Flexible liquid tank control system

A control system and liquid filling technology, which is applied in the direction of displaying liquid level indicators, containers, packaging, etc. through pressure measurement, which can solve the problems of liquid tank overflow, ignorance, and evacuation, and achieve the effect of reducing labor intensity and avoiding evacuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

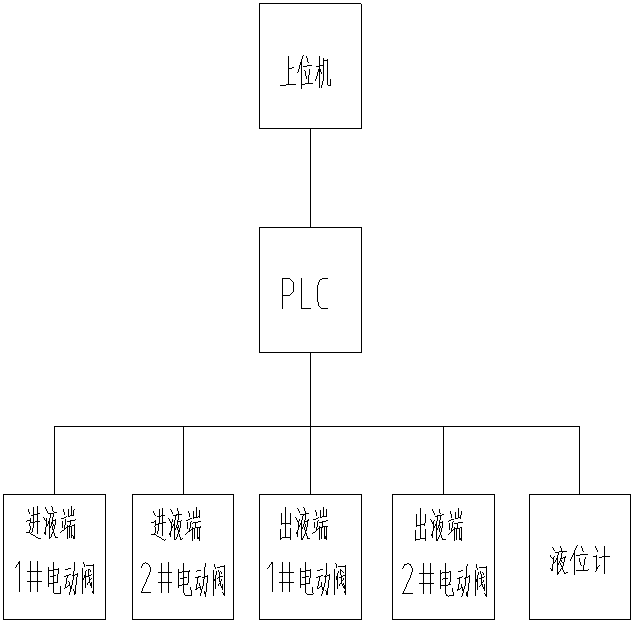

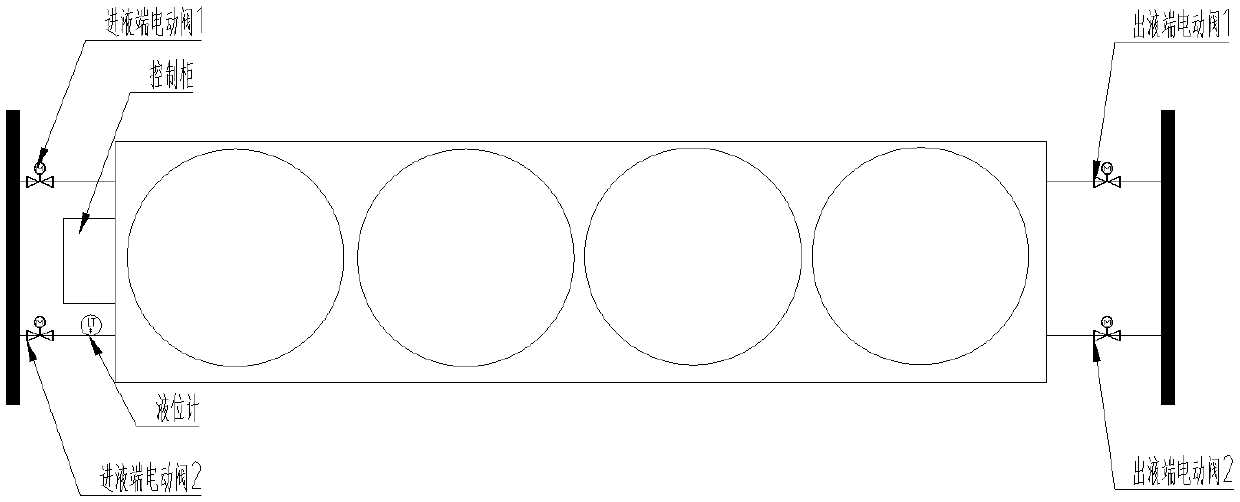

[0022] In this example, if figure 1 , 2 As shown, a flexible liquid irrigation control system includes four tank warehouses, and the tank warehouses are connected by bottom manifolds. Surrounded by steel structure support. There are two electric valves installed in parallel on the tank bottom manifold at the liquid inlet, two electric valves installed in parallel on the tank bottom manifold at the liquid outlet, and a liquid level gauge (pressure transmitter) installed at the liquid outlet on the manifold, and a control box mounted on the bottom of the tank. There is a liquid level indicator on the control cabinet to display the current liquid level value, a control knob of the electric valve at the liquid inlet end is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com