Online measurement method and device for anode current of aluminum electrolytic cell

An anode current and aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problem that the anode current measurement method of the aluminum electrolytic cell cannot obtain stable and reliable anode current signals in real time for a long time, and achieve the effects of simple structure, convenient operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

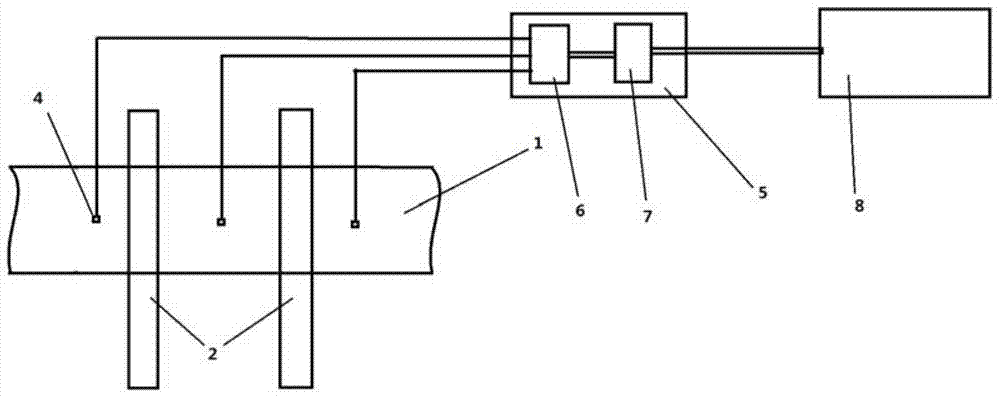

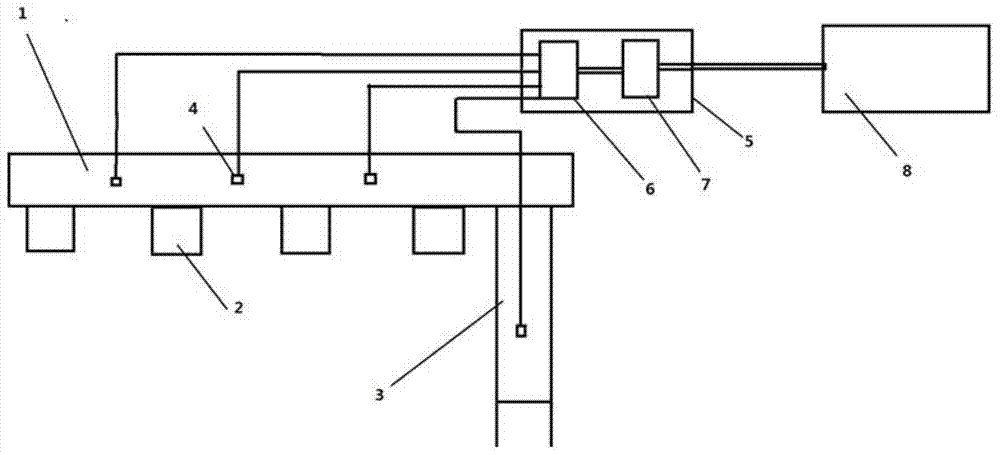

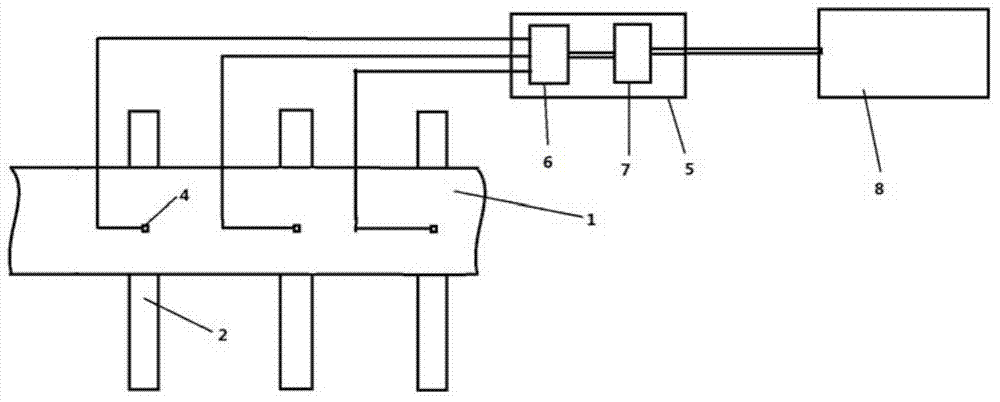

[0034] An online measurement method for the anode current of an aluminum electrolytic cell, by setting a plurality of main measuring points on the anode beam busbar or column busbar, the voltage value on the main measuring point is obtained, and the anode beam busbar and the For the resistance network of the column busbar, the current value of each anode guide rod is calculated by numerical simulation method.

[0035] The measuring point is set on the outer surface, inner surface, upper edge or lower edge of the anode beam busbar between every two anode guide rods.

[0036] The measuring points are set on both sides of the anode guide rod, in the middle of the anode beam busbar or in the middle of the column busbar.

[0037] It also includes an auxiliary measurement point, the auxiliary measurement point is set at the upper edge of the bridge bus;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com