Automatic anaerobic three-phase separation system and control method

A three-phase separation and automatic technology, applied in anaerobic digestion treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problem of difficult adjustment of air chamber pressure, so as to avoid excessive pressure of air chamber and ensure processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

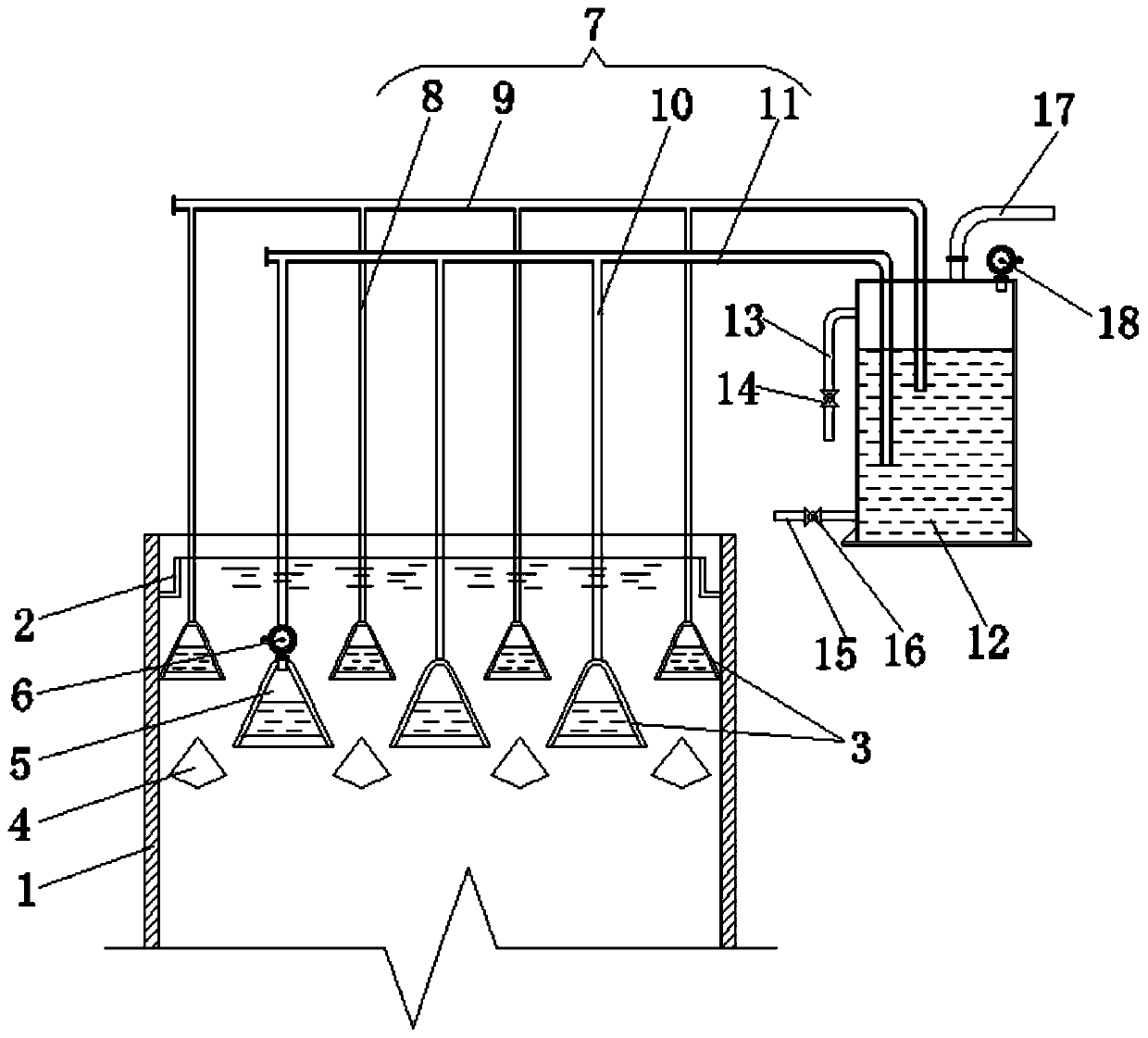

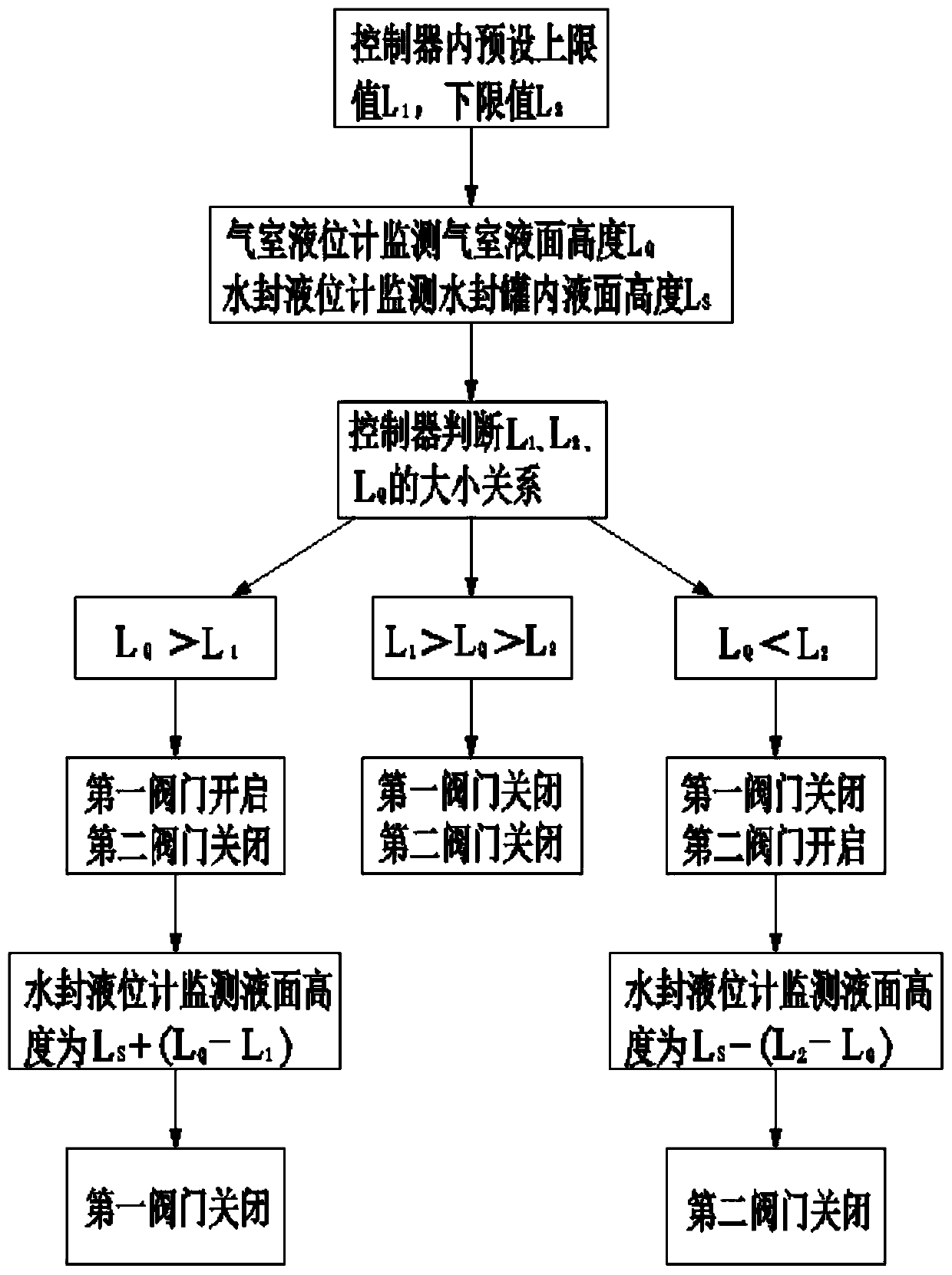

[0026] Such as figure 1 , figure 2 As shown, an automatic anaerobic three-phase separation system is used to realize the treatment of wastewater, so that the three phases of gas, liquid and solid are well separated, the supernatant is discharged, and the sludge flows back into the reactor through the return slot of the three-phase separator to ensure Sludge concentration, biogas is directly discharged into the atmosphere after passing through the water-sealed tank, or is used as energy recovery. Its structure mainly includes reactor 1, a three-phase separator installed inside reactor 1, and water Packaging components and controllers.

[0027] The reactor 1 has a rectangular parallelepiped structure, and an overflow weir 2 is arranged at the upper end of a pair of parallel end faces. The interior of the reactor 1 is used to contain waste water.

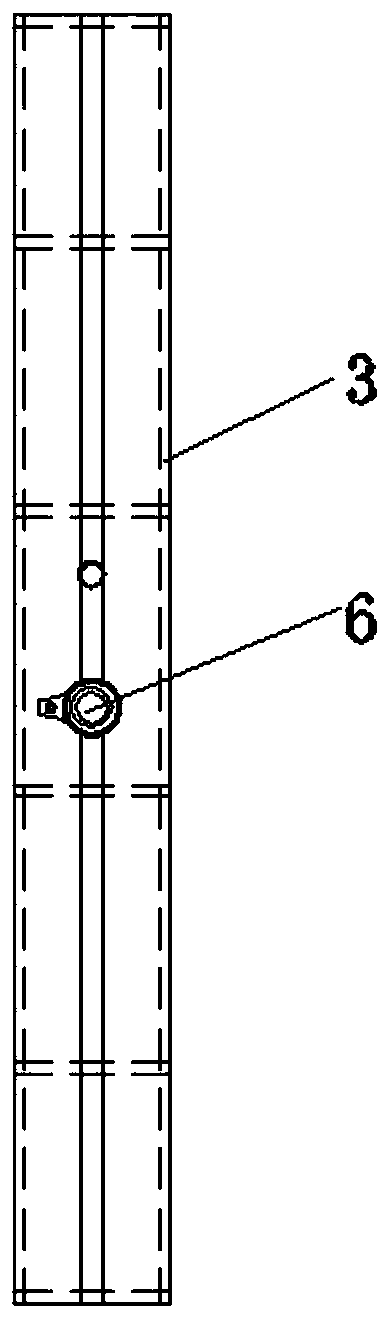

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com