Oil-gas mixing transportation device and process applied to gathering and transportation station yard with high gas oil ratio

A technology for gathering and transportation stations and mixed transportation of oil and gas, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc. It can solve the problems of limited gas-carrying capacity and high engineering investment, so as to avoid equipment pumping out and be safe and reliable High performance, realize the effect of oil and gas mixed transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

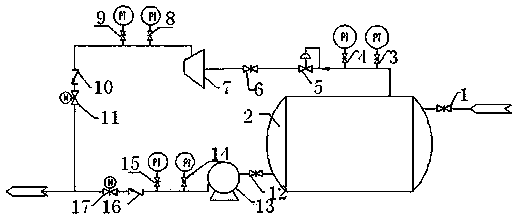

[0024] Such as figure 1 As shown, an oil-gas mixed transportation device suitable for high gas-oil ratio gathering and transportation stations includes a closed separation device 2, a first pressure detection device, an air pressure regulating valve 5, a compressor 7, a second pressure detection device, a gas transmission Valve 11, crude oil export pump 13, third pressure detection device and oil delivery valve 17, an input port is provided on one side of the airtight separation device 2, and a gas outlet is provided on the top of the airtight separation device 2, and the gas outlet is sequentially connected to the first The inlet of the pressure detection device, air pressure regulating valve 5, compressor 7, second pressure detection device and gas delivery valve 11, the lower part of the other side of the airtight separation device 2 is provided with a liquid outlet, and the liquid outlet is sequentially connected to the crude oil export pump 13, The third pressure detectio...

Embodiment 2

[0027] On the basis of Example 1, the oil and gas mixed transportation device suitable for high gas-oil ratio gathering and transportation stations also includes an inlet valve 1, a stop valve 6 and a first gate valve 12, and the inlet valve 1 is connected to the airtight separation device 2 for input On the pipeline, the shut-off valve 6 is connected to the pipeline between the air pressure regulating valve 5 and the compressor 7, and the first gate valve 12 is connected to the pipeline between the airtight separation device 2 and the crude oil export pump 13. The inlet valve 1 is used to control the mixed medium of oil and gas from the upstream, the stop valve 6 is used to control the gas closing of the gas pipeline and protect the equipment on the gas pipeline, and the first gate valve 12 is used to control the flow of the separated liquid and protect the crude oil output at the same time. The pump 13 is optimized in process, simple in process, and high in safety and reliabi...

Embodiment 3

[0033] Such as figure 1 As shown, an oil-gas mixed transportation process suitable for high gas-oil ratio gathering and transportation stations, the upstream oil-gas mixed medium enters the airtight separation device 2 through the inlet valve 1 for oil-gas separation, and when the separated gas volume is greater than the standard value, After the gas is measured by the first pressure transmitter 3 and the first local pressure gauge 4, the first local pressure gauge 4 responds to the interlocking air pressure regulating valve 5 to adjust and increase the gas discharge volume, and at the same time start the compressor 7 and turn on the output. Gas valve 11, the gas is output through the shut-off valve 6 and the compressor 7, the pressure is measured by the second local pressure gauge 8 and the second pressure transmitter 9, and then the gas is exported through the first check valve 10 and the gas delivery valve 11; separation The output oil is transferred through the first gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com