Patents

Literature

36results about How to "Real-time monitoring of liquid level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

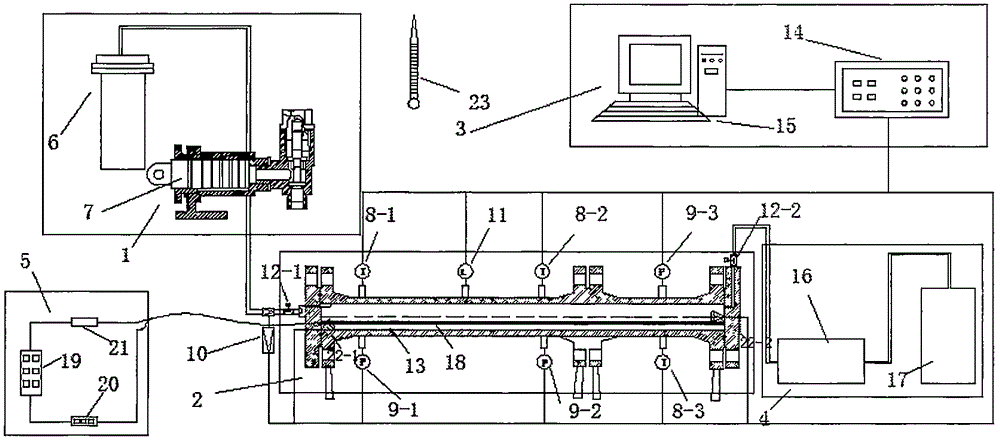

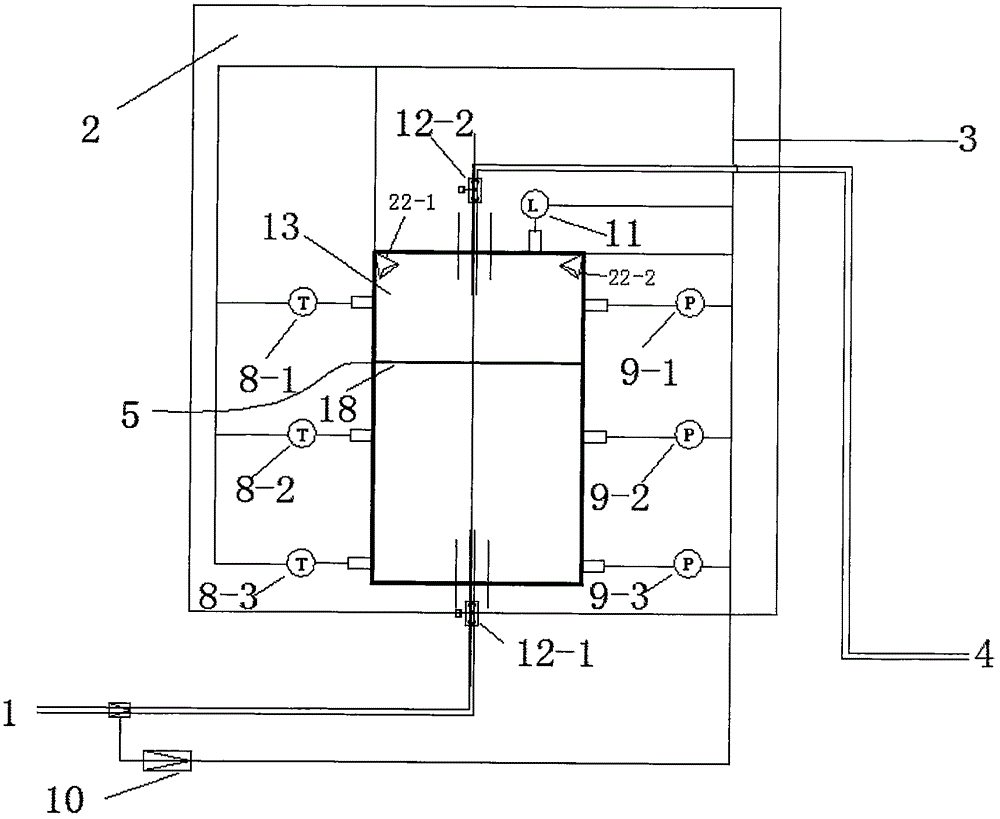

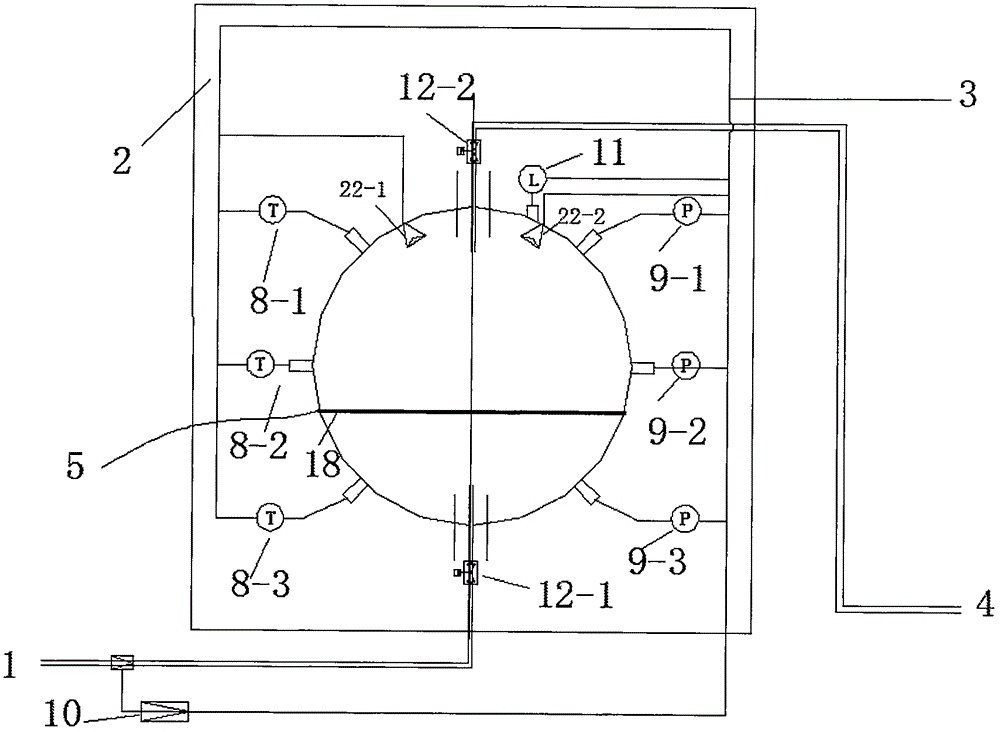

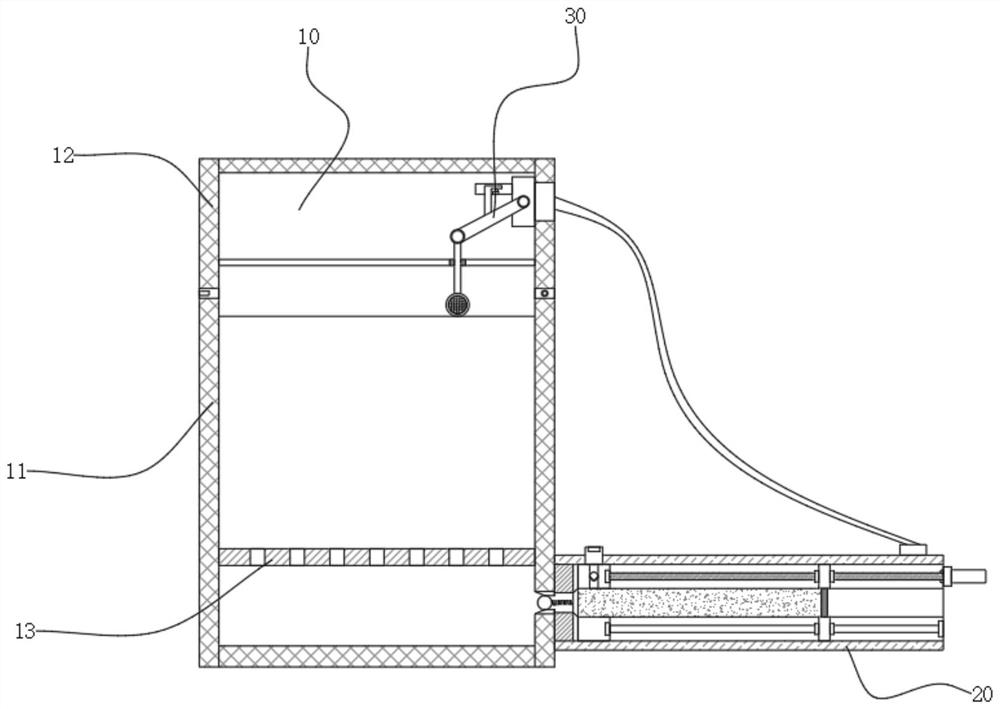

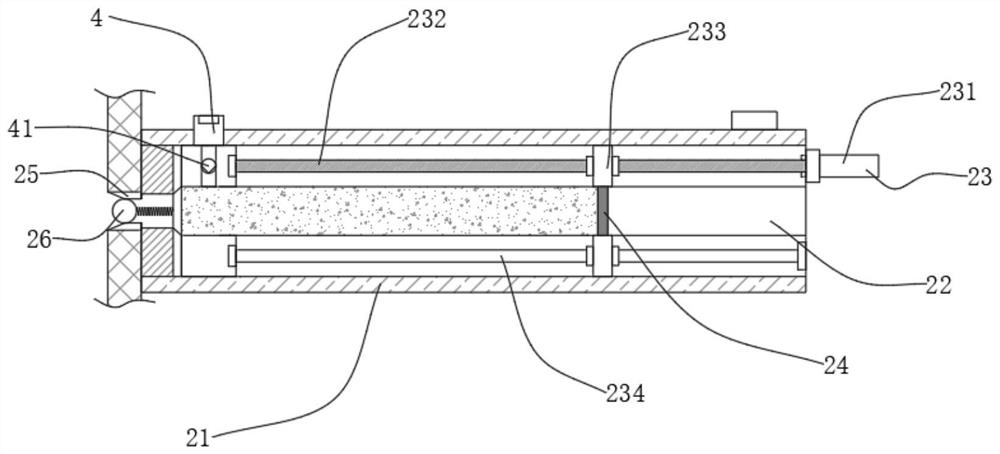

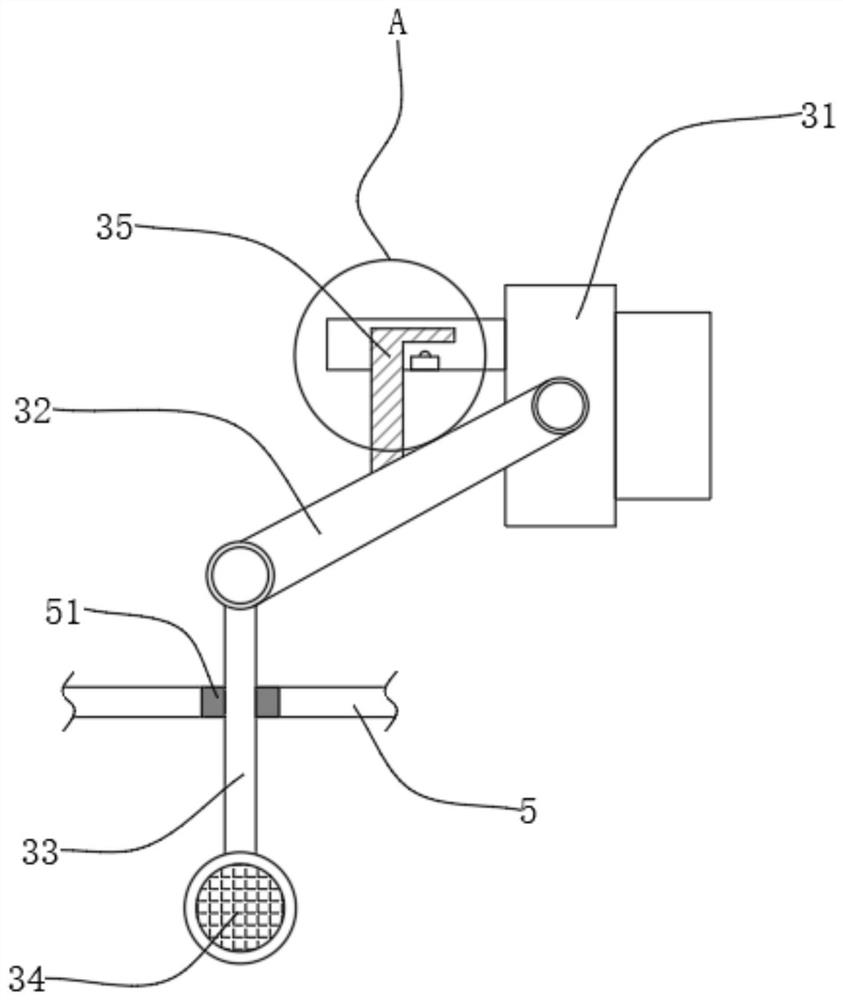

Simulated testing system of liquid-state CO2 phase change process

InactiveCN106645269ARealize phase state judgmentMonitor pressure in real timeInvestigating phase/state changeData acquisitionHigh pressure

The invention discloses a simulated testing system of a liquid-state CO2 phase change process. The simulated testing system comprises five parts including a liquid-state CO2 pump pressure injection system, a sealed high-pressure-resisting container system, a data acquisition and storage system, a waste gas and waste liquid recycling and cyclic utilization system and a manual heating system, wherein the liquid-state CO2 pump pressure injection system comprises a Dewar flask mounted beside sealed high-pressure-resisting containers and a manual variable piston pump; the sealed high-pressure-resisting container system comprises three sealed high-pressure-resisting containers with different types, including a pipeline type low-temperature-resisting and high-pressure-resisting container, a spherical type low-temperature-resisting and high-pressure-resisting container and a storage tank type low-temperature-resisting and high-pressure-resisting container; the data acquisition and storage system comprises a temperature sensor, a pressure sensor, a liquid level sensor and an infrared thermal imager which are mounted in each sealed high-pressure-resisting container. The simulated testing system disclosed by the invention can be used for monitoring changes of parameters including temperature, pressure, liquid levels and the like of liquid-state CO2 in the sealed high-pressure-resisting containers in real time; a phase state attributed graph of the CO2 is combined and phase state judgment of the CO2 in the system is realized.

Owner:XIAN UNIV OF SCI & TECH +1

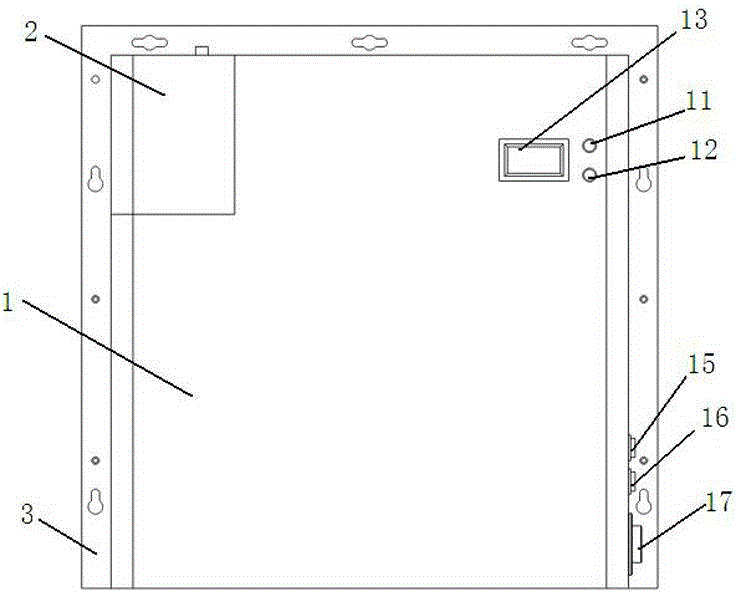

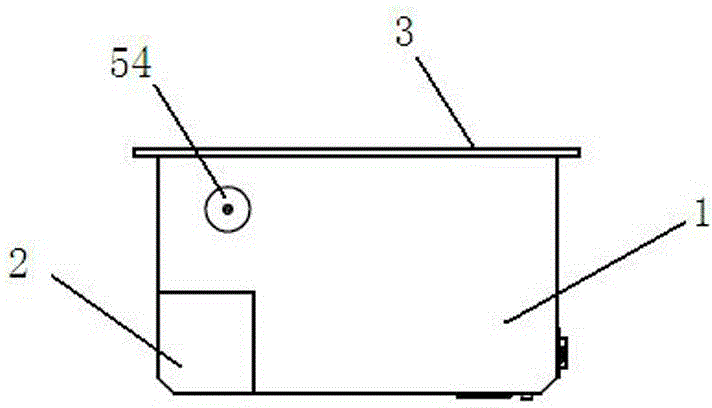

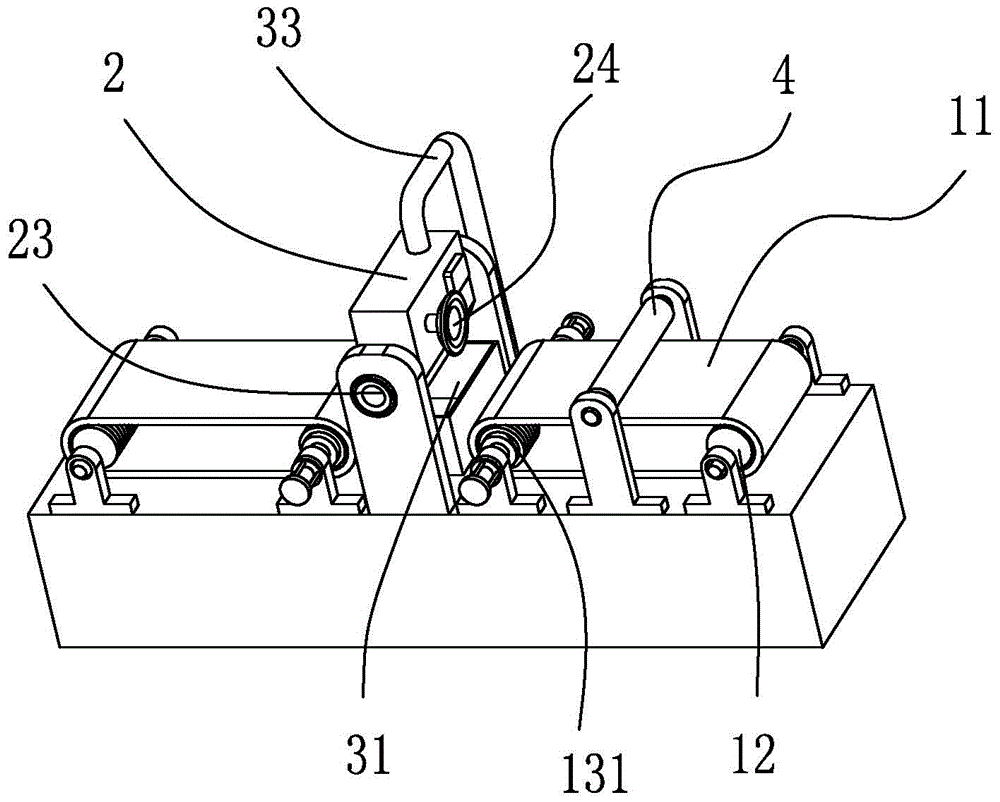

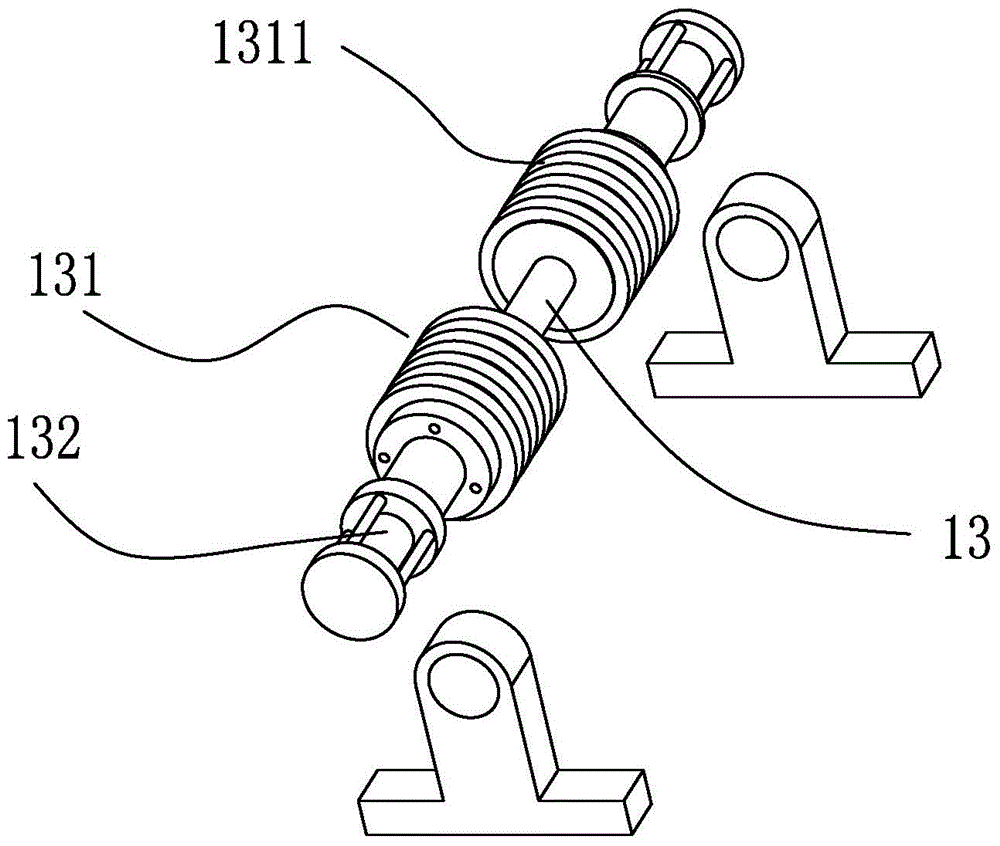

Intelligent internal combustion engine fuel economizer

ActiveCN104373258ABurn fullyReal-time monitoring of voltage fluctuationsNon-fuel substance addition to fuelInternal combustion piston enginesElectrolysisOxygen

The invention provides an intelligent internal combustion engine fuel economizer, and belongs to the technical field of fuel-economizing devices. The intelligent internal combustion engine fuel economizer comprises a power supply assembly used for controlling the fuel economizer to intelligently work, a water pipeline assembly used for circularly supplying water, a gas pipeline assembly used for conveying mixed gas, and at least one electrolysis module used for generating the mixed gas composed of ozone, oxygen and hydrogen, wherein the power supply assembly is electrically connected with the electrolysis module, the water pipeline assembly and the electrolysis module are communicated in a water circulating mode in the longitudinal axis direction, the water pipeline assembly and the gas pipeline assembly are communicated in the longitudinal axis direction, the electrolysis module, the water pipeline assembly, the gas pipeline assembly and the power supply assembly are encapsulated into a whole through a large outer shell, a back plate and a small outer shell, and the electrolysis module and the water pipeline assembly are separated from the gas pipeline assembly and the power supply assembly through a surrounding plate. The intelligent internal combustion engine fuel economizer is simple in structure and easy to install and maintain, can determine the real-time operation state of an engine by monitoring the voltage condition of a vehicle-mounted power supply in real time, and can provide adjustable current for the electrolysis module so that an electrolysis process can be more efficient, and the fuel-economizing efficiency of the fuel economizer is improved.

Owner:HUZHOU KANGLONG ELECTRONICS

Cow and sheep water drinking device

The invention discloses a cow and sheep water drinking device which comprises a water drinking trough connected with a water inlet pipe. The water inlet pipe is connected to a water drinking pool anda trace element pool through a T-joint. The water drinking pool and the trace element pool are installed on an enclosure roof. The water inlet pipe is connected with the trace element pool through theT-joint, trace elements are put in the trace element pool after being mixed with water, when cow and sheep need trace elements, trace element liquid in the trace element pool flows into the water drinking trough through the trace element pool, trace element intake is conducted in the water drinking process, the function of the water drinking trough is added, the utilization rate of the water inlet pipe is increased, automatic inflow is realized, manual addition is avoided, time and labor are better saved, the trace element amount is easier to control, and the water drinking device has the advantages of being simple in structure and low in cost.

Owner:GUIZHOU NORMAL UNIVERSITY

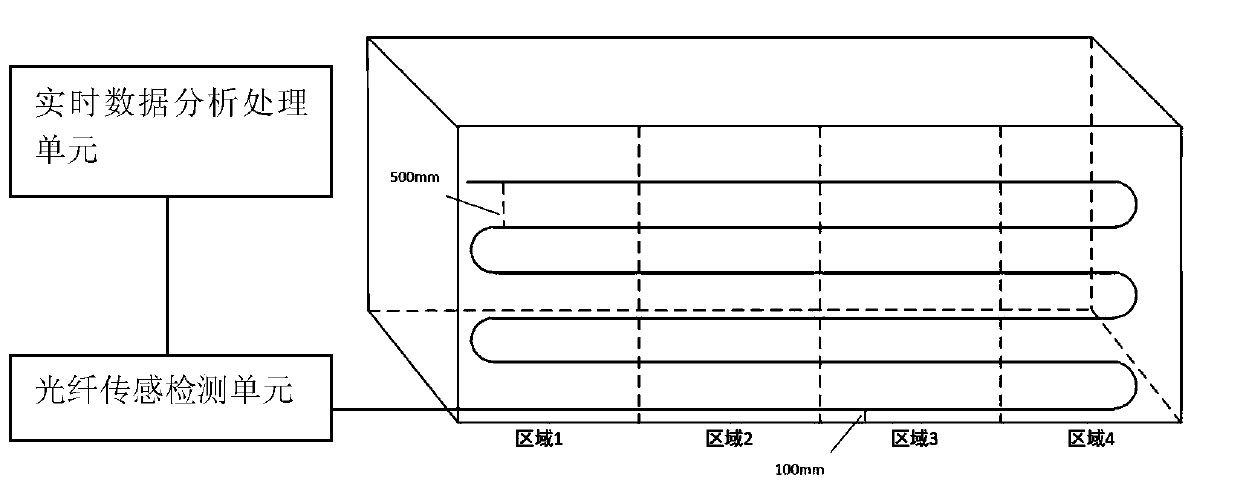

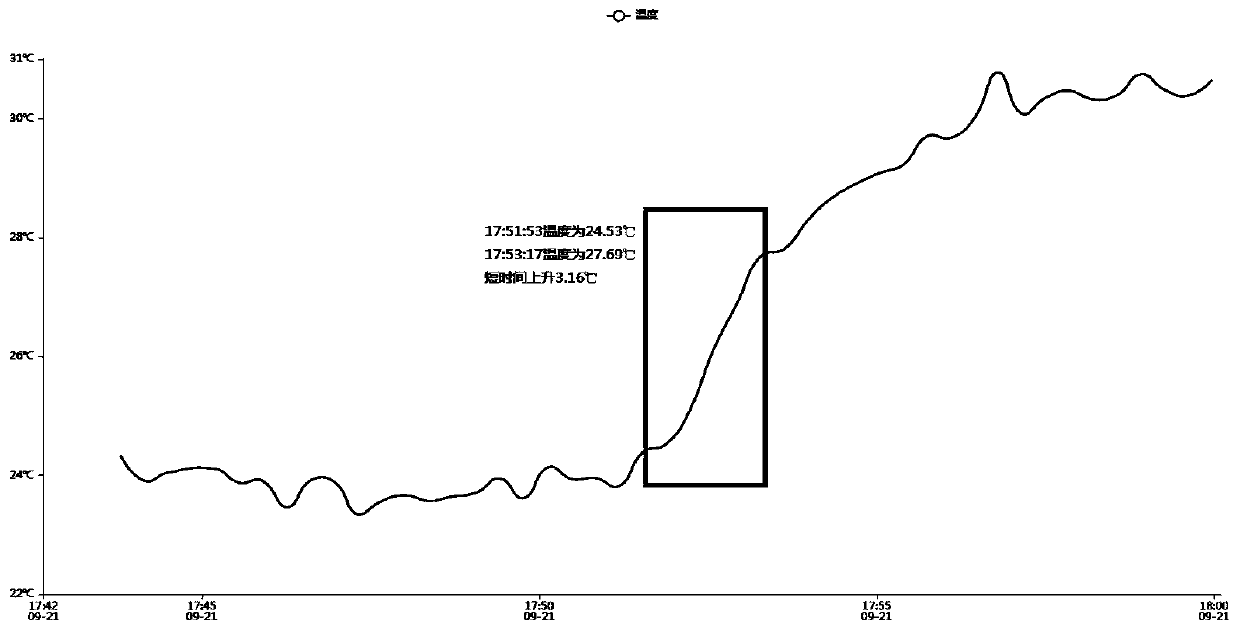

Concrete pouring height real-time monitoring method and system

InactiveCN110849321AReal-time monitoring of liquid levelImprove real-time performanceThermometers using physical/chemical changesHeight/levelling measurementReal-time dataMonitoring system

The invention discloses a concrete pouring height real-time monitoring method. The method comprises the steps of: laying temperature sensing optical fibers in a pouring area; performing real-time monitoring of the temperature of the pouring area through the temperature sensing optical fibers; when a difference value between a temperature value t1 acquired by a certain temperature detection point on a horizontal section and a temperature value t2 acquired by the point before a preset time interval T exceeds a preset difference value [Delta]t, recording the point as an abnormal fluctuation point; and when the number of the abnormal fluctuation points on the horizontal section exceeds a preset value x, judging that the concrete covers the horizontal section. The invention further discloses aconcrete pouring height real-time monitoring system. The system comprises temperature sensing optical fibers, an optical fiber sensing and detection unit, a real-time data analyzing and processing unit. By adopting the technical scheme mentioned above, the liquid level height of the whole concrete pouring area can be monitored in real time, the pouring liquid level height of the area can be monitored when the optical fibers are distributed in a certain area, and the concrete pouring height real-time monitoring method and system are particularly suitable for large concrete structures.

Owner:上海中兴思秸通讯有限公司

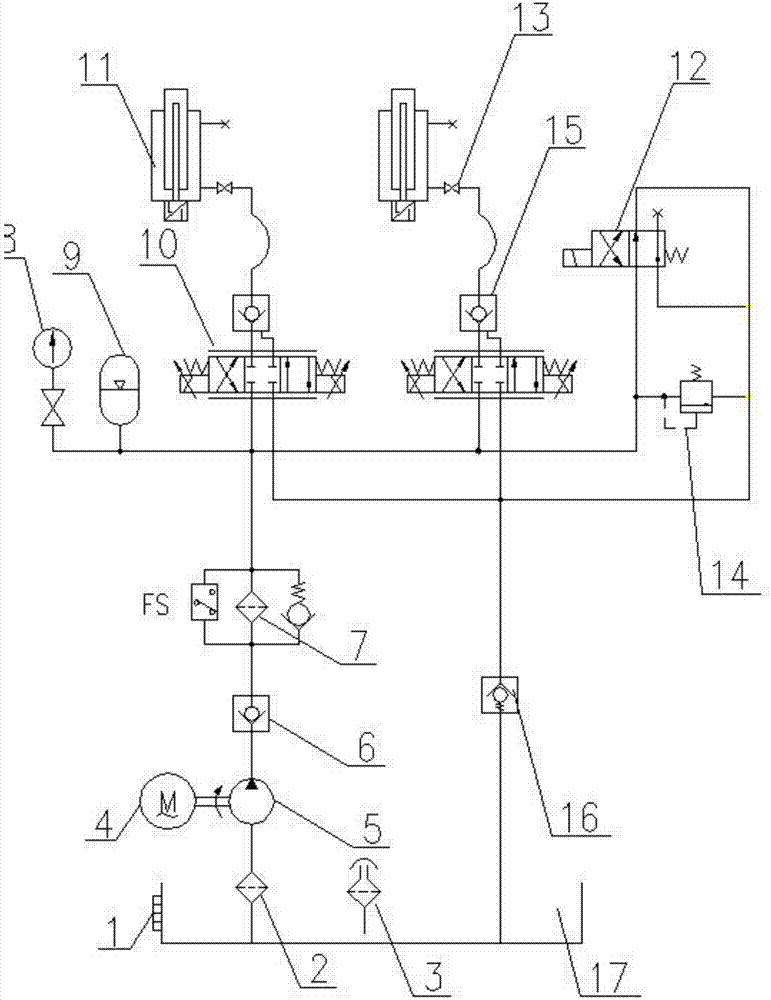

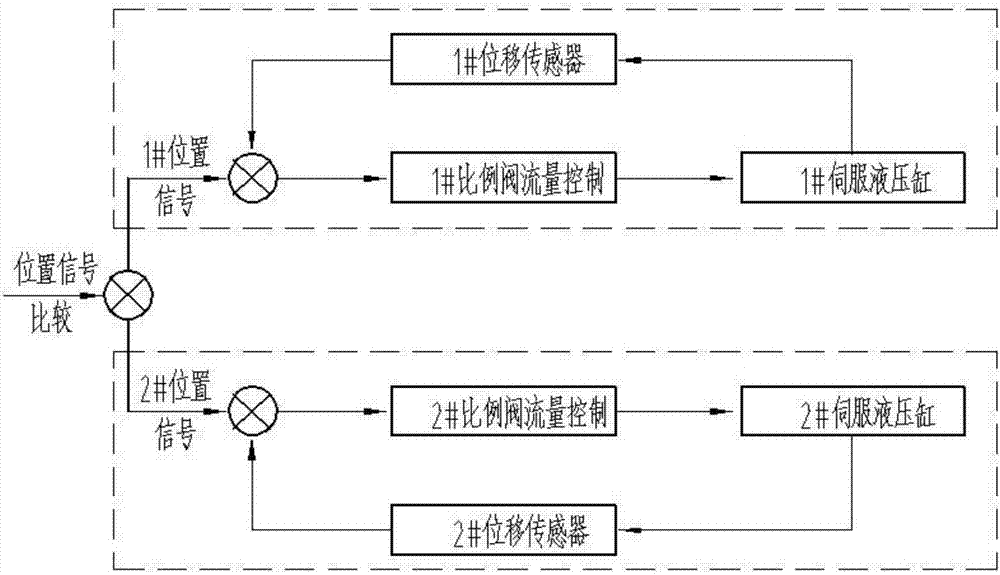

Hydraulic servo synchronization system

InactiveCN106884833AOperation standardQuick responseFluid-pressure actuator testingServomotor componentsFuel tankReversing valve

The invention relates to a hydraulic servo synchronization system. The hydraulic servo synchronization system comprises an oil tank, an auxiliary unit and a reversing valve, wherein the oil tank is used for storing oil liquid; the auxiliary unit is provided with an auxiliary oil way for conveying oil liquid; the reversing valve is provided with a first oil way and a second oil way which are connected with each other in parallel; the reversing valve is used for reversing; the first oil way, the second oil way and the reversing valve are communicated with the auxiliary oil way. Through the hydraulic servo synchronization system, a main unit and the auxiliary unit are used for achieving the synchronization purpose jointly, so that the hydraulic servo synchronization system is accurate in operation and rapid in response; the operating efficiency is improved.

Owner:泸州市长江液压件装备有限公司

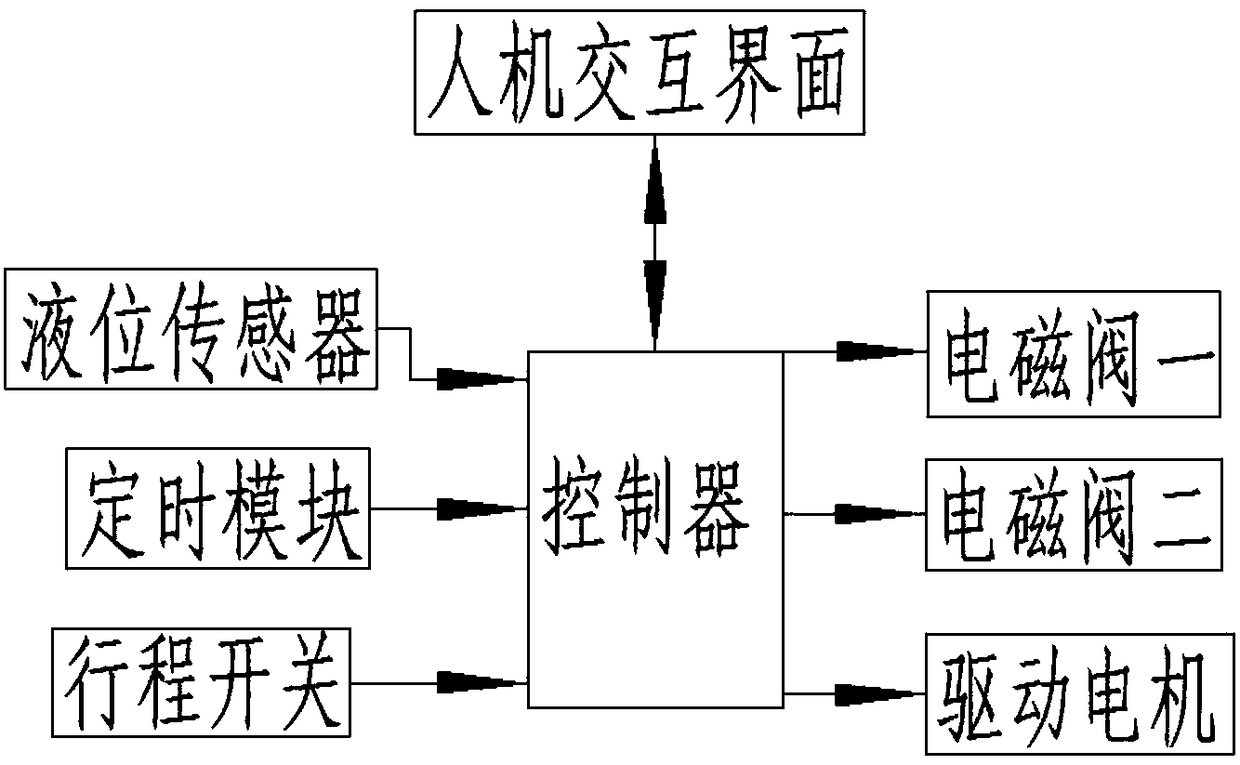

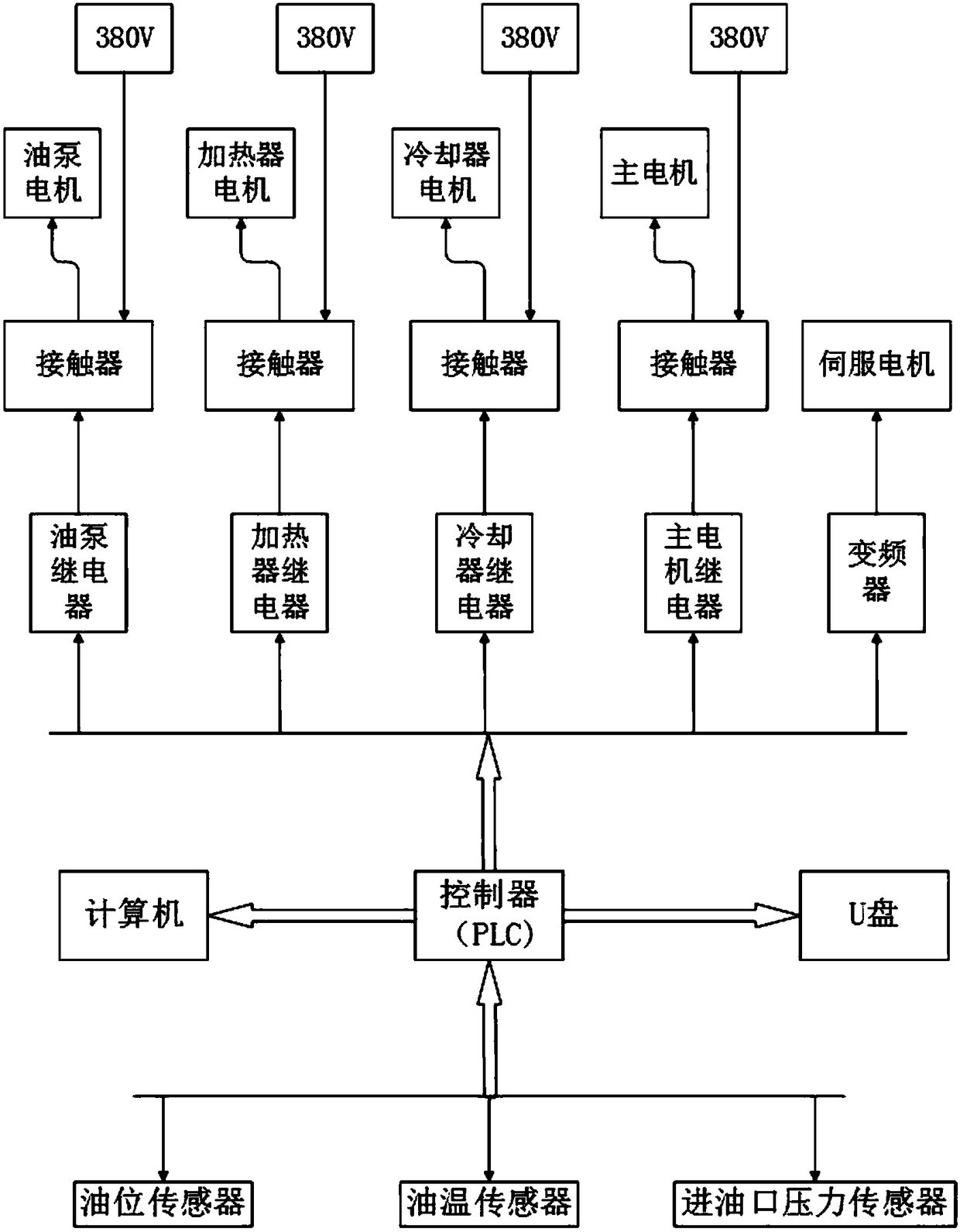

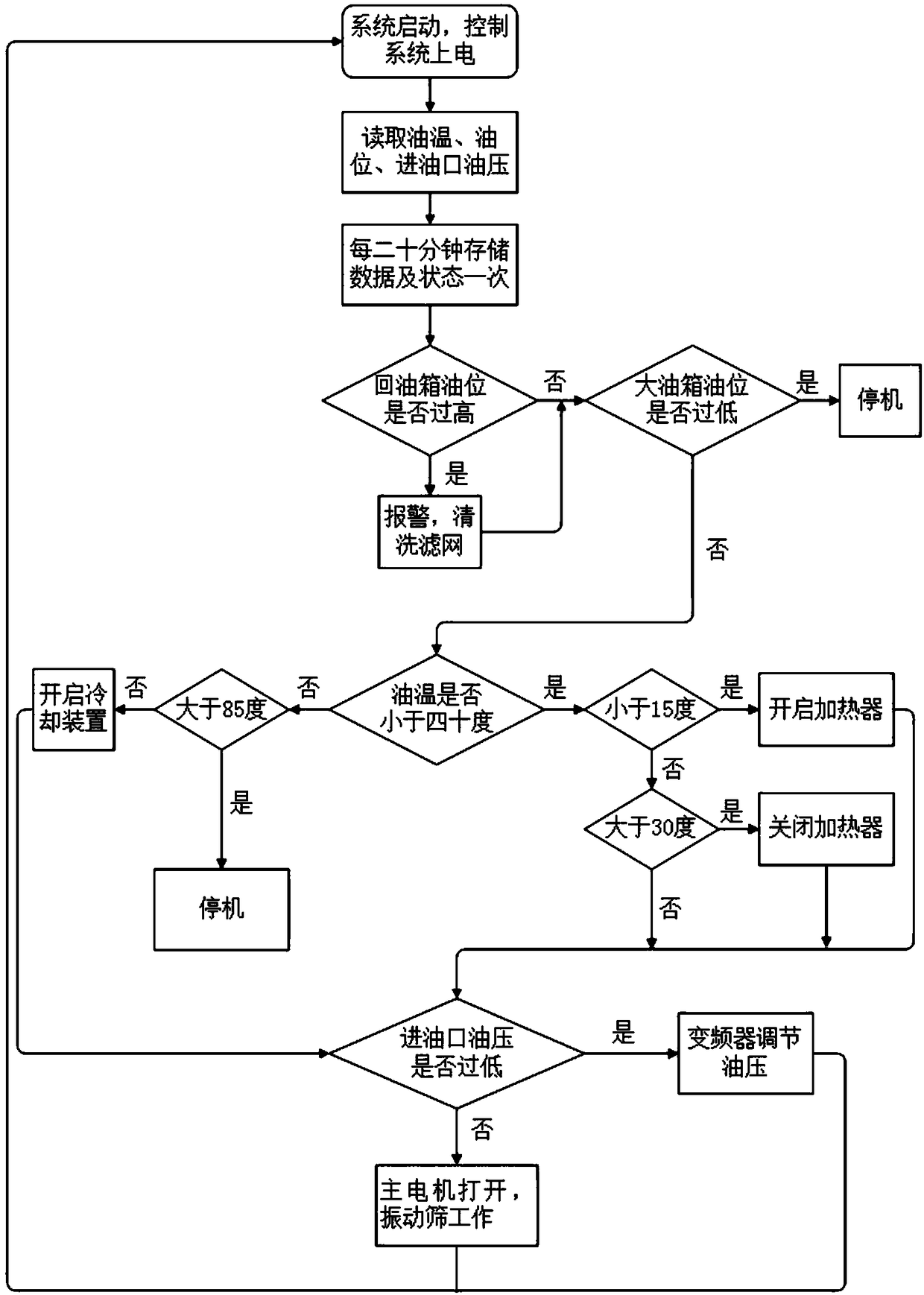

State monitoring control system for large-scale vibrating screen

PendingCN108287582AMonitor temperature in real timeMonitor pressure in real timeSimultaneous control of multiple variablesFuel tankEngineering

The invention discloses a state monitoring control system for a large-scale vibrating screen, comprising a controller, relays, contactors, motors, sensors and transmitters thereof; the sensors are installed in a fuel tank of the vibrating screen for measuring corresponding data inside the fuel tank, and the data is output through the sensor transmitters; the controller is used to receive and process various data and perform corresponding control, the input end of the controller is connected to the output ends of the sensor transmitters, and the output end of the controller is connected to theinput ends of the relays; the output ends of the relays are connected with the input ends of the corresponding contactors; the output ends of the contactors are connected with the corresponding motors; and the motors are used for driving corresponding devices. The system can monitor the oil temperature and pressure data of the oil pool in real time, and realize real-time control of oil pool temperature and pressure according to these real-time monitoring data, forming a stable and effective lubricating oil film. The system is convenient to operate and high in intelligent degree, and the control precision is improved.

Owner:湖北松滋松川矿山机械有限公司

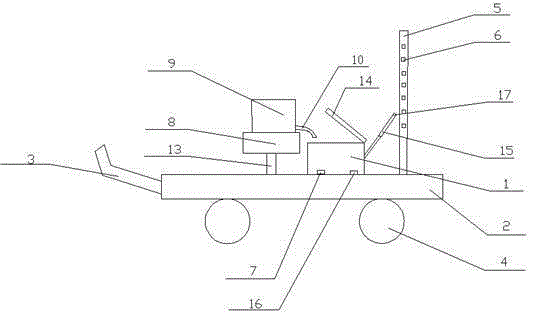

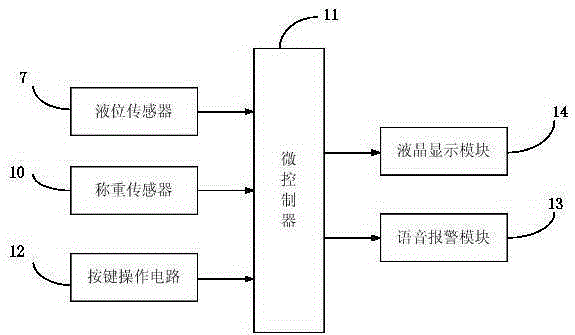

Chemical spraying device used in lemon orchard

InactiveCN106577601ASimple structureReasonable designInsect catchers and killersMicrocontrollerLiquid-crystal display

The invention discloses a chemical spraying device used in a lemon orchard. The chemical spraying device comprises a box body, a walking device, a metering device and a control device. A box cover is hinged to the upper end of the box body. A chemical spraying rod is connected to the side wall of the box body. A liquid level sensor and a water pump are arranged in the box body. The walking device comprises an underpan, a push rod and four vehicle wheels, wherein the pushing rod is fixedly connected to the underpan, and the four vehicle wheels are arranged at the bottom end of the underpan. A support is arranged on the underpan and provided with multiple stop blocks. The box body is placed on the underpan. The metering device comprises a mechanical scale and a liquid containing barrel. The mechanical scale is internally provided with a weighing sensor. A faucet is arranged below the side wall of the liquid containing barrel. The control device comprises a microcontroller. The input end of the microcontroller is connected with a key operation circuit, and the output end of the microcontroller is connected with a voice alarm module and a liquid crystal display module. By means of the chemical spraying device, the liquid level of the box body can be monitored through the mechanical scale in real time; a voice alarm can be given; water and a farm chemical can be matched precisely; and the box body is carried through the walking device, and the effects of saving time and labor are achieved.

Owner:CHONGQING YISHAN AGRI DEV CO LTD

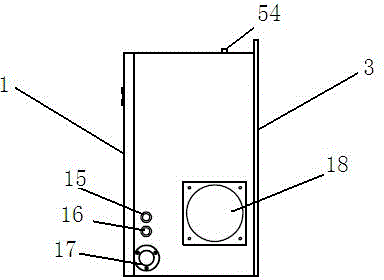

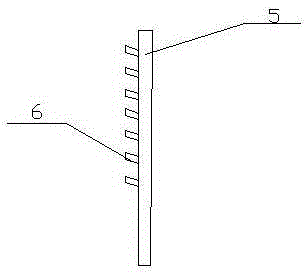

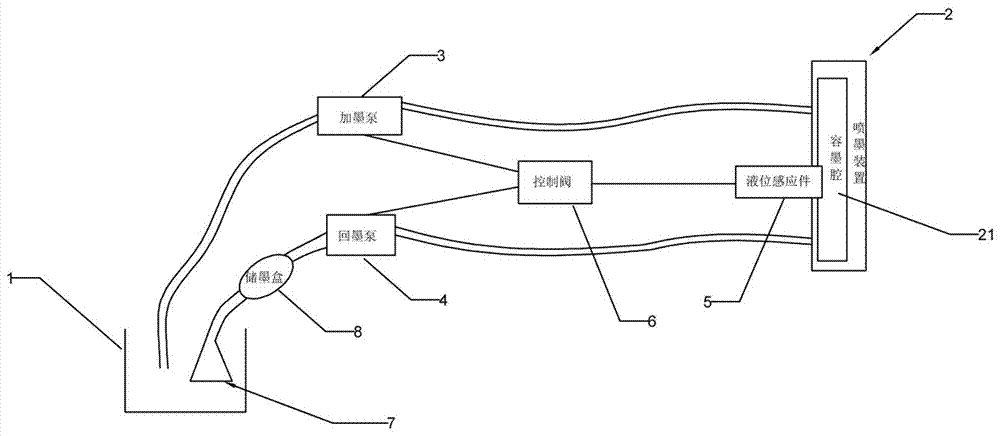

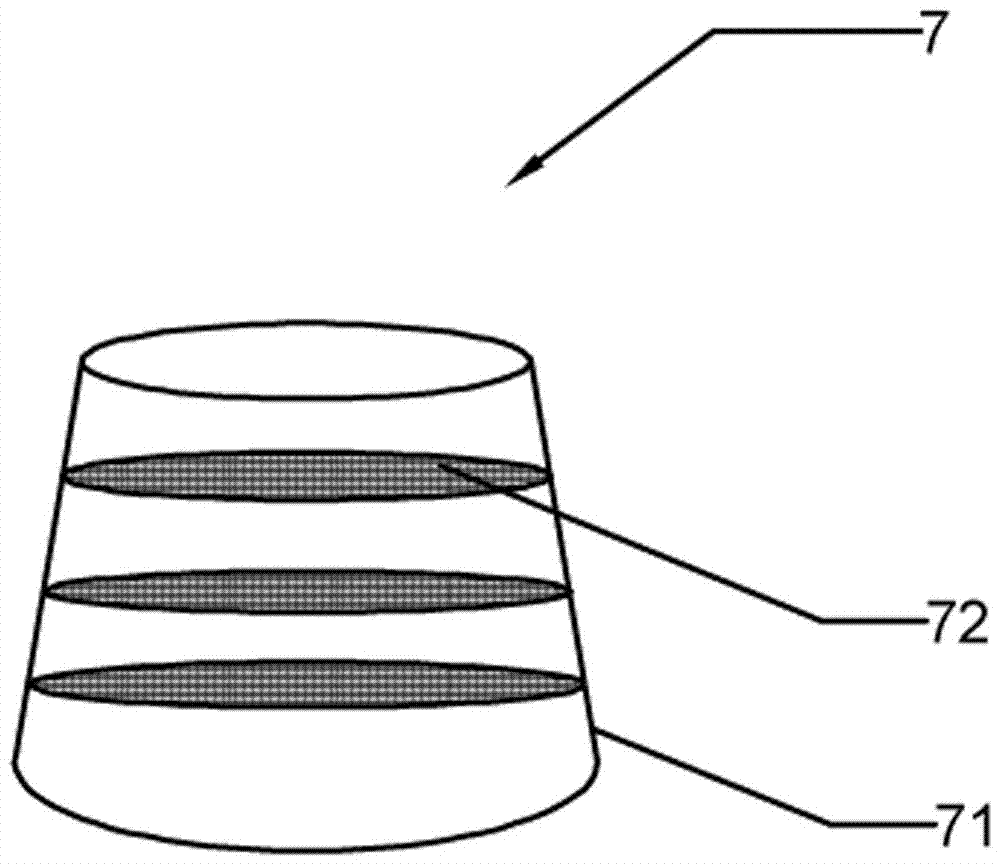

Automatic ink supply system

ActiveCN107571615AReal-time monitoring of liquid levelGuaranteed stabilityScreen printersElectricityEngineering

The invention provides an automatic ink supply system and belongs to the technical field of screen ink printing. The automatic ink supply system is used for automatically supplying ink to a screen inkprinting machine and comprises a printing workbench and an ink barrel. An ink spraying device provided with an ink containing cavity for containing ink is arranged at one end of the printing workbench. The automatic ink supply system comprises an ink feeding pump, an ink return pump, a liquid level sensing part used for sensing the ink level of the ink containing cavity, and a control valve electrically connected with the ink feeding pump, the ink return pump and the liquid level sensing part; an input port of the ink feeding pump communicates with the ink barrel; an output port of the ink feeding pump communicates with the ink spraying device; an input port of the ink return pump communicates with the ink spraying device; an output port of the ink return pump communicates with the oil barrel; and the control valve is used for starting the ink return pump for suction operation when the liquid level sensing part senses that the ink level is higher than a preset liquid level. Through the automatic ink supply system, the liquid level of ink in the ink containing cavity can be monitored in real time, the ink is supplemented in time through the action of the control valve, the stability and uniformity of the ink are ensured, and the quality of finished printed products is improved.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

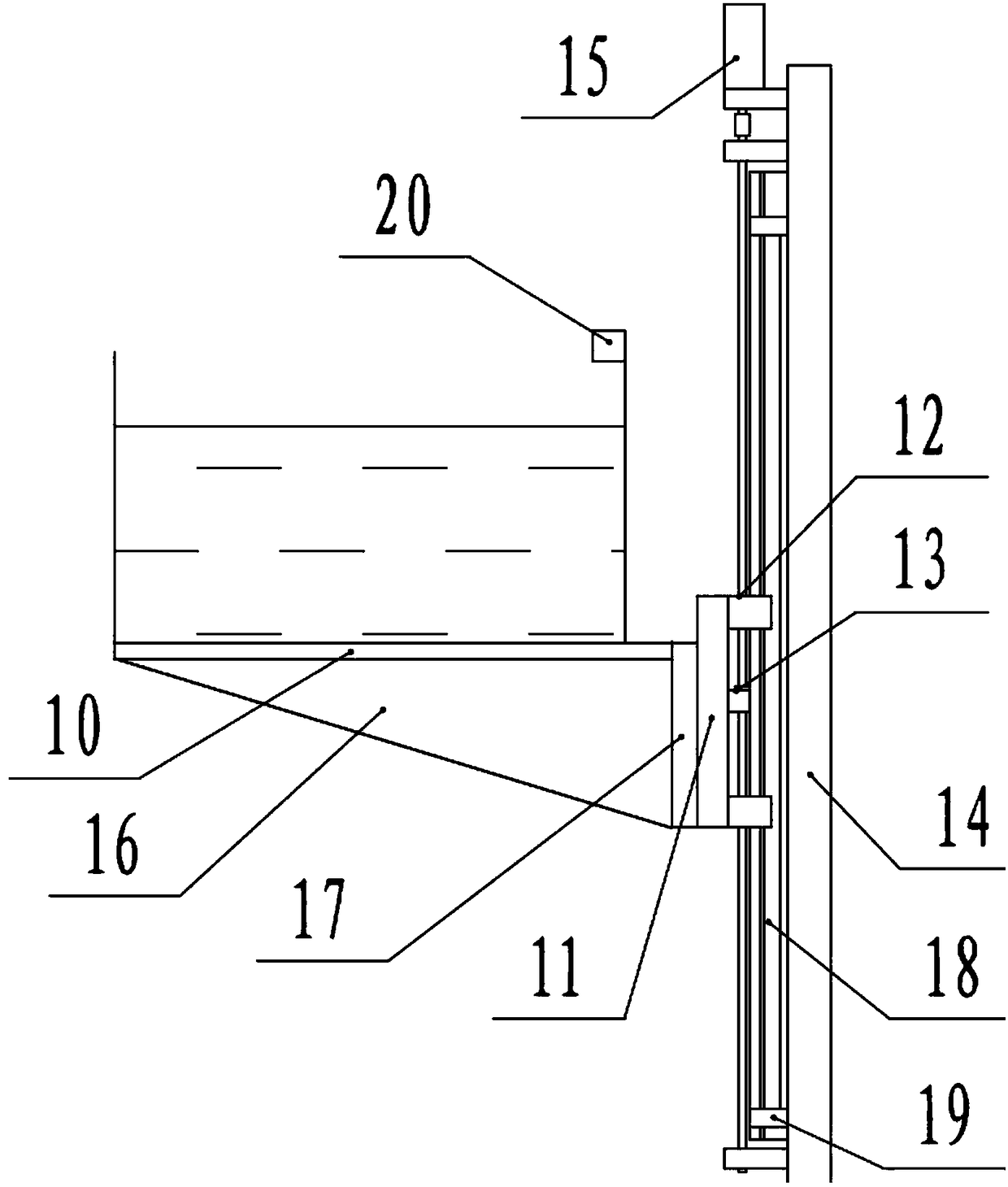

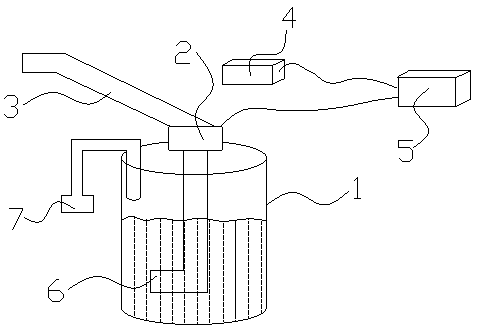

Device for quantitatively injecting wax into ceramic handicraft article

ActiveCN102391915AMonitor temperature in real timeReal-time monitoring of liquid levelCandle preparation apparatusWaxControl system

The invention discloses a device for quantitatively injecting wax into a ceramic handicraft article, which comprises a liquid wax pump, a control system, a temporary storage bin with heat insulation effect and a blanking bin, wherein an outlet of the liquid wax pump is connected with an inlet of the temporary storage bin, the outlet of the temporary storage bin is connected with the inlet of the blanking bin, a liquid level control valve is mounted on a pipeline between the temporary storage bin and the blanking bin, an electric heating device, a temperature monitoring device and a liquid level monitoring device are mounted in each of the temporary storage bin and the blanking bin, at least one discharge port is arranged on the blanking bin, and the liquid wax pump and the liquid level control valve, as well as the electric heating devices, the temperature monitoring devices and the liquid level monitoring devices in the temporary storage bin and the blanking bin are electrically connected with the control system. The device has the advantages of ensuring the quantitative wax injection into the ceramic handicraft article, simultaneously realizing automation and improving the production efficiency.

Owner:FUJIAN JIAMEI GRP

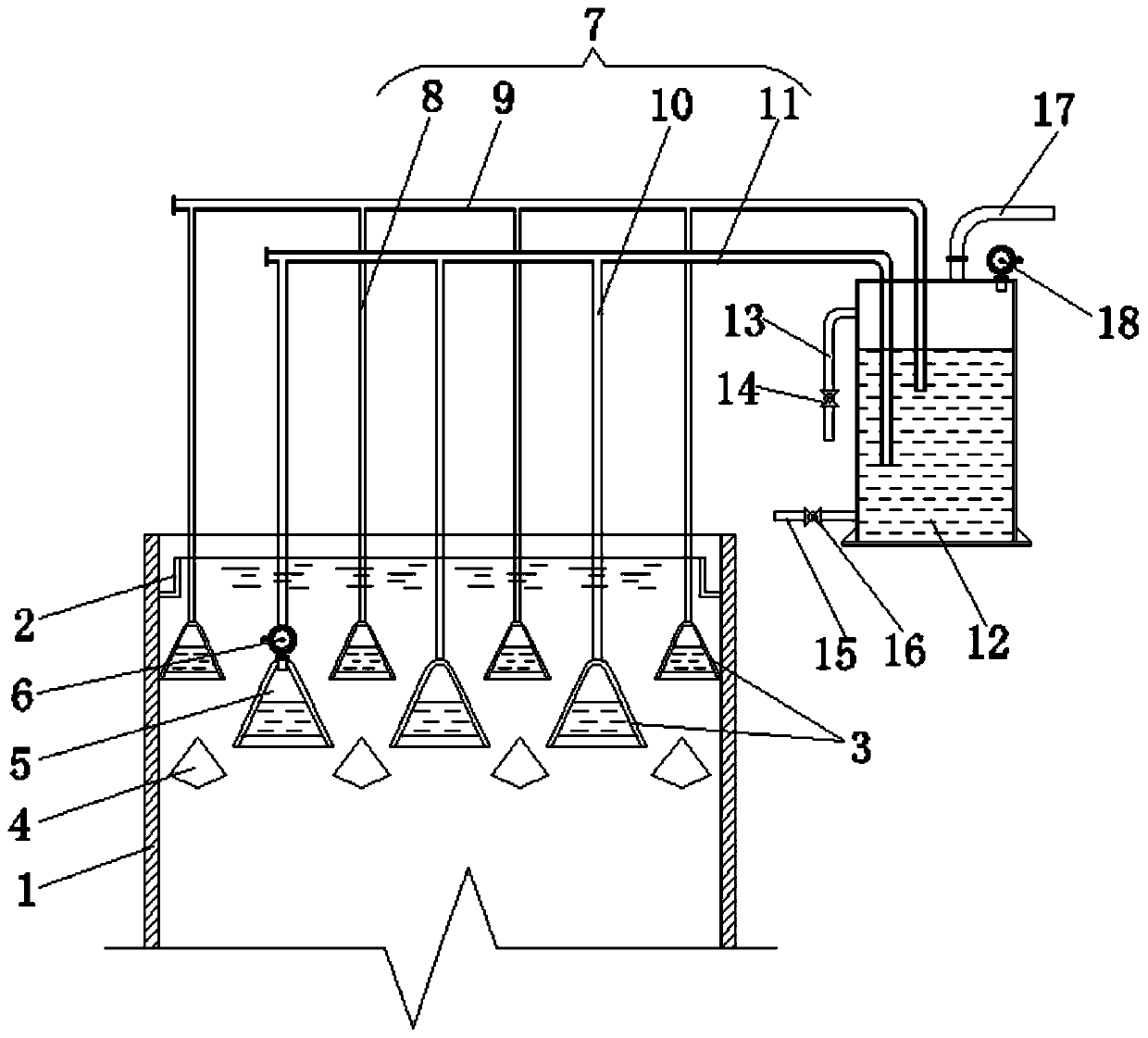

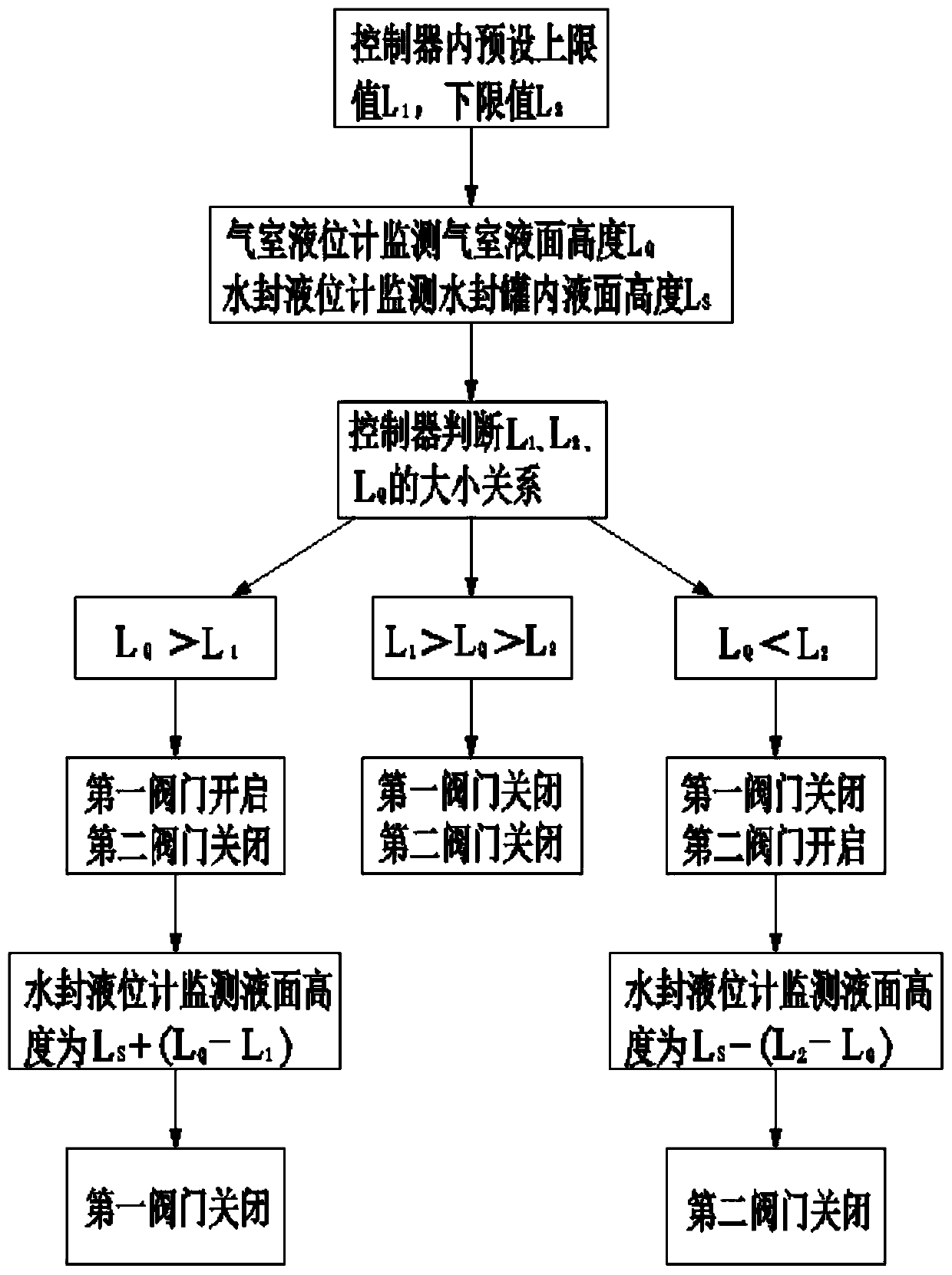

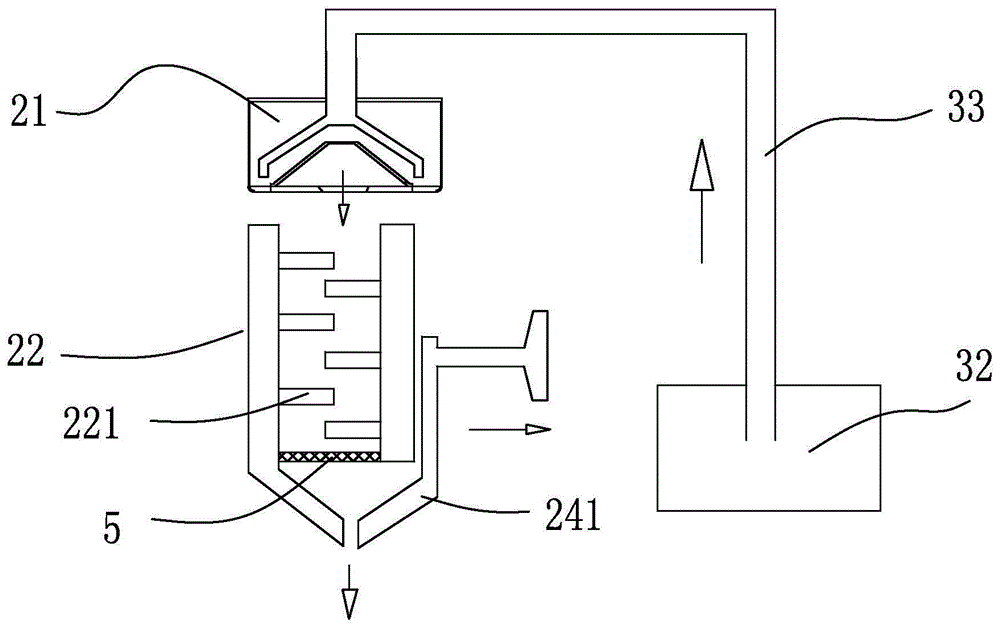

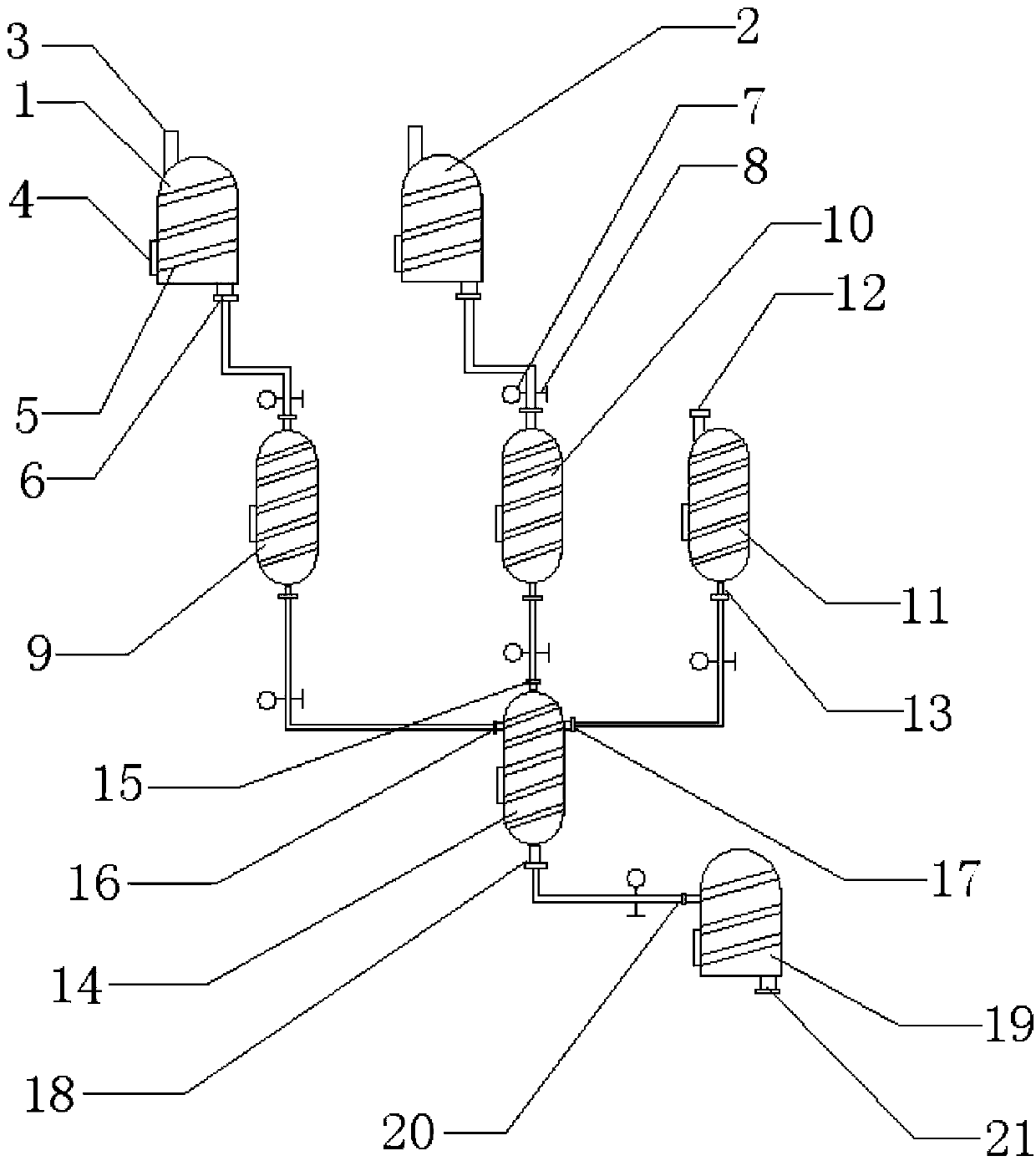

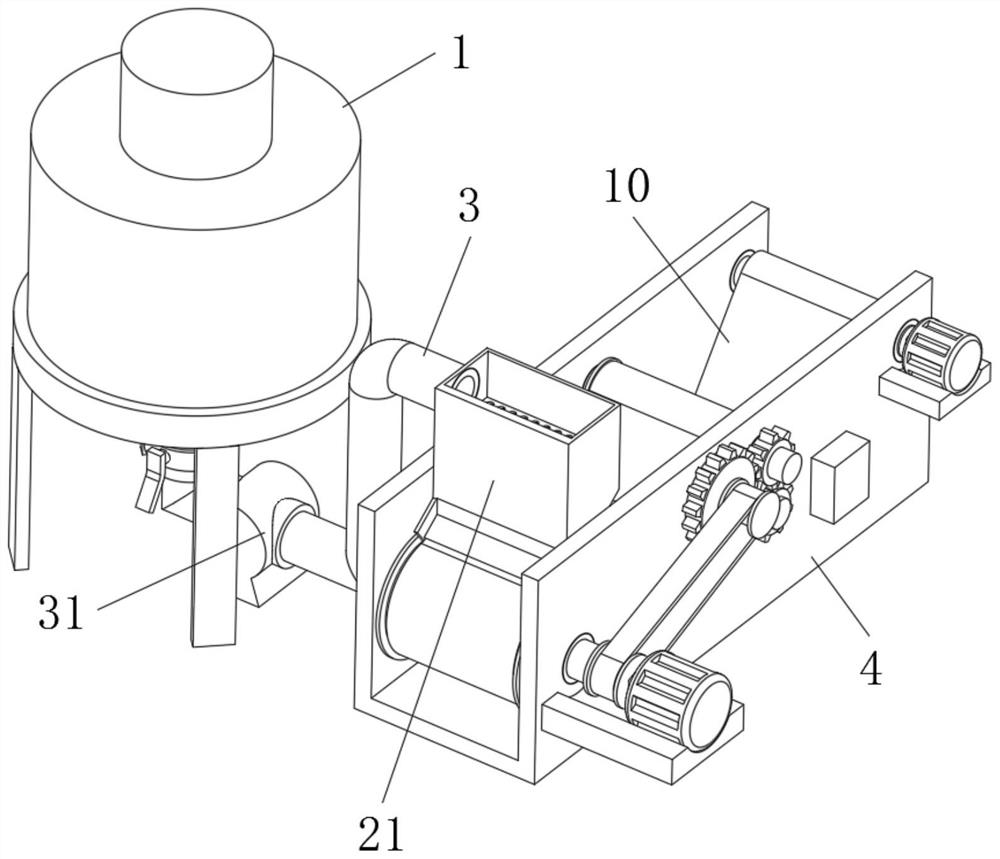

Automatic anaerobic three-phase separation system and control method

InactiveCN110745942AAutomatic pressure adjustmentReal-time monitoring of liquid levelWater treatment parameter controlTreatment with anaerobic digestion processesThermodynamicsEngineering

The invention relates to an automatic anaerobic three-phase separation system and a control method. The system comprises a reactor, a three-phase separator arranged inside the reactor, and a water-sealing assembly and a controller which are arranged outside the reactor, wherein the three-phase separator comprises a plurality of gas collecting hoods arranged in parallel, a gas collecting pipe communicating with the upper ends of the gas collecting hoods, and a gas chamber liquid level gauge installed on the upper end of any one gas collecting hood, the water-sealing assembly comprises a water-sealing tank, and a gas outlet pipe, a water inlet pipe, a water outlet pipe and a water-sealing liquid level gauge which are installed on the water-sealing tank, the gas collecting pipe extends into the water-sealing tank, a first valve is installed on the water inlet pipe, a second valve is installed on the water outlet pipe, and the controller is electrically connected with the gas chamber liquid level gauge, the water-sealing liquid level gauge, the first valve and the second valve, respectively. The three-phase separation system consisting of the three-phase separator with a double-layer inverted V-shaped structure, and a water-sealing tank is adopted, and the gas chamber pressure can be automatically adjusted through the coordinated control of the controller to match system operation.

Owner:苏州红昇环保科技有限公司

Coating circulation system of automatic curtain coating machine

InactiveCN104607362AReduce wasteFast showerLiquid surface applicatorsCoatingsEngineeringLiquid level sensor

The invention discloses a coating circulation system of an automatic curtain coating machine. The coating circulation system comprises two conveying belts, wherein a curtain coating device is arranged above the conveying belts; a coating recovery groove is formed between the conveying belts; the curtain coating device comprises a temporary storage box; the coating recovery groove is communicated with a storage pond; the storage pond is connected with a pump body; the pump body is connected with the temporary storage box by a pipeline; an infrared liquid level sensor is arranged on an inner wall of the temporary storage box and electrically connected with the pump body. Therefore, the waste of paint coatings in a curtain coating process can be reduced.

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

Cracking waste-gas alkaline wash spraying tower for recovery of electromagnetic induction-based battery

PendingCN110694452AReal-time monitoring of liquid levelReal-time monitoringDispersed particle separationStationary filtering element filtersActivated carbonWater storage tank

The invention discloses a cracking waste-gas alkaline wash spraying tower for recovery of an electromagnetic induction-based battery. The tower includes a tower body, a base is fixedly connected to the bottom side of the tower body, and a water storage tank, a first packing plate, a first spraying device, a second packing plate, a second spraying device, a defogging dehumidifying layer, an activated carbon layer and a gas discharge pipe are sequentially arranged in the tower body from the bottom to the top; a filtering screen plate is fixedly connected to the inner side wall of the water storage tank, and the water storage tank is divided into a sewage tank and a water pumping tank by the filtering screen plate; and one side wall, close to the sewage tank, of the tower body is provided with the water discharge pipe communicating with the sewage tank. The tower has a perfect sewage circulation treatment system, can save a large amount of water resources, and has an excellent purification effect on waste gas generated by cracking of the battery; and in addition, the liquid level in the water pumping tank and the concentration of an alkaline liquid contained in a spraying liquid can be conveniently monitored in real time to determine if the spraying liquid needs to be replaced or the alkali concentration needs to be replenished.

Owner:成都六九一四科技有限公司

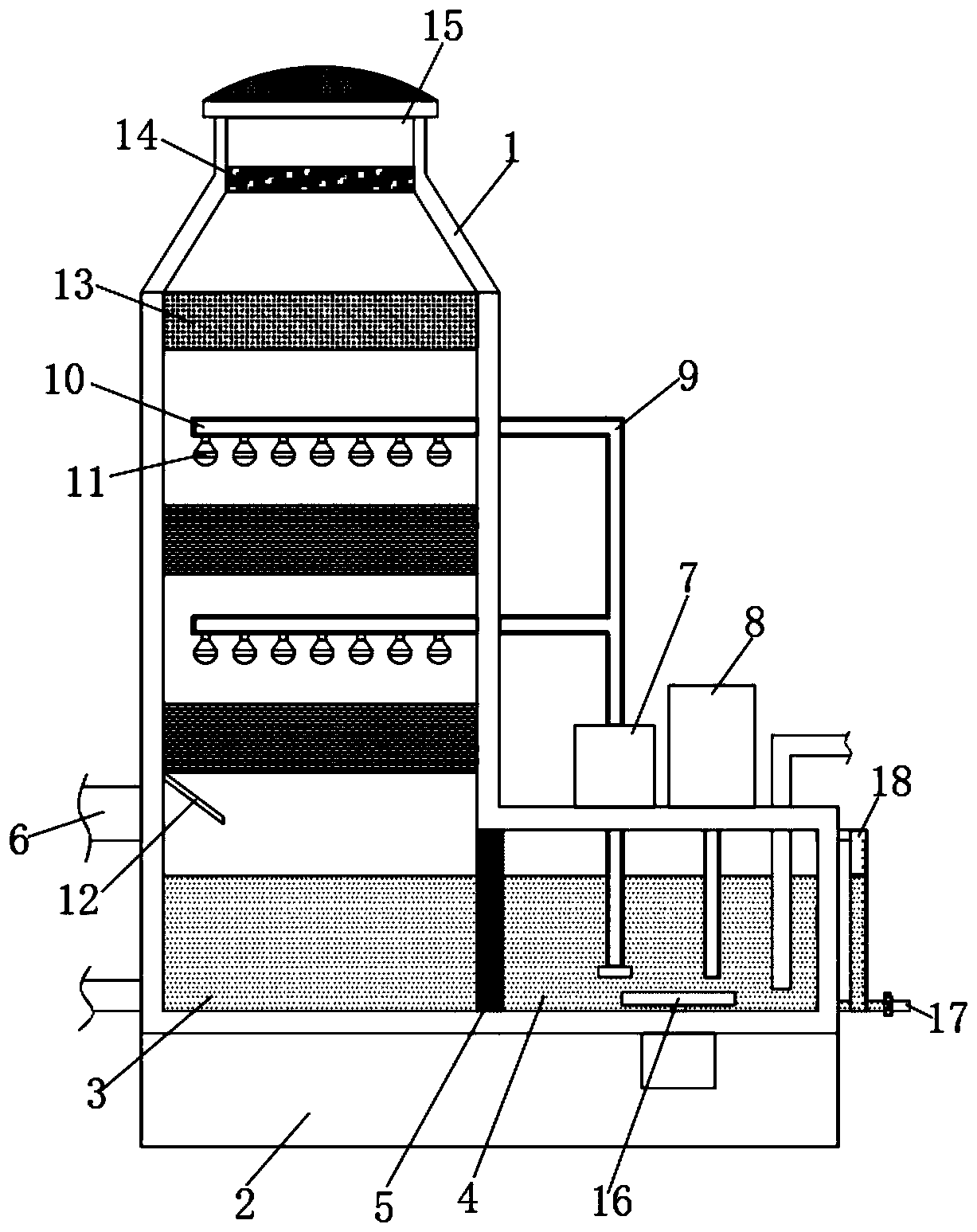

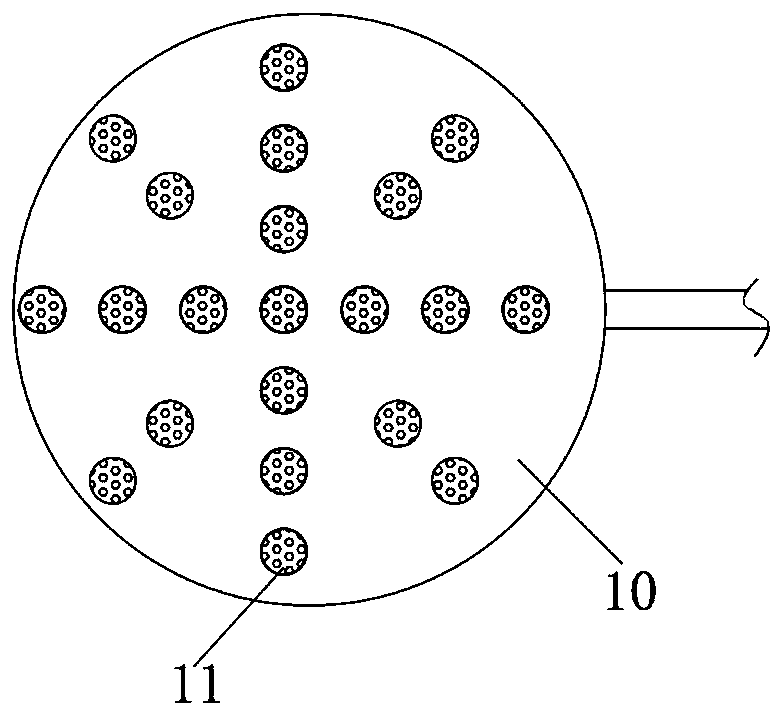

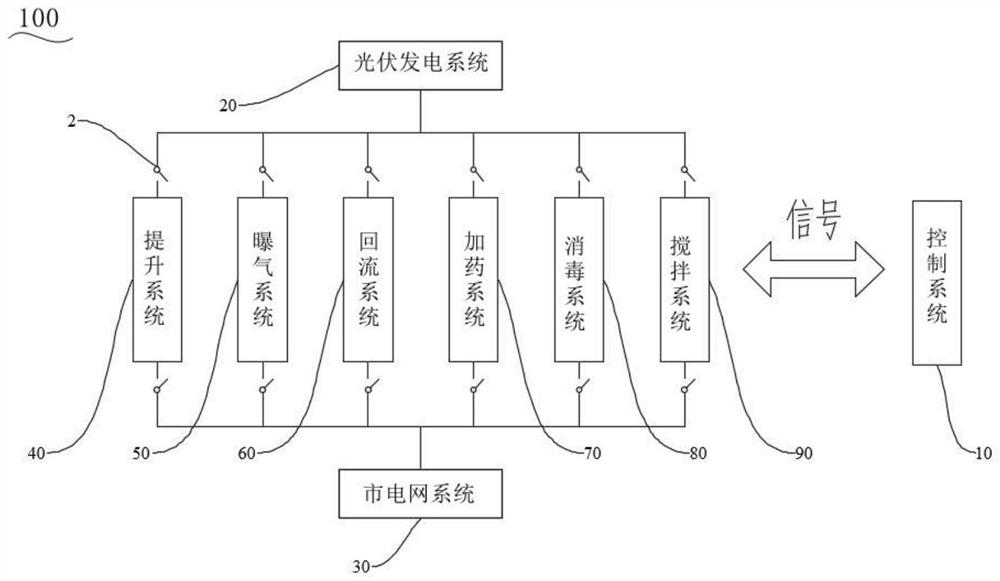

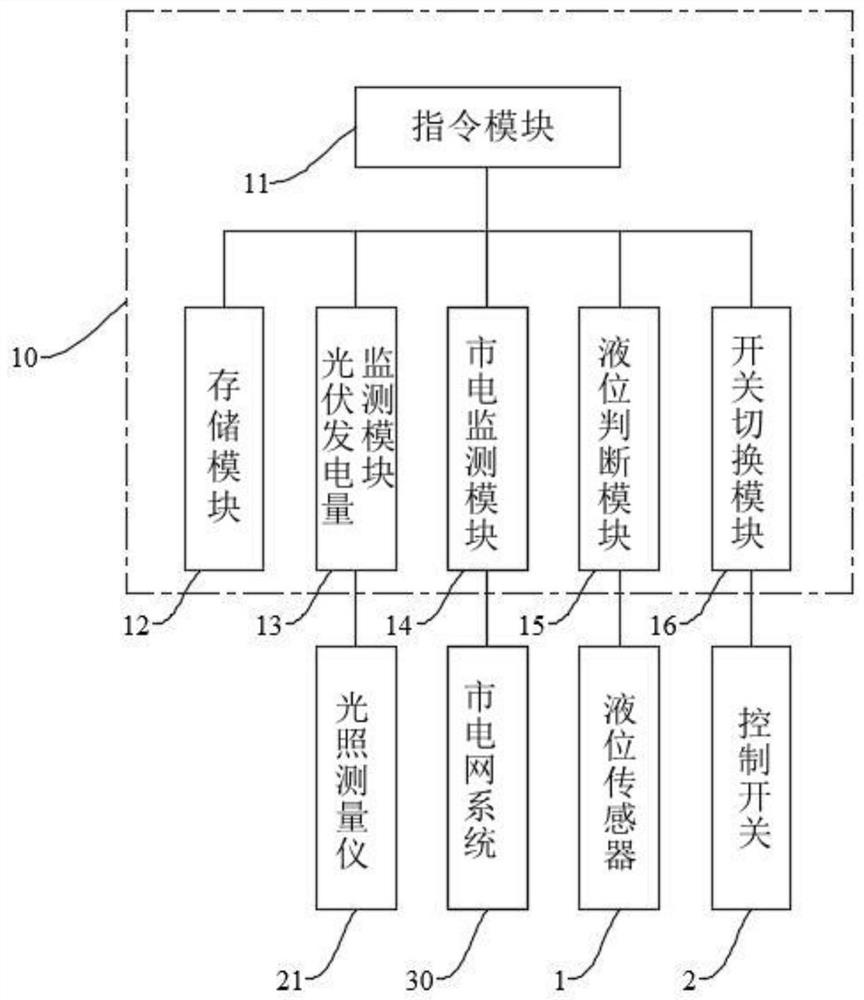

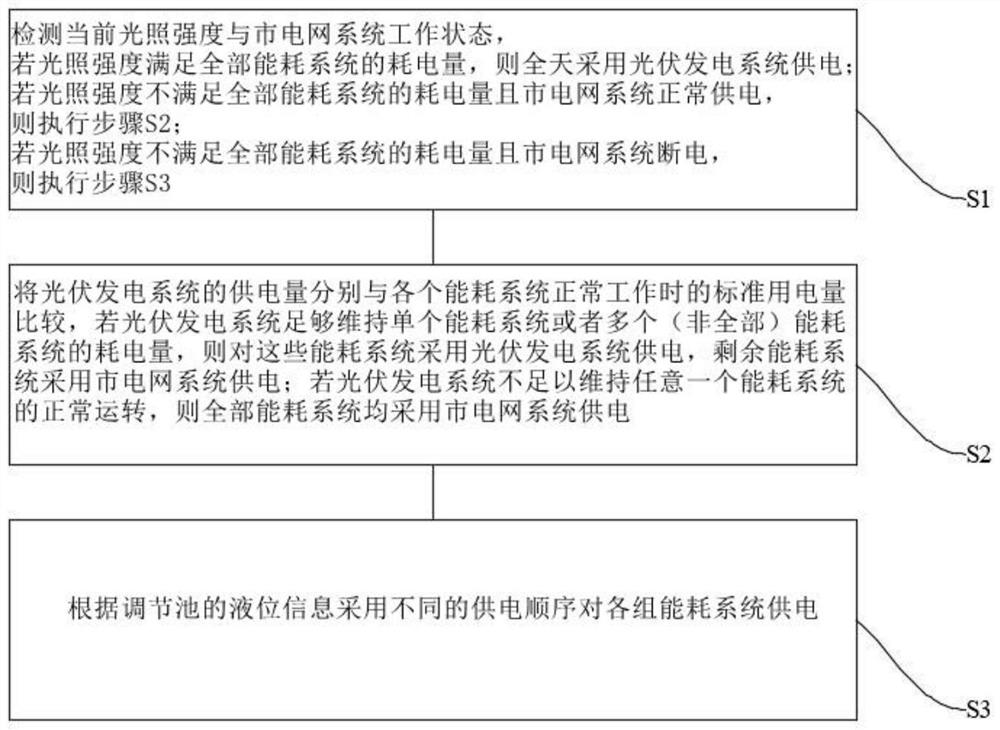

Photovoltaic power generation sewage treatment integrated equipment and control method thereof

ActiveCN114772815AImprove operational efficiencyReduce operating energy consumptionWater treatment parameter controlBatteries circuit arrangementsControl engineeringPower grid

The invention discloses photovoltaic power generation sewage treatment integrated equipment and a control method thereof, an energy consumption part of the integrated equipment is sequentially divided into various energy consumption systems, and when the illumination intensity is strong enough, a photovoltaic power generation system is adopted to supply power all day long; when the photovoltaic power generation system is weak and the commercial power grid system normally supplies power, the power supply proportion of the photovoltaic power generation system and the commercial power grid system is reasonably distributed according to different energy consumption systems according to the power supply amount of the photovoltaic power generation system; and when the photovoltaic power generation system is weak and the commercial power grid system is powered off, different power supply sequences of the energy consumption system are selected according to the liquid level height of the regulating reservoir so as to realize ordered single power supply of the photovoltaic power generation system. Through the mode, a cooperative control mode of the photovoltaic power generation system and the commercial power grid system under different working conditions such as sufficient illumination, insufficient illumination and commercial power outage is provided, the operation efficiency of equipment is improved, and the operation energy consumption of the equipment is reduced.

Owner:CHINA CONSTR THIRD BUREAU GREEN IND INVESTMENT CO LTD

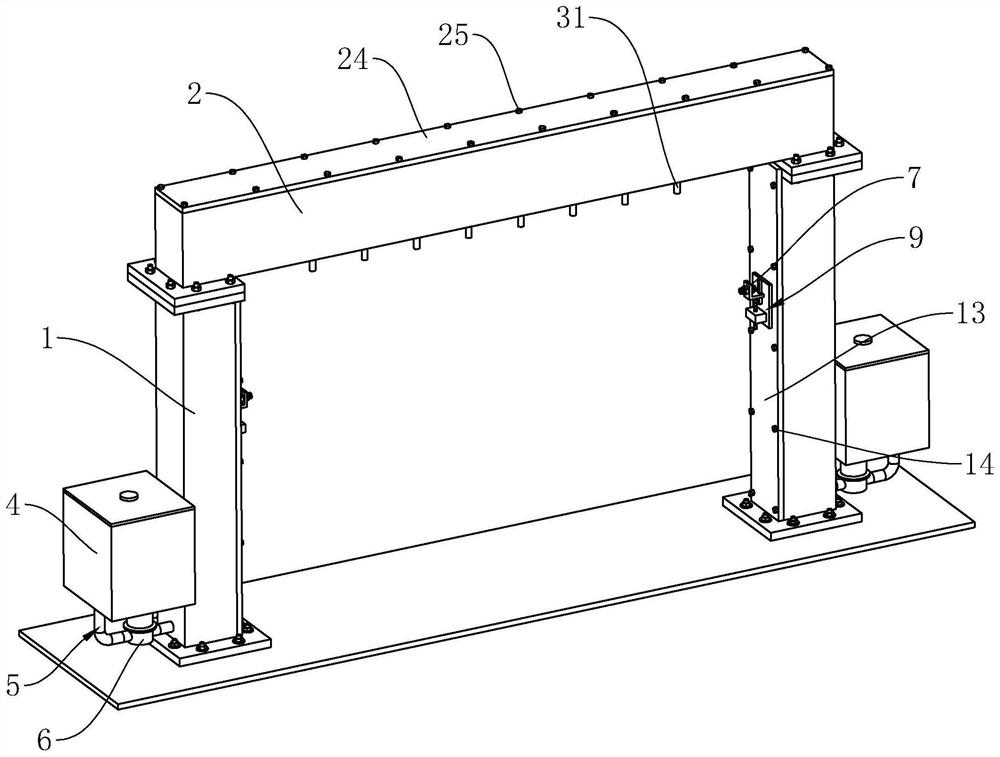

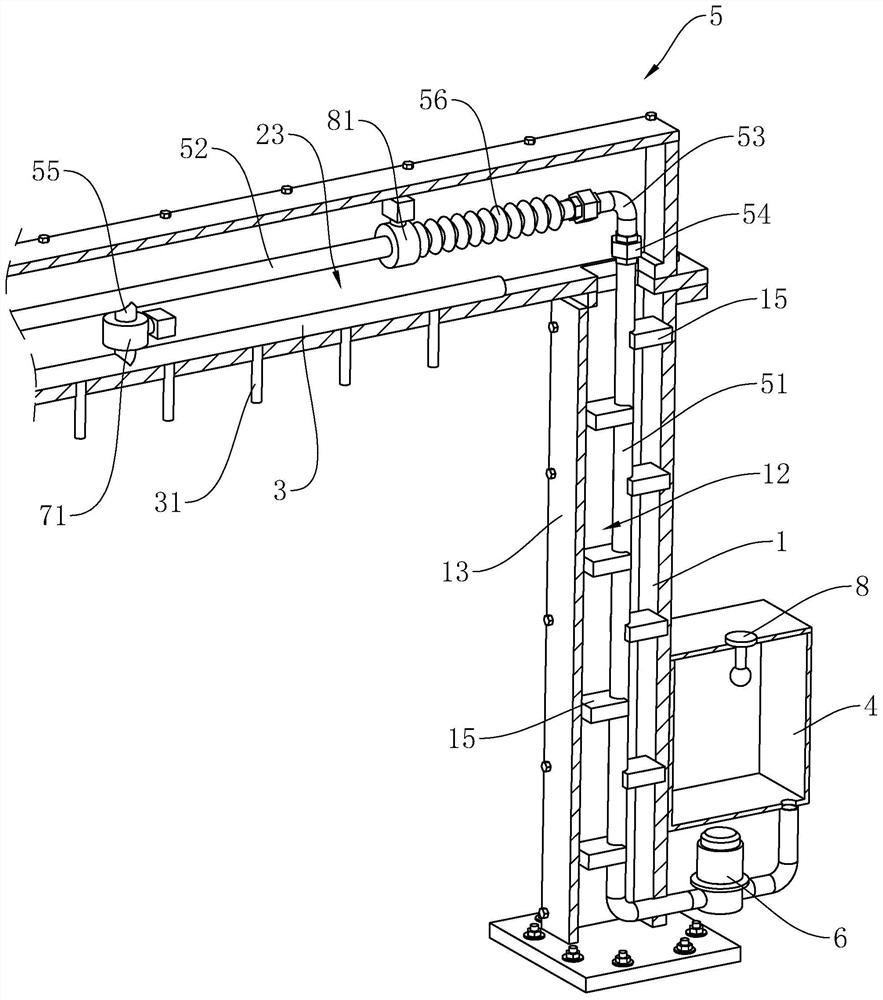

Locomotive anti-freezing solution spraying device and spraying system thereof

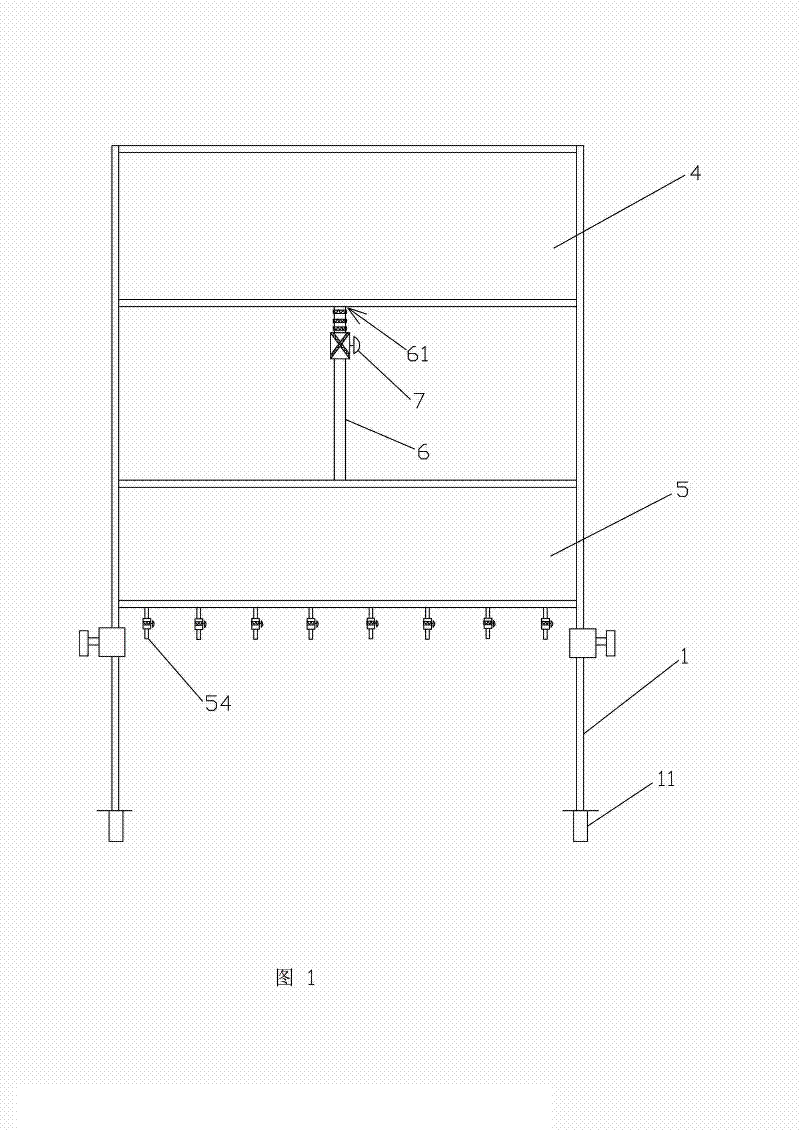

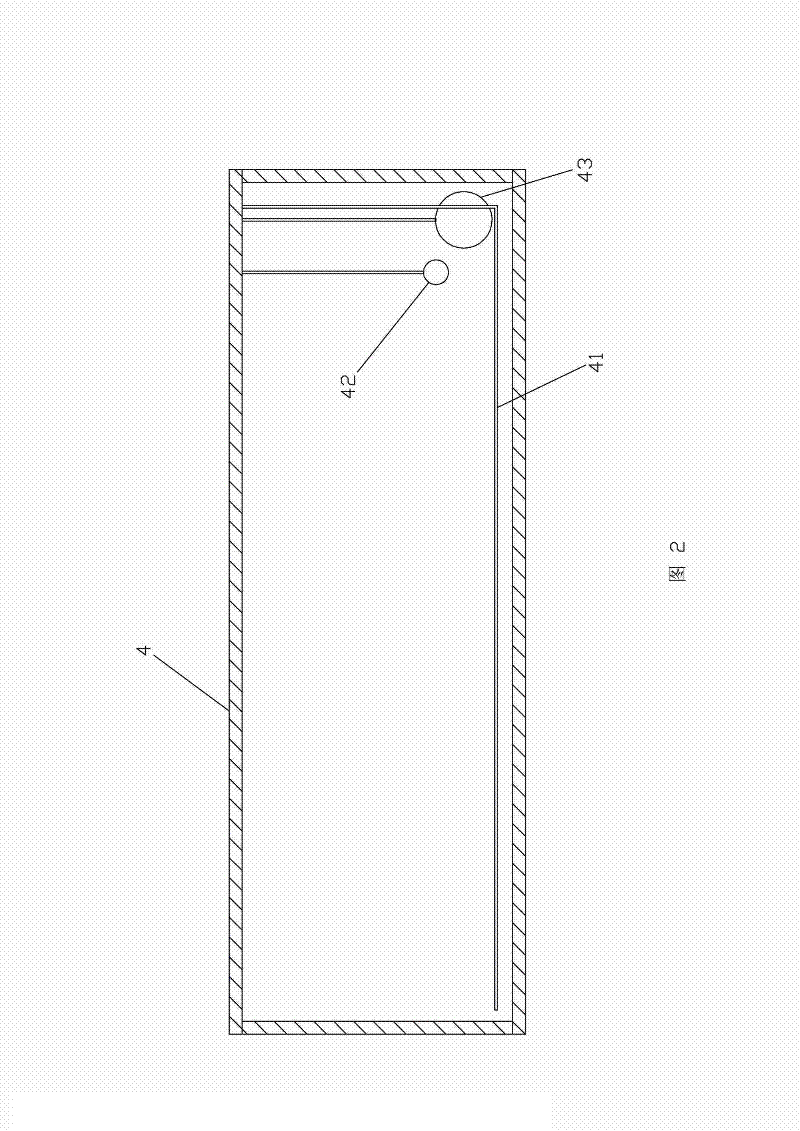

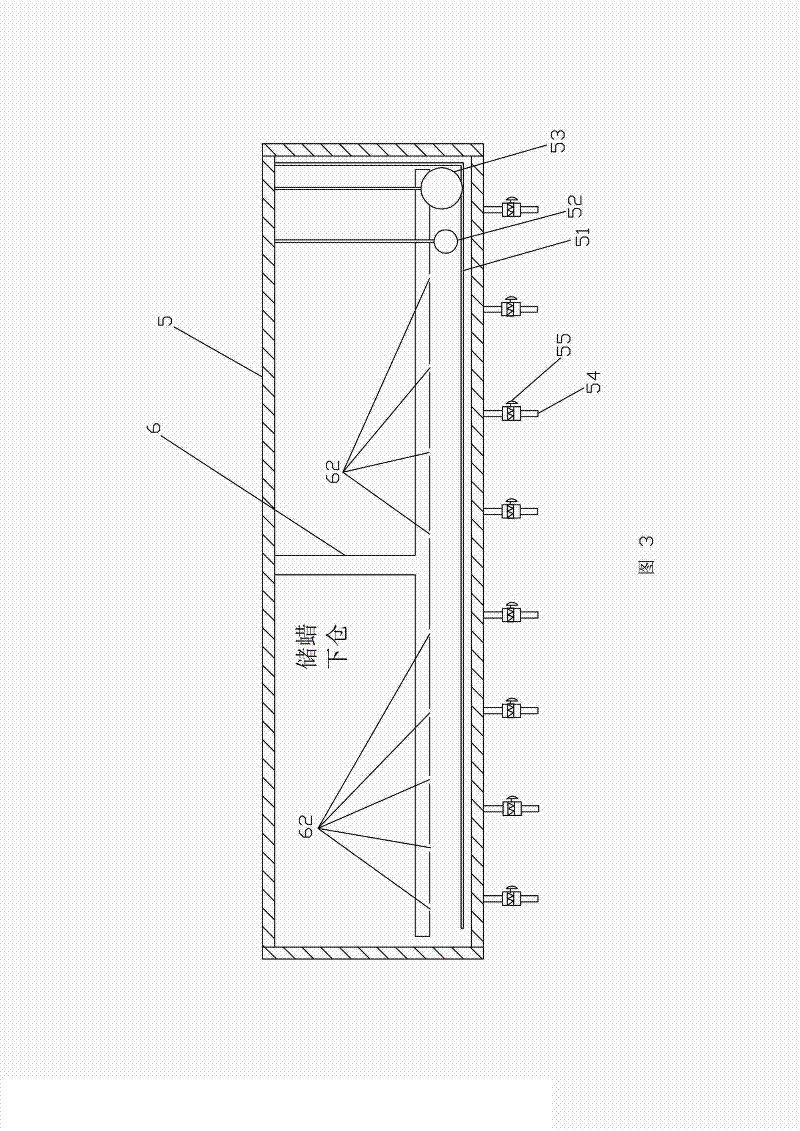

InactiveCN112170039ASimple and fast constructionImprove construction efficiencyLiquid spraying apparatusLiquid storage tankSupport plane

The invention relates to a locomotive anti-freezing solution spraying device and a spraying system thereof. The locomotive anti-freezing solution spraying device comprises a supporting frame and a spraying mechanism arranged on the supporting frame. The supporting frame comprises two stand columns used for being installed on the two sides of a rail, and a cross beam detachably connected onto the two stand columns in a chained mode. The spraying mechanism comprises a spraying pipe detachably connected onto the cross beam, a plurality of spraying heads arranged on the spraying pipe and providedwith downward spraying openings, two liquid storage tanks arranged on the two stand columns respectively, a conveying pipeline communicating the two liquid storage tanks with the spraying pipe, and awater suction pump arranged on the conveying pipeline. The conveying pipeline is detachably connected with the supporting frame. The locomotive anti-freezing solution spraying device provided by the invention has the effects of being convenient to build and high in construction efficiency.

Owner:盛忆镐科技(江苏)有限公司

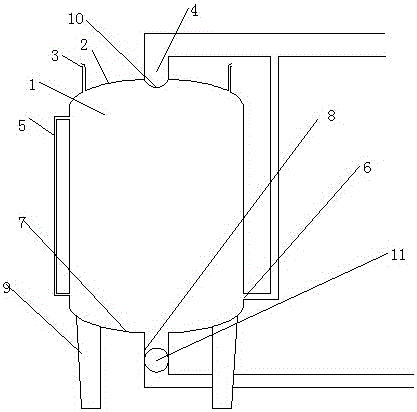

Storage tank storing MBS raw material

InactiveCN105059761ANot prone to precipitationQuality assuranceLarge containersProcess engineeringHolding tank

The invention discloses a storage tank storing an MBS raw material. The storage tank comprises a tank body (1). An upper end socket (2) is arranged at the upper end of the tank body (1). Exhaust ports (3) are formed in the left end and the right end of the upper end socket (2) respectively. A first raw material inlet (4) is formed in the end of the upper end socket (2). A filtering net (10) is arranged below the first raw material inlet (4). A liquidometer (5) is arranged on the left side of the tank body (1). The liquidometer (5) is communicated with the tank body (1) through a pipeline. A second raw material inlet (6) is formed in the right lower side of the tank body (1). A lower end socket (7) is arranged at the bottom of the tank body (1), a raw material outlet (8) is formed in the end of the lower end socket (7), and the lower portion of the raw material outlet (8) is connected with an adjusting valve (11). The storage tank has the beneficial effects that raw material deposition can be reduced, the pressure in the tank can be kept constant, and the phenomenon of wall bonding is reduced.

Owner:湖州杨氏塑料助剂有限公司

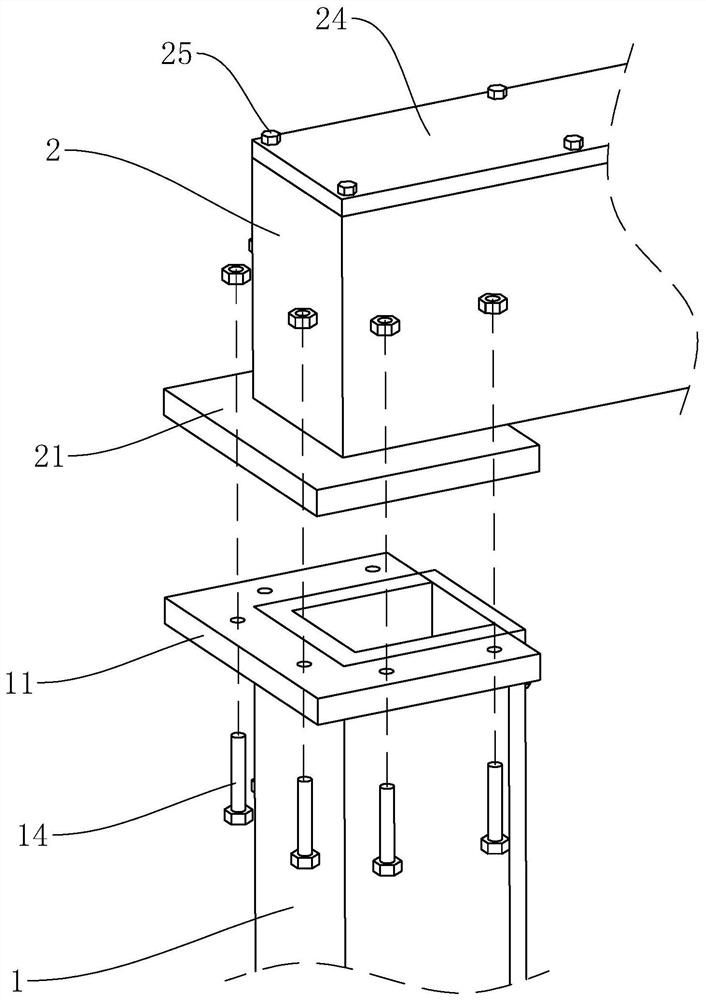

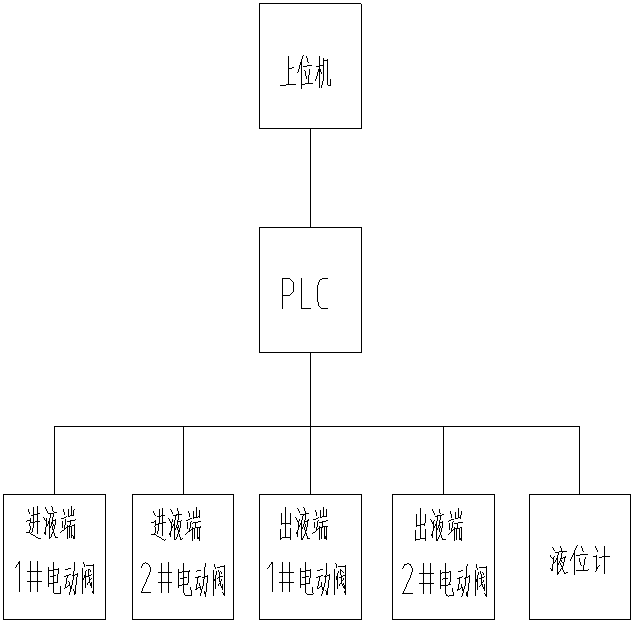

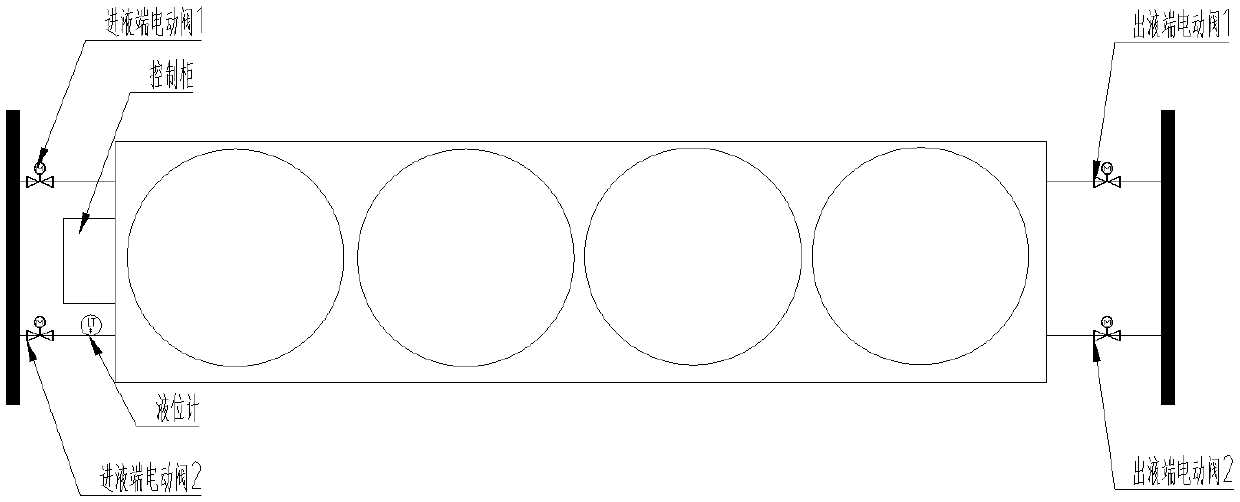

Flexible liquid tank control system

PendingCN110654737AReduce labor intensityAvoid taking timeLarge containersLevel indicators by pressure measurementLiquid tankConnection control

The invention discloses a flexible liquid tank control system which comprises a tank body, an electric valve bank, a liquidometer, a PLC control cabinet and an upper computer, wherein the tank body comprises a plurality of tank cabins connected by bottom manifolds, and a liquid outlet pipeline and a liquid inlet pipeline are separately arranged at the head and tail of the tank body; the electric valve bank is arranged in the liquid outlet pipeline and the liquid inlet pipeline of the tank body for controlling input and discharge of an oil liquid; the liquidometer is arranged in the liquid outlet pipeline for metering the oil liquid level in the current tank body; the PLC control cabinet is mounted at the bottom of the tank body, and the PLC control cabinet is electrically connected to theelectric valve and the liquidometer; and the upper computer is connected to the PLC control cabinet and controls the electric valve according to the liquid level information to adjust the liquid levelheight in the tank body automatically. As the PLC controller is connected to the upper computer to control a valve at the liquid outlet end and a valve at the liquid inlet valve of the liquid tank inreal time, so that remote liquid supply and drainage are controlled, and the labor intensity of an operator is reduced. Meanwhile, by arranging the liquidometer, the liquid level condition in the tank can be monitored in real time, so that the liquid tank is prevented from being evacuated.

Owner:SICHUAN HONGHUA ELECTRIC

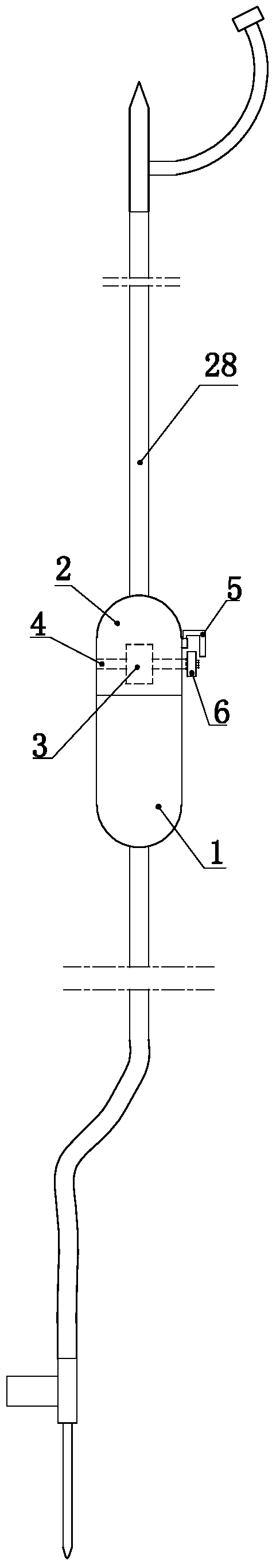

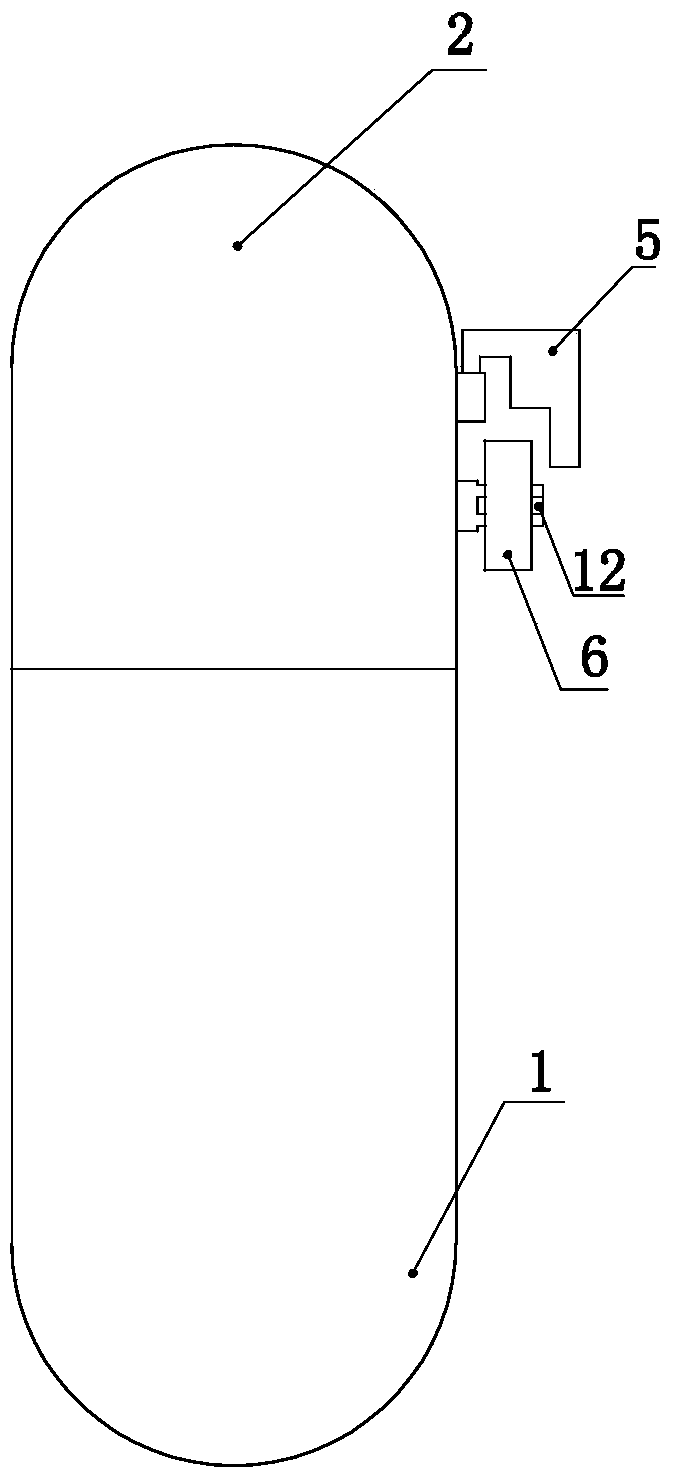

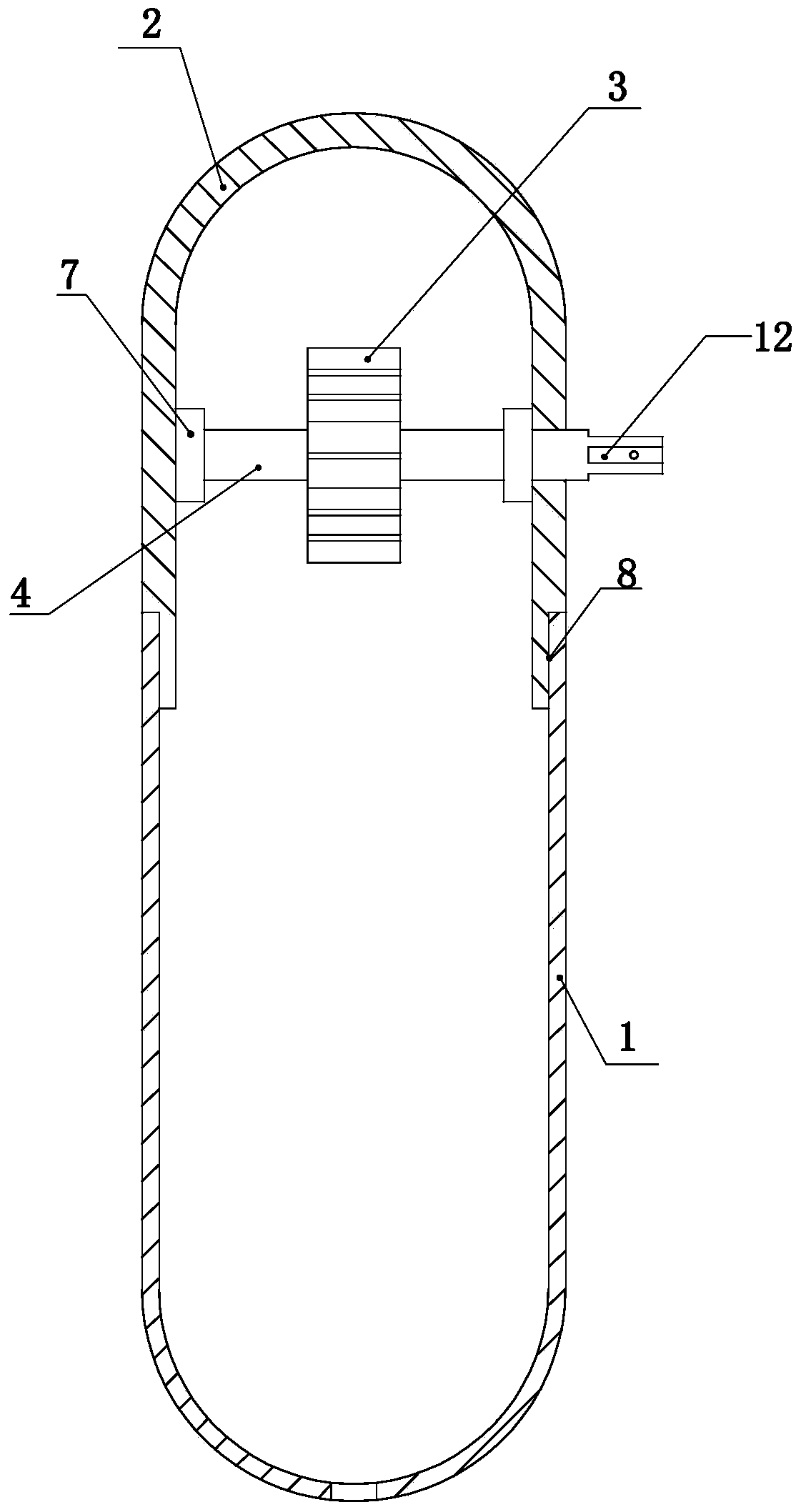

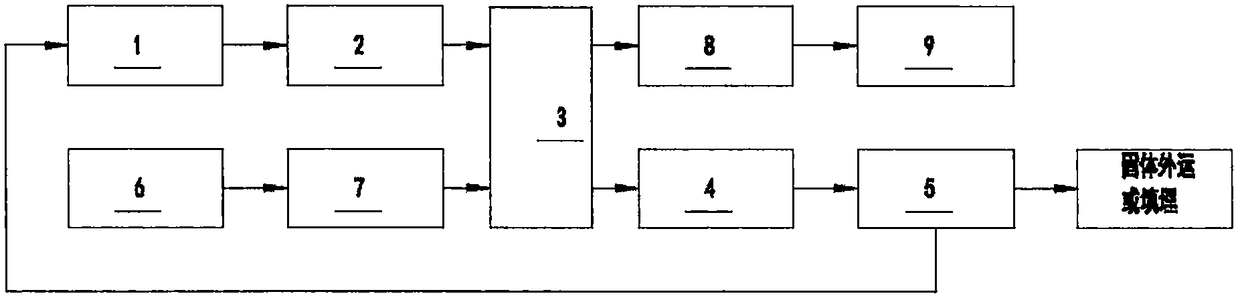

An infusion set with a liquid level monitoring device

ActiveCN104998321BReal-time monitoring of liquid levelEnsure the safety of infusionFlow monitorsIntravenous needlesWater wheel

Owner:SHANDONG PROVINCIAL HOSPITAL

Desulfurization wastewater flue bypass waste heat wet-process desalination zero-emission system

InactiveCN108911331AEasy to handleRun fastWater/sewage treatment by centrifugal separationWaste water treatment from gaseous effluentsTherapeutic effectSmall footprint

The invention provides a desulfurization wastewater flue bypass waste-heat wet-process desalination zero-emission system. The system is characterized in that an adjusting tank, a circulating pump, anevaporation chamber, a pH adjusting device and a centrifugal dehydrator are sequentially connected; the centrifugal dehydrator is connected with the adjusting tank; and a high-temperature flue-gas bypass baffle door, a booster fan, an evaporation chamber, a low-temperature flue-gas baffle door and a desulfurization tower are connected in sequence. The treatment process of the system is short, theoccupied area is small, the energy consumption is low, the automation degree is high, the operation cost is low, the treatment effect is effectively guaranteed, and the pollution to the environment isreduced.

Owner:厦门派力特科技有限公司

Pathology department specimen soaking device and a using method

PendingCN113281133AImprove storage effectReal-time monitoring of liquid levelPreparing sample for investigationAqueous solutionEngineering

The invention belongs to the technical field of pathology department specimen storage, and discloses a pathology department specimen soaking device and a using method. The pathology department specimen soaking device comprises a box body assembly; a liquid supplementing assembly is installed on one side of the box body assembly; the liquid supplementing assembly comprises a liquid supplementing box, a liquid supplementing bin, a driving part, a piston plate, a liquid inlet end and a check ball, wherein the liquid supplementing box is internally provided with the liquid supplementing bin, the driving part is installed on the outer side wall of the liquid supplementing box, and the piston plate is installed on an output shaft of the driving part; a floating ball in a detection assembly can monitor the liquid level height of a formaldehyde aqueous solution in real time; when the height of the aqueous solution is reduced, the floating ball triggers a switch, the switch controls the driving part on the liquid supplementing assembly to work, the driving part drives the piston plate to work, and the piston plate automatically pumps the formaldehyde aqueous solution into a sample soaking box, therefore, the formaldehyde aqueous solution in the sample soaking box can be always kept at a certain liquid level height, and the storage effect of specimens is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

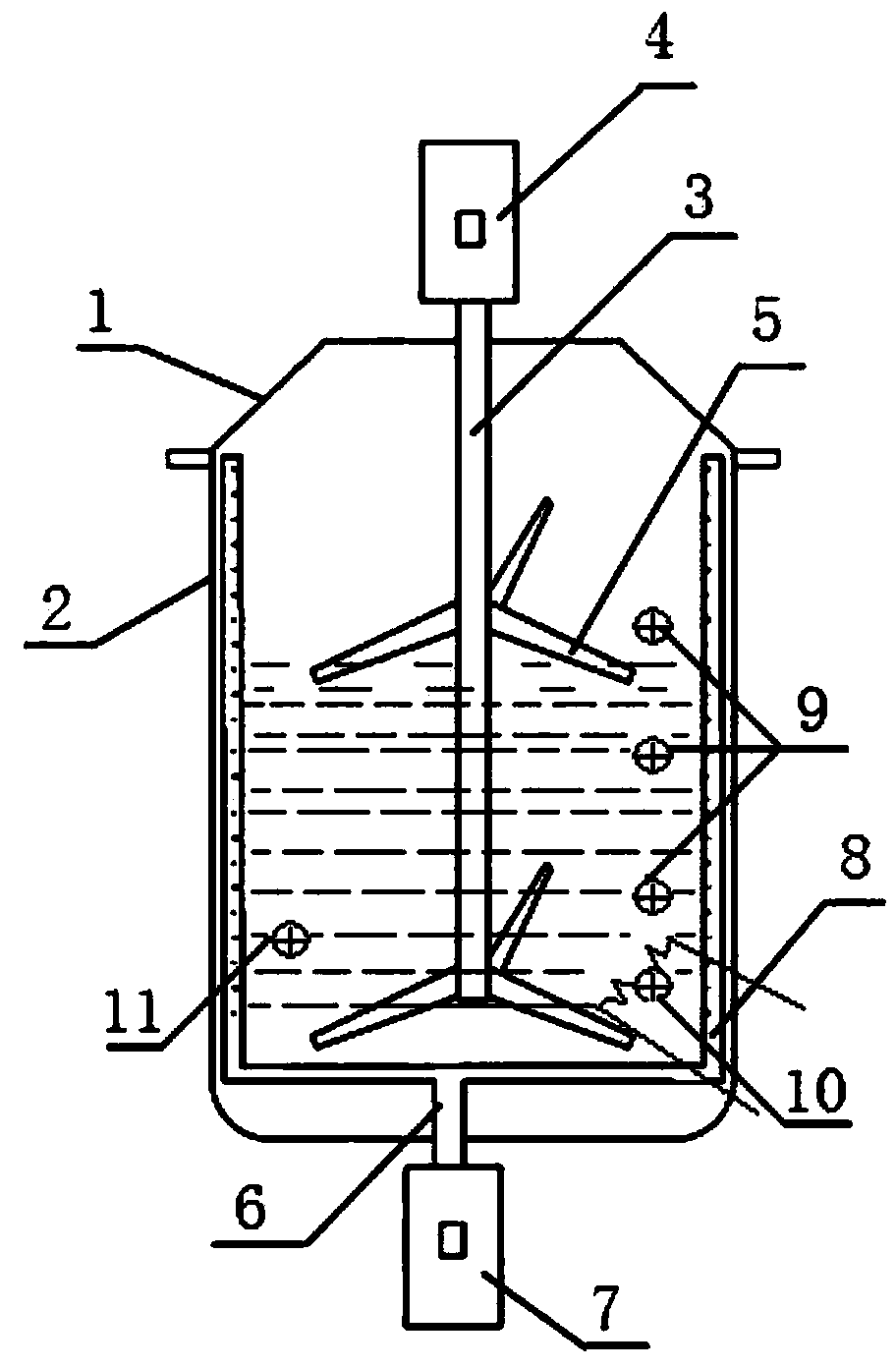

New aliphatic polyurethane paint mixing device

InactiveCN104096500AWell mixedEfficient removalRotary stirring mixersMixer accessoriesDrive motorEngineering

The invention discloses an aliphatic polyurethane paint mixing device, which comprises a kettle and a kettle cover connected to the kettle. The aliphatic polyurethane paint mixing device is characterized in that a stirring shaft penetrates through the kettle cover, the stirring shaft outside the kettle cover is connected to a stirring motor, the stirring shaft inside the kettle cover is provided with a stirring paddle, a rotating wheel is arranged at the center of the bottom of the kettle, the rotating wheel is connected to a scraper which can rotate closely to the inner wall of the kettle, the rotating wheel is connected to a drive motor on the outer side of the kettle, and a liquid level sensor, a heater and a temperature sensor are also arranged in the kettle. According to the aliphatic polyurethane paint mixing device, the materials of the aliphatic polyurethane paint are uniformly mixed, residues on the kettle wall can be effectively cleared, situation of liquid level in the mixing kettle can be monitored in real time, meanwhile required temperature is provided for mixing the aliphatic polyurethane paint, and product quality is ensured.

Owner:苏州多贝机械科技有限公司

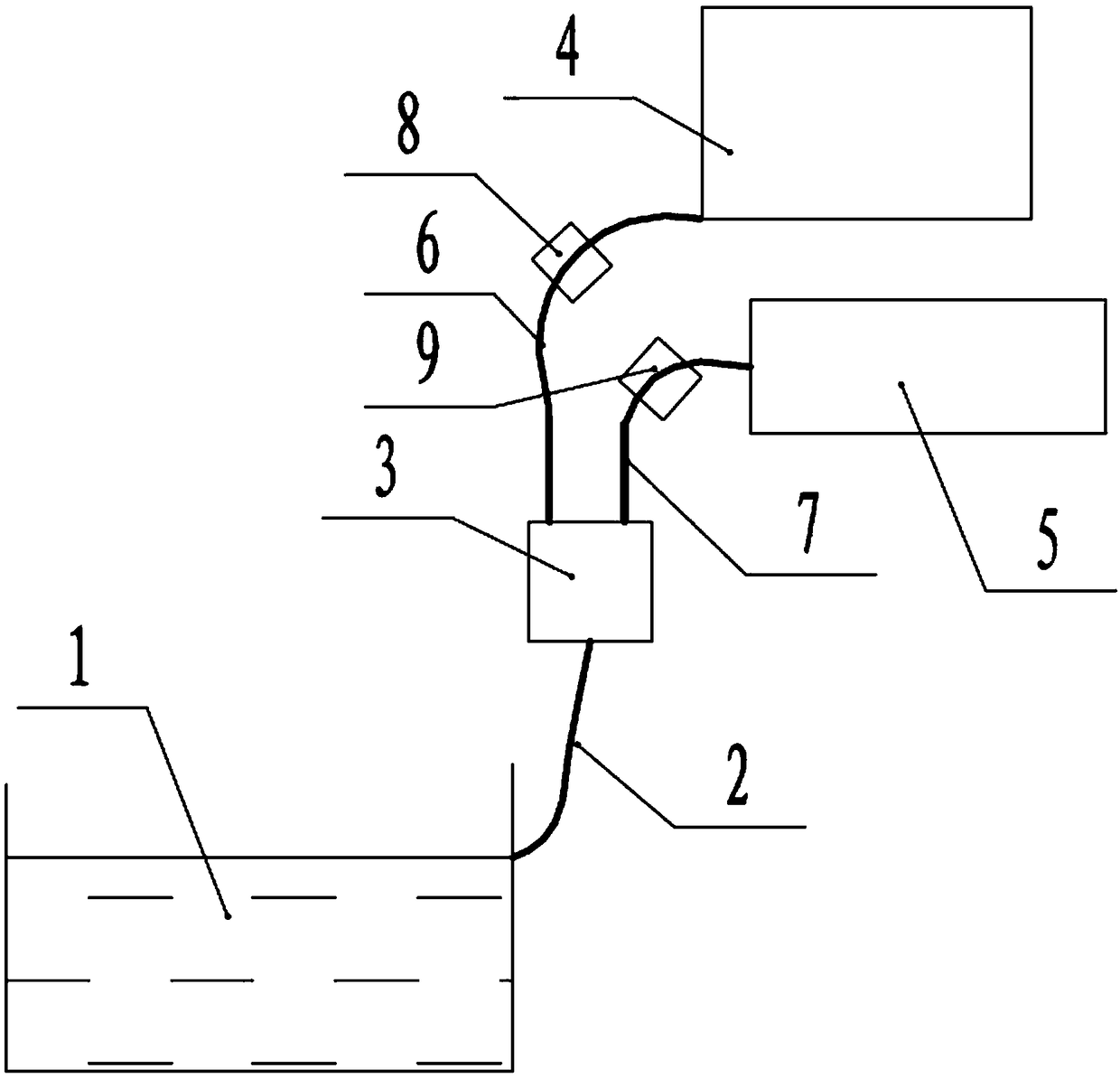

Liquid level online real-time monitoring system for quantitative casting of magnesium alloy

PendingCN111250686AAccurate speed controlPrecise control of working hoursMolten metal supplying equipmentsCasting parameters measurement/indication devicesInfraredControl system

The invention discloses a liquid level online real-time monitoring system for quantitative casting of a magnesium alloy. The liquid level online real-time monitoring system comprises a PLC control system and an infrared position detecting instrument. The infrared position detecting instrument is arranged over a smelting furnace and is used for collecting liquid level height data of the smelting liquid in the smelting furnace and sending collected data to a PLC control system. The PLC control system controls the rotating speed and time of a melt pump according to a preset volume of casting meltand a signal fed back by the infrared position detecting instrument to control the casting amount of magnesium liquid. Infrared rays with relatively strong penetrability are adopted to penetrate through smoke dust so as to monitor the liquid level height of a magnesium solution in real time. Moreover, the liquid level online real-time monitoring system has the characteristics of quick data acquisition, high precision and the like, so that the product quality of a magnesium alloy casting is more reliable, and the magnesium liquid is also saved.

Owner:CHONGQING UNIV +1

New dispensing equipment

InactiveCN103861487AReal-time monitoring of liquid levelPrecisely control the transmission flowMixer accessoriesEmulsificationBiochemical engineeringViscosity

New dispensing equipment includes a preparation tank set, a conveying tank set, a mixing tank and a total storage tank, each tank body is provided with a liquid level meter, external wall of each tank body is provided with a heat tracing pipe coil, each pipe communicating two tank bodies is provided with a flow meter and a valve. The new dispensing equipment has the advantages that: the new dispensing equipment is simple in structure and easy to use, can effectively monitor the liquid level in each tank body in real time, precisely controls material transmission flow, and can avoid the occurrence of viscosity increasing phenomenon of raw materials due to the decrease of temperature.

Owner:TIANJIN BINHAI NEW AREA DAGANG TAIFENG CHEM

Heat storage material compounding and cooling device

PendingCN107661717ACompounding speed increasedAdequate cooling and heat exchangeRotary stirring mixersTransportation and packagingElectricityHeat storage material

The invention discloses a heat storage material compounding and cooling device and relates to the technical field of heat storage material cooling. The heat storage material compounding and cooling device comprises a stirring tank which is used for preparing a heat storage material, a stirring mechanism, a cooling layer and a control component; the stirring mechanism comprises a stirring motor anda stirring shaft; the stirring shaft is provided with a plurality of stirring blades which are arranged at an interval from top to bottom; the cooling layer wraps the outer wall of the stirring tank;a water inlet and a water outlet are formed in the upper part of the cooling layer; the control component is electrically connected with the stirring mechanism. By providing the heat storage materialcompounding and cooling device, stirring the heat storage material by adopting a plurality of stirring blades which are arranged at an interval from top to bottom and cooling the outer wall of the stirring tank by adopting the cooling layer, the problem of slow compounding and cooling speed in the existing heat storage material cooling technology is solved.

Owner:SHENZHEN ENESOON SCI & TECH

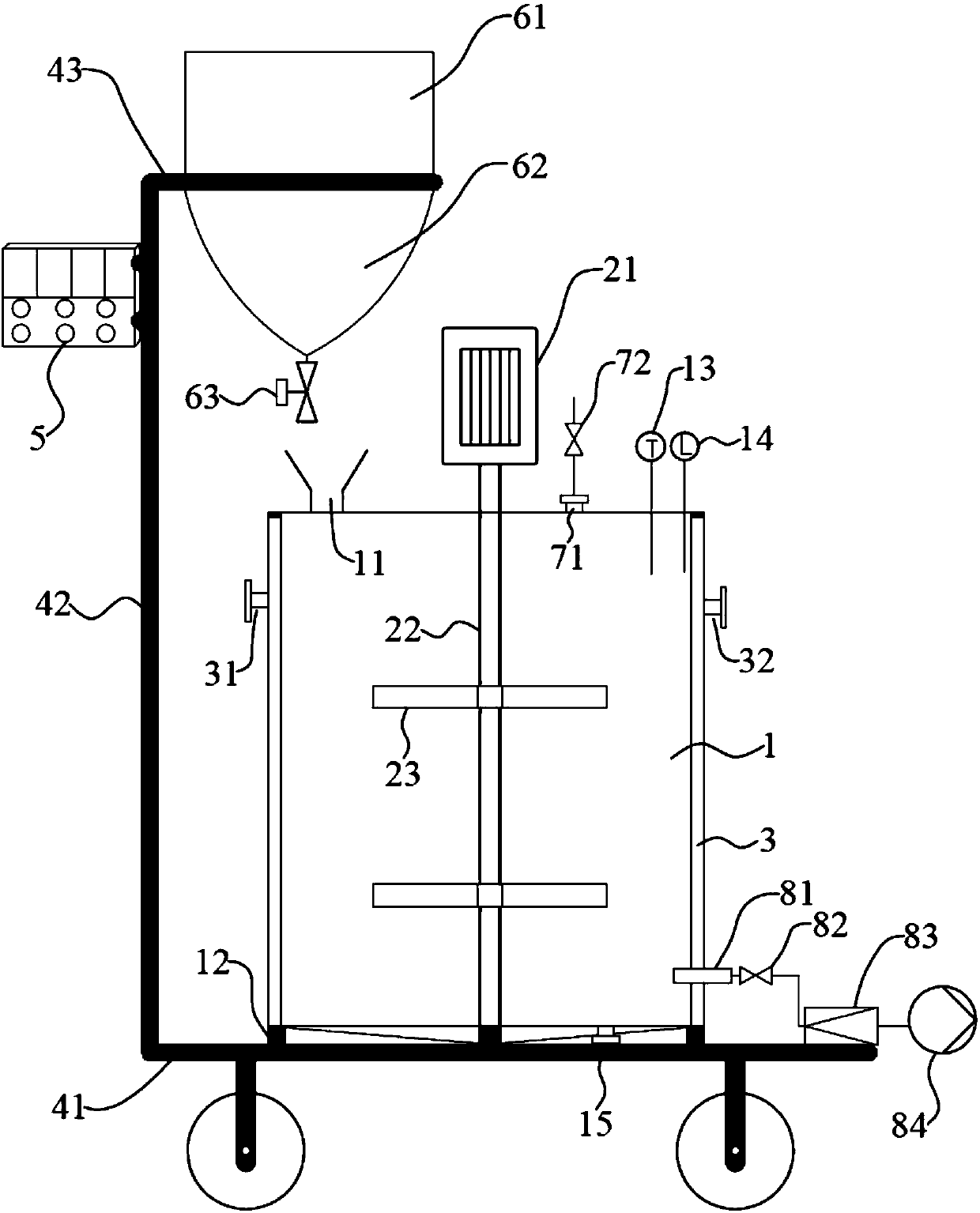

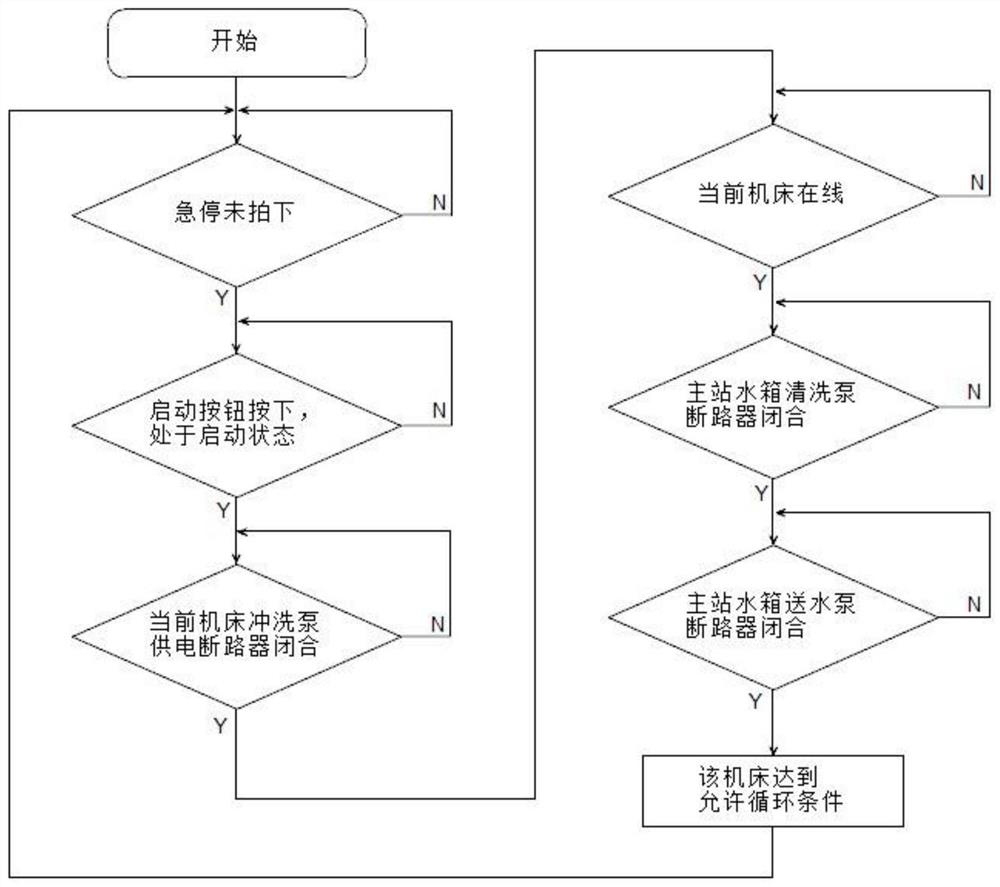

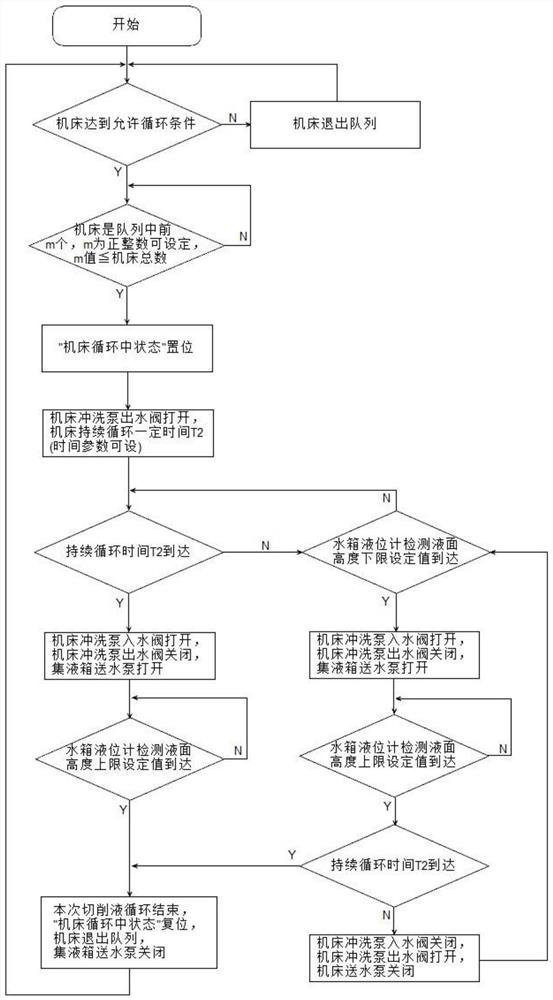

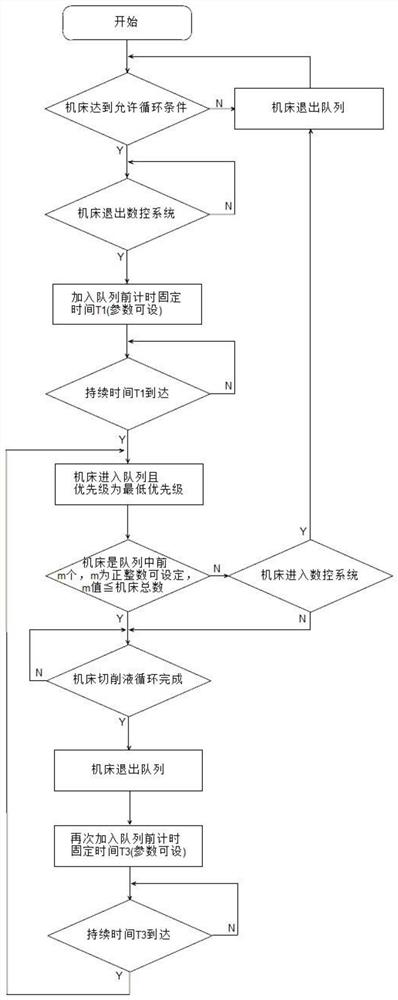

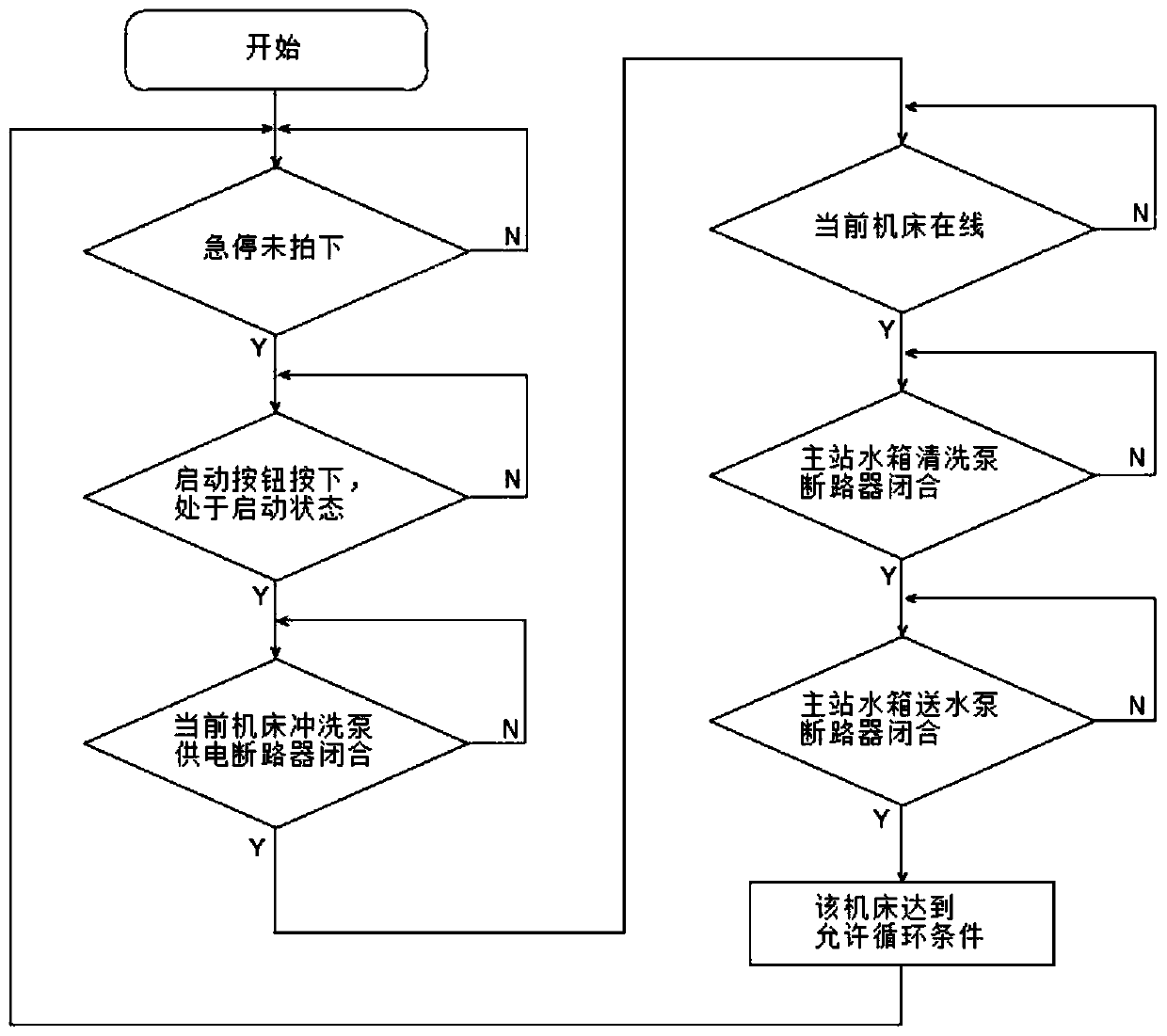

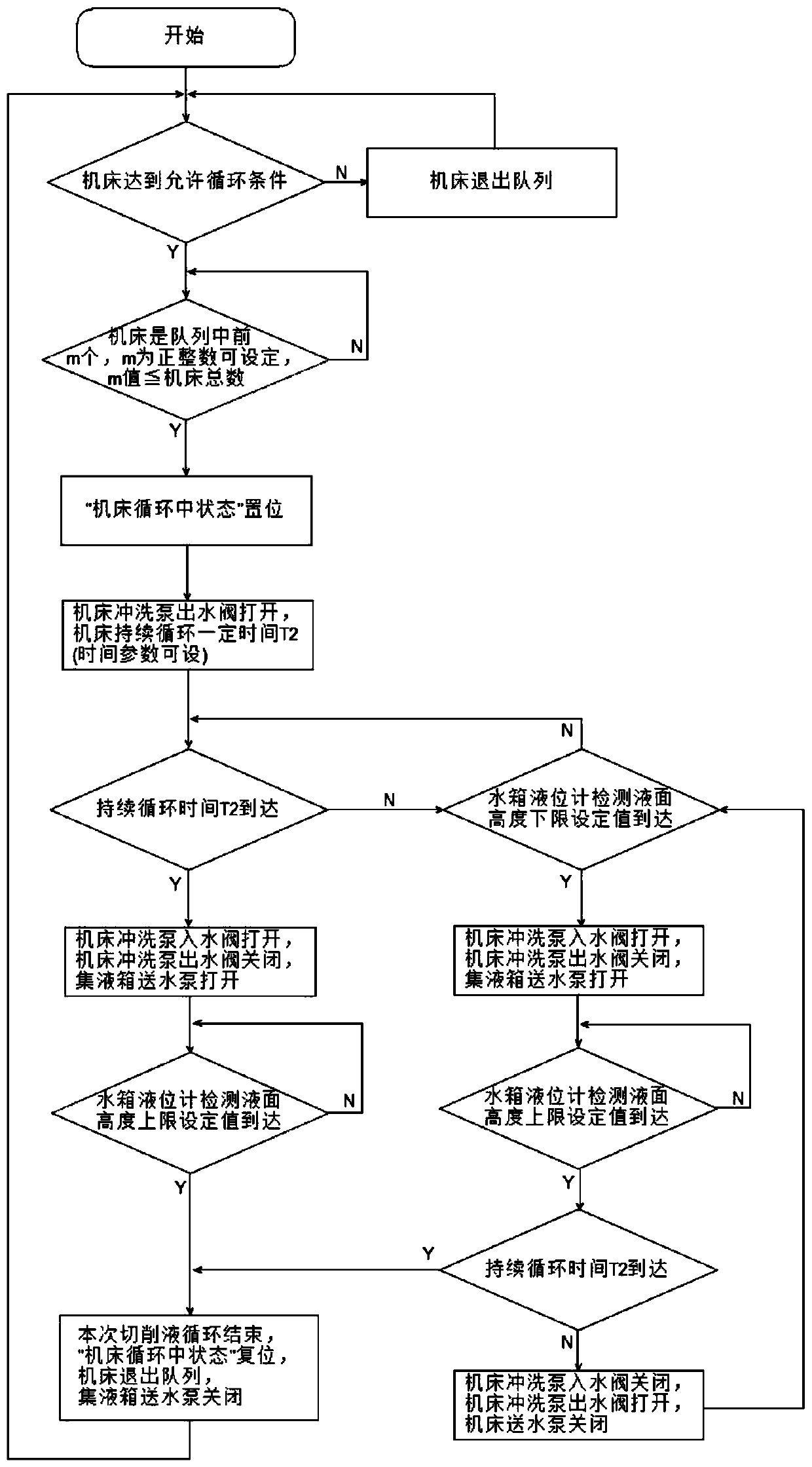

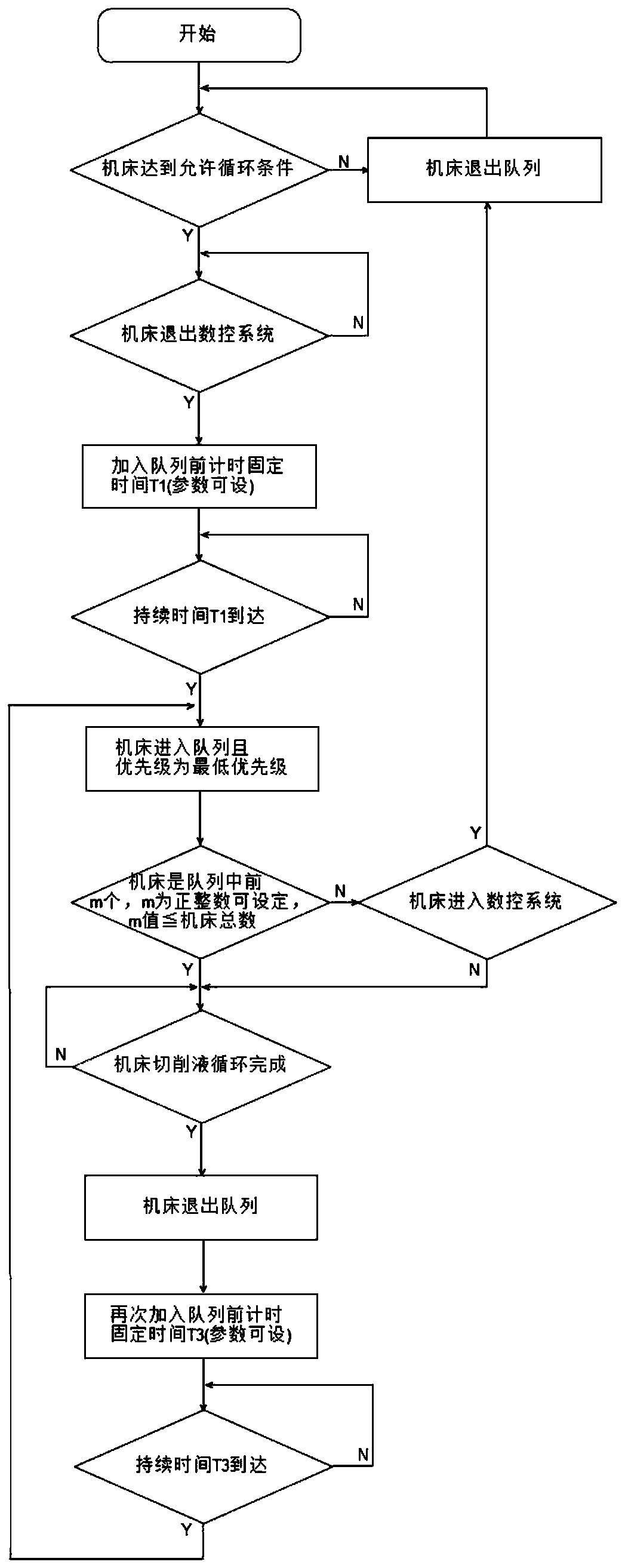

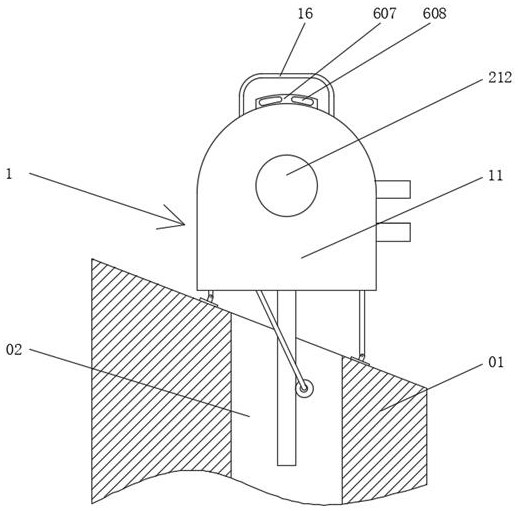

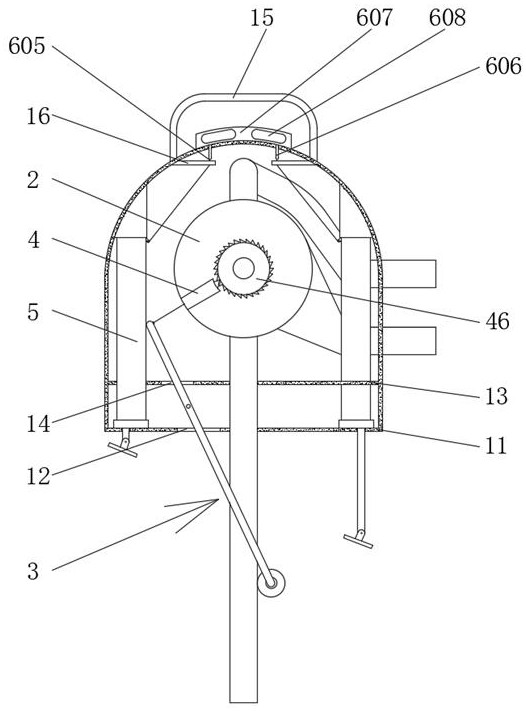

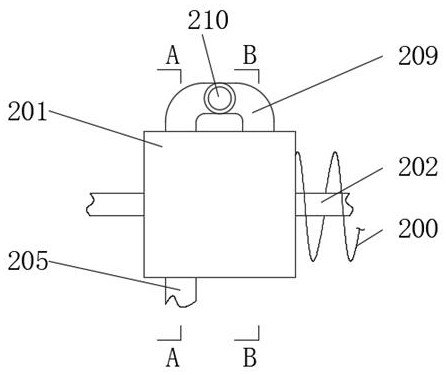

A centralized processing control method for engraving center cutting fluid

ActiveCN110549774BReduce replacement timeExtended service lifeModel makingEngravingEngravingSolenoid valve

The invention discloses a centralized processing control method for cutting fluid in an engraving center, which includes n engraving centers and their cutting fluid water tanks, an electrical control cabinet, a liquid collection tank, a main return liquid pipeline, and a main delivery pipe The liquid pipeline and each branch cutting liquid circuit, the cutting liquid water tank of each engraving center includes a flushing pump, 3 solenoid valves and a liquid level sensor, and the liquid collection tank includes a water delivery pump and a clean water pump And 1 liquid level sensor, n online / offline knobs are installed on the electrical control cabinet to indicate whether the cutting fluid of the water tank of the corresponding engraving center participates in automatic circulation, to detect a single engraving center, and to judge the cutting fluid of the water tank of a single engraving center Whether to participate in the system cycle; add a single engraving center to the cycle queue and update the cycle queue; check the cutting fluid circulation status of the engraving center in the cycle queue, and start material processing. The invention realizes the automatic circulating filtration treatment of the waste cutting fluid of multiple engraving centers.

Owner:西安精雕软件科技有限公司

Centralized treatment control method for cutting fluids of carving centers

ActiveCN110549774AEnsure normal flowAvoid pollutionModel makingEngravingElectrical controlEngineering

The invention discloses a centralized treatment control method for cutting fluids of carving centers. According to the centralized treatment control method, n carving centers and cutting fluid water tanks thereof, one electrical control cabinet, one fluid collecting tank, one main fluid return pipeline, one main fluid conveying pipeline and all branch cutting fluid loops are involved. The cuttingfluid water tank of each carving center comprises one flushing pump, three electromagnetic valves and one liquid level sensor. The fluid collecting tank internally comprises one water conveying pump,one water purification pump and one liquid level sensor; n online / offline knobs are installed on the electrical control cabinet and used for indicating whether or not the cutting fluids of the water tanks of the corresponding carving centers participate in automatic circulation or not, each single carving center is detected, and whether or not the cutting fluid of the water tank of the carving center participates in system circulation is judged; each single carving center joins in a circulation queue, and the circulation queue is updated; the circulation states of the cutting fluids of the carving centers in the circulation queue are detected, and then material processing begins. By means of the method, full-automatic circular filtering treatment on the waste cutting fluids of multiple carving centers is achieved.

Owner:西安精雕软件科技有限公司

Grouting device for hydraulic engineering construction

InactiveCN114319365ASave energyWork lessFoundation engineeringMarine site engineeringArchitectural engineeringSlurry

The grouting device for hydraulic engineering construction comprises a center control integrated device, the center control integrated device comprises a center control box, a fixing through hole located in the left end of the center control box is formed in the bottom face of the center control box, a centralizing plate located at the bottom of the center control box is fixedly connected to the inner wall of the center control box, and an overturning hole located in the left end of the centralizing plate is formed in the centralizing plate; the liquid level height of slurry in a drill hole can be monitored in real time through the monitoring mechanism, so that the state locking mechanism is triggered when necessary, the state of the switching mechanism can be controlled through the state locking mechanism, and the problem that the slurry overflows due to overfilling is solved; the grouting device for hydraulic engineering construction can directly stand on a construction surface around a drill hole, and the standing height of the grouting device for hydraulic engineering construction can be controlled through the standing locking mechanism, so that the grouting device for hydraulic engineering construction is suitable for various complex construction surfaces; and the practicability of the grouting device for hydraulic engineering construction is improved.

Owner:刘丽兵

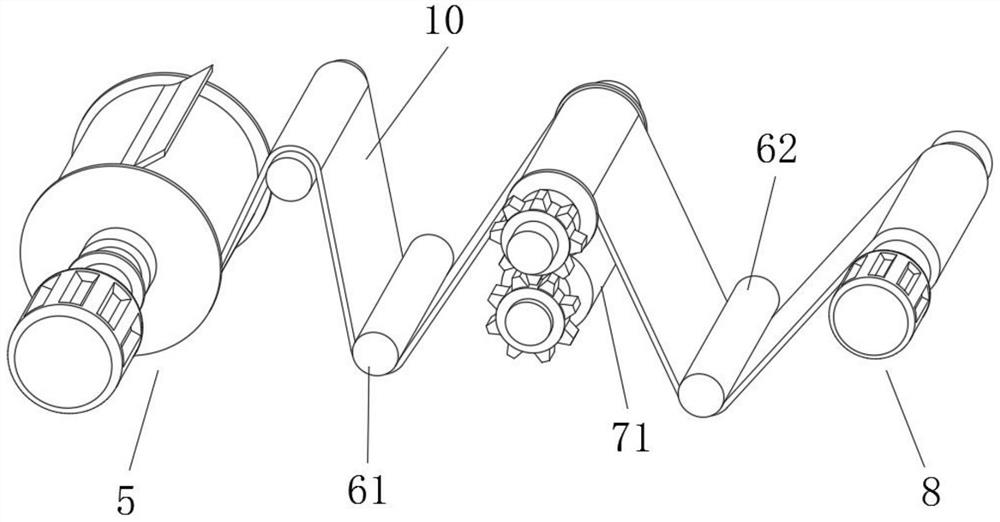

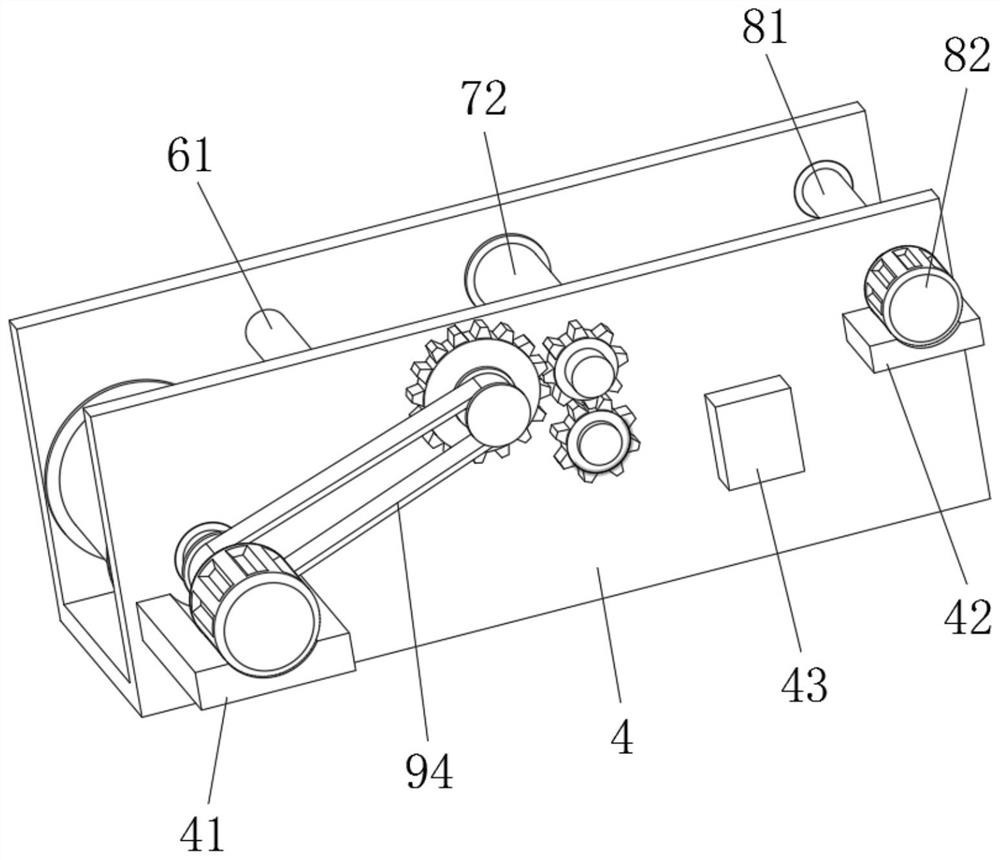

Intelligent rubber production equipment for soft capsule production and rubber production process

PendingCN114767536AChange spacingChange thicknessCapsule deliveryDomestic articlesParaffin oilsProcess engineering

The invention relates to the technical field of soft capsule production, and discloses intelligent rubber production equipment for soft capsule production and a rubber production technology.The intelligent rubber production equipment comprises a glue solution preparation pot, a heating and stirring mechanism is arranged in the glue solution preparation pot, a conveying pipe is arranged at the bottom end of the glue solution preparation pot, and a conveying pump is arranged on the surface of the conveying pipe; a thickness adjusting mechanism is arranged at the output end of the conveying pipe, rubber is arranged at the output end of the thickness adjusting mechanism, a supporting seat is arranged at the bottom of the thickness adjusting mechanism, and a forming mechanism, a guide rod, a waxing mechanism, a winding mechanism and a transmission mechanism are arranged between the two side walls of the supporting seat. According to the intelligent rubber production equipment for soft capsule production, rubber with different thicknesses is manufactured by adjusting the distance between a pressing plate and a discharging inclined plate, a cooling system is arranged in a forming roller, condensate water circularly flows in a spiral water pipe, glue liquid on the surface of the forming roller is rapidly cooled and formed, and the production efficiency is improved. Paraffin oil is uniformly smeared on the surfaces of the rubber sheets through rotation of the waxing roller, and the rubber sheets are prevented from being adhered together.

Owner:李加龙

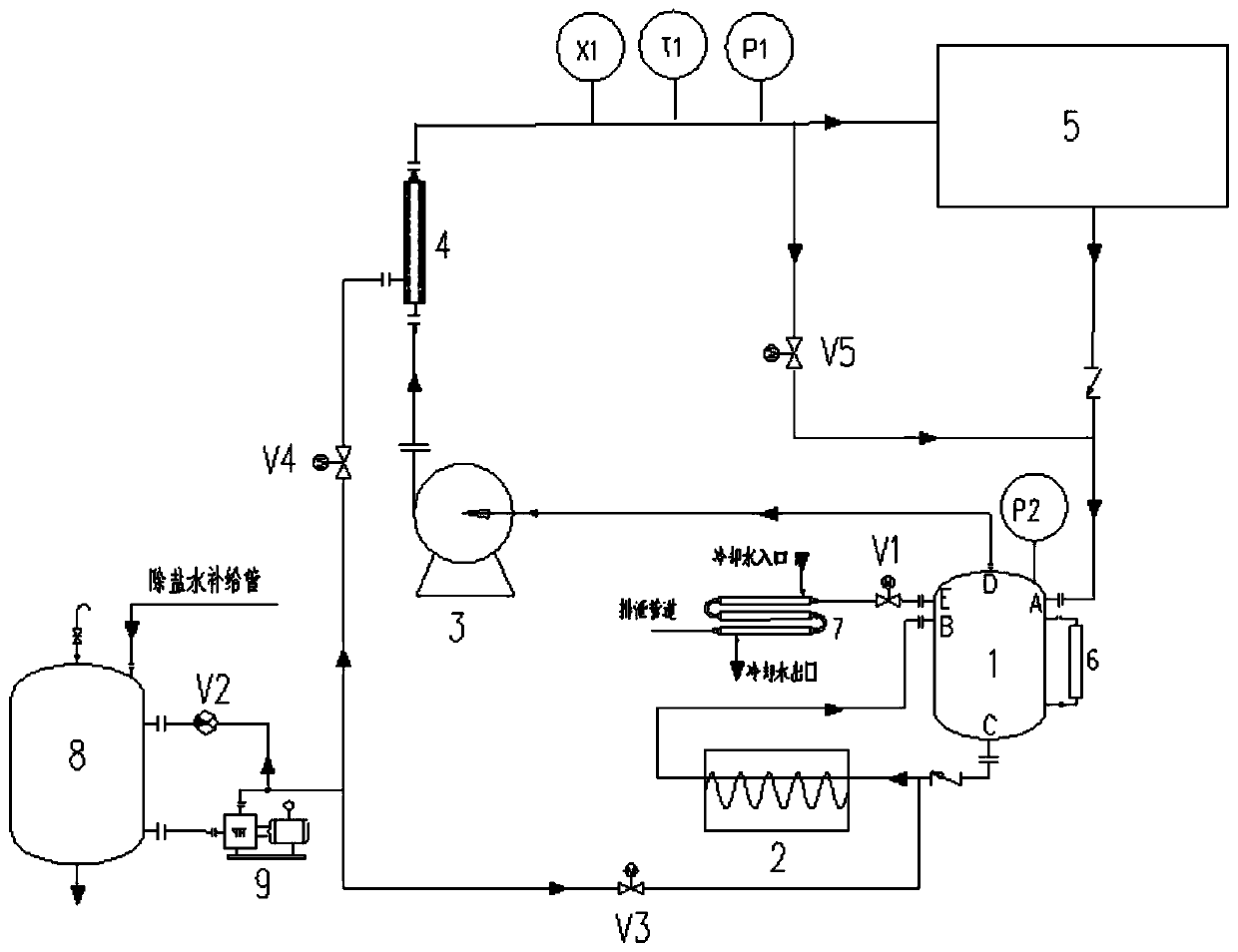

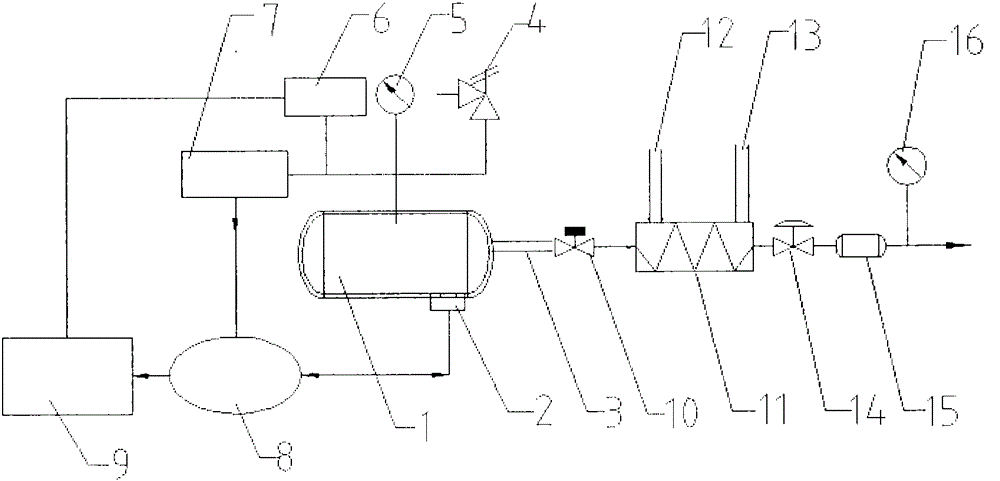

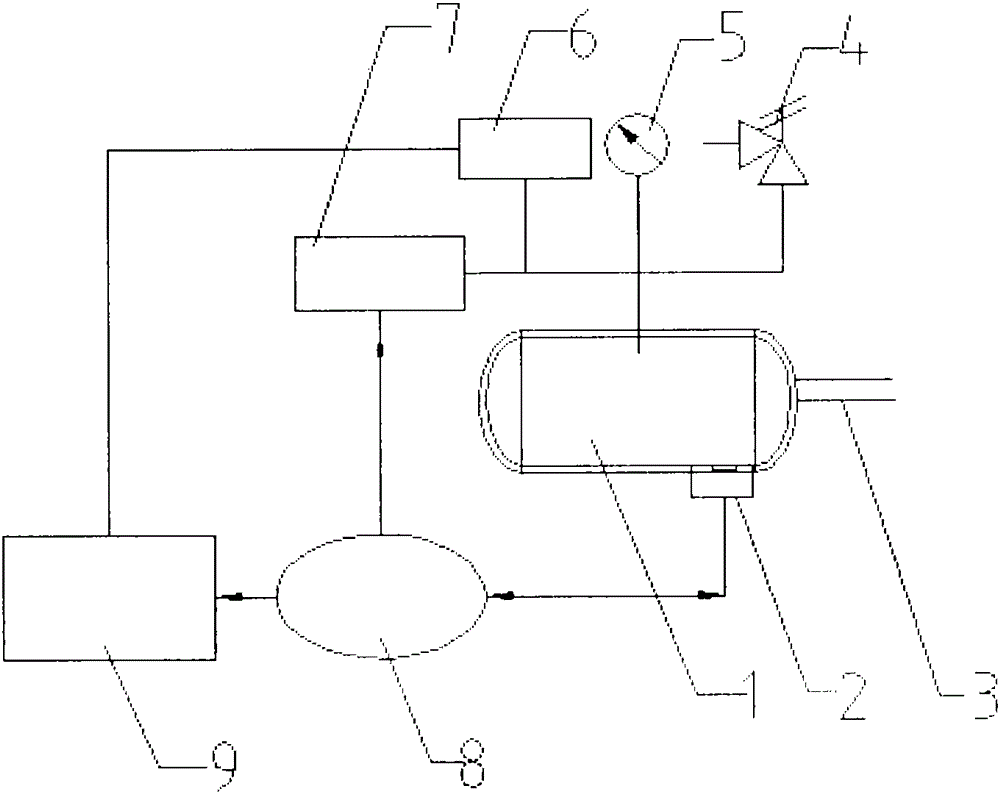

A direct supplementary pressure high temperature steam circulation system

ActiveCN108798621BGuaranteed temperatureImprove energy savingFluid removalThermodynamicsWater storage tank

Owner:XI AN JIAOTONG UNIV

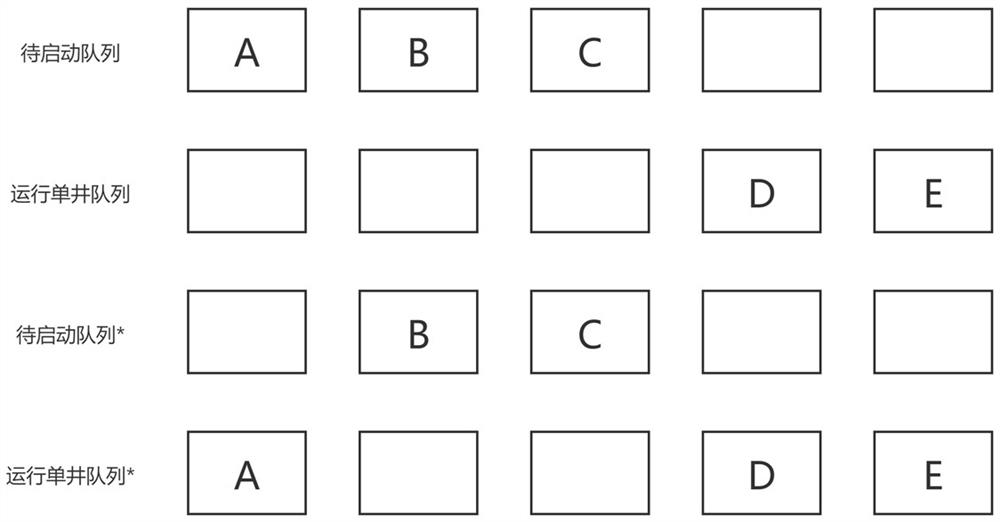

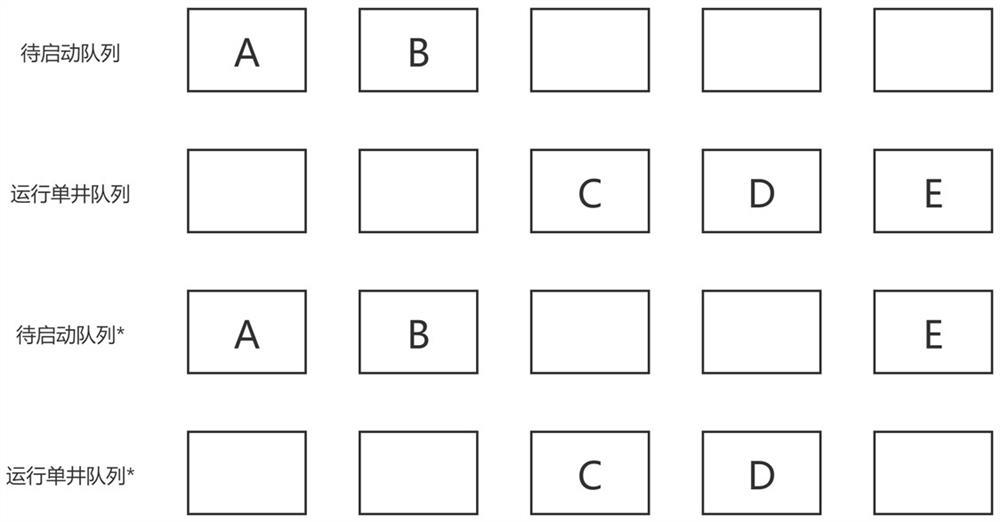

Automatic dispatching method for water source well of waterworks

PendingCN114371662ARealize energy saving and consumption reductionReal-time monitoring of liquid levelProgramme control in sequence/logic controllersWater storageWater source

An automatic dispatching method for a water supply well of a waterworks comprises the steps that 1, the power consumption per ton of water of each single well is calculated and counted; 2, a to-be-started queue and a running single well queue are established according to the single well running state; 3, according to a statistical result, single wells are ranked in size in the to-be-started queue and the running single well queue; 4, single well starting and stopping are judged and executed according to the liquid level of the water plant water storage pond; energy conservation and consumption reduction of the water source well are realized by utilizing a water plant master control PLC, a local area network communication network and pump room measurement and control equipment to the maximum extent; the power consumption cost is reduced for operation of a water plant, time and manpower are saved, the production and management efficiency is improved, and intelligent operation management of the water supply system is promoted.

Owner:济宁金水科技有限公司

Intelligent pressurization device for LNG storage bottle

InactiveCN106322107ASimple structureFunctionalContainer filling methodsPressure vesselsGas cylinderDisplay device

The invention belongs to the technical field of automobile accessories, and provides an intelligent pressurization device for an LNG storage bottle. The intelligent pressurization device comprises the LNG storage bottle, a heating module, a pressure sensor, a displayer and a PLC intelligent control system. The bottom of the LNG storage bottle is provided with the heating module. The heating module is connected with the PLC intelligent control system. The top of the LNG storage bottle is provided with a liquid level meter and a pressure meter. A safety valve is installed on an opening of the LNG storage bottle. One side of the LNG storage bottle is provided with a liquid outlet pipe. The liquid outlet pipe is connected with one end of a gasifier. The other end of the gasifier is connected with the PLC intelligent control system. The PLC intelligent control system is connected with the displayer. The intelligent pressurization device is simple in pressurization loop, convenient to operate, applicable to various environments and high in safety performance.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com