Differential pressure anti-evacuation mortar pump

A mortar pump, differential pressure technology, applied in the field of pressure differential anti-evacuation mortar pump, can solve the problems of no raw material, mortar pump idling, uncertain pulp supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

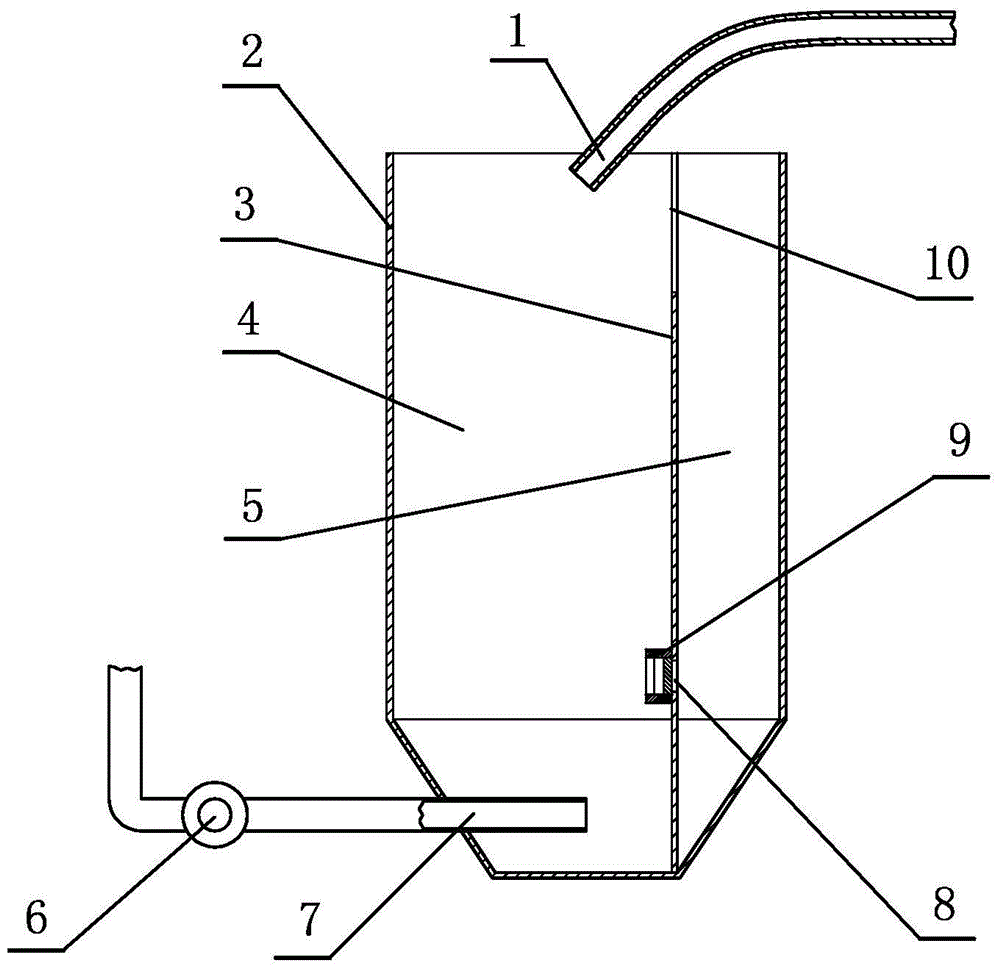

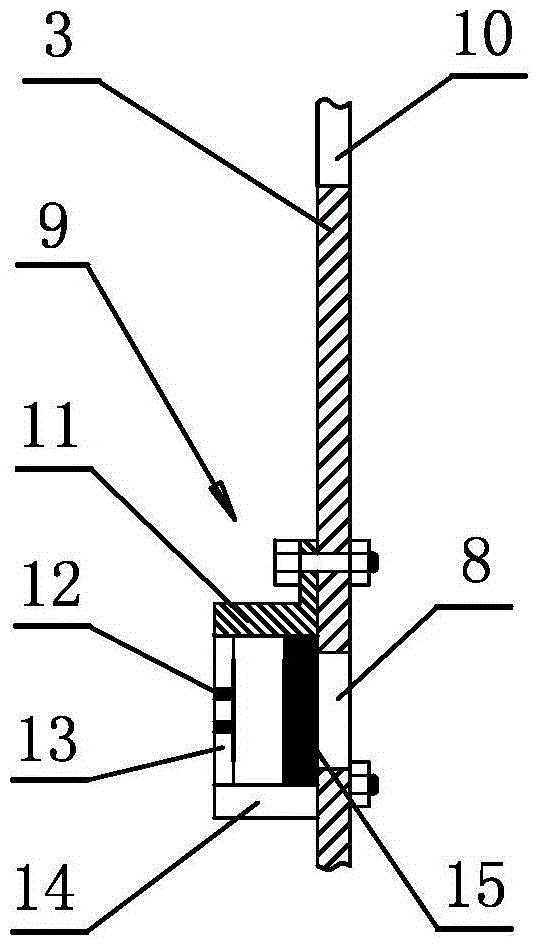

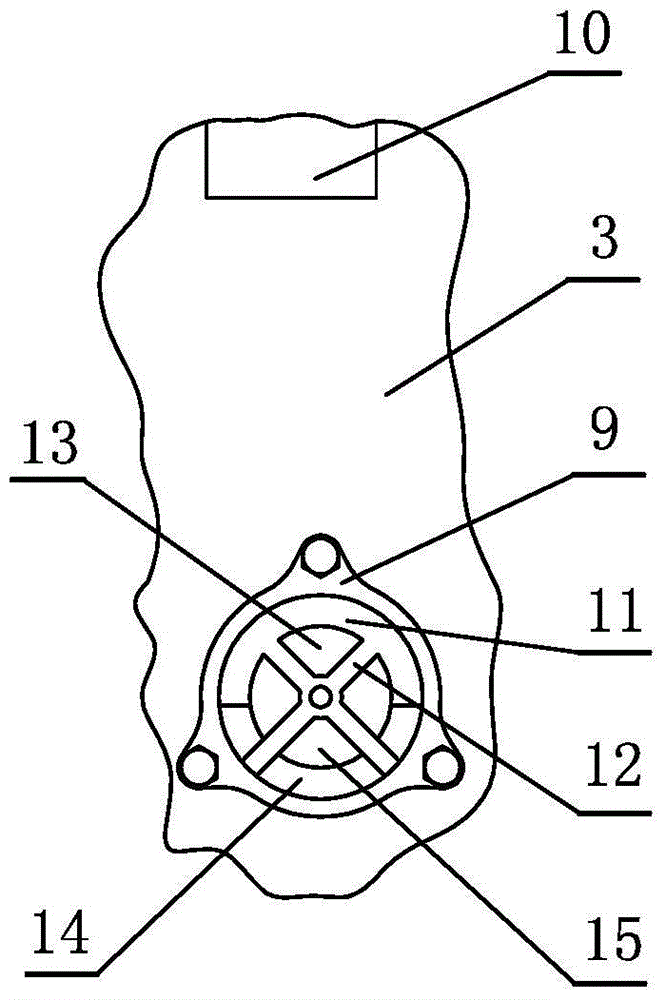

[0026] The general idea of the present invention is: the mortar tank 2 is divided into two cavities, and a differential pressure valve is arranged between them. When the mortar level in one cavity is too low, the differential pressure valve is opened and the mortar in the other cavity is put in to prevent the mortar pump from being evacuated. Three embodiments are introduced below around this idea.

[0027] The first embodiment: as figure 1 As shown, this differential pressure type anti-evacuation mortar pump has a main body of a mortar tank 2, the top of the mortar tank 2 is opposite to the outlet of the slurry pipe 1, and a mortar pump 6 is arranged below the mortar tank 2, and the inlet of the mortar pump 6 7. In the lower part of the mortar tank 2, the characteristics are: the mortar tank 2 is provided with a partition 3, which divides the inner space of the tank into two parts, the main cavity 4 and the auxiliary cavity 5, and the upper part of the partition 3 has a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com