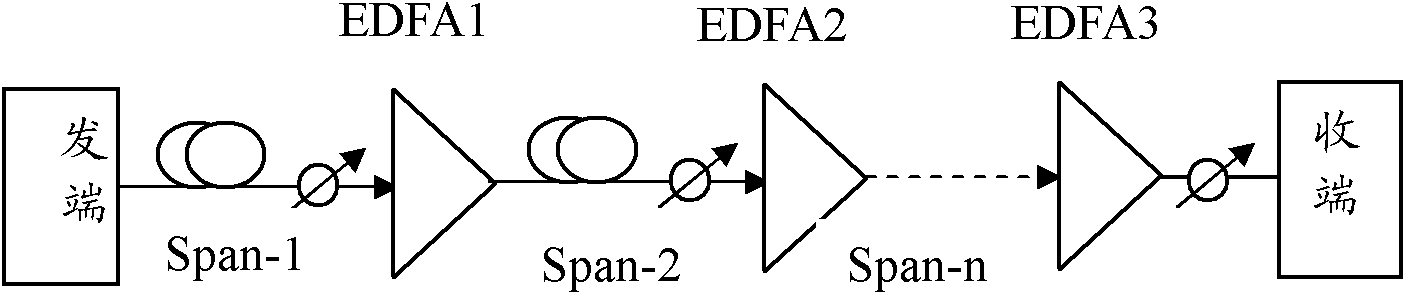

Method and device for debugging optical power

InactiveCN102201863AImprove communication performanceAvoid taking timeTransmission monitoring/testing/fault-measurement systemsOptical powerLength wave

The embodiment of the invention provides a method and device for debugging optical power, relates to the technical field of communications and is used for effectively saving debugging time. The method comprises the following steps: determining the regulating information and debugging sequence of each debugging station; and sending the corresponding regulating information and the debugging sequence information to each debugging station respectively, wherein the debugging sequence information corresponding to the debugging station indicates a preposed debugging station and a follow-up debugging station of the debugging station, thus each debugging station debugs the optical power in accordance with the regulating information and the debugging sequence corresponding to the debugging station. The method and device can be applied to wavelength division networks.

Owner:HUAWEI TECH CO LTD

Telephone apparatus having e-mail transmitting function

InactiveUS7403770B2Easy to operatePromote disseminationAutomatic call-answering/message-recording/conversation-recordingSpecial service for subscribersProcedural approachElectronic mail

A telephone apparatus 100 having a mail transmitting function, comprising: a calling unit operable to originate a call to a phone number of a recipient; a response judging unit operable to judge whether a response to the call is returned; and a mail program control unit operable to start up a mail transmission program if the response judging unit judges in the negative.

Owner:KYOCERA CORP

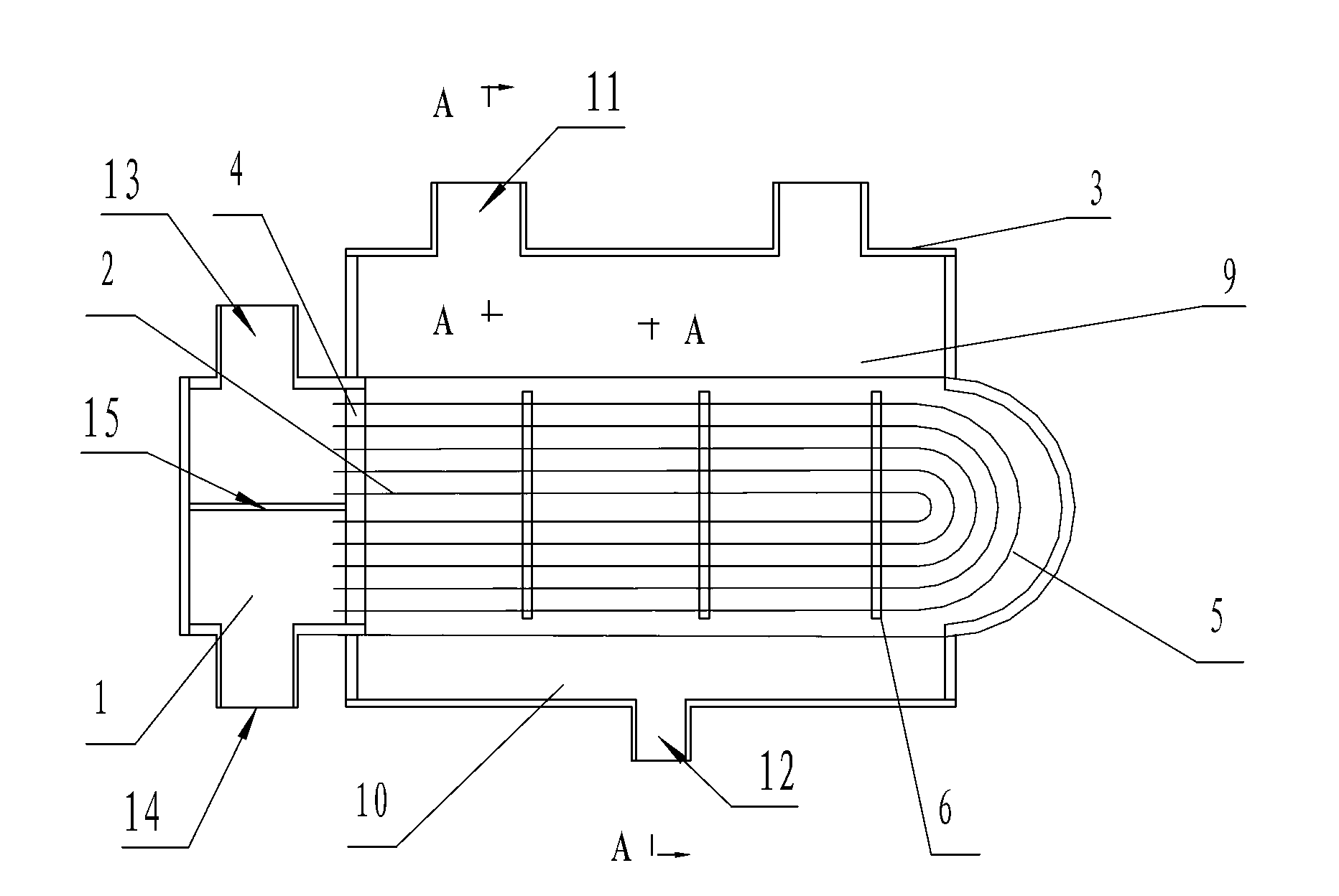

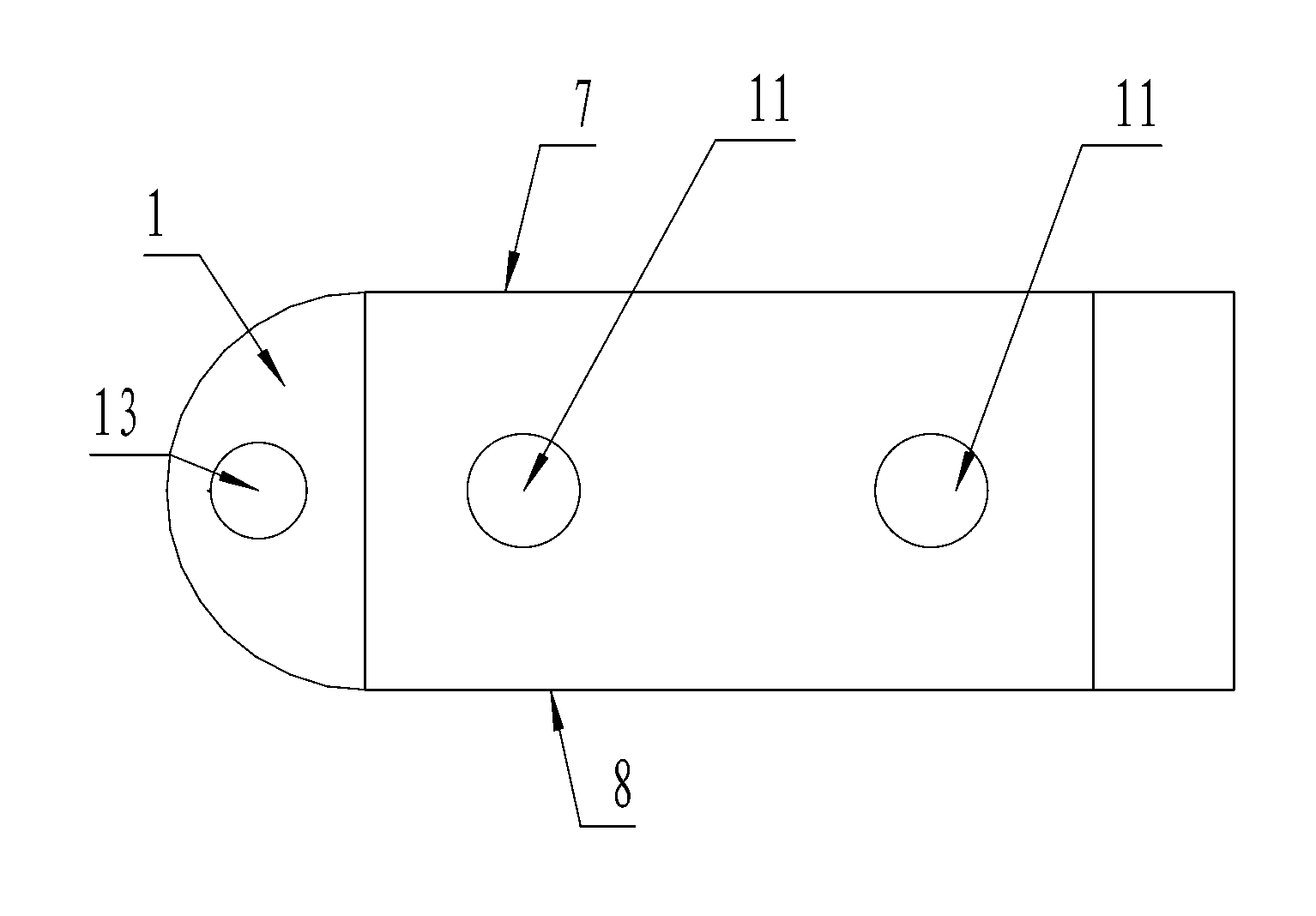

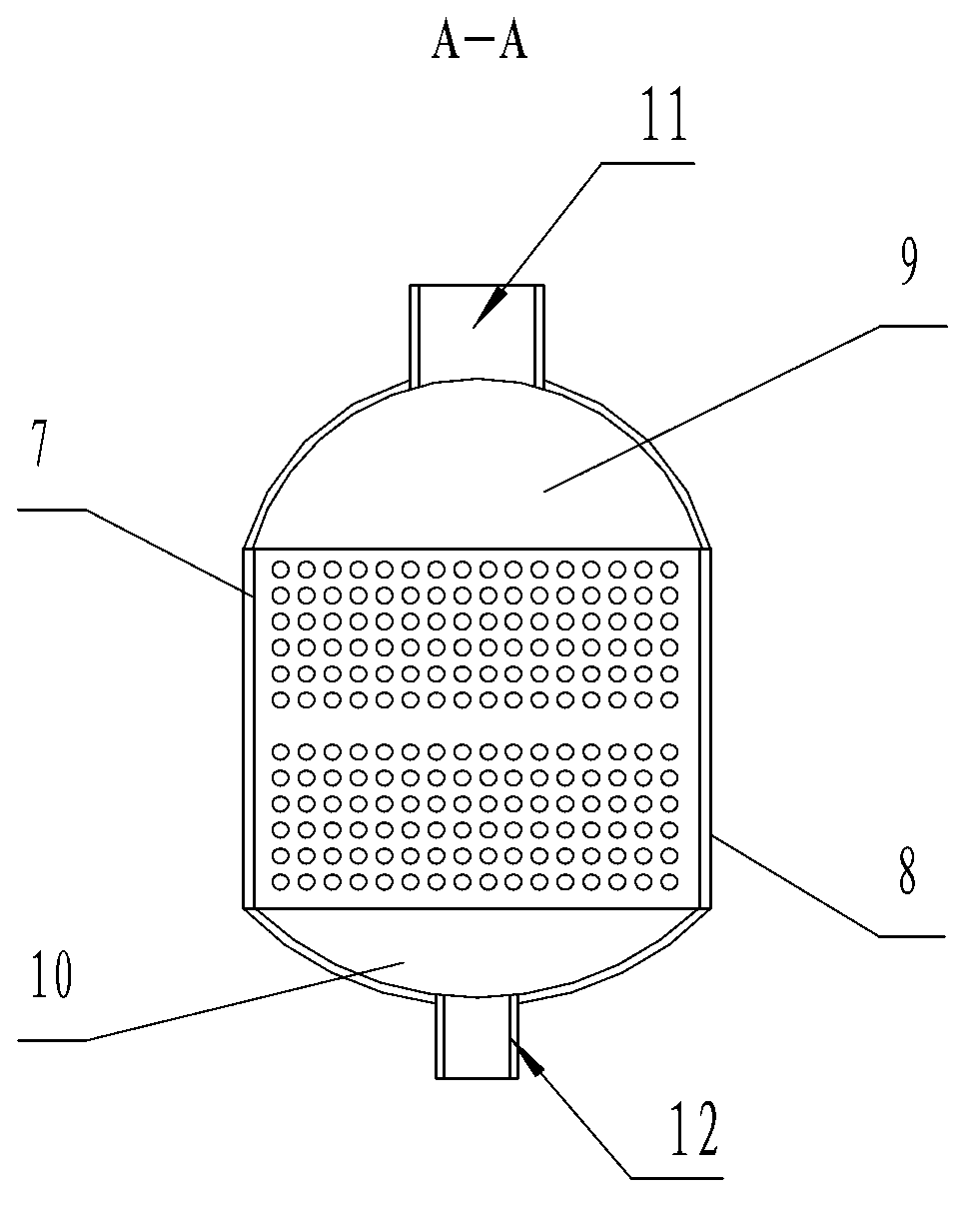

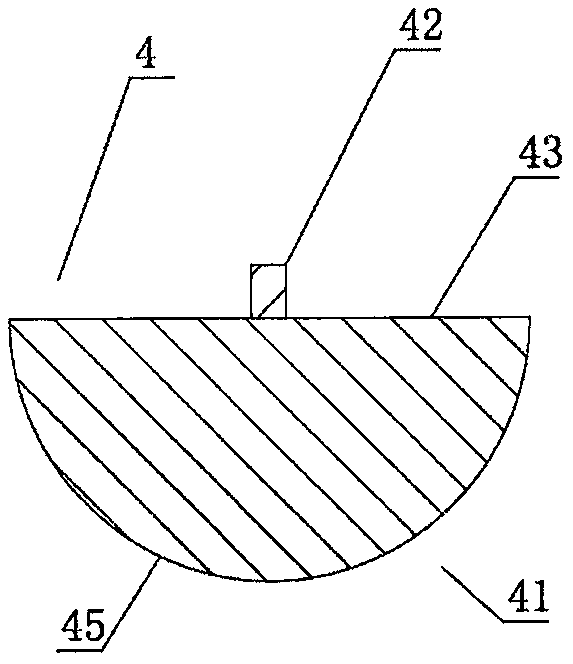

Rectangular fully welded U-shaped tube type heating network heater

InactiveCN103307911AAvoid direct impactReduce consumptionStationary tubular conduit assembliesEngineeringTubes types

The invention discloses a rectangular fully welded U-shaped tube type heating network heater, which belongs to heat transfer equipment, particularly to steam-water heat transfer equipment using U-shaped heat transfer tubes. The rectangular fully welded U-shaped tube type heating network heater comprises a heat transfer tube bundle formed by the U-shaped heat transfer tubes and mounted in a casing, and a tube box provided with a secondary heat medium inlet and a secondary heat medium outlet and mounted at one end of the casing, wherein the heat transfer tube bundle is formed by a rectangular tube plate, the U-shaped heat transfer tubes and rectangular support plates; the U-shaped heat transfer tubes sequentially penetrate at least two rectangular support plates and the rectangular tube plate and are in welding connection and expanded joint with the two types of plates; a semi-circular steam ingoing collection box with a steam inlet is welded above parallel side plates A and B of the casing, and a semi-circular water outgoing collection box with an outgoing water outlet is welded below the side plates A and B; the semicircular cylinder-shaped tube box with the secondary heat medium inlet and the secondary heat medium outlet is welded to the end of the casing, at which the rectangular tube plate is welded. Compared with the conventional U-shaped tube type heat transfer equipment, the fully welded structure is more reliable in sealing, stronger in temperature resistance and pressure resistance, and simpler in structure.

Owner:SHANDONG BEICHEN MECHANICAL & ELECTRICAL EQUIP

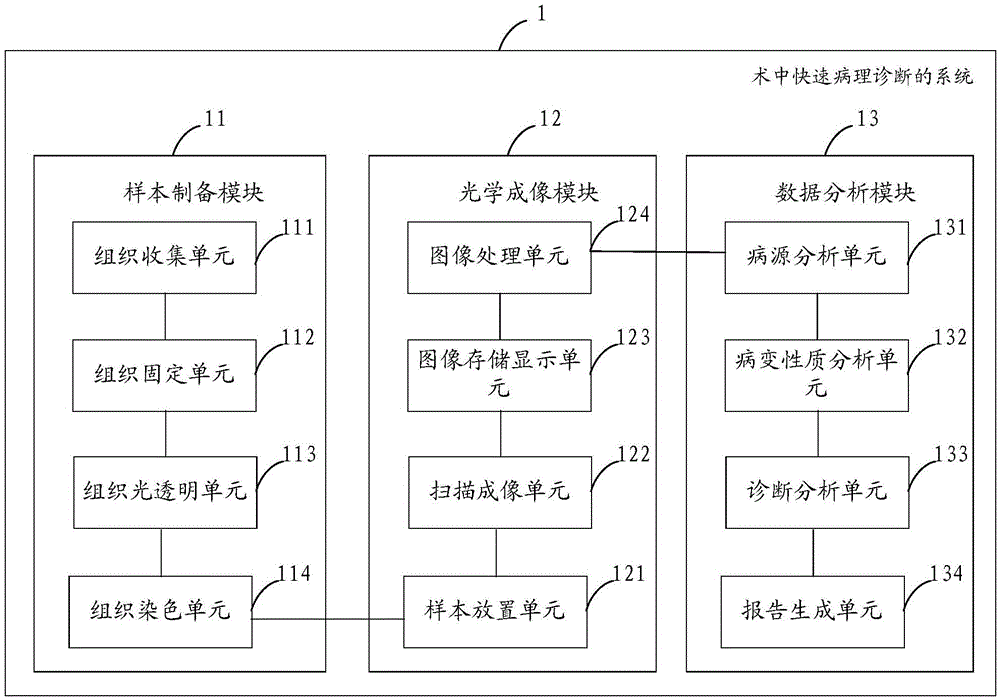

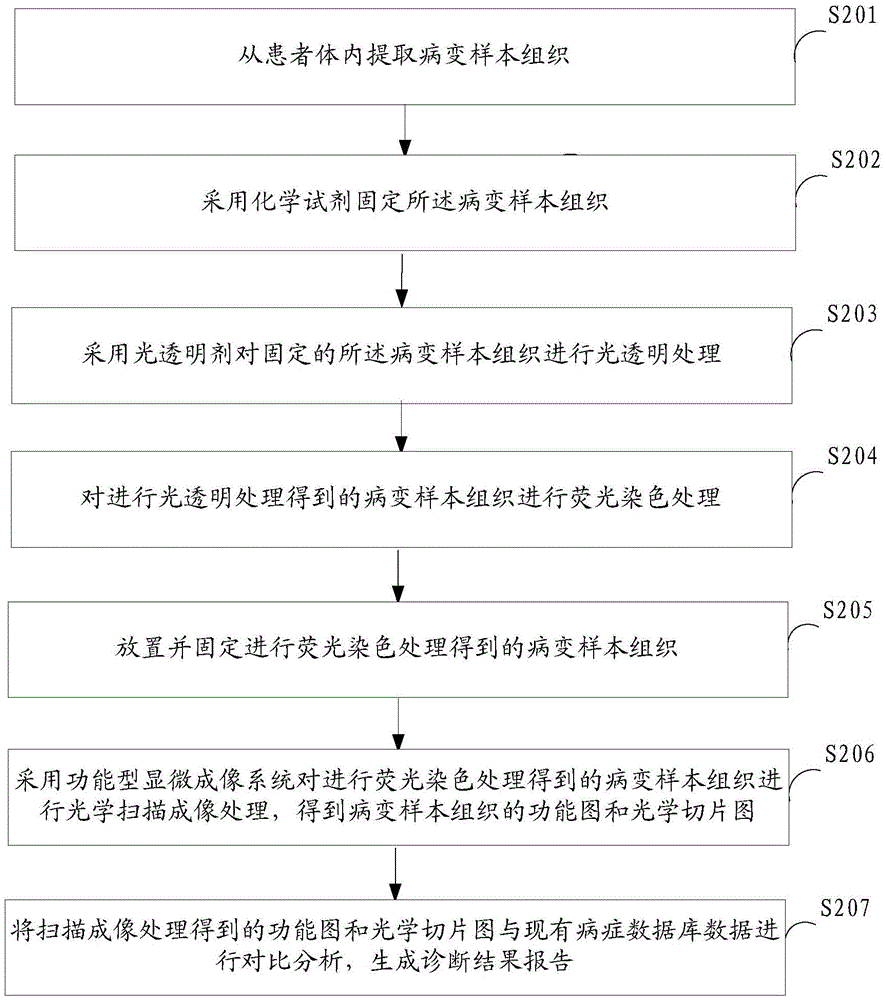

Rapid intraoperative pathological diagnosis system and method

ActiveCN105606573ARealize the function of optical sectioningAvoid taking timePreparing sample for investigationFluorescence/phosphorescenceOptical clearingFluorescence

The invention is suitable for the technical field of medical information and provides a rapid intraoperative pathological diagnosis system and method. The system comprises a sample preparation module, an optical imaging module and a data analysis module, wherein the sample preparation module extracts a diseased sample tissue from a patient body, fixes the diseased sample tissue by adopting a chemical reagent, then performs optical clearing treatment on the diseased sample tissue by adopting an optical clearing agent and finally performs fluorescent staining treatment on the diseased sample tissue; the optical imaging module first arranges and fixes the diseased sample tissue subjected to the fluorescent staining treatment, and then performs optical scanning imaging treatment on the diseased sample tissue subjected to the fluorescent staining treatment, by adopting a functional microimaging system, so as to obtain a functional diagram and an optical section diagram of the diseased sample tissue; and the data analysis module performs comparative analysis on the functional diagram and the optical section diagram as well as existing disease database data to generate a diagnosis result report. The system and the method are high in section-making speed and high in section-making quality.

Owner:SHENZHEN INST OF ADVANCED TECH

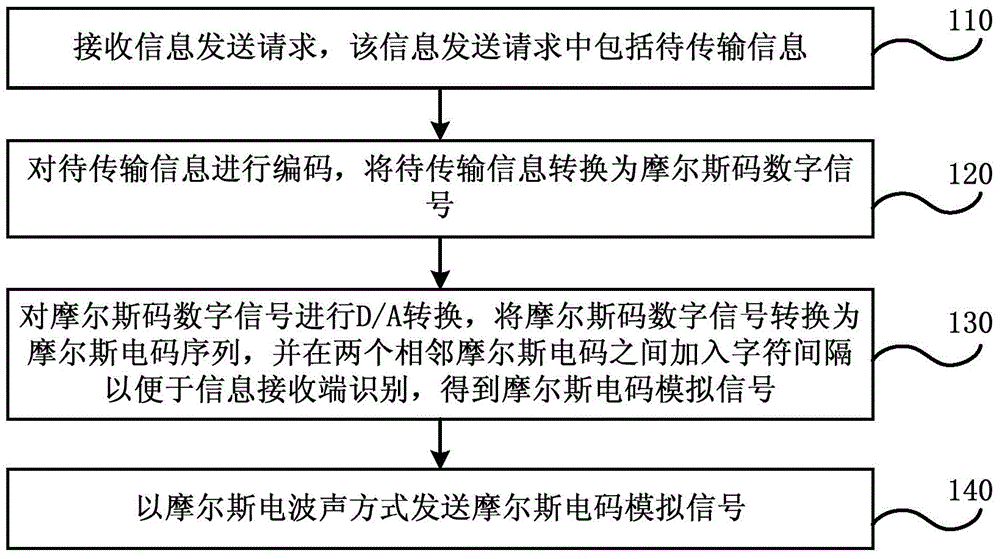

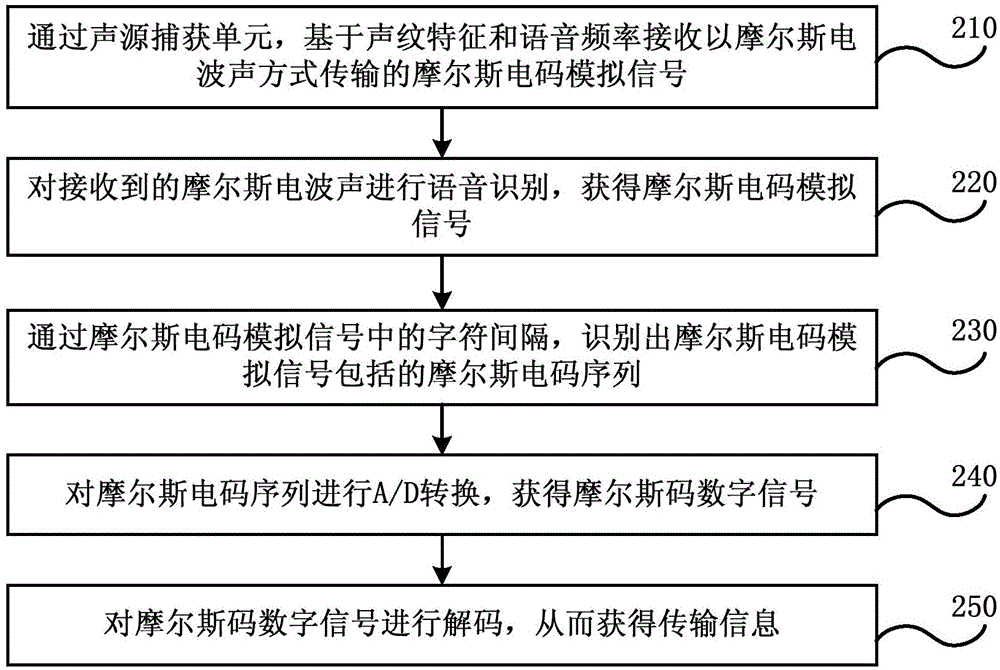

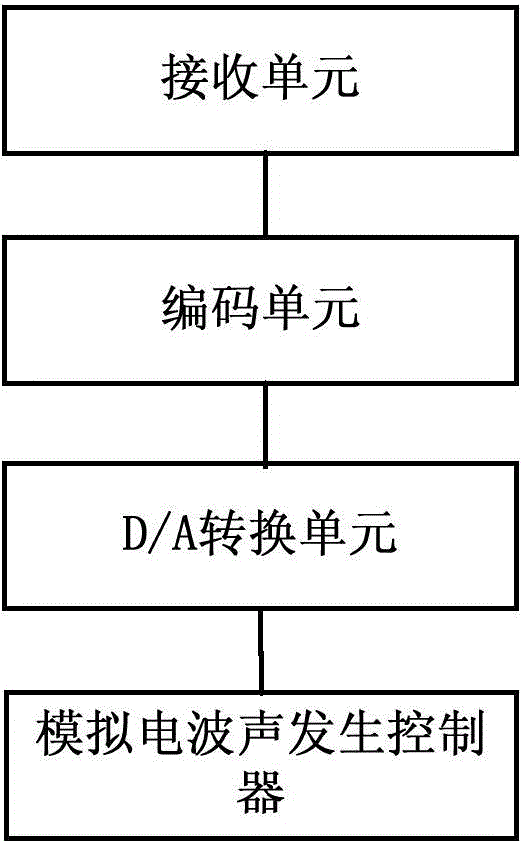

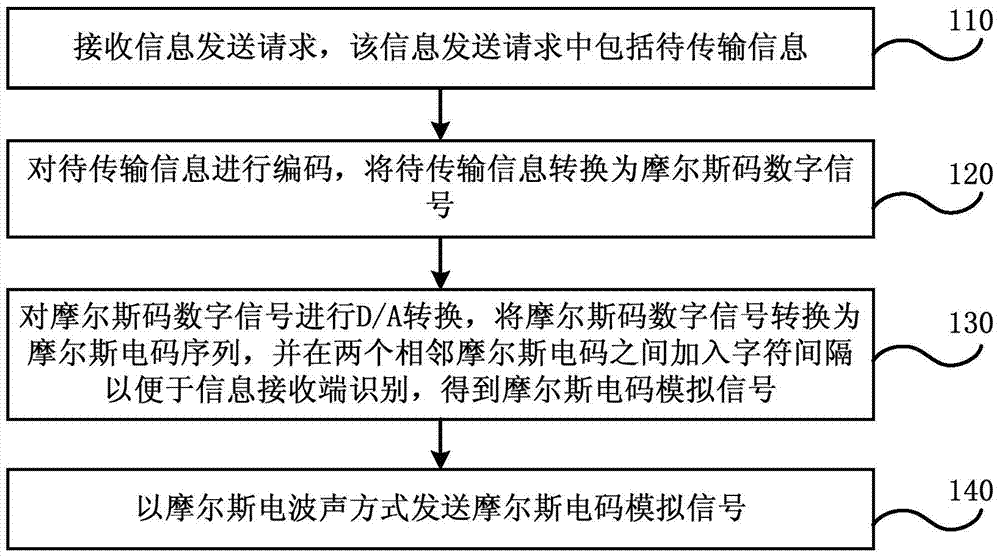

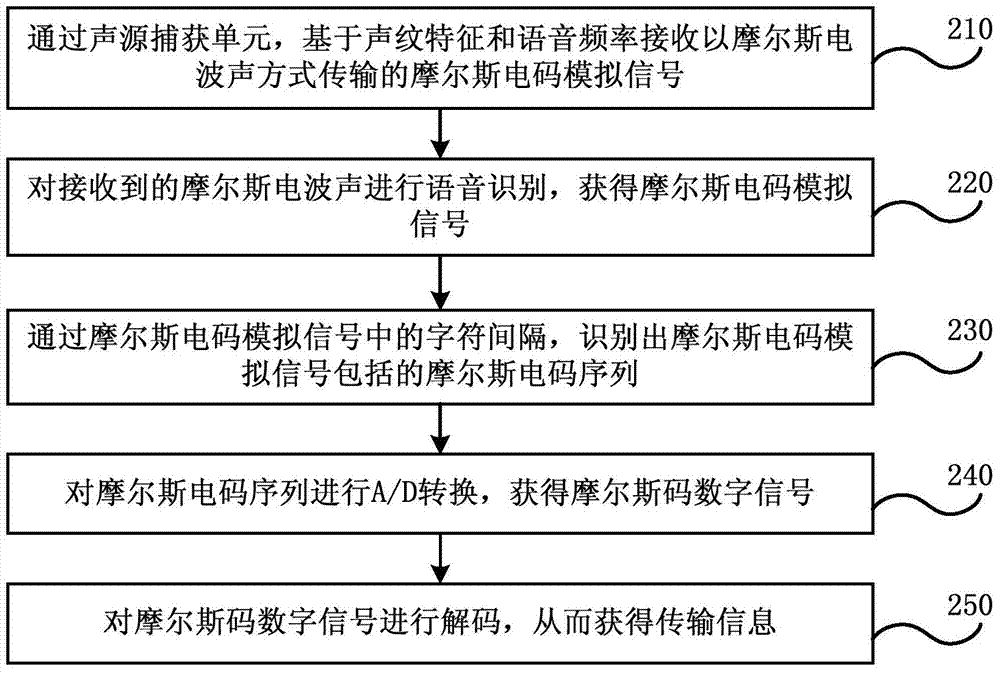

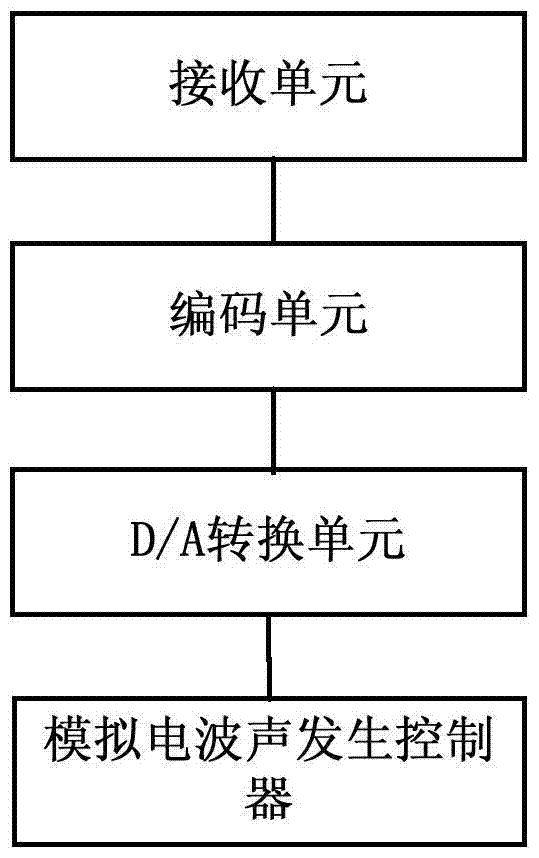

Short-distance information exchange method and system, information sending device, information receiving device and terminal

ActiveCN105471517AImprove exchange efficiencyAchieve direct communicationSonic/ultrasonic/infrasonic transmissionDot-and-dash systemComputer hardwareInformation transmission

Embodiments of the invention disclose a short-distance information exchange method and system, an information sending device, an information receiving device and a terminal. The method comprises the following steps: receiving an information sending request, wherein the information sending request comprises information to be transmitted; carrying out coding on the information to be transmitted, and converting the information to be transmitted into a Morse code digital signal comprising Morse numbers and / or Morse letters; carrying out D / A conversion on the Morse code digital signal according to a Morse code encoding table to enable the Morse code digital signal to be converted into a Morse code sequence, and adding a character interval between two adjacent Morse codes to obtain a Morse code analog signal, wherein the Morse code sequence comprises more than one Morse codes arranged in sequence; and sending the Morse code analog signal in a Morse electric wave sound manner. Therefore, tedious and complex operation of carrying out pairing between user terminals sharing the information can be reduced, information transmission time is reduced, and information exchange efficiency is improved.

Owner:CHINA TELECOM CORP LTD

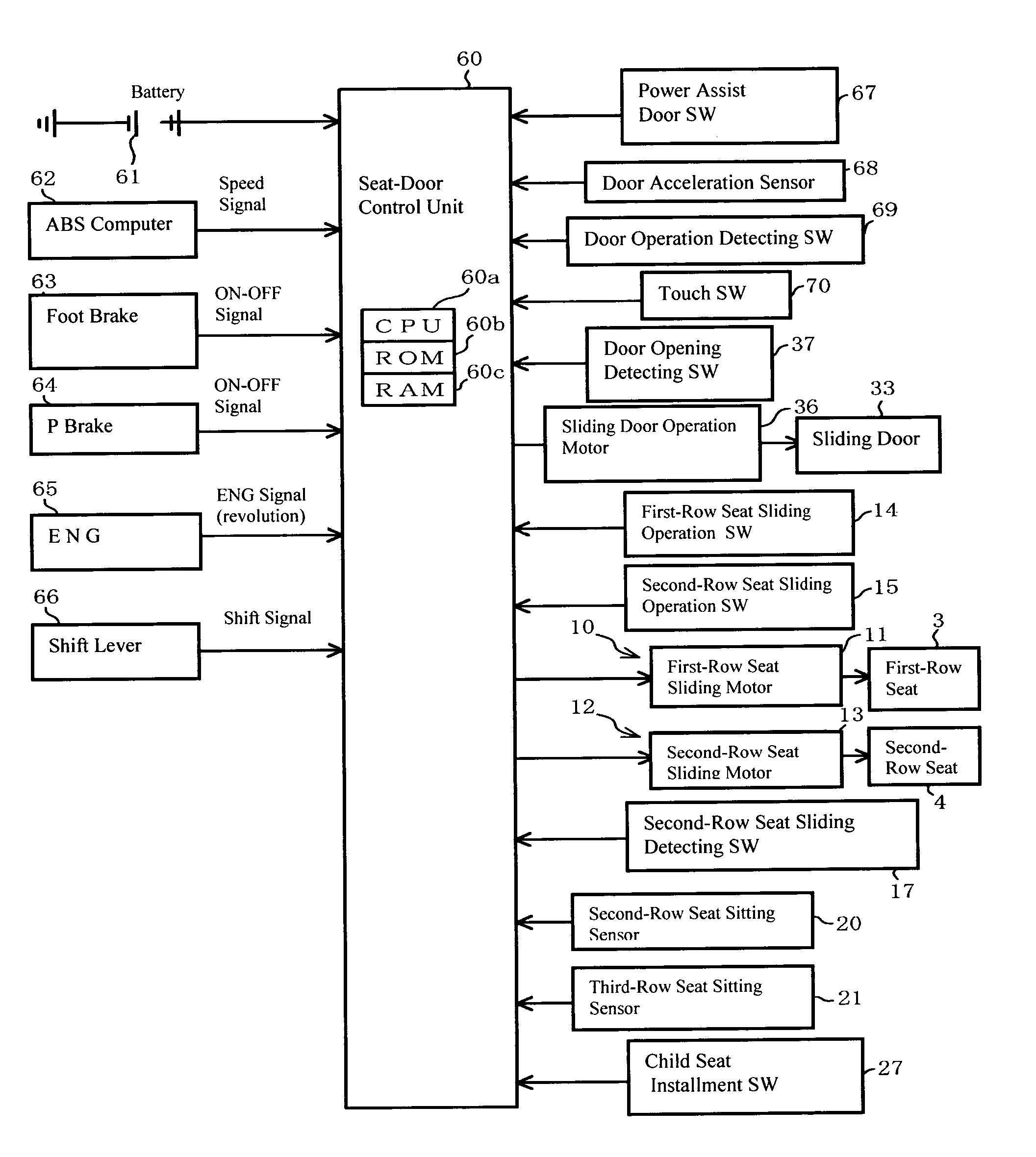

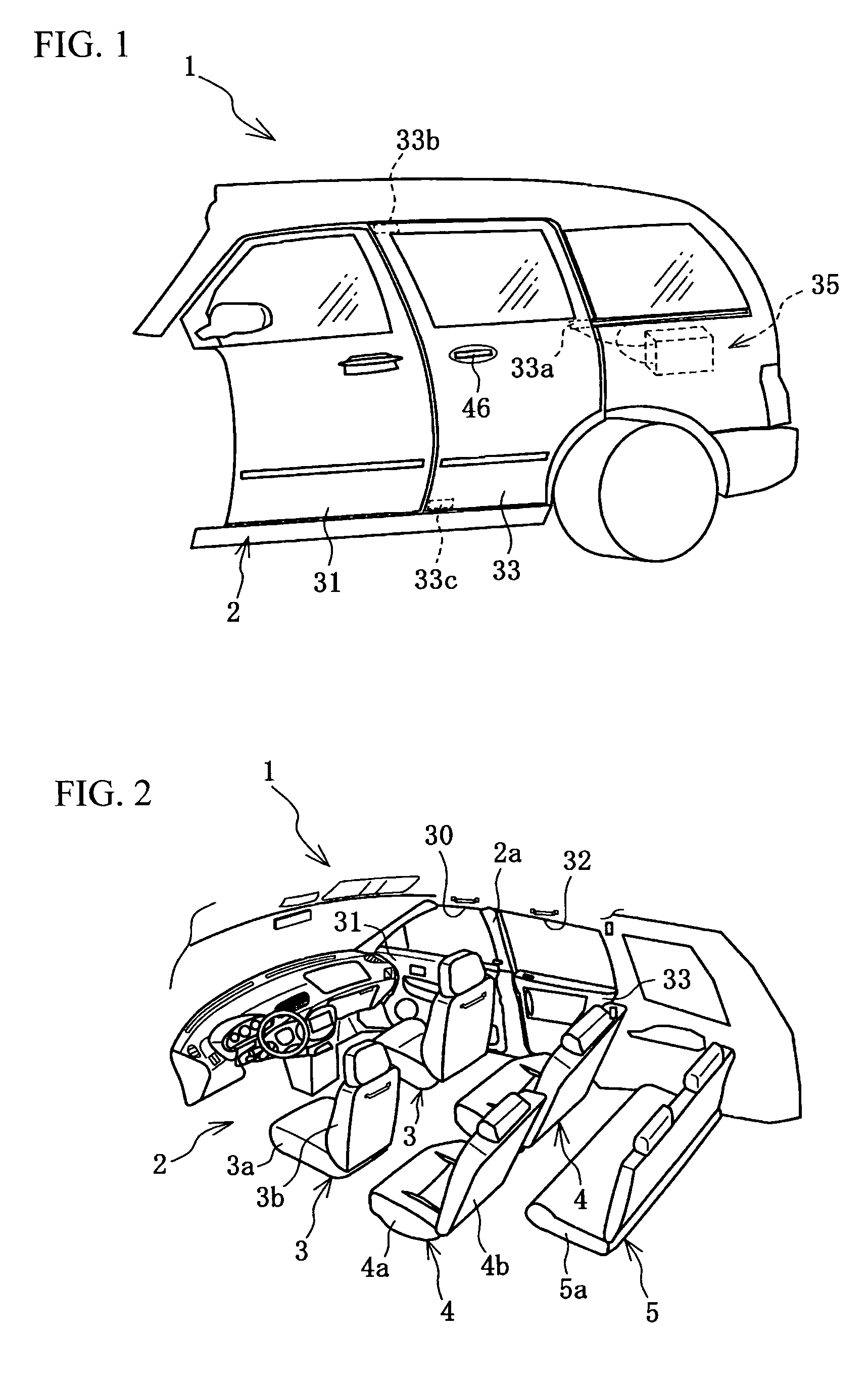

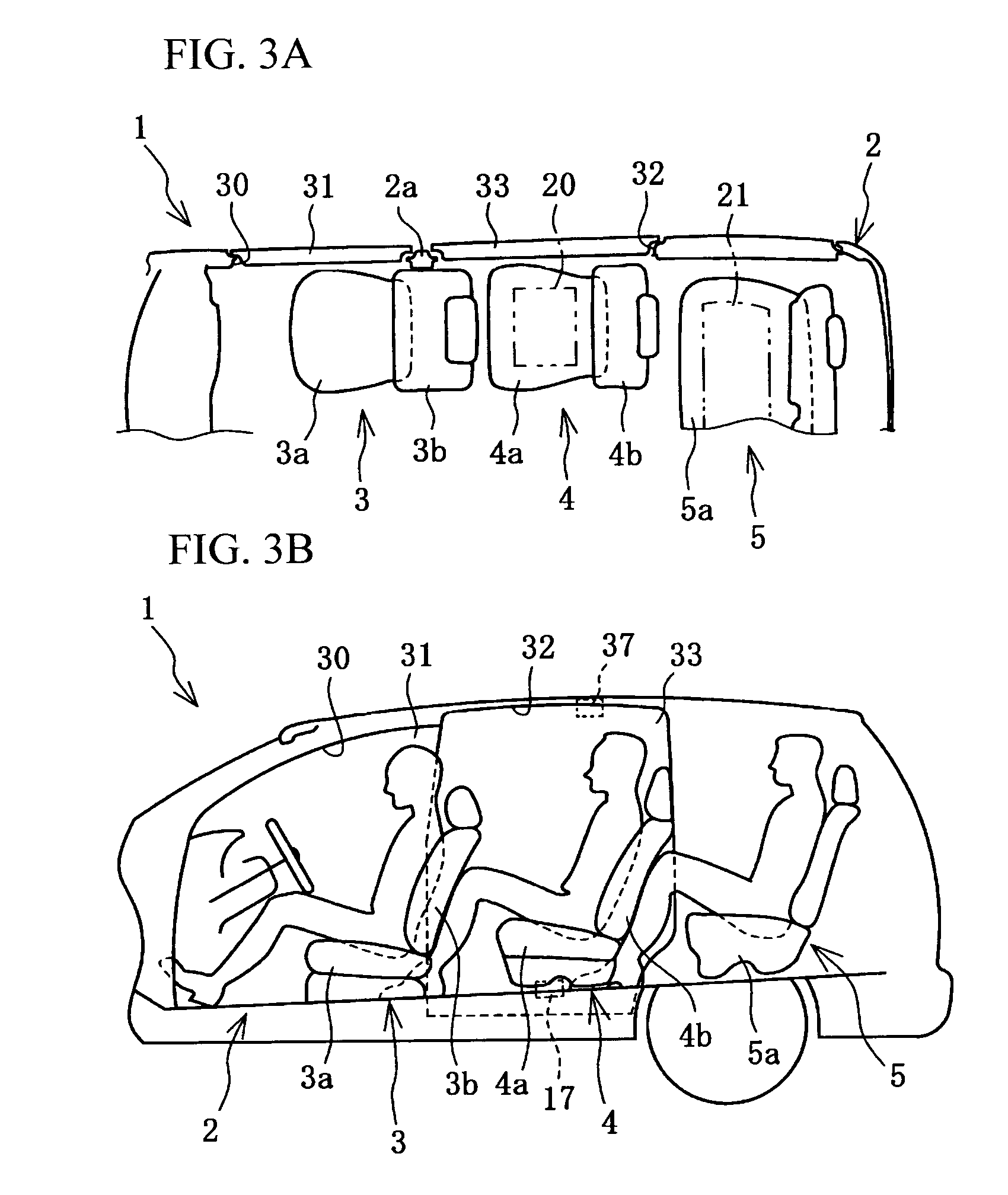

Seat control device for vehicle

InactiveUS7023108B2Easy to operateReduce the necessary timeElectric devicesElectrical apparatusForward slidingEngineering

When ingress intention of a passenger who is supposed to sit on a second seat is predicted, a distance between a first seat and the second seat is expanded automatically. Accordingly, taking time for access to the second seat can be avoided, thereby decreasing necessary time for having access and improving accessibility to the second seat. When a full-open mode is selected (Yes in S1); the passenger does not sit on the third-row seat (Yes in S2); the passenger does not sit on the second-row seat (Yes in S3); and a child seat is not installed on the second-row seat (Yes in S4), a second-row seat sliding motor is driven and a first-row seat driving mechanism operates. Accordingly, forward sliding of the second-row seat starts (S5), and a sliding door is driven backward to open fully.

Owner:MAZDA MOTOR CORP

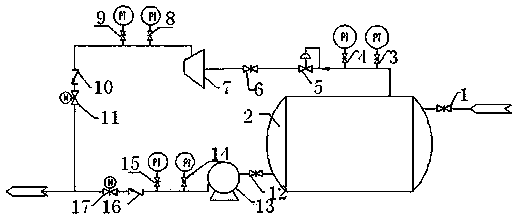

Oil-gas mixing transportation device and process applied to gathering and transportation station yard with high gas oil ratio

The invention belongs to the technical field of oil-gas mixing transportation, and particularly relates to an oil-gas mixing transportation device and process applied to a gathering and transportationstation yard with high gas oil ratio. The oil-gas mixing transportation device comprises a sealed separating device, a first pressure detection device, an air pressure regulator, a compressor, a second pressure detection device, a gas transmission valve, a crude oil transfer pump, a third pressure detection device and an oil transportation valve; an input hole is formed in one side of the sealedseparating device; a gas outlet is formed in the top of the sealed separating device; the gas outlet is connected with the first pressure detection device, the air pressure regulator, the compressor,the second pressure detection device and the inlet of the gas transmission valve through a pipeline in sequence; a liquid outlet is formed in the lower part of the other side of the sealed separatingdevice, and is connected with the crude oil transfer pump, the third pressure detection device and the oil transportation valve through a pipeline in sequence. The outlets of the gas transmission valve and the oil transportation valve are subjected to outward-outputting through pipeline converging, the requirement of oil-gas mixing transportation when the oil-to-gas ratio is relatively high is met, and the device and the process have the advantages of simple flow, process optimization, high reliability, and high degree of automation.

Owner:XIAN CHANGQING TECH ENG

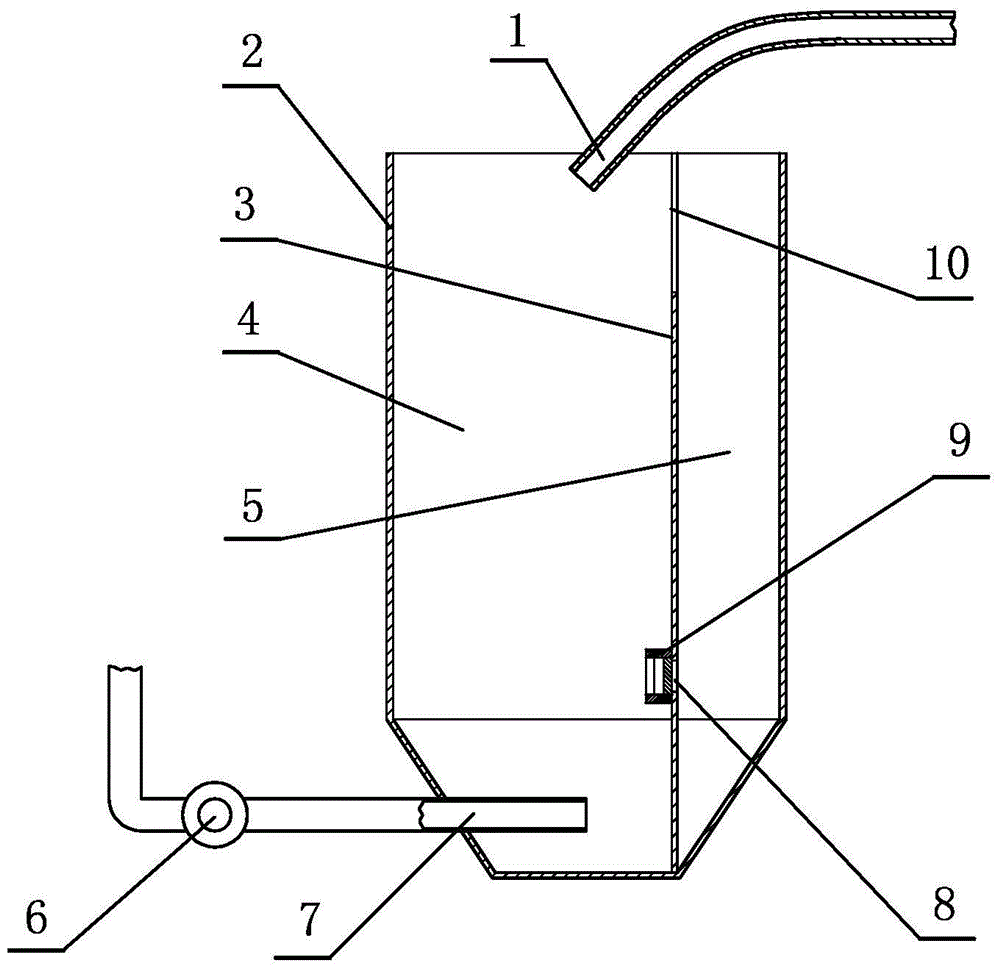

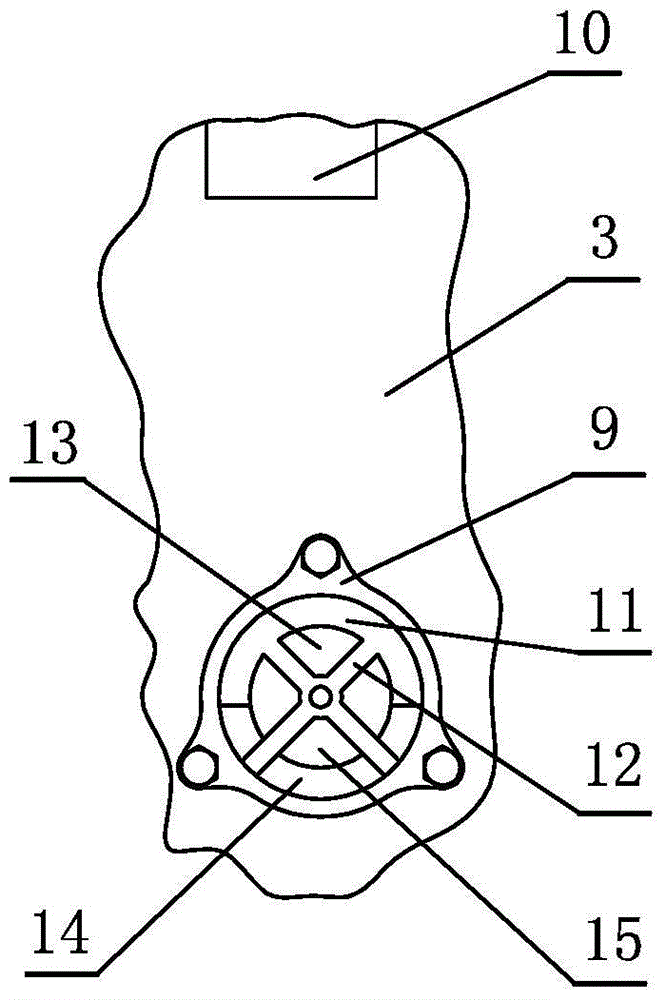

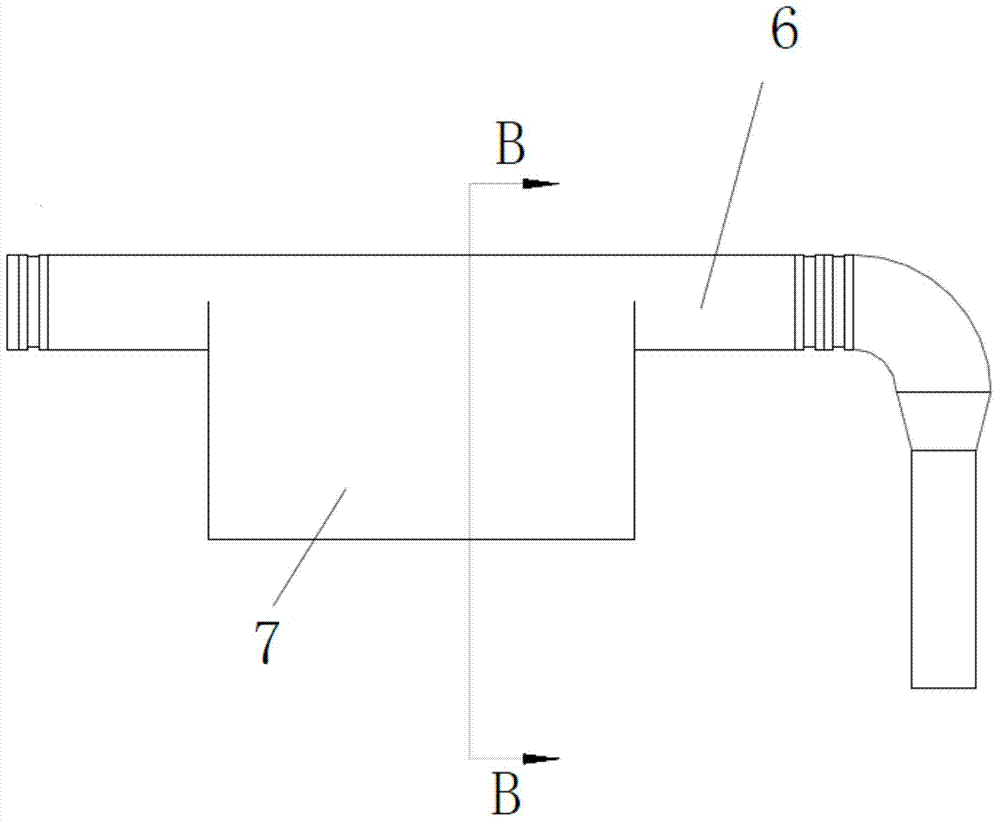

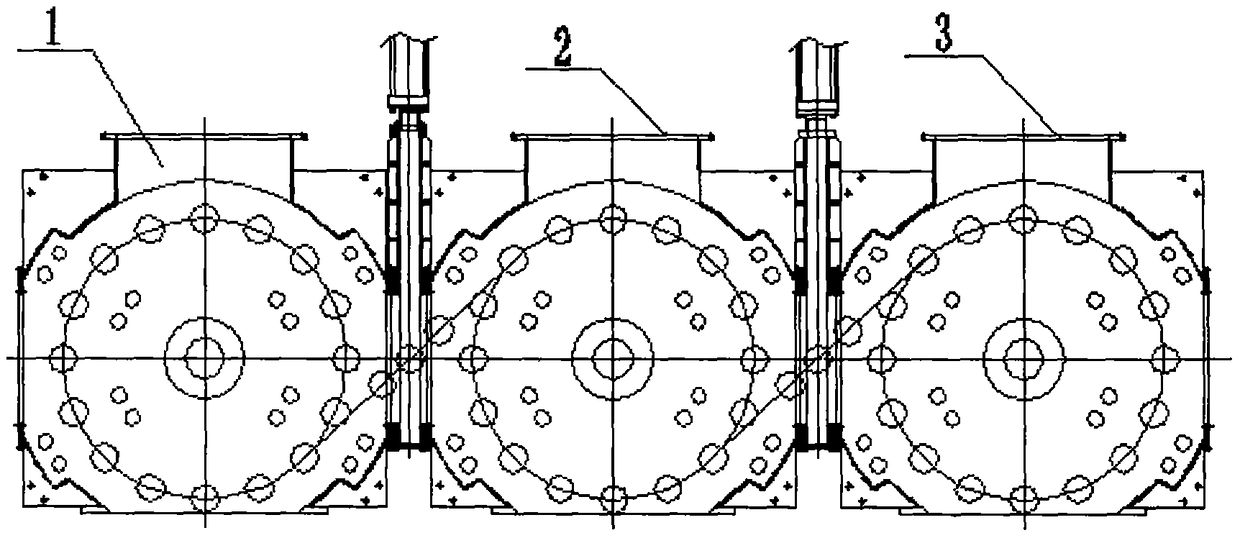

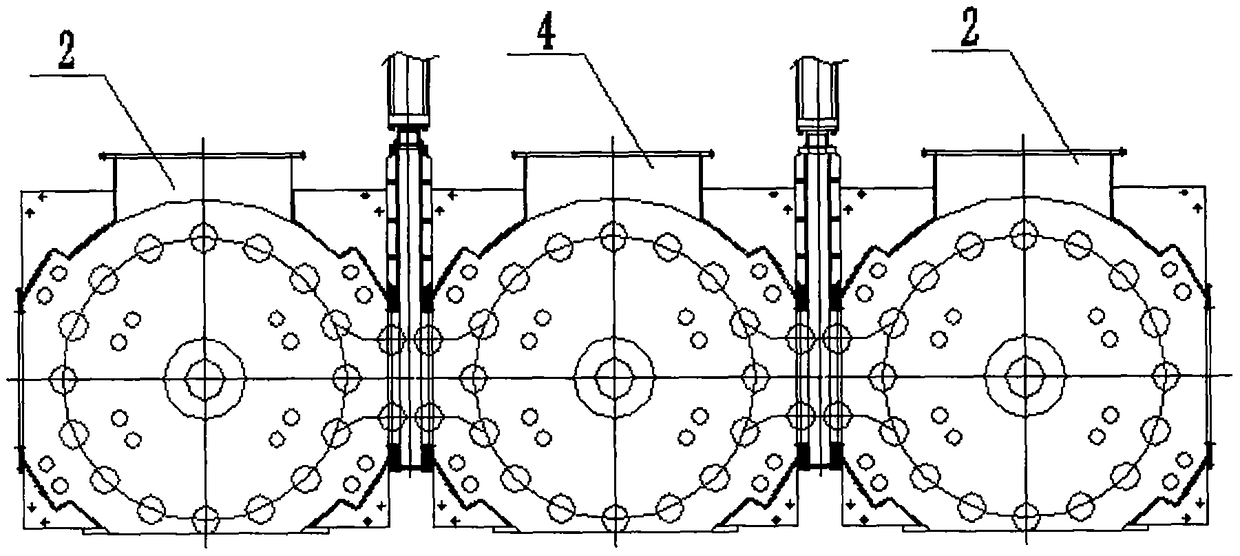

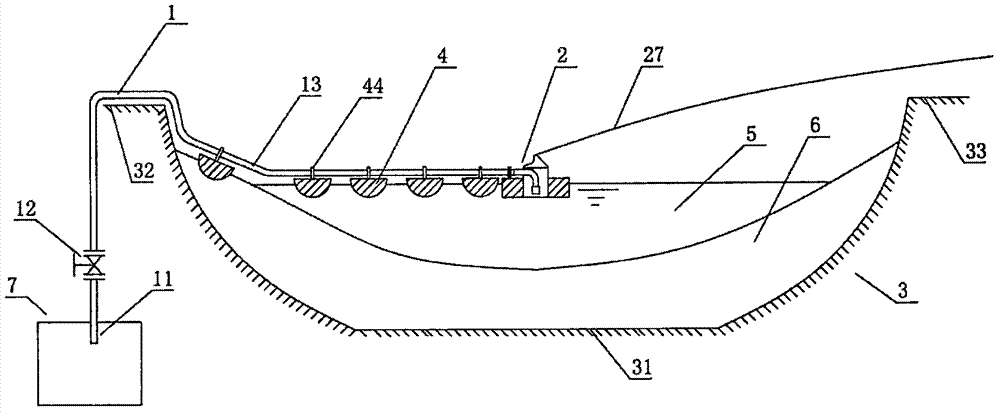

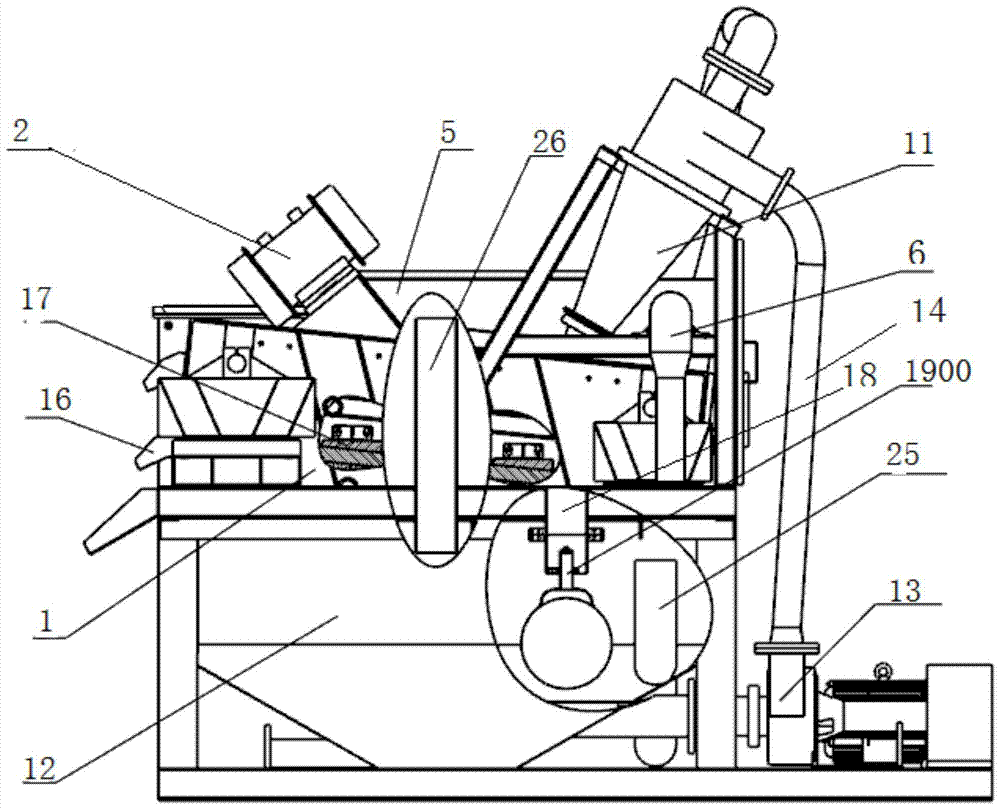

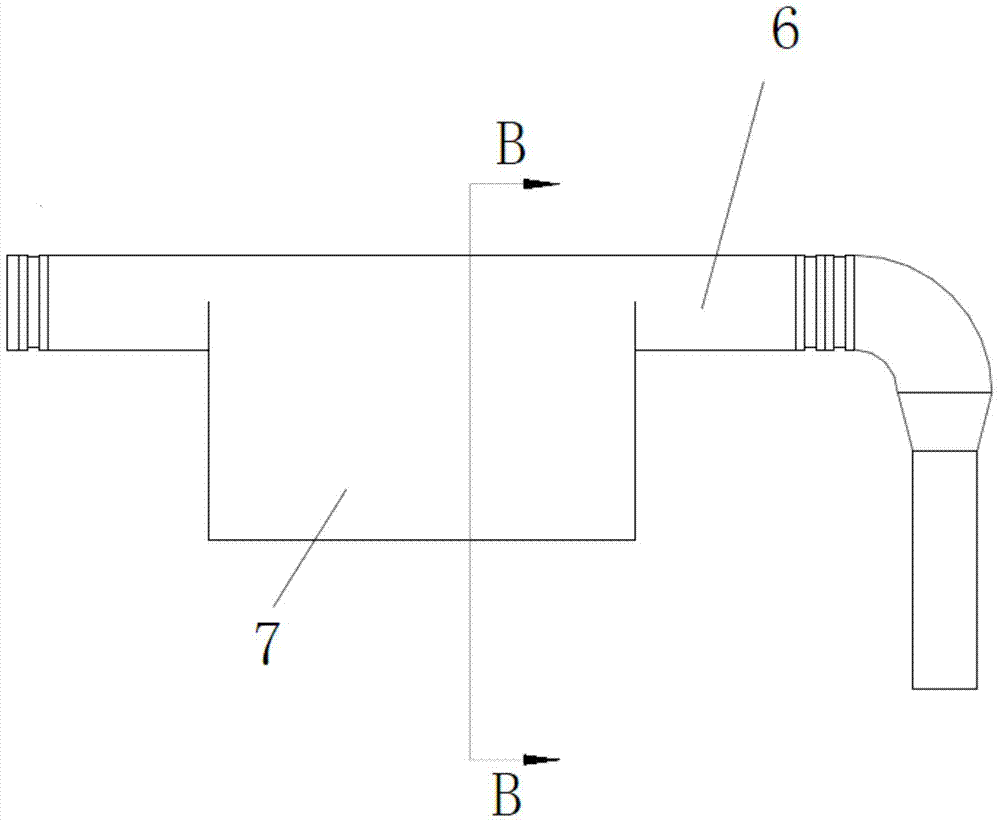

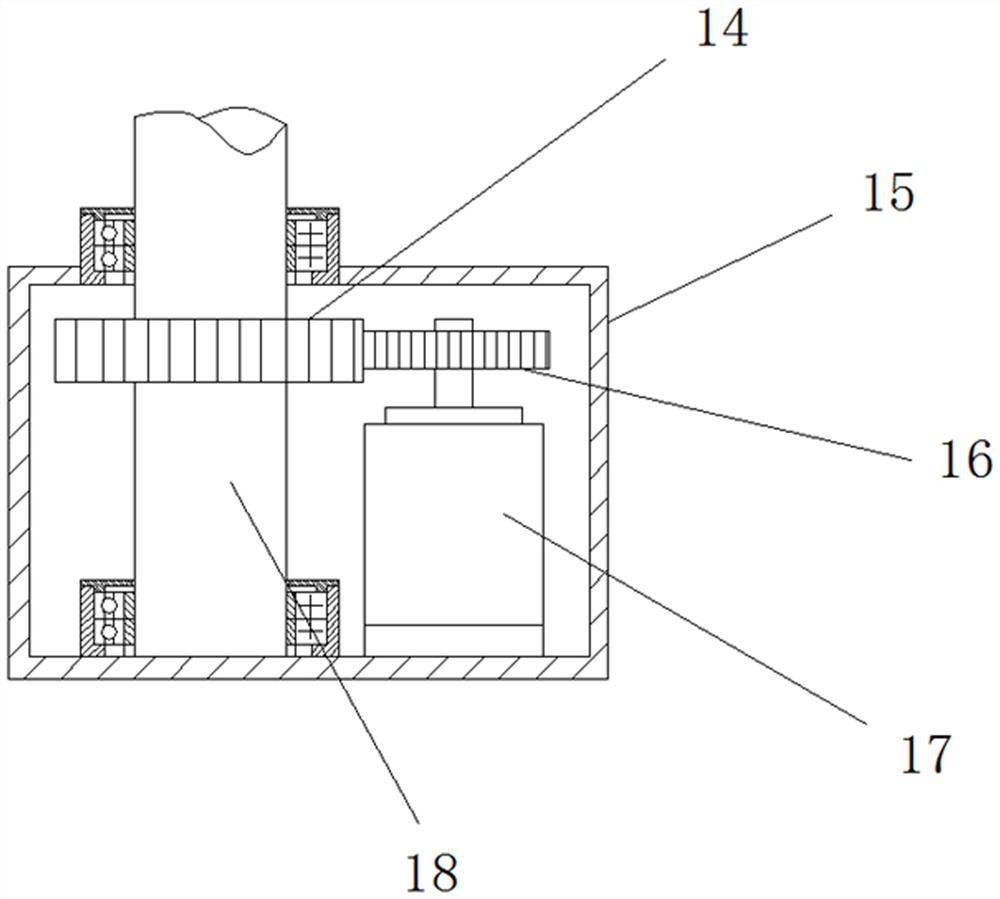

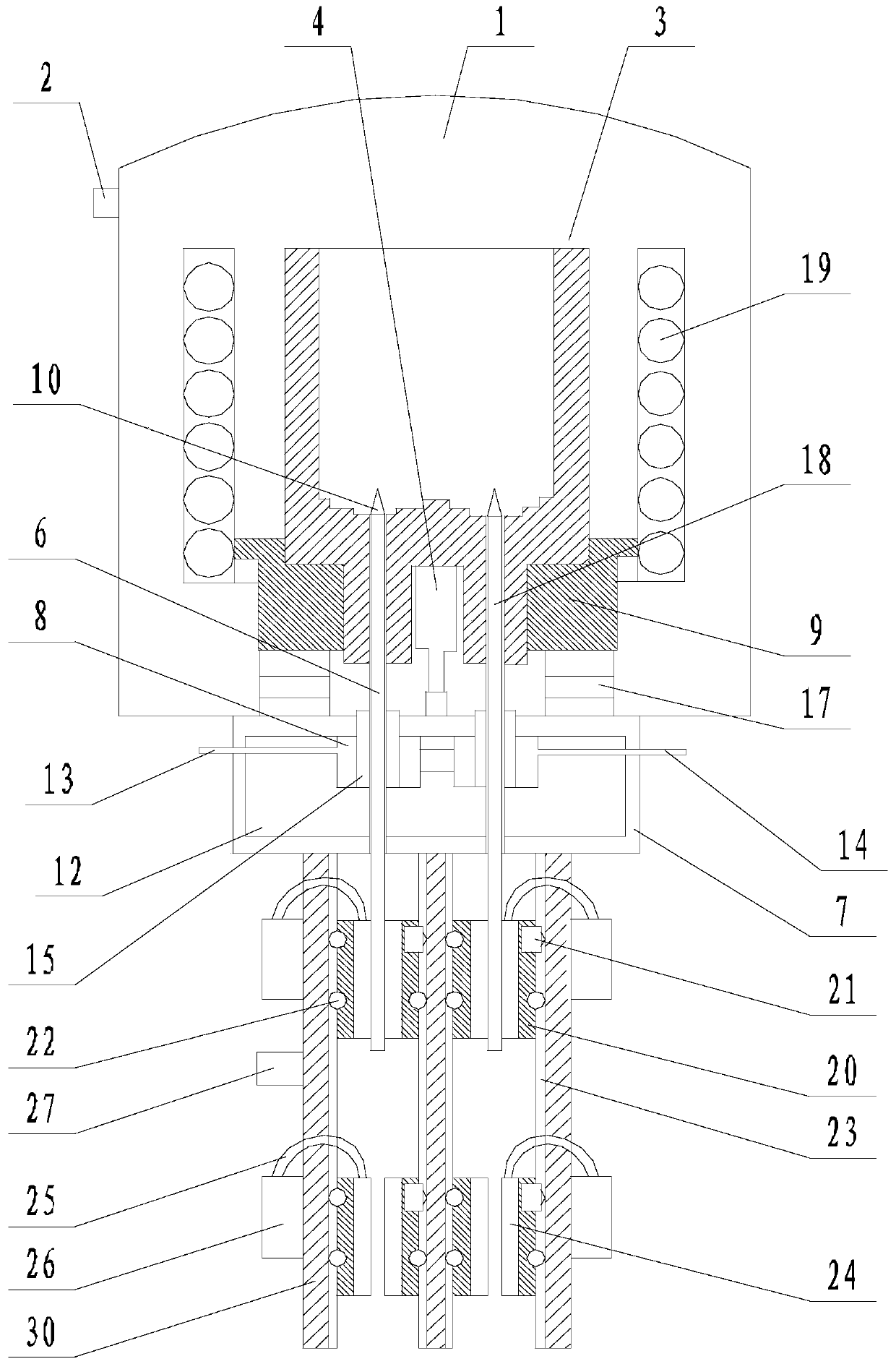

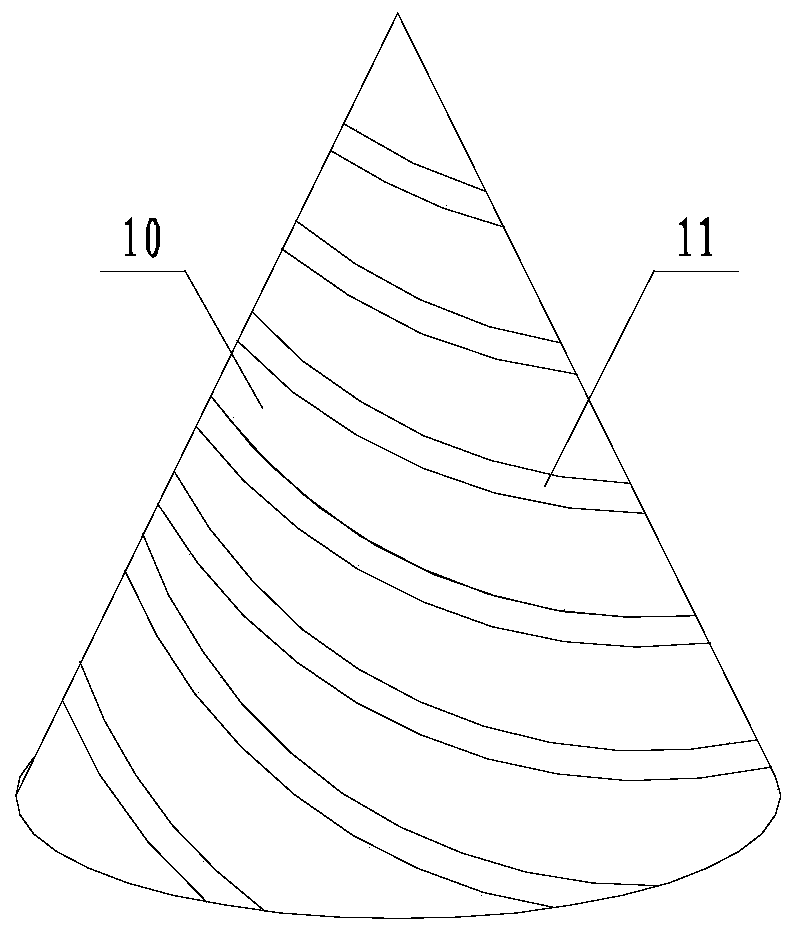

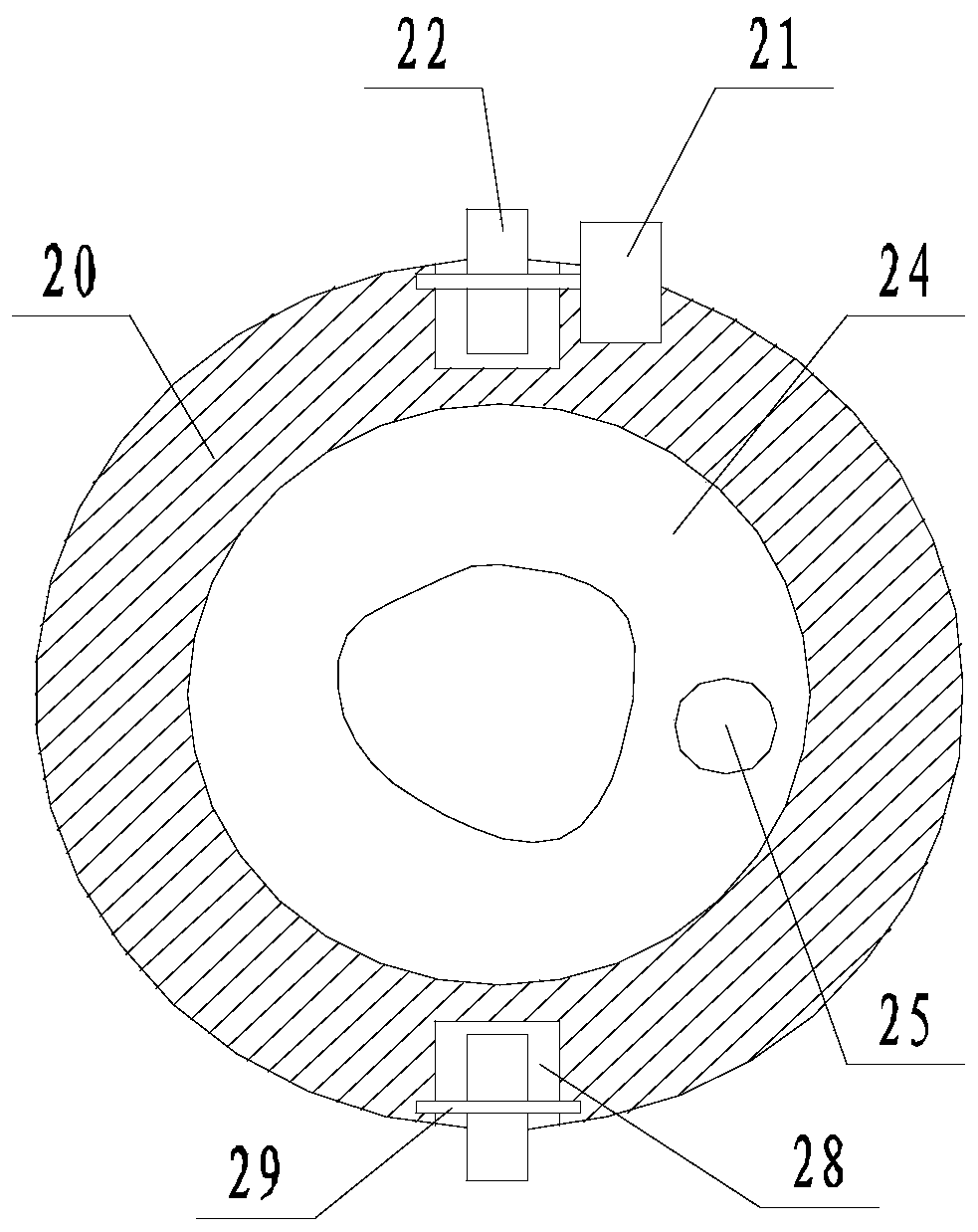

Differential pressure anti-evacuation mortar pump

ActiveCN104454621BEnsure continuous and stable workAvoid taking timePump componentsPump controlDifferential pressurePiston

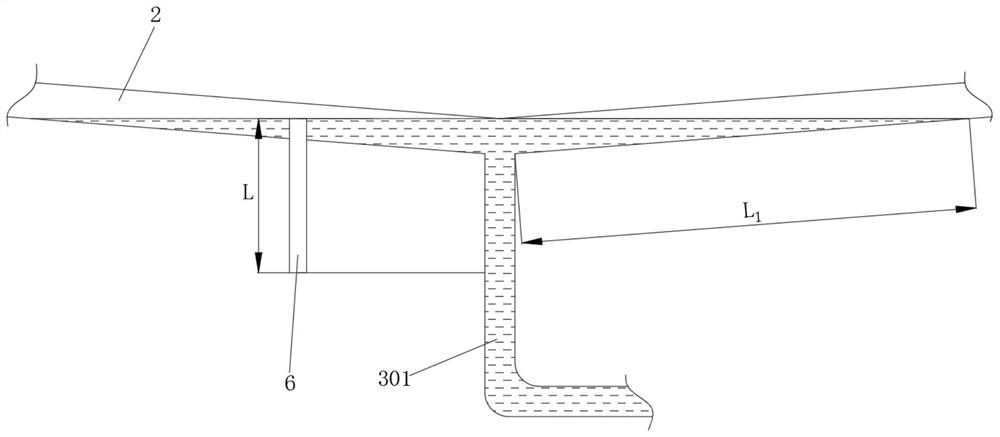

The invention relates to a silica sand producing device, namely a differential pressure type evacuation preventing mortar pump. The differential pressure type evacuation preventing mortar pump comprises a mortar tank (2) and a mortar pump body (6), and the inlet of the mortar pump body (6) is located at the lower portion in the mortar tank (2). The differential pressure type evacuation preventing mortar pump is characterized in that a partition plate (3) is arranged in the mortar tank (2) and divides the space in the tank into a main cavity (4) and an auxiliary cavity (5), a notch (10) is formed in the upper portion of the partition plate (3), a water draining hole (8) is formed in the lower portion of the partition plate (3), a differential pressure valve (9) is installed on the part, on one side of the water draining hole (8) and the main cavity (4), of the partition plate (3), the differential pressure valve (9) is provided with a tubular sliding sleeve (11), an end cover (12) is arranged at the outer end of the sliding sleeve (11), a water draining port (14) is formed in the lower side wall of the sliding sleeve (11), a piston disk (15) is arranged in the sliding sleeve (11), and the inner side face of the piston disk (15) and a plate face around the water draining hole (8) are closed matched faces. The differential pressure type evacuation preventing mortar pump has the advantages that in the working process of the mortar pump, a part of mortar or clean water is stored in the auxiliary cavity, when the liquid face of the mortar in the main cavity ascends to the appointed position, the differential pressure valve is automatically opened, the mortar is supplemented in the main cavity, mortar pump evacuation is avoided, and the stable work of the mortar pump is ensured.

Owner:TONGLIAO SILICA SAND IND

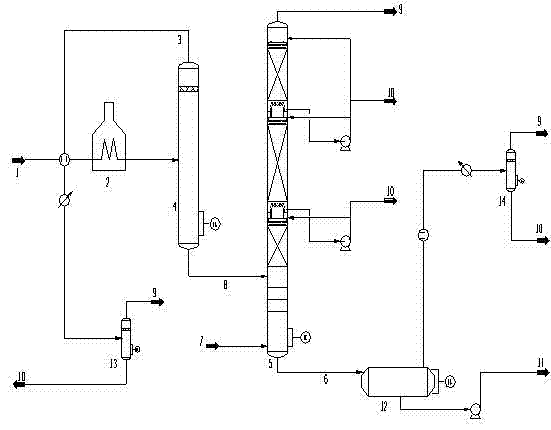

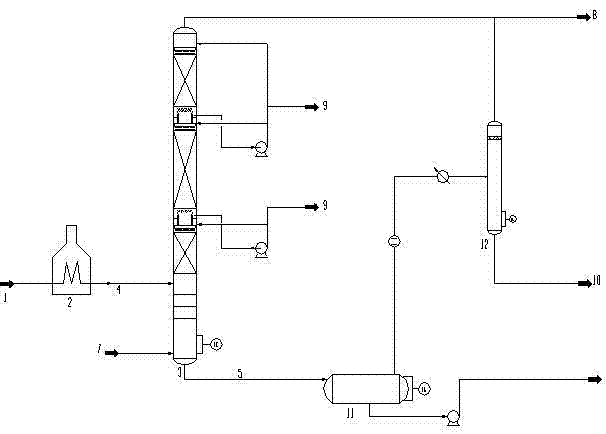

Reduced pressure distillation method with low energy consumption and deep total distillation rate

ActiveCN103242896AIncrease gasification rateReduce pressure drop lossTreatment with plural serial refining stagesThermodynamicsEconomic benefits

The invention discloses a reduced pressure distillation method with low energy consumption and deep total distillation rate. By arranging a reduced pressure flashing tower behind a reduced pressure heating furnace, light fractions vaporized by heat are separated out, load of a reduced pressure distillation tower is reduced and energy consumption of an apparatus is reduced; by arranging a reduced pressure flashing tank behind the reduced pressure distillation tower, relatively light fractions in reduced pressure residues can be further flashed under a vacuum degree higher than that of the bottom of a reduced pressure distillation tower, yield of reduced pressure distillate oil is increased, and thus a reduced pressure distillation operation with low energy consumption and deep total drawing rate can be realized. With the reduced pressure distillation method, the content of fractions with a temperature lower than 500 DEG C in the reduced pressure residues can be reduced to the minimum, so that the distillation rate of the reduced pressure distillation is increased and economic benefits of the apparatus can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

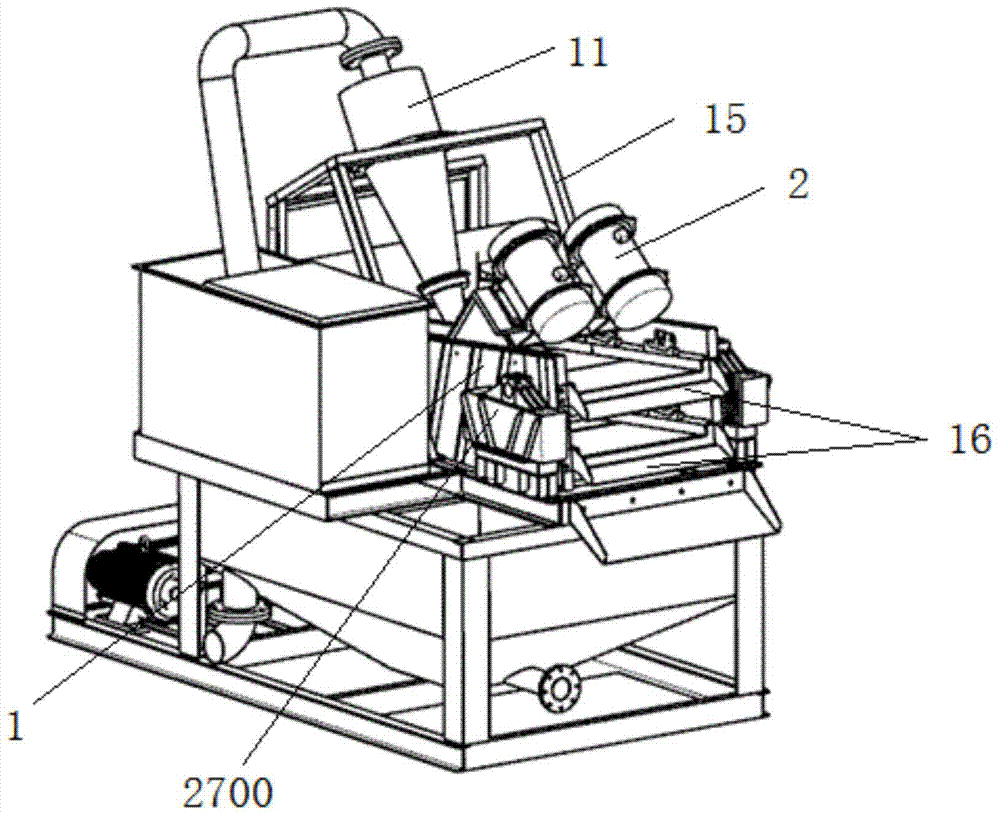

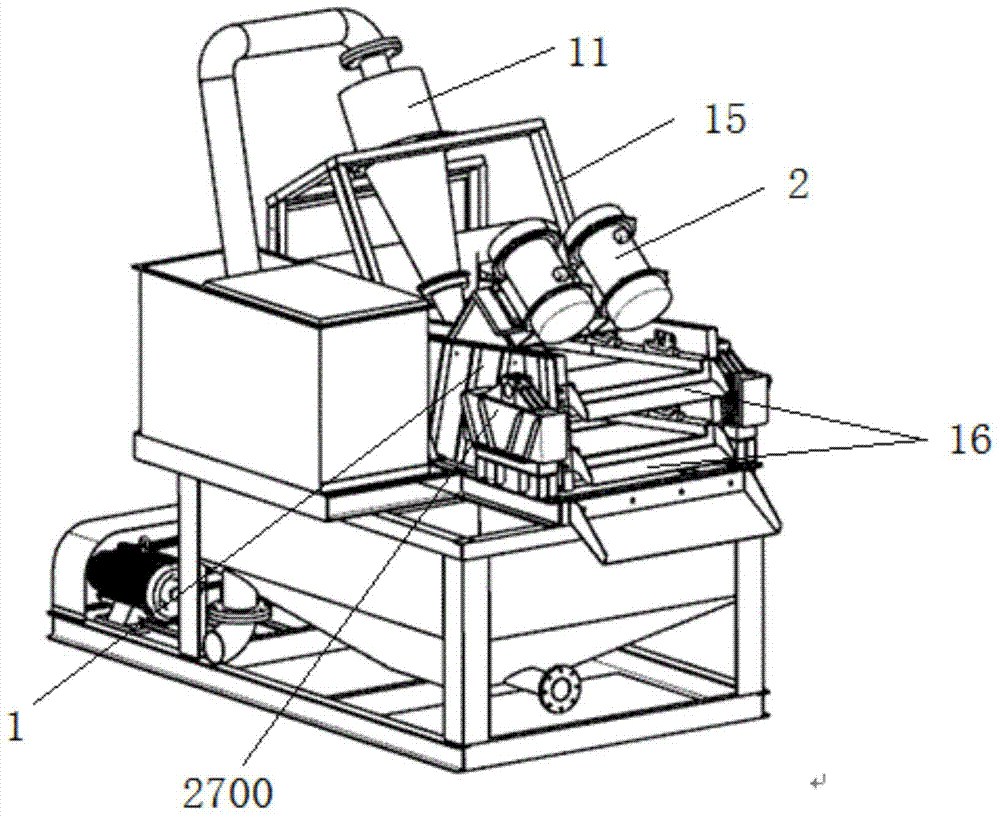

Slurry sediment diversion machine for treating waste materials

The invention provides a slurry sediment diversion machine for treating waste materials. The slurry sediment diversion machine comprises a feeding assembly, a sieving assembly and a material storage box, wherein the feeding assembly comprises a feeding pipe, a discharging hopper and a damping plate arranged in the discharging hopper; the outlet direction of the discharging hopper is vertical to the feeding pipe; one end of the damping plate is fixedly arranged on an inner wall of the discharging hopper and is inclined downwards, and the other end of the damping plate is suspended in the discharging hopper; the sieving assembly comprises a primary sieve body and a secondary sieve body which are arranged in a vibration sieve box, a whirlcone, a transferring box, a sand slurry pump and a material passing pipe; the secondary sieve body is arranged above the primary sieve body; the screen hole diameter of the primary sieve body is greater than that of the secondary sieve body; discharged materials of the discharging hopper fall into the primary sieve body; and discharged materials of the vibration sieve box fall into the transferring box. The treated slurry can be used for constructing to be recycled so that the slurry quality is guaranteed, and the environment pollution is reduced, and furthermore, the difficulties of waste slurry recycling in the construction and the like are overcome.

Owner:广东绿建环保科技有限公司 +1

Integrated coating machine production line

InactiveCN108588669AAvoid taking timeAvoid heating timeVacuum evaporation coatingSputtering coatingContinuous productionManufacturing engineering

The invention discloses an integrated coating machine production line. The integrated coating machine production line comprises two continuous production technologies, namely, a first production modeand a second production mode, wherein the first production mode includes a chamber for feeding a workpiece into a furnace, a first coating chamber, and a chamber for discharging the workpiece from thefurnace; the second production mode includes second coating chambers, and an intermediate chamber for feeding in and discharging from the furnace; the first coating chamber is arranged in the middlepart in the first production mode; one side of the first coating chamber is provided with the chamber for feeding the workpiece into the furnace, and the other side of the first coating chamber is provided with the chamber for discharging the workpiece from the furnace; the intermediate chamber for feeding in and discharging from the chamber is formed in the middle part in the second production line, and the second coating chambers are arranged at two sides of the intermediate chamber for feeding in and discharging from the furnace. With the adoption of the integrated coating machine production line, the evacuating time and the heating time of the coating chambers before each coating can be avoided, so that the working cycle can be greatly, and the production efficiency can be improved; the arrangement mode of the first production mode is suitable for the workpiece of which the evacuating time, the heating time and the coating time are basically the same; and the arrangement mode of the second production line is suitable for the workpiece with long evaporating time and short heating time and long coating time.

Owner:FOSHAN NANHAI JINGDINGTAI MACHINERY EQUIP CO LTD

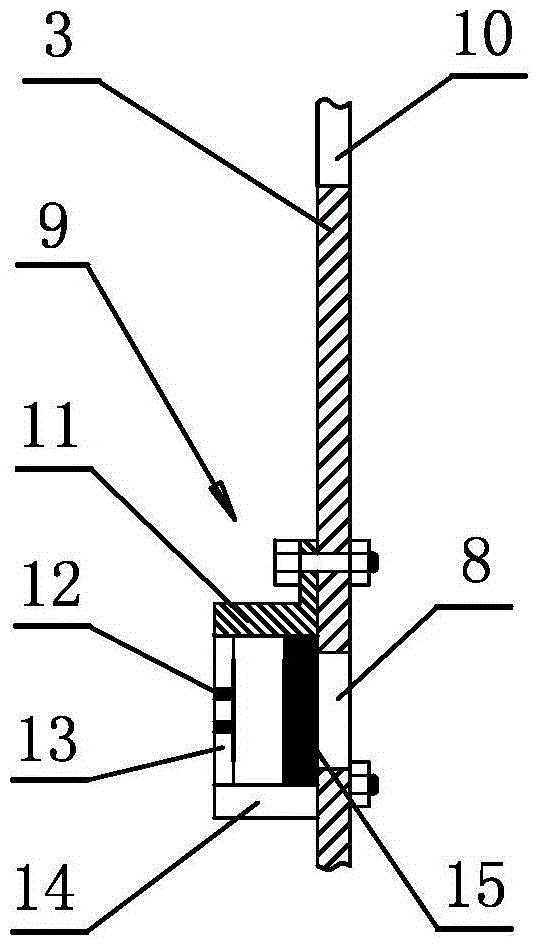

Mobile siphonic water decanter

InactiveCN106968326AAvoid taking timeAvoid destructionSludge treatment by de-watering/drying/thickeningSewerage structuresSiphonExhaust valve

The invention relates to a mobile siphonic water decanter. The water decanter comprises a hose and a water intake heat part. A sluice valve is arranged nearby the water outlet end of the hose, a float block is arranged bellow a part of hose in a pond, and the water inlet end of the hose is connected with the water intake heat part. The water intake heat part is provided with a hollow cavity, a bent pipe penetrates through the upper portion of the cavity, a float ring is fixedly arranged around the periphery of the lower portion of the cavity, the end, in the cavity, of the bent pipe is opened vertically downward, and the other end, outside the cavity, of the bent pipe is connected with the water inlet end of the hose through a pipe clamp; the end, in the cavity, of the bent pipe is connected with a bottom valve and vertical downward, and the portion, in the cavity, of the bent pipe is provided with an exhaust pipe which an exhaust valve; a pull rope is fastened to the upper end of the cavity. When the mobile siphonic water decanter is used, the liquid supernatant can be discharged in time and cannot become turbid, the hose is avoided from being evacuated, water in the hose is prevented from flowing backwards to a drying pond, and the condition which induces a siphon phenomenon in the hose is avoided from being damaged.

Owner:TAIZHOU UNIV

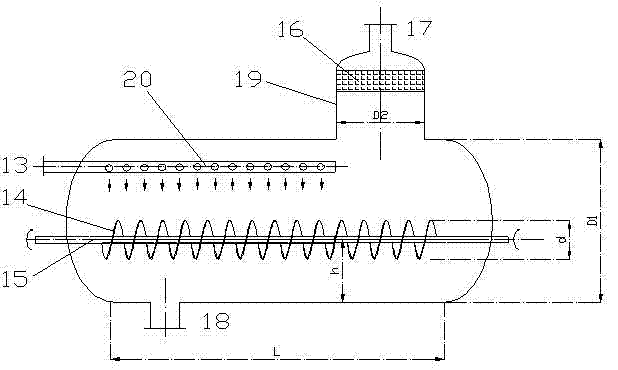

Deep reduced pressure flash tank and reduced pressure deep distillation method

ActiveCN103242886AReduce cracking lossImprove decompression yieldVacuum distillationGas phaseEngineering

The invention discloses a deep reduced pressure flash tank and a reduced pressure deep distillation method. The reduced pressure flash tank comprises a tank body and internal members of the tank. The internal members comprises a feeding inlet distributor arranged in a gas phase zone at the upper part of the reduced flash tank and a rotary disk arranged above a liquid surface of the lower part liquid phase zone, wherein the rotary disk is fixed on a rotary shaft arranged in an axis direction of the tank body. In the reduced pressure deep distillation method, the reduced pressure flash tank is arranged behind the reduced pressure tower; the atmospheric pressure bottom oil is heated by a reduced pressure furnace and introduced to the reduced pressure tower through a reduced pressure transfer line; reduced pressure light fraction oil is pumped out from the lateral line of the reduced pressure tower; reduced pressure heavy oil is pumped out from the bottom of the tower and introduced to the reduced pressure flash tank; the obtained gas phase is introduced to a gas-liquid separation tank; the reduced pressure light fraction oil is discharged from the bottom of the gas-liquid separation tank; and the flashed reduced pressure residual oil is discharged from the bottom of the reduced pressure flash tank. The deep reduced pressure flash tank and the reduced pressure deep distillation method can obviously increase distillation yield during a distillation process of crude oil, reduce energy consumption during the process and increase economic benefits of the apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

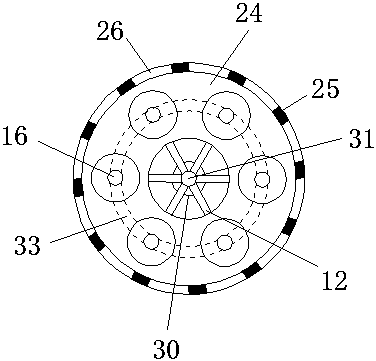

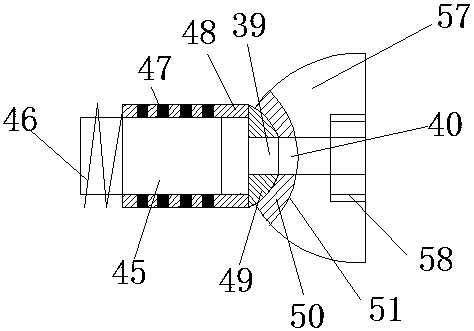

Automatic back flushing type water dispenser

PendingCN109019935ATo achieve the purpose of water purificationExtended service lifeSpecific water treatment objectivesTreatment involving filtrationOutput deviceEngineering

The invention relates to an automatic back flushing type water dispenser, which comprises a water inlet pipe, the water inlet pipe passes through a shell and isto be connected to the left end of a tee, the right end of the tee is connected to a horizontal pipe, the lower end of the tee is connected to a vertical pipe, the horizontal pipe is connected to filter elements through a water main and first connectors, the upper part of the side of one filter element is connected to the vertical pipe through a second connector, and the lower part of the side of the filter element is connected to a purified water pipe and a tap through a third connector; the filter elements are mounted on a rotary disk, a water output device is arranged on the bottoms of the filter elements, a motor is mounted on the bottom of the shell, the output shaft of the motor is connected to a rotary shaft, and the rotary shaft is connected to the rotary disk. The invention solves the problem that conventional water purifiers need to be stopped for cleaning after being used for a period of time.

Owner:绿之韵生物工程集团有限公司

A mud sand separator for waste disposal

The invention provides a slurry sediment diversion machine for treating waste materials. The slurry sediment diversion machine comprises a feeding assembly, a sieving assembly and a material storage box, wherein the feeding assembly comprises a feeding pipe, a discharging hopper and a damping plate arranged in the discharging hopper; the outlet direction of the discharging hopper is vertical to the feeding pipe; one end of the damping plate is fixedly arranged on an inner wall of the discharging hopper and is inclined downwards, and the other end of the damping plate is suspended in the discharging hopper; the sieving assembly comprises a primary sieve body and a secondary sieve body which are arranged in a vibration sieve box, a whirlcone, a transferring box, a sand slurry pump and a material passing pipe; the secondary sieve body is arranged above the primary sieve body; the screen hole diameter of the primary sieve body is greater than that of the secondary sieve body; discharged materials of the discharging hopper fall into the primary sieve body; and discharged materials of the vibration sieve box fall into the transferring box. The treated slurry can be used for constructing to be recycled so that the slurry quality is guaranteed, and the environment pollution is reduced, and furthermore, the difficulties of waste slurry recycling in the construction and the like are overcome.

Owner:广东绿建环保科技有限公司 +1

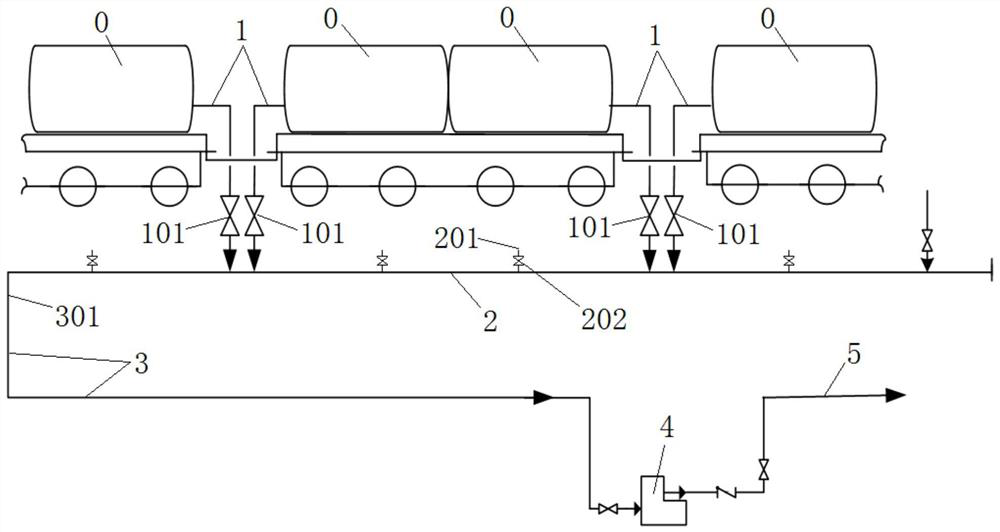

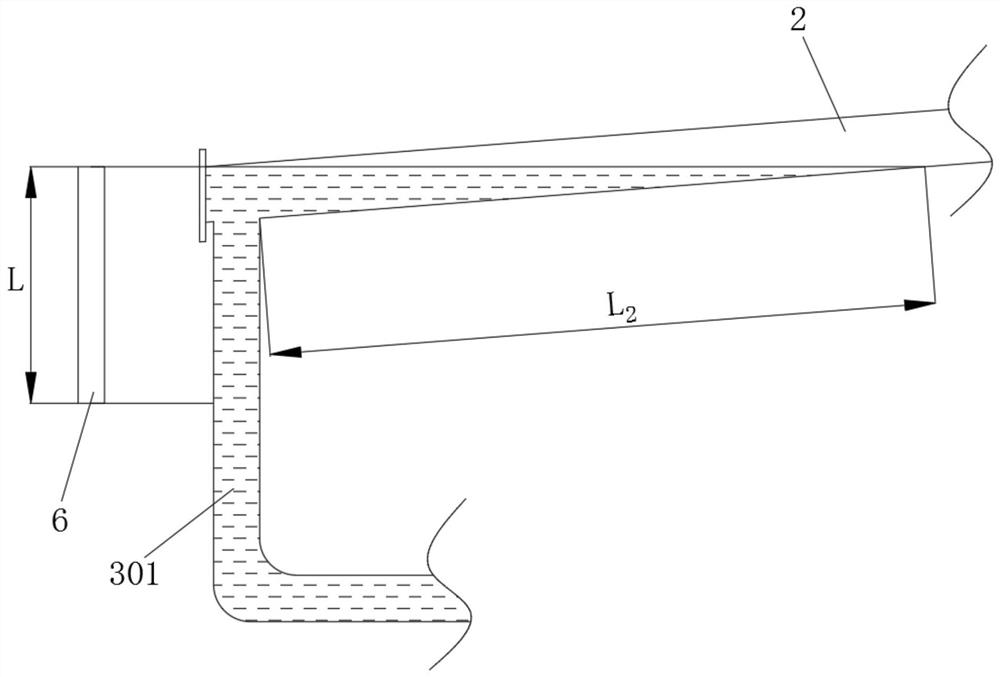

Heavy oil railway unloading system capable of predicting unloading completion

ActiveCN111847370AAvoid taking timeEnsure long-term safe operationLiquid transferring devicesFuel oilSafe operation

The invention discloses a heavy oil railway unloading system capable of predicting unloading completion. The heavy oil railway unloading system comprises a unloading crane pipe; a heavy oil outlet ofthe unloading crane pipe communicates with an oil collecting pipe; a lowest point of the oil collecting pipe is connected with an inlet of an oil transfer pump group through an oil conduit, and an outlet of the oil transfer pump group is connected with a destination oil tank through an oil delivery pipe; the oil collecting pipe has a certain slope in the direction of the oil conduit, and the partconnecting the oil conduit with the oil collecting pipe is a vertical pipe; the connection between the oil collecting pipe and the vertical pipe is provided with a double-flange liquid level gauge; and a low pressure side of the double-flange liquid level gauge is connected with the top of the inner wall of the lowest point of the oil collecting pipe, and a high pressure side of the double-flangeliquid level gauge is connected with a pressure measuring point in the vertical pipe. According to the invention, the pre-judgment of the completion of the unloading of the heavy oil in the oil collecting pipe can be realized, the completion of the unloading is not judged by pumping a machine pump any more, but judged by the liquid level of the heavy oil when the unloading is about to being completed, measures are taken in advance to avoid pumping the machine, and the long-term safe operation of the equipment is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible liquid tank control system

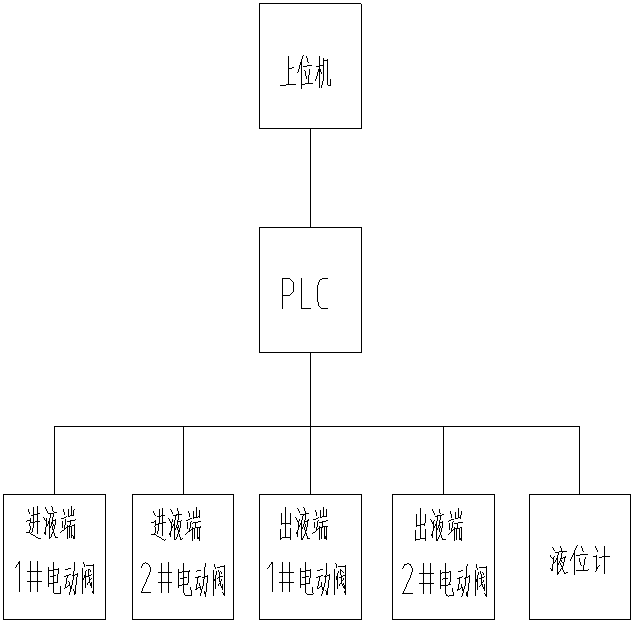

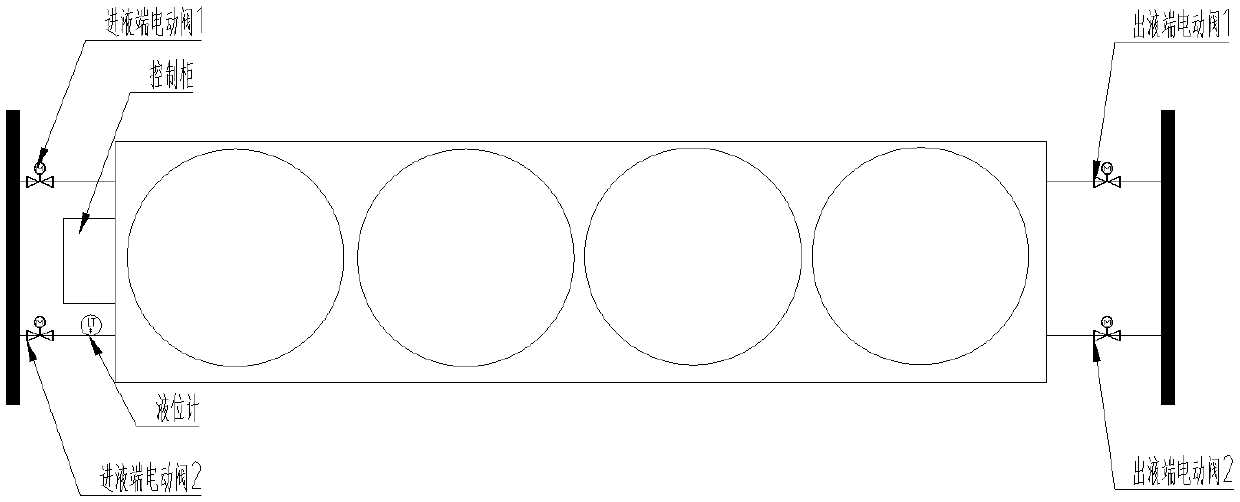

PendingCN110654737AReduce labor intensityAvoid taking timeLarge containersLevel indicators by pressure measurementLiquid tankConnection control

The invention discloses a flexible liquid tank control system which comprises a tank body, an electric valve bank, a liquidometer, a PLC control cabinet and an upper computer, wherein the tank body comprises a plurality of tank cabins connected by bottom manifolds, and a liquid outlet pipeline and a liquid inlet pipeline are separately arranged at the head and tail of the tank body; the electric valve bank is arranged in the liquid outlet pipeline and the liquid inlet pipeline of the tank body for controlling input and discharge of an oil liquid; the liquidometer is arranged in the liquid outlet pipeline for metering the oil liquid level in the current tank body; the PLC control cabinet is mounted at the bottom of the tank body, and the PLC control cabinet is electrically connected to theelectric valve and the liquidometer; and the upper computer is connected to the PLC control cabinet and controls the electric valve according to the liquid level information to adjust the liquid levelheight in the tank body automatically. As the PLC controller is connected to the upper computer to control a valve at the liquid outlet end and a valve at the liquid inlet valve of the liquid tank inreal time, so that remote liquid supply and drainage are controlled, and the labor intensity of an operator is reduced. Meanwhile, by arranging the liquidometer, the liquid level condition in the tank can be monitored in real time, so that the liquid tank is prevented from being evacuated.

Owner:SICHUAN HONGHUA ELECTRIC

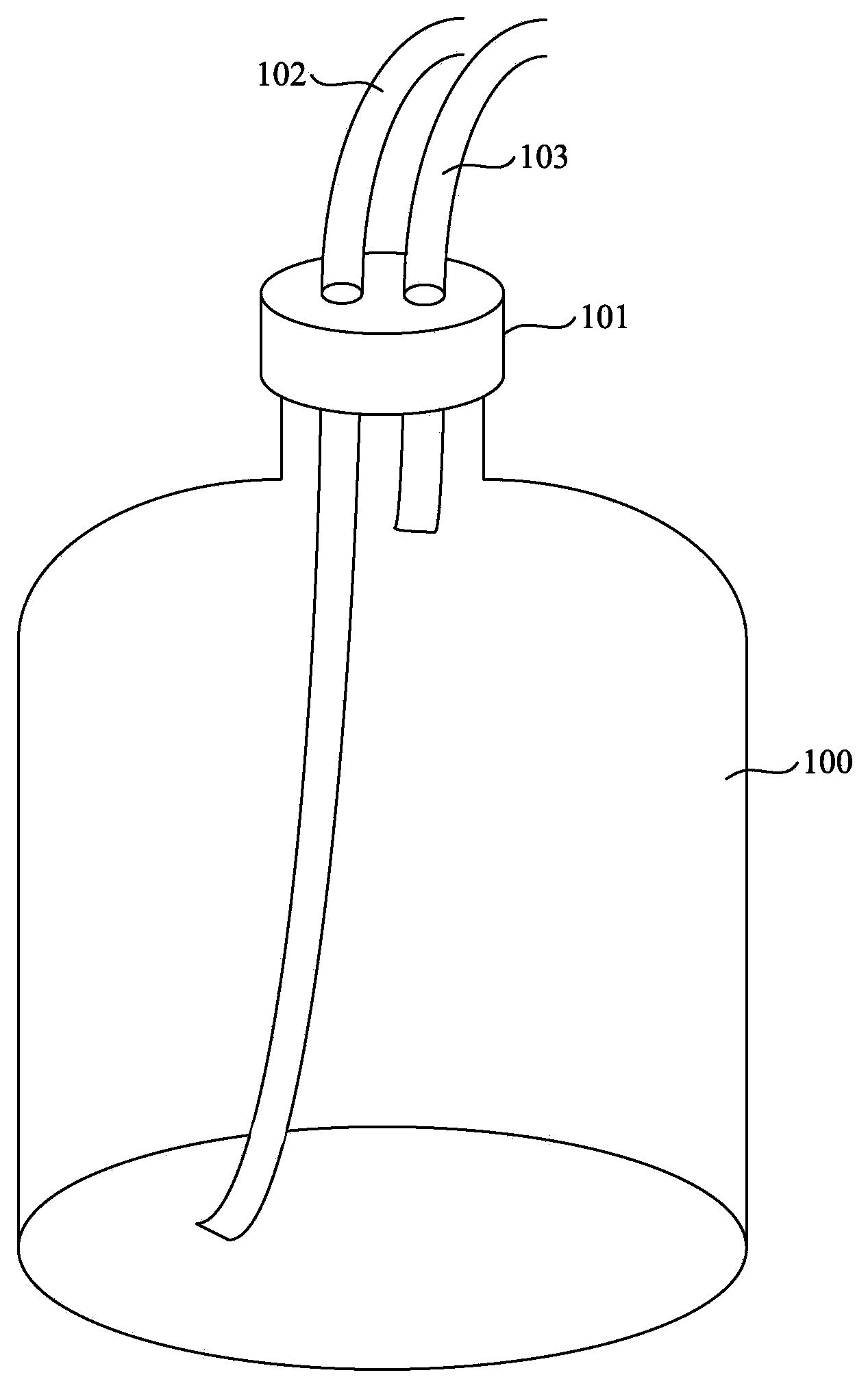

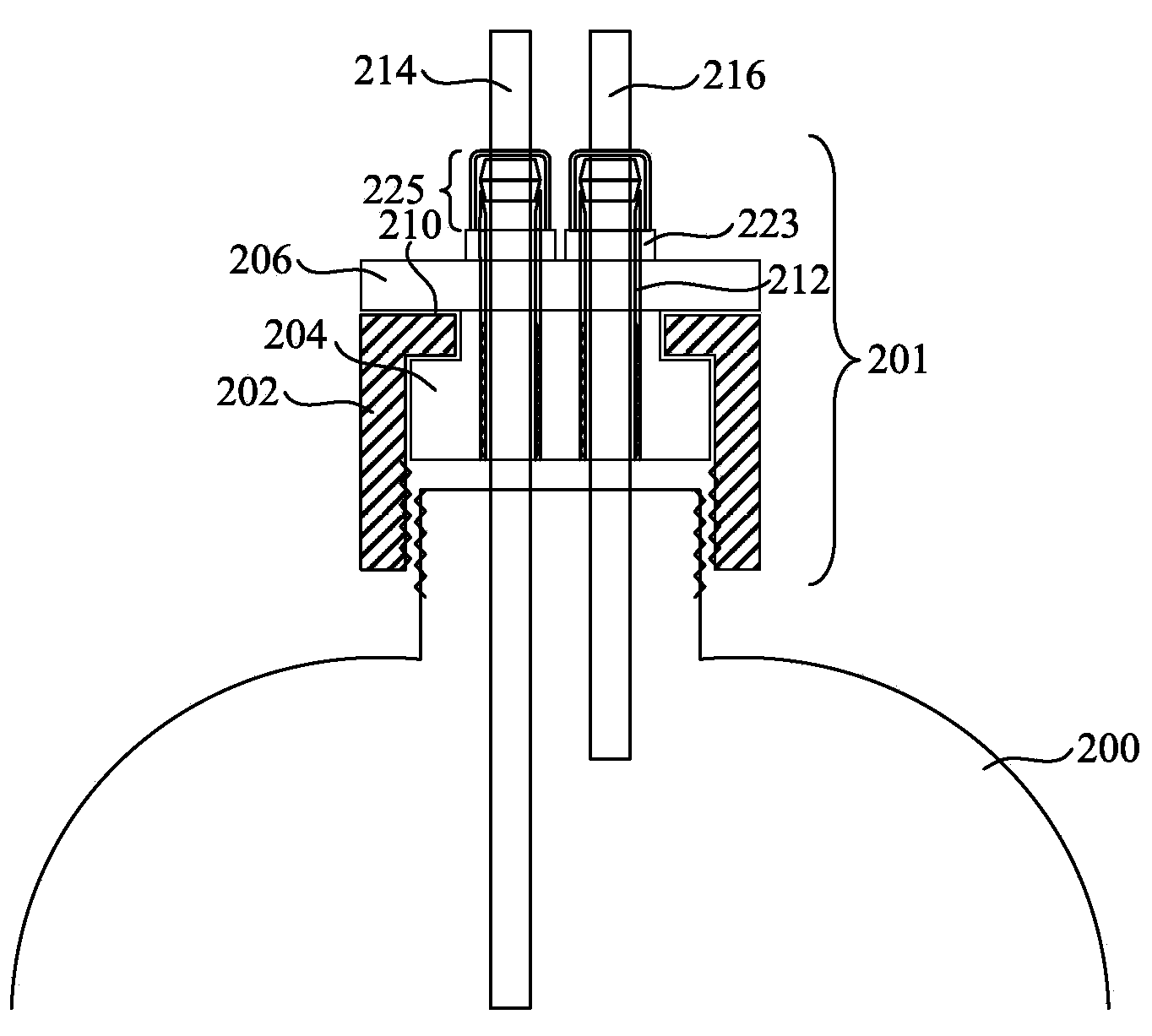

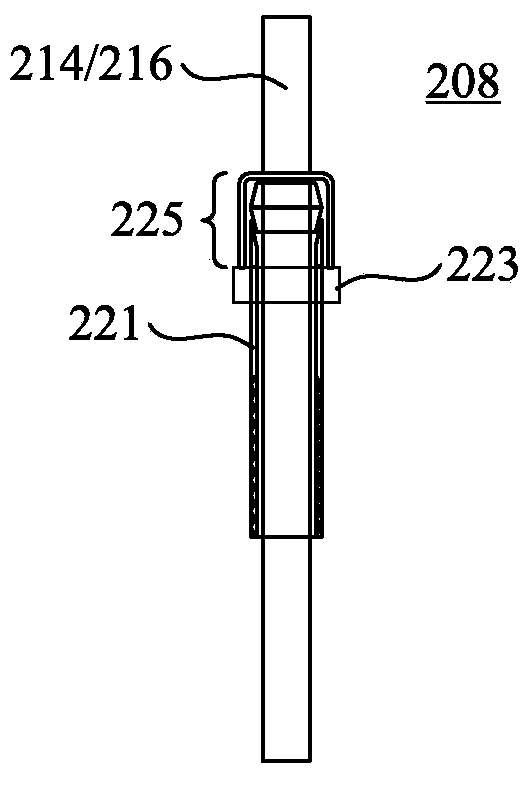

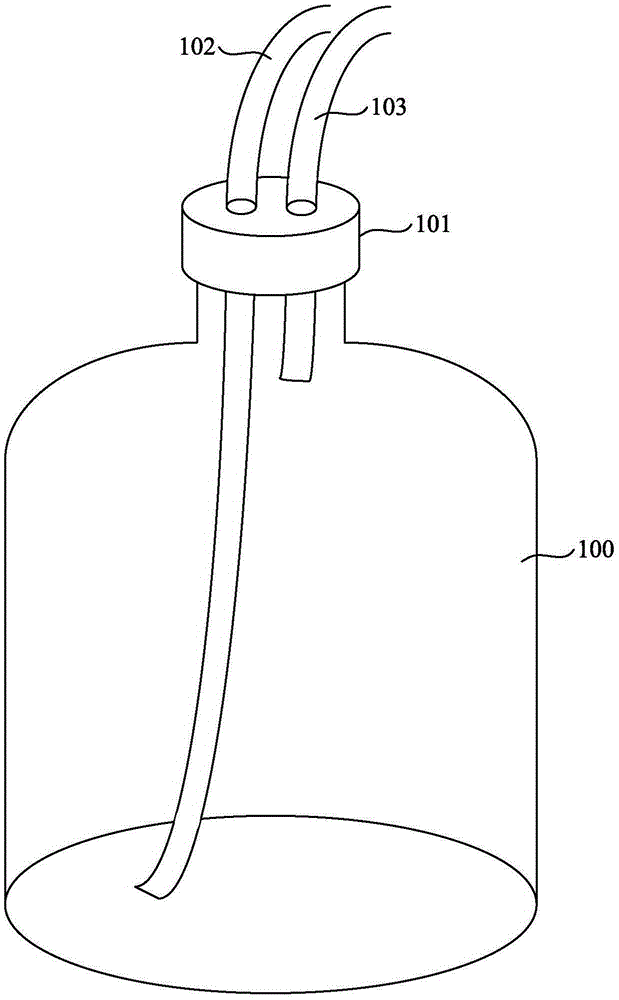

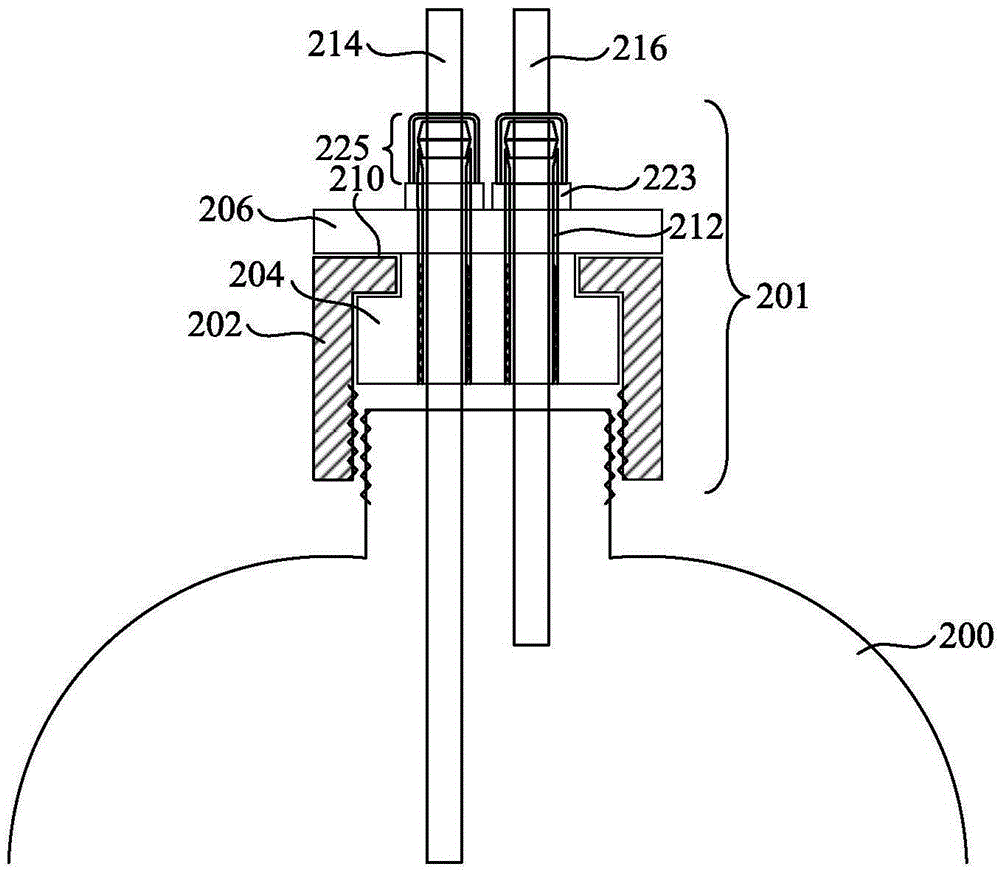

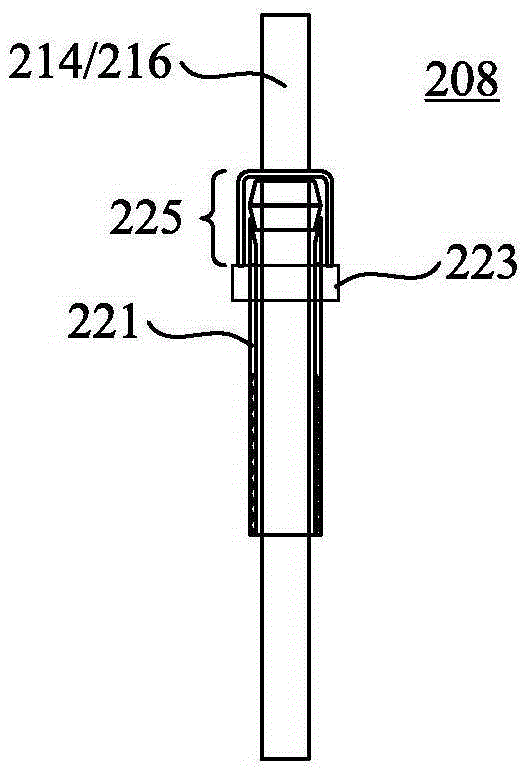

Cap of photoresist bottle and photoresist bottle

The invention provides a cap of a photoresist bottle and the photoresist bottle. The cap of the photoresist bottle comprises a bottle cap body, a cap core, a cover plate and a photoresist tube guide locking piece. The bottle cap body is connected with the opening of the photoresist bottle in a threaded mode through threads on the inner side of the lower portion of the bottle cap body. The cap core is located above the opening and on the inner side of the upper portion of the bottle cap body. The cover plate is located above the bottle cap body and the cap core and fixed to the cap core. An annular groove is formed between the cover plate and the cap core, the front end of the upper portion of the bottle cap body is embedded into the annular groove, and therefore the bottle cap body and the cover plate can neither be separated nor rotate independently, and the bottle cap body and the cap core can neither be separated nor rotate independently. Vertically-through holes are formed in the cap core and the cover plate, the photoresist tube guide locking piece penetrates through the holes and is fixed to the cap core and / or the cover plate in a threaded mode. The photoresist tube guide locking piece is hollow, and a photoresist tube guiding photoresist penetrates through the photoresist tube guide locking piece to be inserted into the photoresist bottle by a proper depth and is fixed to bottle cap body in a locking mode. According to the cap of the photoresist bottle and the photoresist bottle, the photoresist tube can be fixed to the cap of the photoresist bottle, evacuation caused when the photoresist tube can not be inserted to the bottom of the photoresist bottle is prevented, and therefore photoresist shortage of wafers is avoided.

Owner:ADVANCED SEMICON MFG CO LTD

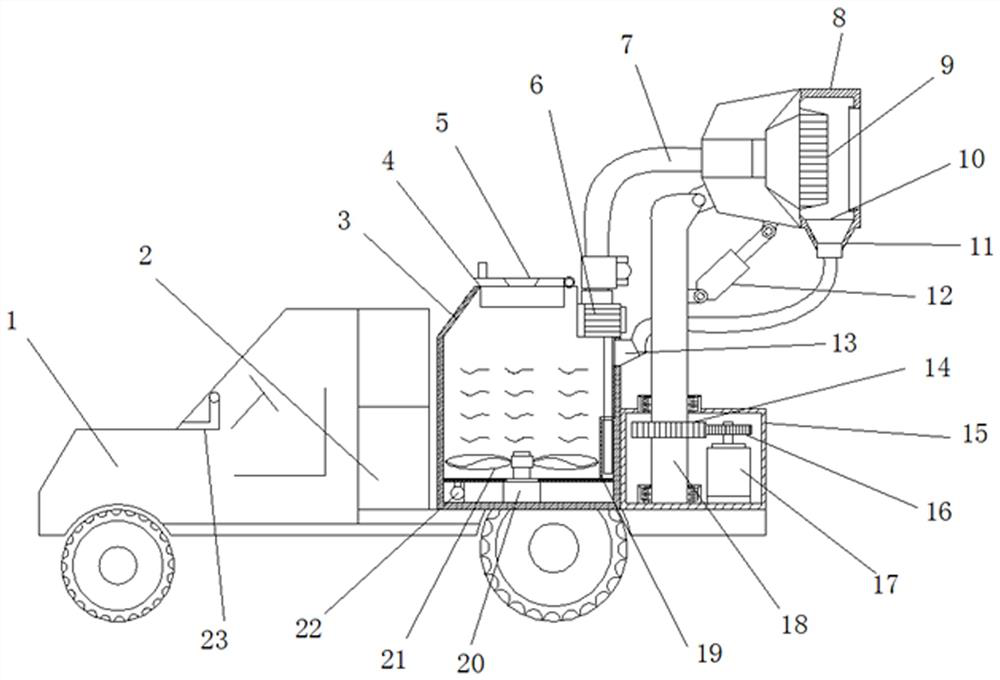

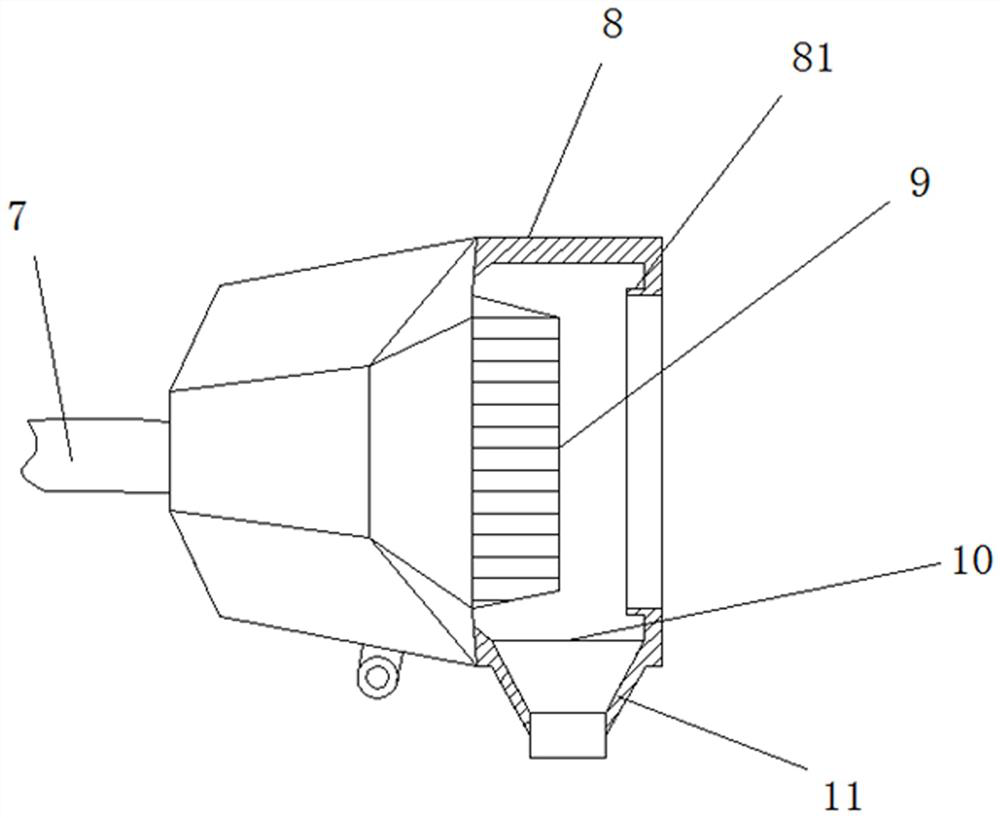

Spraying device for land comprehensive improvement and ecological restoration and using method thereof

PendingCN113426323ASpray evenlyFast mixingRotary stirring mixersSpraying apparatusAnimal scienceControl system

The invention discloses a spraying device for land comprehensive improvement and ecological restoration and a using method thereof, and belongs to the technical field of agricultural equipment. The spraying device comprises a vehicle body, a hydraulic control system, a restoration liquid tank and a spraying assembly; a hydraulic control system and a repairing liquid tank are respectively arranged in the middle of the vehicle body; and the spraying assembly is arranged at the tail part of the vehicle body. A leakage-proof shell is installed on the outer side of the spraying end of the spraying device, the sprayed and flying repairing liquid is shielded and recycled, the front-section repairing liquid and the rear-section repairing liquid with insufficient spraying pressure are recycled and flow back into the tank body to be stirred and sprayed again, and resource waste is reduced; meanwhile, the repairing liquid can be stirred in the whole spraying process, the mixing speed of the repairing liquid is high, and spraying is uniform; a liquid level sensor is additionally arranged in a tank body, the liquid level of the repairing liquid in the tank body is monitored in real time through the liquid level sensor, an audible and visual alarm prompts technicians to add the repairing liquid in time, evacuation of a pump body is prevented, and the service life of the device is prolonged.

Owner:广西壮族自治区自然资源生态修复中心

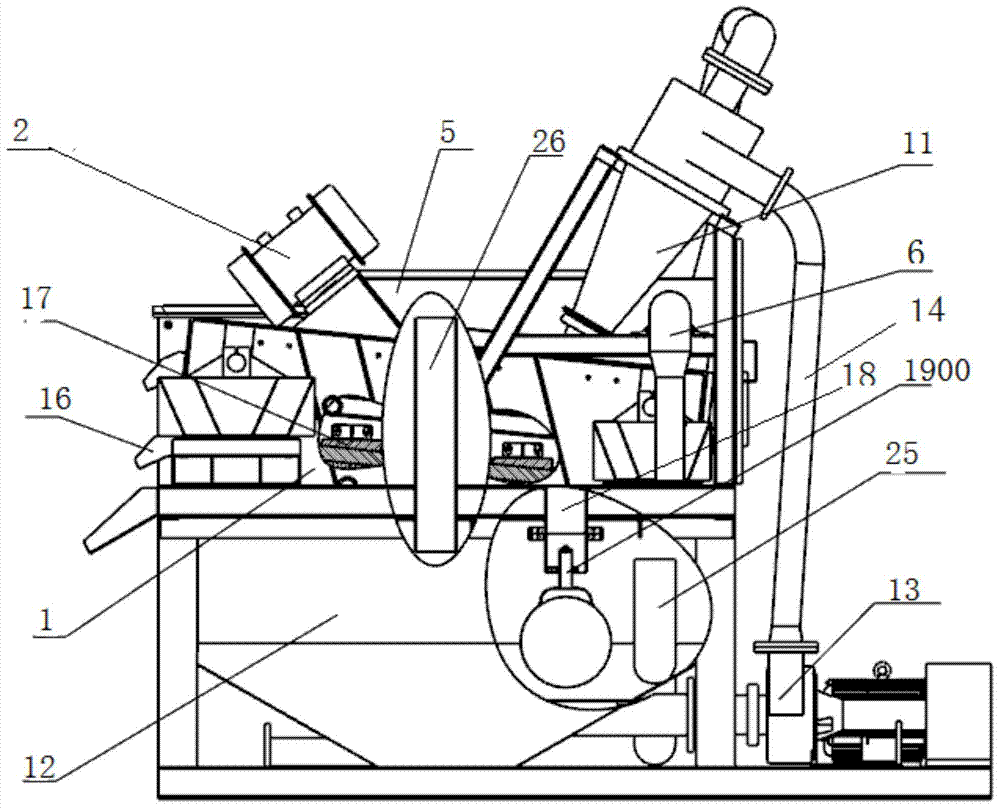

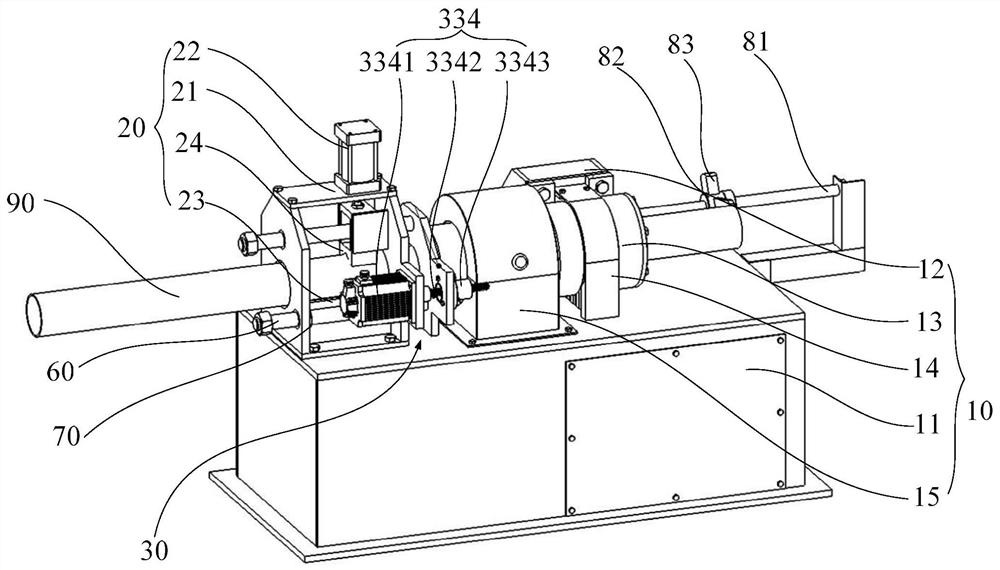

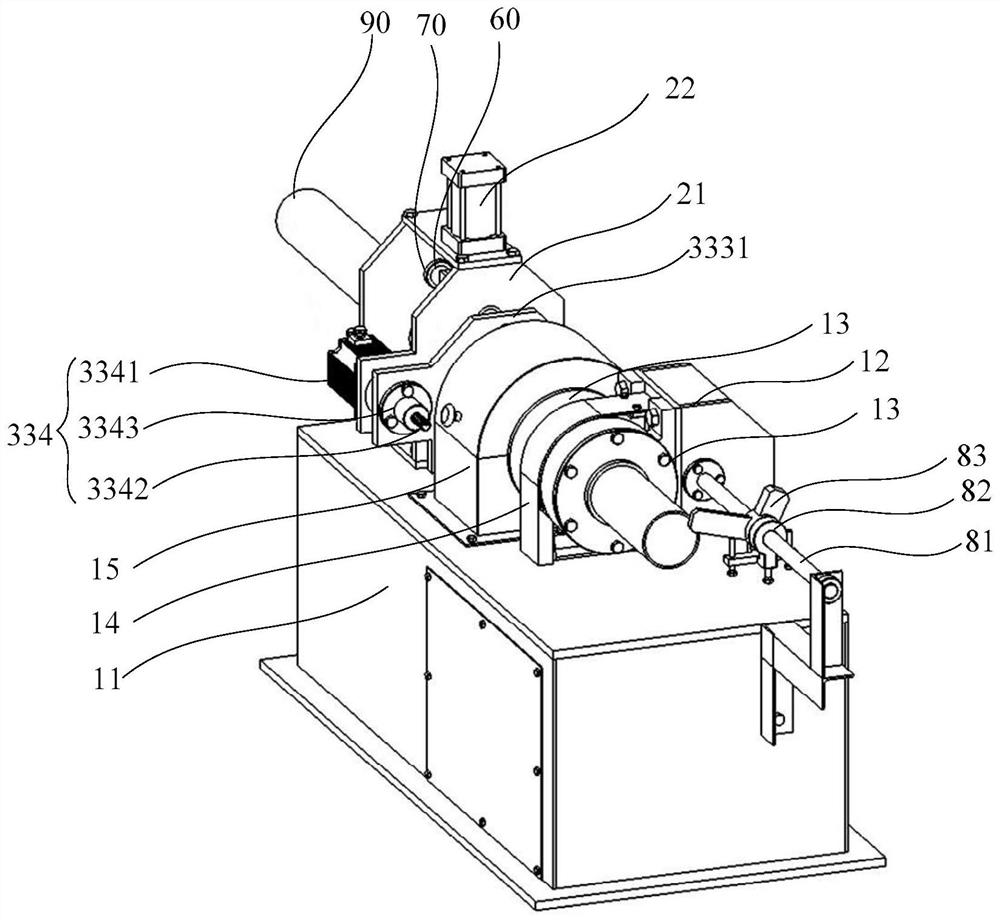

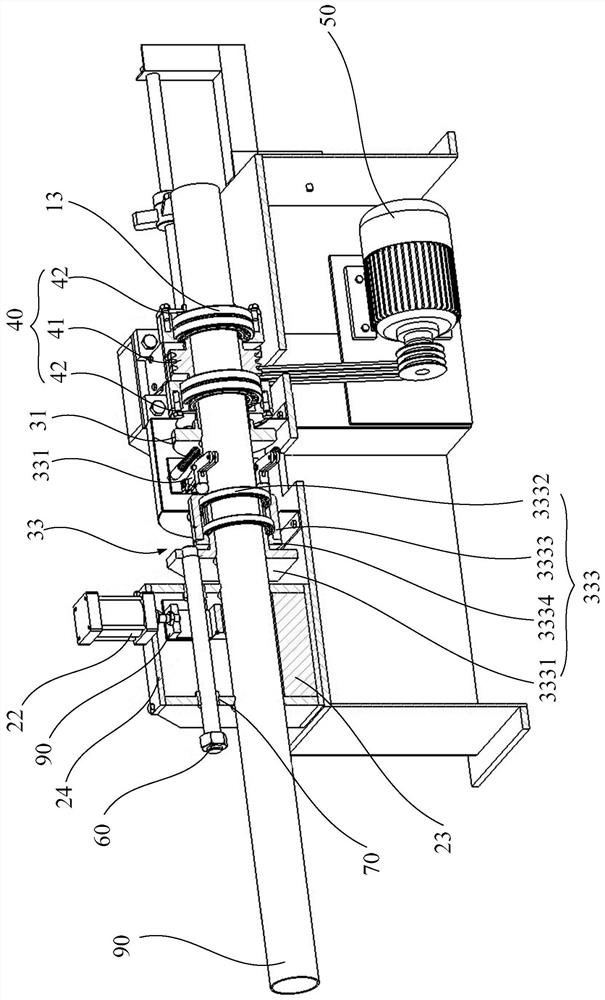

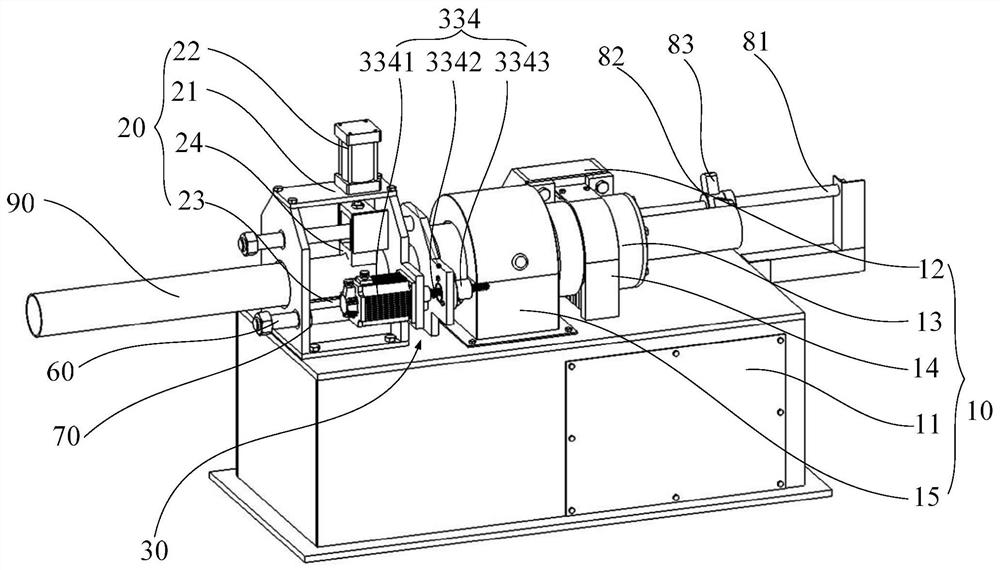

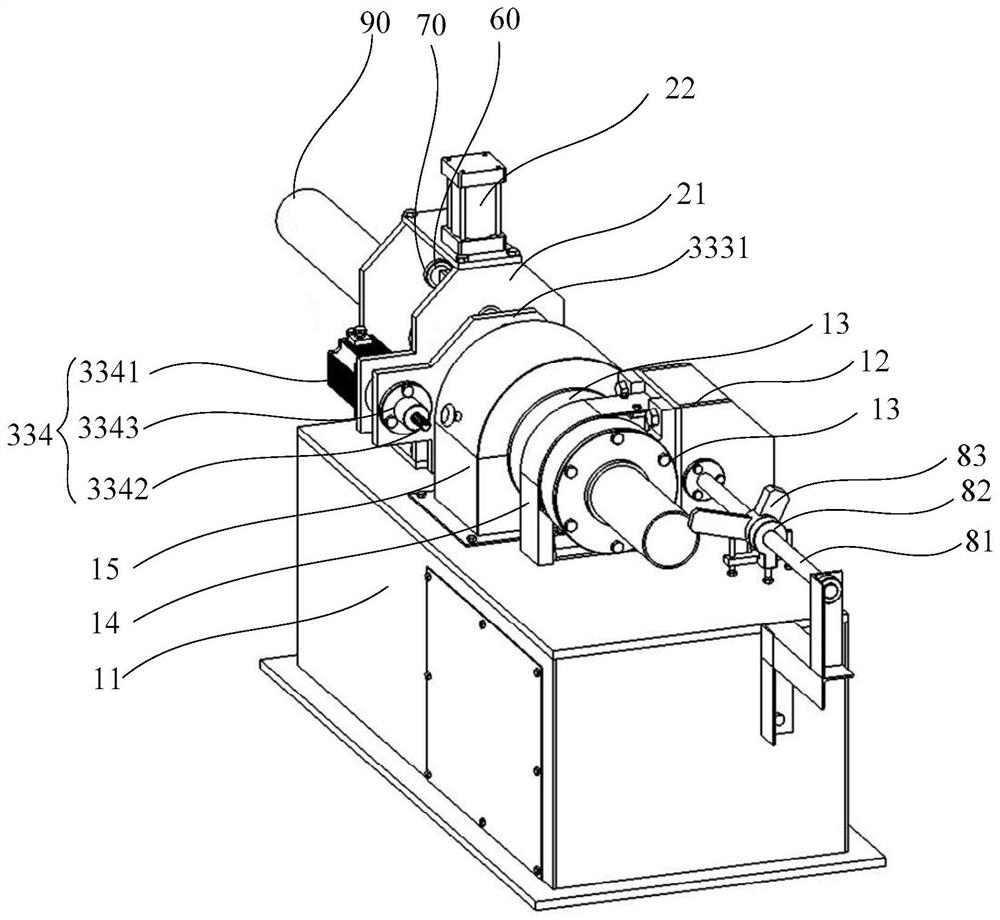

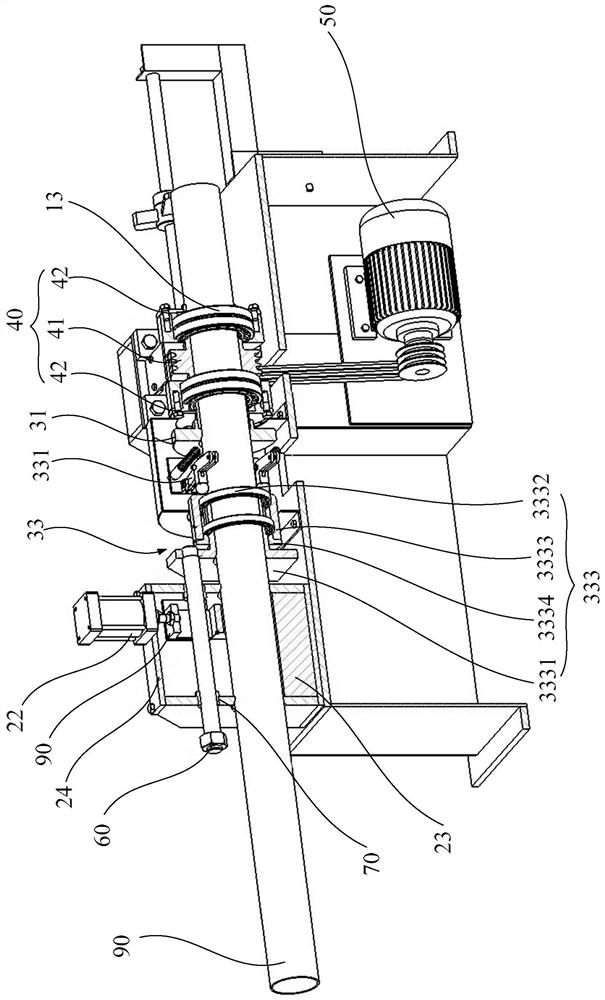

Cutting machine

ActiveCN113601212AReduce lossImprove cutting efficiencyFeeding apparatusPositioning apparatusDrive wheelStructural engineering

The invention provides a cutting machine. The cutting machine comprises a rack, a clamping mechanism, a hob device, a driving wheel and a power device. The hob device comprises a cutting wheel seat, a cutting wheel assembly and a driving assembly. According to the cutting machine, a pipe is clamped on the hob device, the side wall of the pipe is tightly attached to the middle position of the cutting wheel assembly, a notch of the cutting wheel assembly is perpendicular to the pipe, then the cutting wheel seat and the driving assembly act, a blade of the cutting wheel assembly cuts the pipe wall of the pipe, the power device drives the cutting wheel assembly to integrally rotate around the pipe through the driving wheel, and continuous feeding is performed to continuously cut the pipe in a rolling mode along with pushing of the driving assembly until the pipe is cut off. Scrap iron is not formed in the pipe cutting process, and the loss amount of the pipe is reduced. The cutting wheel assembly is adopted to cut the pipe in a rolling mode, the contact mode of the blade of the cutting wheel assembly and a protruding rib inside the pipe is changed, that is, the blade is not in direct impact contact with the rib, and the damage probability of the blade is correspondingly reduced.

Owner:扎赉诺尔煤业有限责任公司

Protection device of pump and pump assembly

The invention discloses a protection device of a pump, and belongs to the field of pump monitoring and protection. The protection device comprises a tuning fork switch, a detection assembly, a protection pipeline used for communicating with an outlet of the pump and a first controller used for controlling the pump to be stopped. A through hole is formed in the pipe wall of the protection pipeline.A vibration tuning fork of the tuning fork switch is mounted in the through hole in an inserted manner. The protection pipeline and a vibration joint of the tuning fork switch are in sealed connection. The detection assembly comprises a detection barrel, a piston, a metal disc and two binding posts. The detection barrel is located on the outer wall of the protection pipeline and communicates withthe protection pipeline. The piston is arranged in the detection barrel in a sliding manner. The metal disc is arranged on the side, back on to the protection pipeline, of the piston. The two bindingposts are arranged oppositely on the inner wall of the detection barrel in a spaced manner. One binding post in the two binding posts is used for being connected with an output circuit of the first controller, and the other binding post in the two binding posts is used for being connected with an input circuit of the pump. By means of the protection device, the situation that the pump stops working due to misoperation of the tuning fork switch can be avoided, and the high efficiency of the pump can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Photoresist plastic bottle caps and plastic bottles

The invention provides a cap of a photoresist bottle and the photoresist bottle. The cap of the photoresist bottle comprises a bottle cap body, a cap core, a cover plate and a photoresist tube guide locking piece. The bottle cap body is connected with the opening of the photoresist bottle in a threaded mode through threads on the inner side of the lower portion of the bottle cap body. The cap core is located above the opening and on the inner side of the upper portion of the bottle cap body. The cover plate is located above the bottle cap body and the cap core and fixed to the cap core. An annular groove is formed between the cover plate and the cap core, the front end of the upper portion of the bottle cap body is embedded into the annular groove, and therefore the bottle cap body and the cover plate can neither be separated nor rotate independently, and the bottle cap body and the cap core can neither be separated nor rotate independently. Vertically-through holes are formed in the cap core and the cover plate, the photoresist tube guide locking piece penetrates through the holes and is fixed to the cap core and / or the cover plate in a threaded mode. The photoresist tube guide locking piece is hollow, and a photoresist tube guiding photoresist penetrates through the photoresist tube guide locking piece to be inserted into the photoresist bottle by a proper depth and is fixed to bottle cap body in a locking mode. According to the cap of the photoresist bottle and the photoresist bottle, the photoresist tube can be fixed to the cap of the photoresist bottle, evacuation caused when the photoresist tube can not be inserted to the bottom of the photoresist bottle is prevented, and therefore photoresist shortage of wafers is avoided.

Owner:ADVANCED SEMICON MFG CO LTD

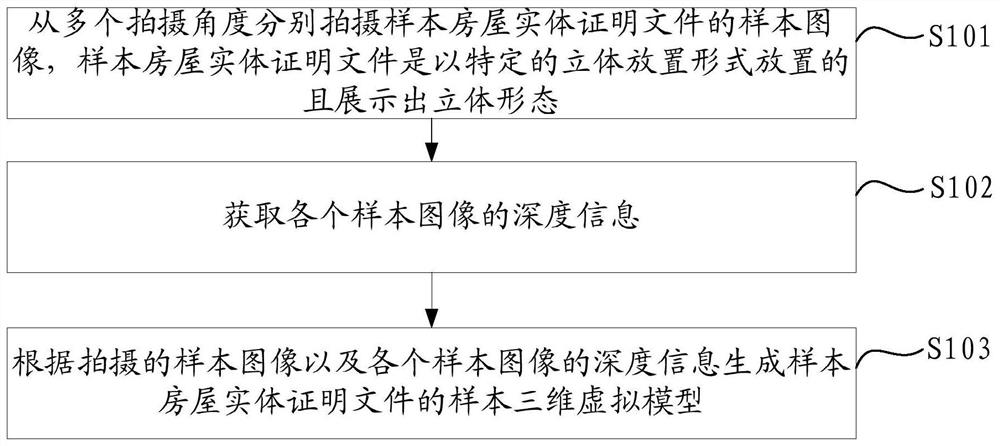

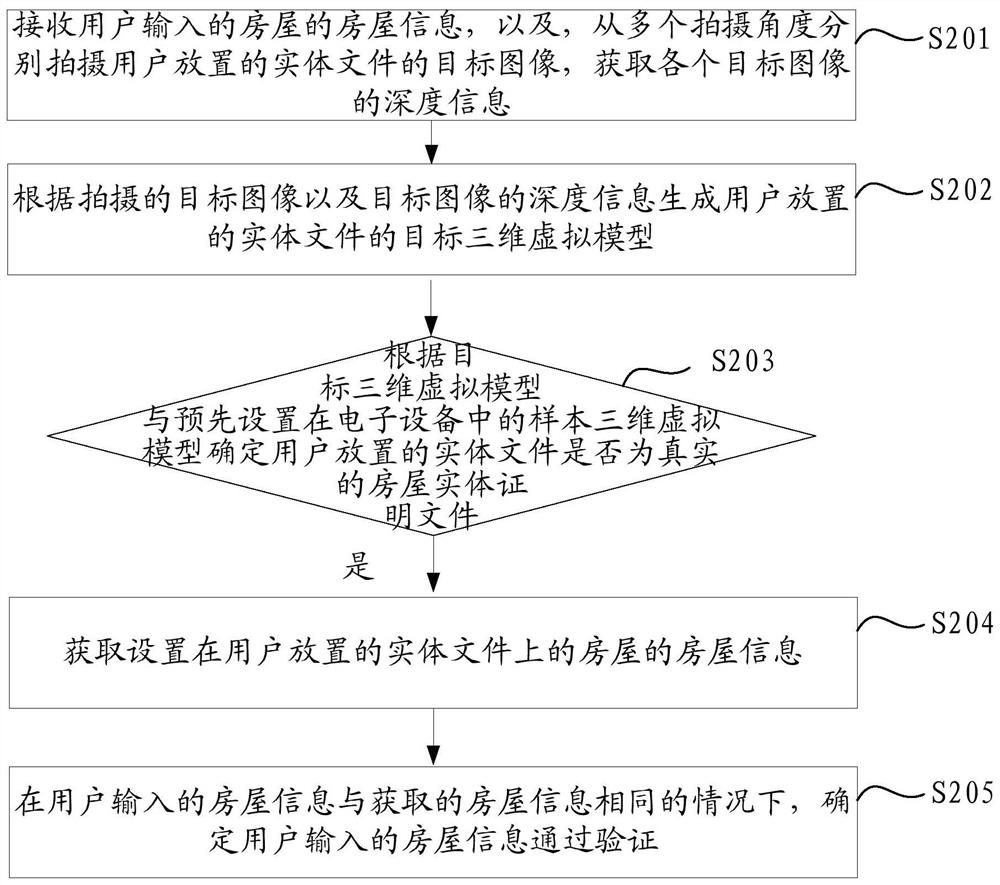

Information processing method and device, electronic equipment and storage medium

ActiveCN113947676AAvoid postingAvoid using separatelyCharacter and pattern recognitionBuying/selling/leasing transactionsInformation processingEngineering

The invention provides an information processing method and device, electronic equipment and a storage medium. When the house information of a house input by the user needs to be verified, the target images of the entity file can be shot from multiple shooting angles, and the depth information of each target image is obtained. A target three-dimensional virtual model of the entity file is generated according to the target image and the depth information of the target image. According to the target three-dimensional virtual model and a preset sample three-dimensional virtual model, whether the entity file is a real house entity proof file is judged, and if the entity file is the real house entity proof file, the house information of a house arranged on the entity file is obtained. If the house information input by the user is the same as the obtained house information, it is determined that the house information input by the user passes verification, no manual participation exists in the process of verifying the house information of the house input by the user, and therefore the labor cost can be reduced.

Owner:BEIJING 58 INFORMATION TTECH CO LTD

Drawing vacuum melting furnace capable of continuous molding and discharging

The invention discloses a drawing type vacuum smelting furnace with continuous forming and discharging functions. The drawing type vacuum smelting furnace is characterized in that the shapes of the cross sections of discharging pipes are set according to the shape of a silicon sectional material needing to be obtained, drawing rods move downwards along the discharging pipes so as to suck a moltenliquid in a crucible, the liquid is driven to gradually fill the discharging pipes and flow downwards, when the liquid flows to the position where a water cooling box is located, the liquid is forcedto be cooled by the water cooling box, the liquid is solidified in a short time when the liquid passes through a crystallization chamber, and finally, the solidified liquid is guided out from the bottom ends of the discharging pipes along with the drawing rods so as to obtain the industrial silicon material with the specified cross section shape. According to the drawing type vacuum smelting furnace, two sleeves which are distributed up and down are arranged below each discharging pipe, the two sleeves are controlled to alternately move up and down in the respective forming range, then uninterrupted continuous drawing of the silicon material can be realized, the silicon material smelted in the crucible is made into a complete and continuous integral structure once, and the automation degree and the finished product integrity are greatly improved.

Owner:石棉达升再生资源有限公司

Offset printing fountain solution self-circulation purification system and purification method

ActiveCN105363277BImprove filtering effectAvoid taking timePrinting pre-treatmentFiltration circuitsSolubilityPurification methods

The invention discloses an offset printing fountain solution self-circulation purification system and method. The system comprises a first water tank, a second water tank, a layered deposition filter, a filter, a third water tank and a control circuit. When through the control circuit, it is found that particle solubility of a fountain solution in the first water tank is less than a preset value, the control circuit controls a 3-way shift switch so that the fountain solution flows into a first chamber, when through the control circuit, it is found that particle solubility of the fountain solution in the first water tank is greater than the preset value, the control circuit controls the 3-way shift switch so that the fountain solution goes through the layered deposition filter, flows into the first chamber, then enters a self-circulation filter system and is subjected to cyclic purification, the control circuit receives signals of a thermometer, a pH detector and a conductivity detector, and when the pH and the conductivity are higher than a corresponding pH threshold and a conductivity threshold, alcohol and water are added into the primary fountain solution according to a certain ratio. The system and method have high fountain solution purification efficiency, realize real-time accurate detection of indexes of the fountain solution, make the fountain solution quality stable and guarantee printing quality.

Owner:力嘉包装(东莞)有限公司 +2

a cutting machine

ActiveCN113601212BReduce lossImprove cutting efficiencyFeeding apparatusPositioning apparatusDrive wheelStructural engineering

The application provides a cutting machine including: a frame, a clamping mechanism, a hob device, a driving wheel and a power device. The hob unit includes: a cutting wheel seat, a cutting wheel assembly and a driving assembly. In the cutting machine provided by this application, the pipe is clamped on the hob device, so that the side wall of the pipe is close to the middle position of the cutting wheel assembly, the cut of the cutting wheel assembly is perpendicular to the pipe, and then the cutting wheel seat and the driving assembly move, Make the blade of the cutting wheel assembly cut into the pipe wall, and the power device drives the cutting wheel assembly to rotate around the pipe through the driving wheel. With the advancement of the driving assembly, the continuous feeding will roll and cut the pipe until the pipe is cut off. During the process, no iron filings are formed, which reduces the loss of pipes. The cutting wheel assembly is used to cut the pipe by rolling, and the contact mode between the blade of the cutting wheel assembly and the raised ribs inside the pipe changes, that is, the blade does not directly form impact contact with the ribs, which reduces the damage of the blade accordingly probability.

Owner:扎赉诺尔煤业有限责任公司

Short-distance information exchange method and system, information sending and receiving equipment, terminal

ActiveCN105471517BImprove exchange efficiencyAchieve direct communicationSonic/ultrasonic/infrasonic transmissionDot-and-dash systemComputer hardwareInformation transmission

The embodiment of the present invention discloses a short-distance information exchange method and system, information sending and receiving equipment, and a terminal, wherein the method includes: receiving an information sending request, and the information sending request includes information to be transmitted; Encoding, converting the information to be transmitted into a Morse code digital signal, including Morse numbers and / or Morse letters; according to the Morse code encoding table, performing D / A conversion on the Morse code digital signal, converting The Morse code digital signal is converted into a Morse code sequence, and a character space is added between two adjacent Morse codes to obtain a Morse code analog signal; the Morse code sequence includes more than one sequence of Morse codes Telecode; Morse code analogue signal sent as Morse radio sound. The embodiments of the present invention can reduce the cumbersome operation of pairing between user terminals sharing information, reduce information transmission time, and improve information exchange efficiency.

Owner:CHINA TELECOM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com