Oil steam zero-discharge oil storage tank device

A technology of oil vapor and oil storage tanks, applied in packaging, transportation, packaging, containers, etc., can solve problems such as power consumption, and achieve the effect of eliminating fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

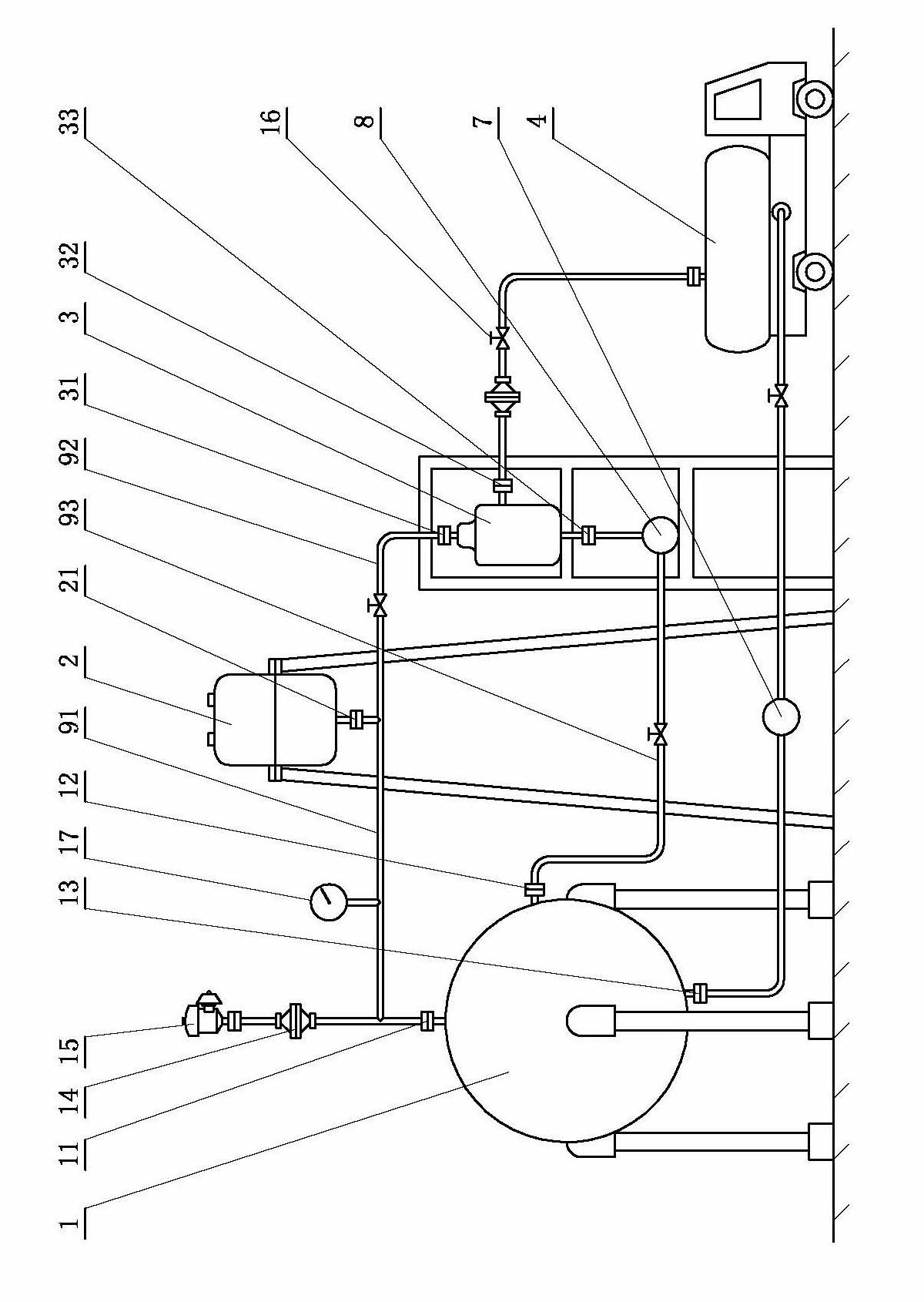

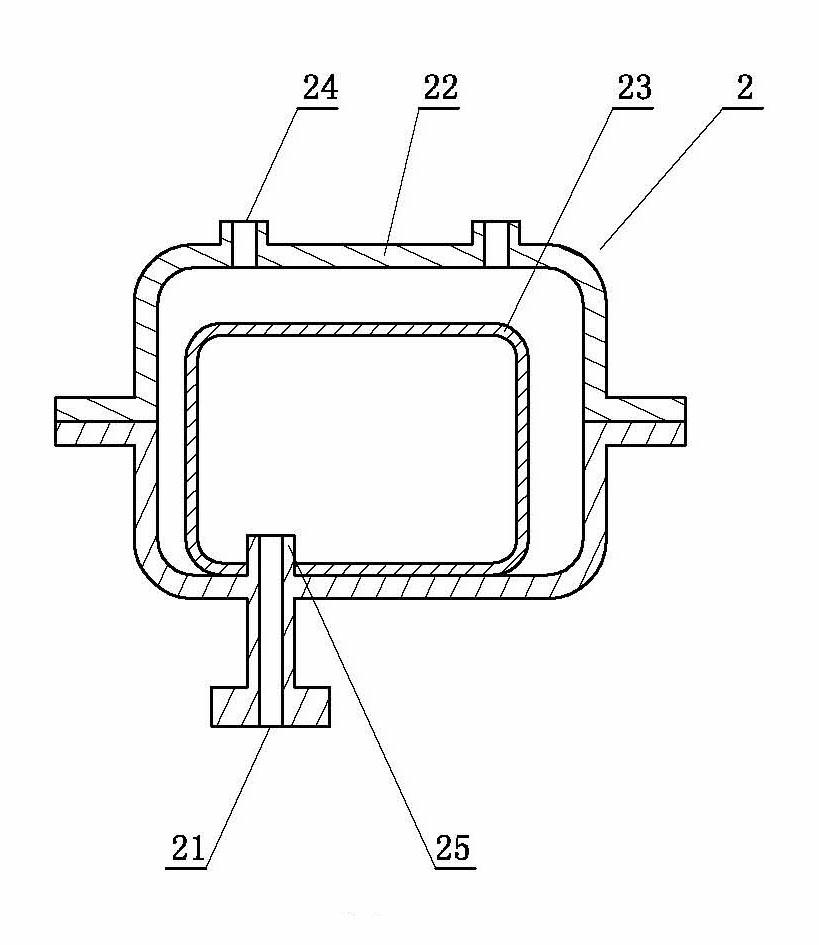

[0015] see figure 1 , figure 2 , the oil vapor zero-emission oil storage tank device of the present invention includes at least one oil storage tank 1, an oil vapor throughput interface 11 and a condensed oil recovery interface 12 are arranged on the upper part or the top of the oil storage tank, and the lower part or the bottom of the oil storage tank Set the liquid oil output interface 13; according to the needs of the design, the oil vapor throughput interface and the condensed oil recovery interface can be set on the upper part of the oil storage tank, and the liquid oil output interface can be set on the lower part of the oil storage tank; the oil vapor can also be set on the top of the oil storage tank The throughput interface and the condensed oil recovery interface, the liquid oil output interface is set at the bottom of the oil storage tank; the preferred solution is to set the oil vapor throughput interface on the top of the oil storage tank, the Set the liquid oil...

Embodiment 2

[0021] The oil storage tank device in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

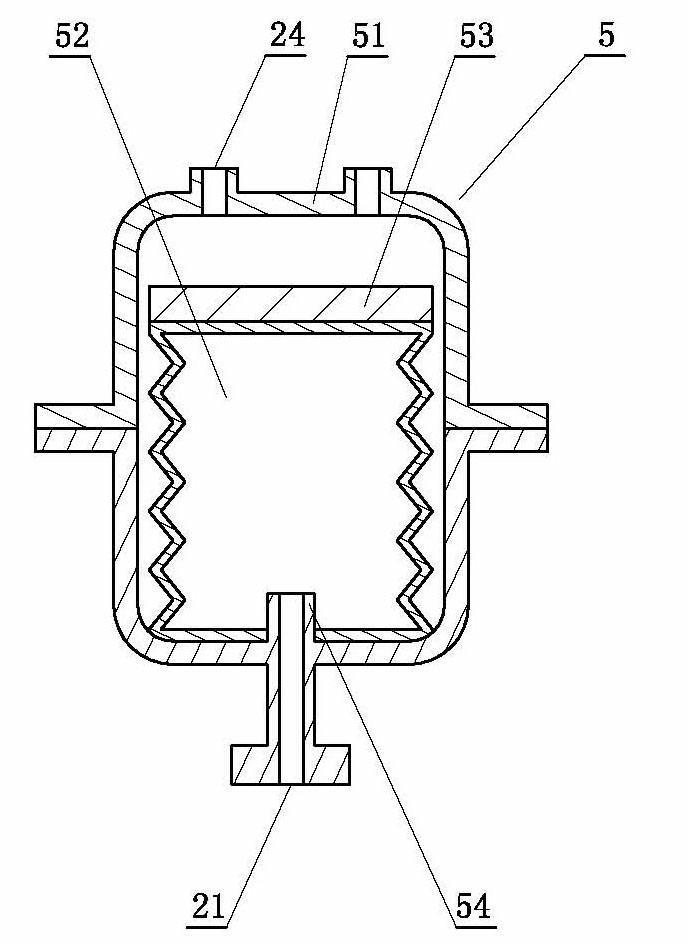

[0022] see image 3 ( image 3is a cross-sectional view), in this embodiment, the oil vapor intake and puff compensator 5 includes a protective cylinder 51, a bellows variable volume air chamber 52, and a counterweight 53, and the bellows variable volume air chamber is arranged on the protective cylinder Inside, the counterweight is arranged on the top of the bellows variable volume air chamber, the oil vapor breathing tube interface 21 is arranged outside the protective cylinder, and a breathing tube 54 is arranged on the bellows variable volume air chamber, The breathing tube communicates with the oil vapor breathing tube interface. The protective tank body is made of carbon steel, and a plur...

Embodiment 3

[0024] The oil storage tank device in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0025] see Figure 4 ( Figure 4 is a sectional view), in this embodiment, the oil vapor huff and puff compensator 6 includes a water-sealed pool 61 and a floating bucket-type variable-volume air chamber 62, and the floating-bucket-type variable-volume air chamber is arranged in the water-sealed pool, The oil vapor breathing tube interface 21 is arranged outside the water-sealed pool, and a breathing tube 64 is arranged in the floating bucket type variable volume air chamber, and the breathing tube communicates with the oil vapor breathing tube interface. In this embodiment, the water-sealed pool and the floating bucket-type variable volume air chamber are made of engineering plastics, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com