Variable-frequency speed regulation constant-pressure water supply control system

A constant pressure water supply and control system technology, applied in water supply pipeline systems, water supply devices, water supply main pipelines, etc., can solve problems such as difficult maintenance, unstable water pressure of the pipe network, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

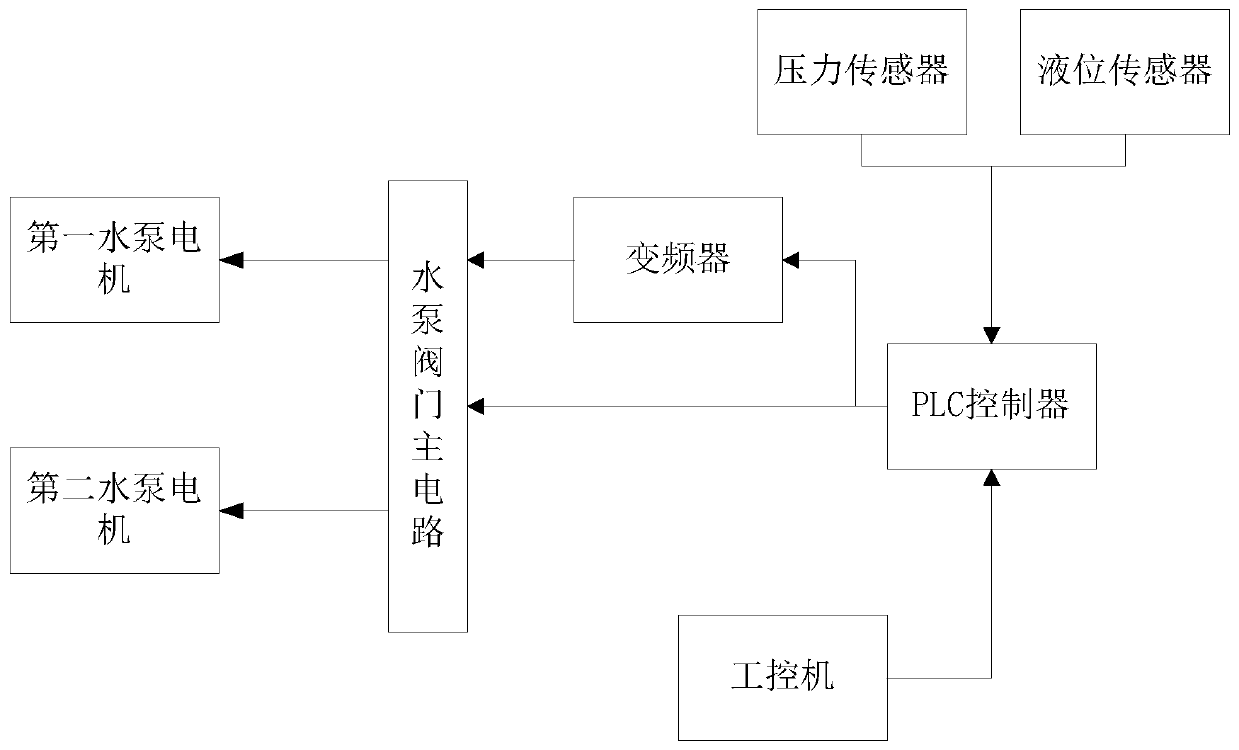

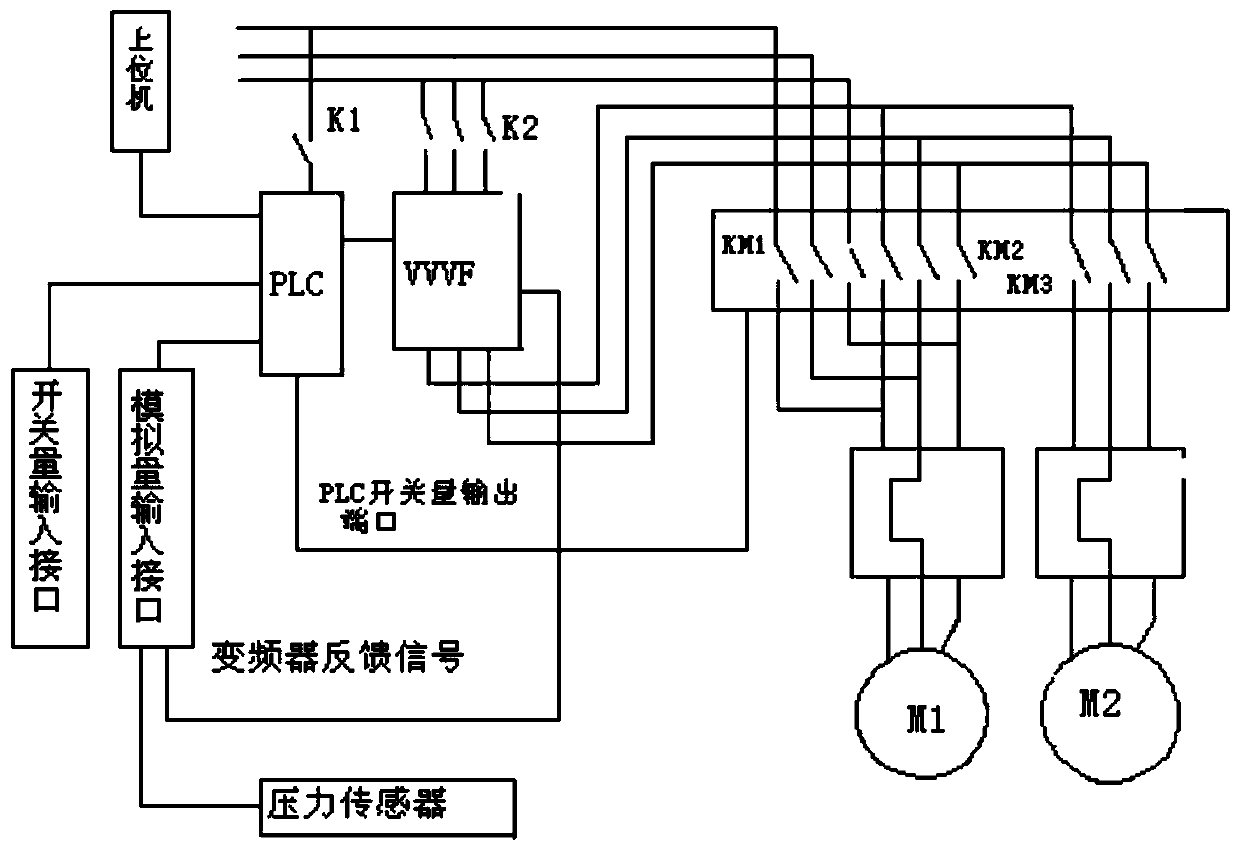

[0064] This embodiment provides a frequency conversion speed regulation constant pressure water supply control system, such as figure 1 , including industrial computer, PLC controller, frequency converter, water pump valve main circuit, sensor module, first water pump motor and second water pump motor, wherein:

[0065] The industrial computer is connected to the PLC controller, and the PLC controller is respectively connected to the inverter, the sensor module and the main circuit of the water pump valve, and the inverter is connected to the first water pump motor and the second water pump motor through the water pump switching circuit;

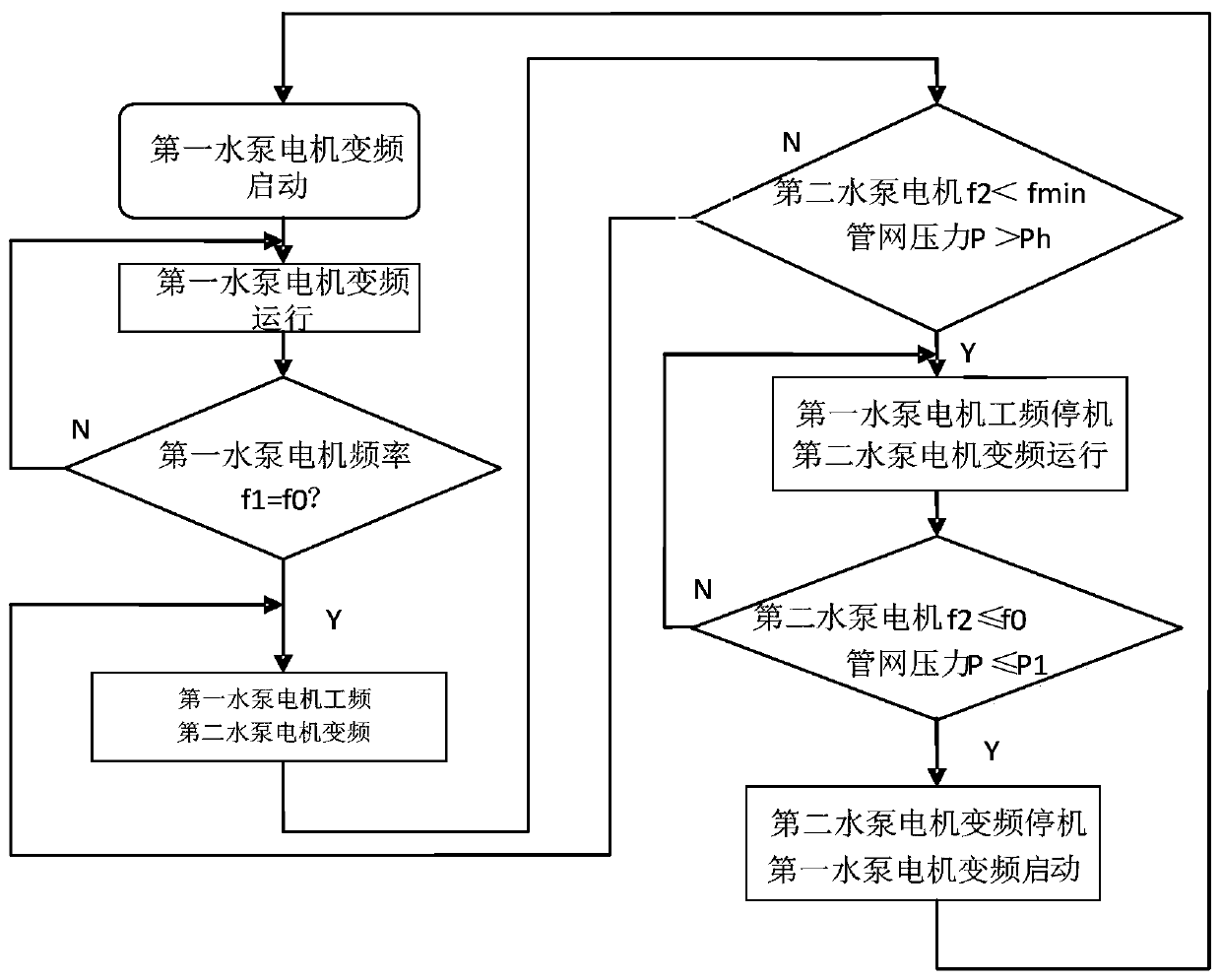

[0066] The frequency converter feeds back the motor frequency signal to the PLC controller, the sensor module samples the pipe network pressure signal and feeds it back to the PLC controller, and the PID module in the PLC controller performs calculations based on the motor frequency signal and the pipe network pressure signal, and sends out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com