Drawing vacuum melting furnace capable of continuous molding and discharging

A vacuum melting furnace, drawing technology, applied in the field of drawing vacuum melting furnace, can solve secondary molding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

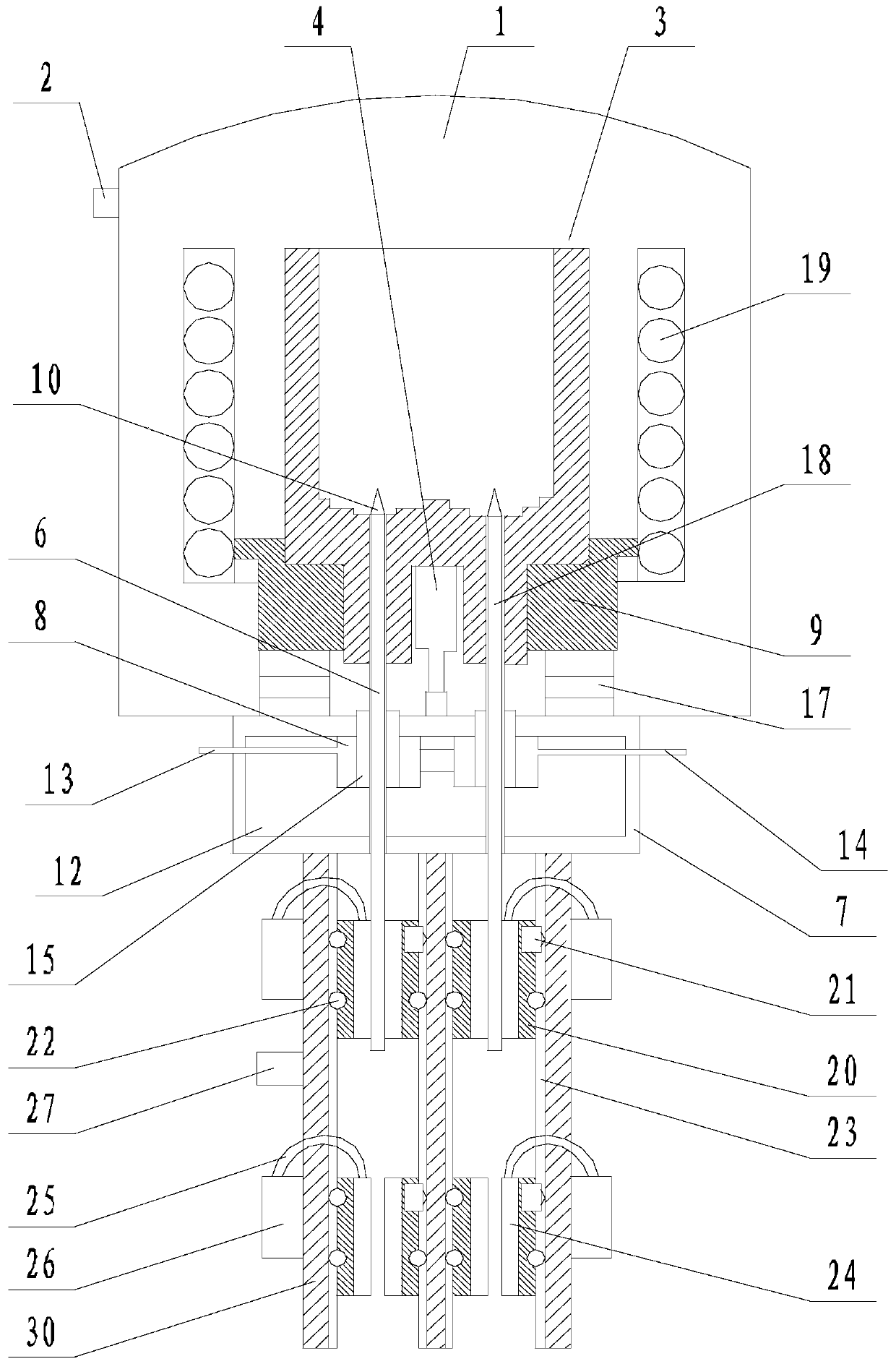

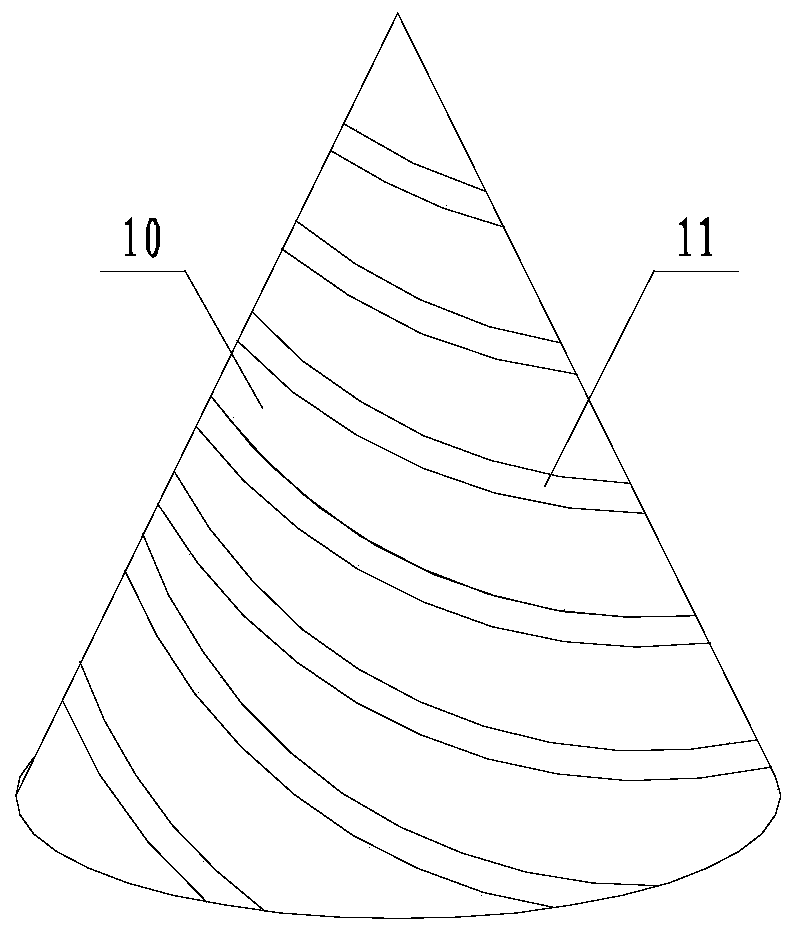

[0030] Such as Figure 1 to Figure 3 The shown drawing-type vacuum melting furnace capable of continuous molding and discharging includes a furnace body 1 with a vacuum suction port 2, a crucible 3 is arranged in the furnace body 1, and an induction heating coil 19 is located outside the crucible 3. The inner bottom surface of the furnace body 1 is provided with a pushing device 4 with the output end facing upwards. The output end of the pushing device 4 is in contact with the bottom of the crucible 3, and the bottom of the crucible 3 is provided with a discharge pipe that runs through the bottom surface of the crucible 3. A drawing rod 6 is arranged in the tube, the cross section of the drawing rod 6 matches the cross section of the discharge pipe, a crystallization chamber 7 is arranged under the furnace body 1, and a water cooling box is arranged on the top surface of the crystallization chamber 7 8. The discharge pipe passes through the water-cooled box 8, and the bottom e...

Embodiment 2

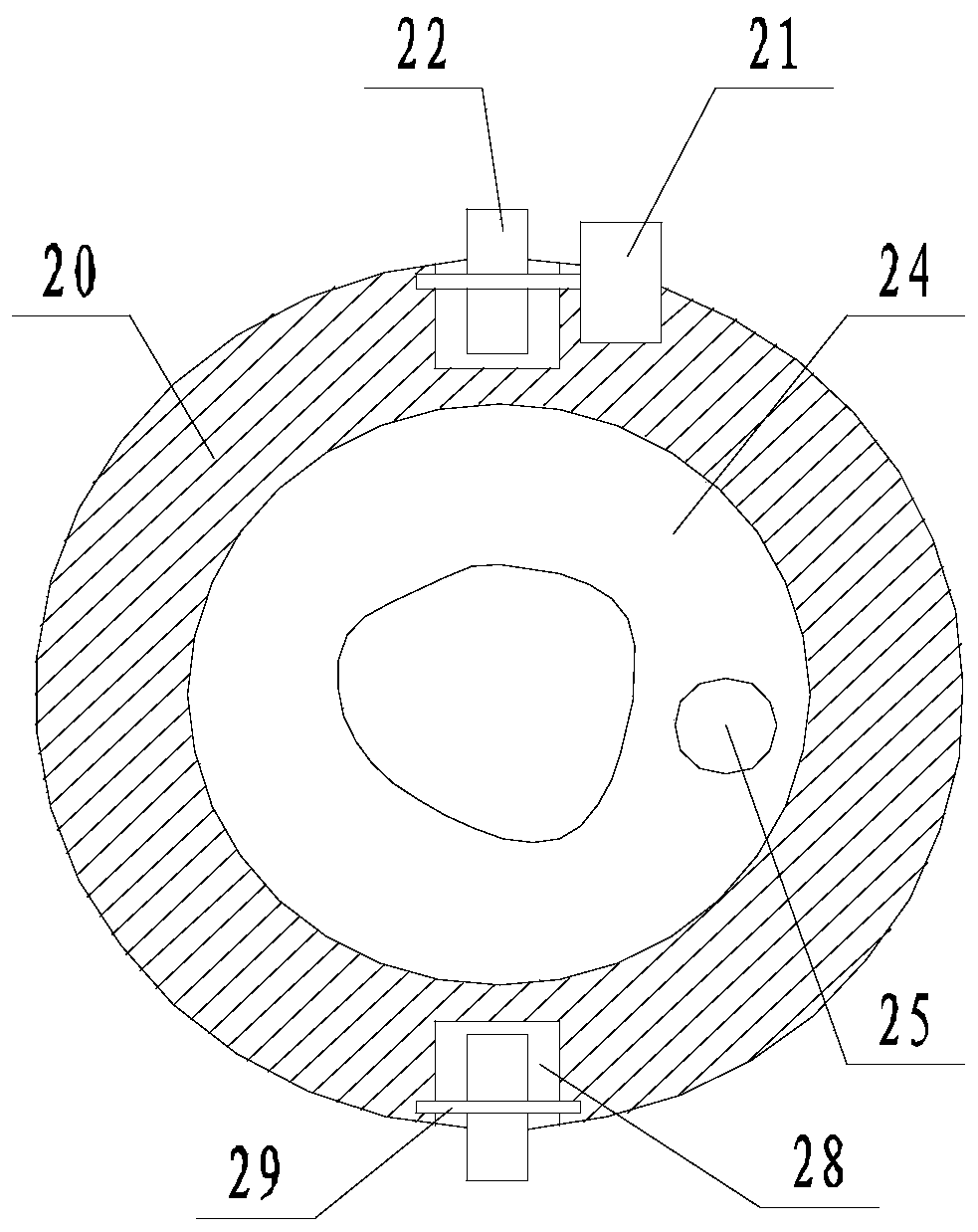

[0032] Such as Figure 1 to Figure 4 In the drawing-type vacuum melting furnace capable of continuous molding and discharging, on the basis of Example 1, a groove is provided on the bottom surface of the crucible 3, and the output end of the pushing device 4 is located in the groove. The crystallization chamber 7 is surrounded by metal plates, and the crystallization chamber 7 is filled with thermal conductive silicone grease 12 . The water cooling box 8 is connected with a water inlet pipe 13 and an outlet pipe 14 , and both the water inlet pipe 13 and the water outlet pipe 14 extend to the outside of the crystallization chamber 7 . The outlet pipe 5 is covered with a silicone sleeve 15 , and the silicone sleeve 15 is fixed on the bottom of the furnace body 1 . The bottom surface of the discharge pipe 5 is flush with the bottom surface of the crystallization chamber 7 , and the discharge pipe 5 is covered with a sealing ring 16 , and the sealing ring 16 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com