Offset printing fountain solution self-circulation purification system and purification method

A purification system and printing dampening solution technology, applied in the field of fountain solution self-circulation purification system, can solve problems such as wasting resources, water tank evacuation and overflow, affecting filtration efficiency, etc., to achieve maximum utilization, avoid evacuation and overflow, and filter good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described below in conjunction with the accompanying drawings.

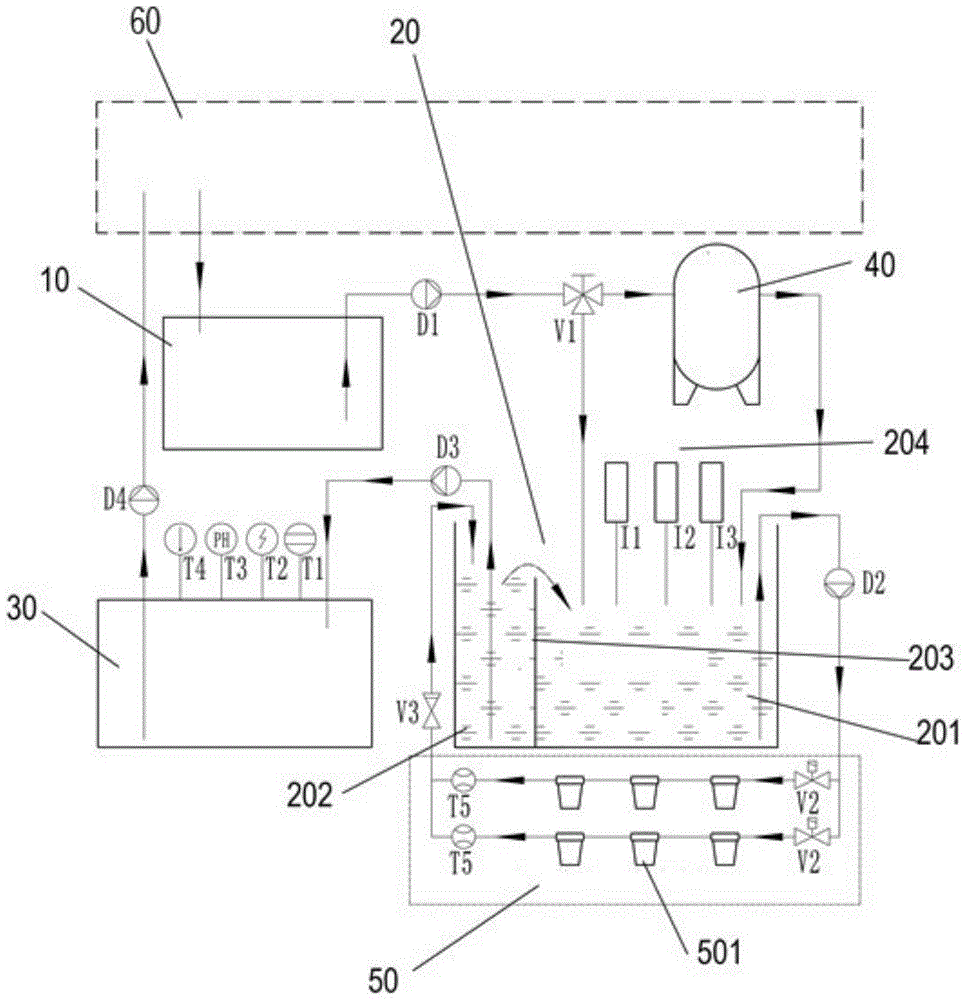

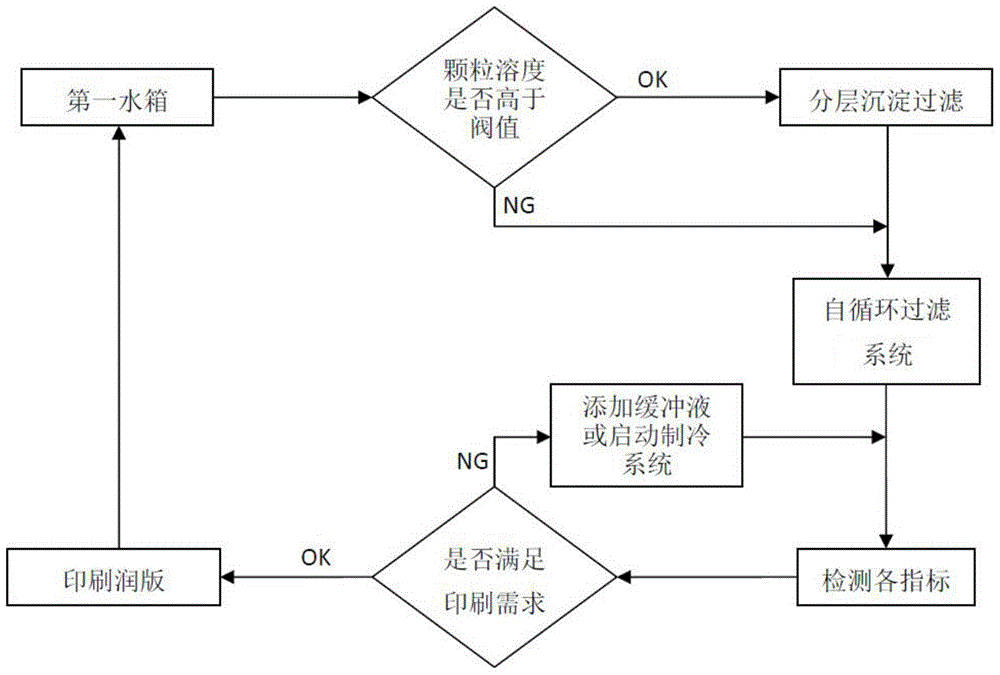

[0034] Such as figure 1 As shown, an offset printing fountain solution self-circulation purification system includes: a first water tank 10, a second water tank 20, a layered sediment filter 40, a filtering device 50, a third water tank 30 and a control circuit.

[0035] The first water tank 10, the first water tank 10 is used to collect the dampening solution of the offset printing machine; the second water tank 20, the second water tank 20 is divided into the first chamber 201 and the second chamber 202 by the dividing plate 203 provided, the dividing plate 203 The height is not higher than the sidewall of the second water tank 202, and the first chamber 201 is provided with the adding device 204 that ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com