Zero-deviation trackless train

A trackless train, deviation technology, applied in the direction of motor vehicles, tractor-trailer combination, transportation and packaging, etc., can solve the problems of not being able to reverse, large turning radius, and the load should not be too large, so as to achieve stable starting and braking, and good turning radius The effect of small size and large transportation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

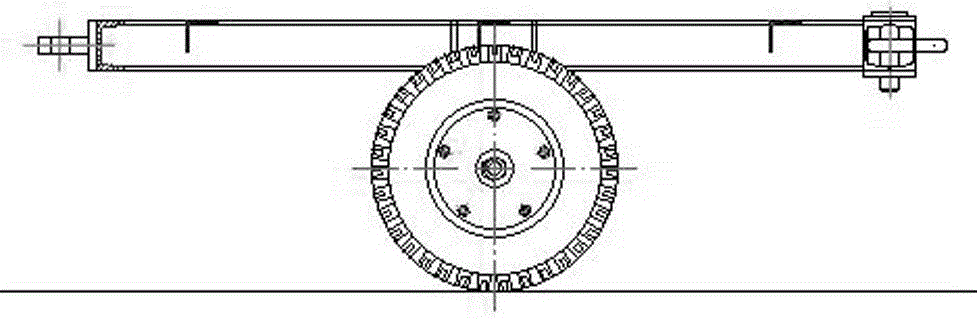

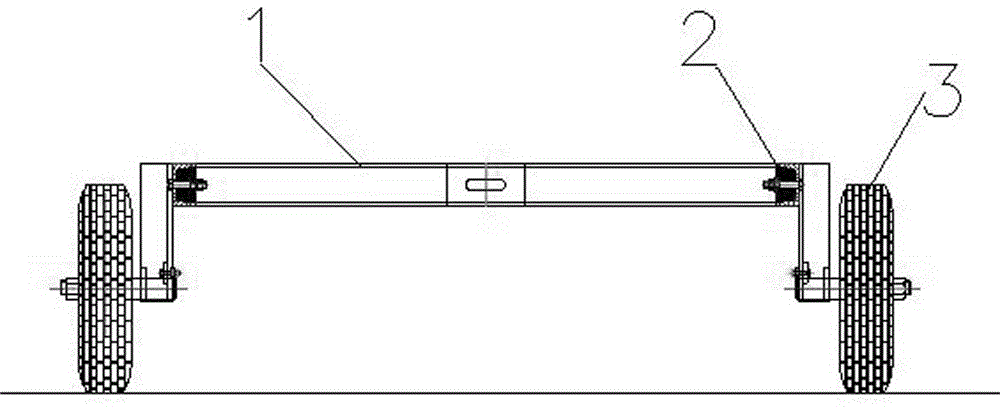

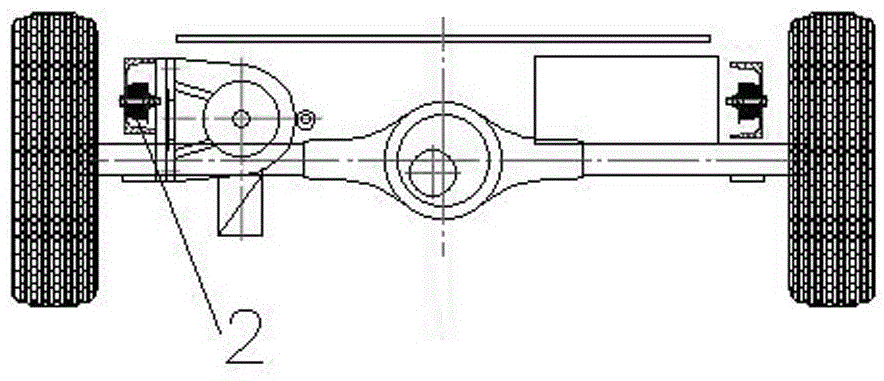

Image

Examples

specific Embodiment

[0064] Example 1. Adding a luggage case or rack to the gun carriage is a trackless train with zero deviation for luggage pulling. Generally, it drives on a better road, the road is smooth, and the train can be longer. It can solve the baggage transfer at one time, improve the current problem of multiple transfers of trackless trains, and reduce the operating cost of baggage transfer. To achieve the purpose of power saving, environmental protection and safety; put in the unmanned steering mechanism, and give the running track signal to realize unmanned driving.

[0065] Example 2. Installing hoppers or racks on the gun frame is a zero-deviation trackless train for freight. At this time, the length of the zero-deviation trackless train is mainly determined by the road conditions, and the power can be powered by generator sets or batteries. Cargo transshipment in docks, freight yards, mining, chemical industry, salt works, metallurgy and other industries.

[0066] Example 3. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com