Method for controlling steam supply pressure of heat supply network of thermal power plant

A technology of a thermal power plant and a control method, which is applied in the field of steam supply pressure control of a thermal power plant heating network, can solve problems such as low-flow erosion of valve cores, achieve low-flow erosion reduction, stable control, and flexible operation modes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

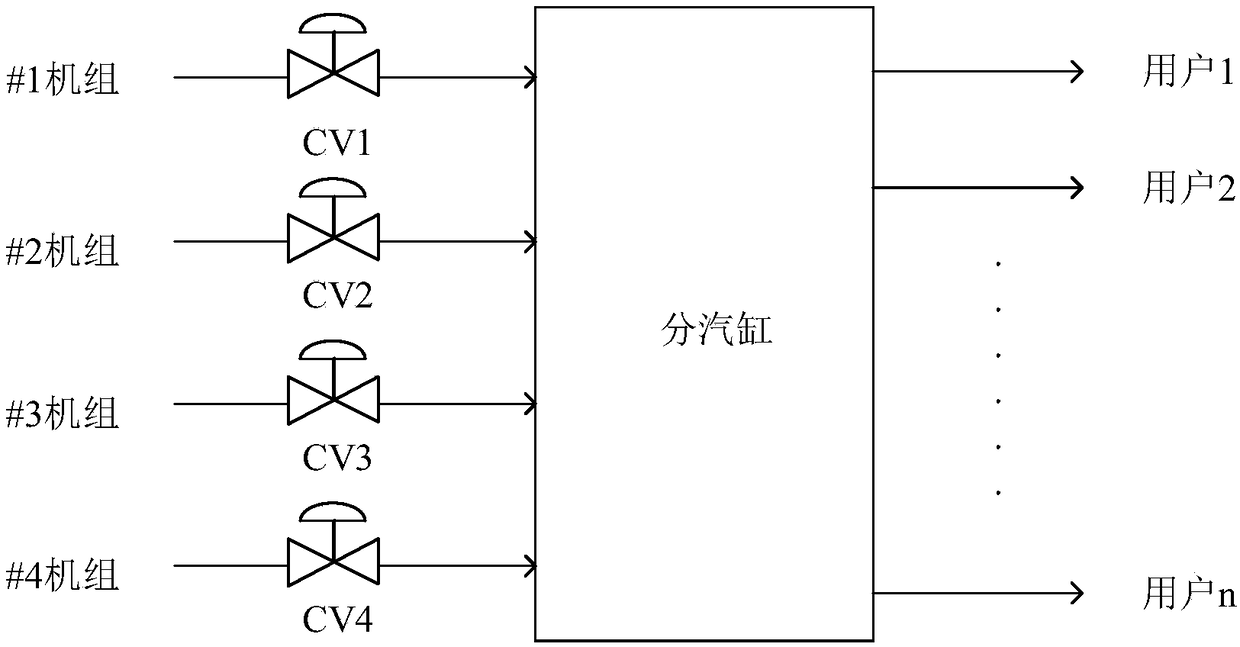

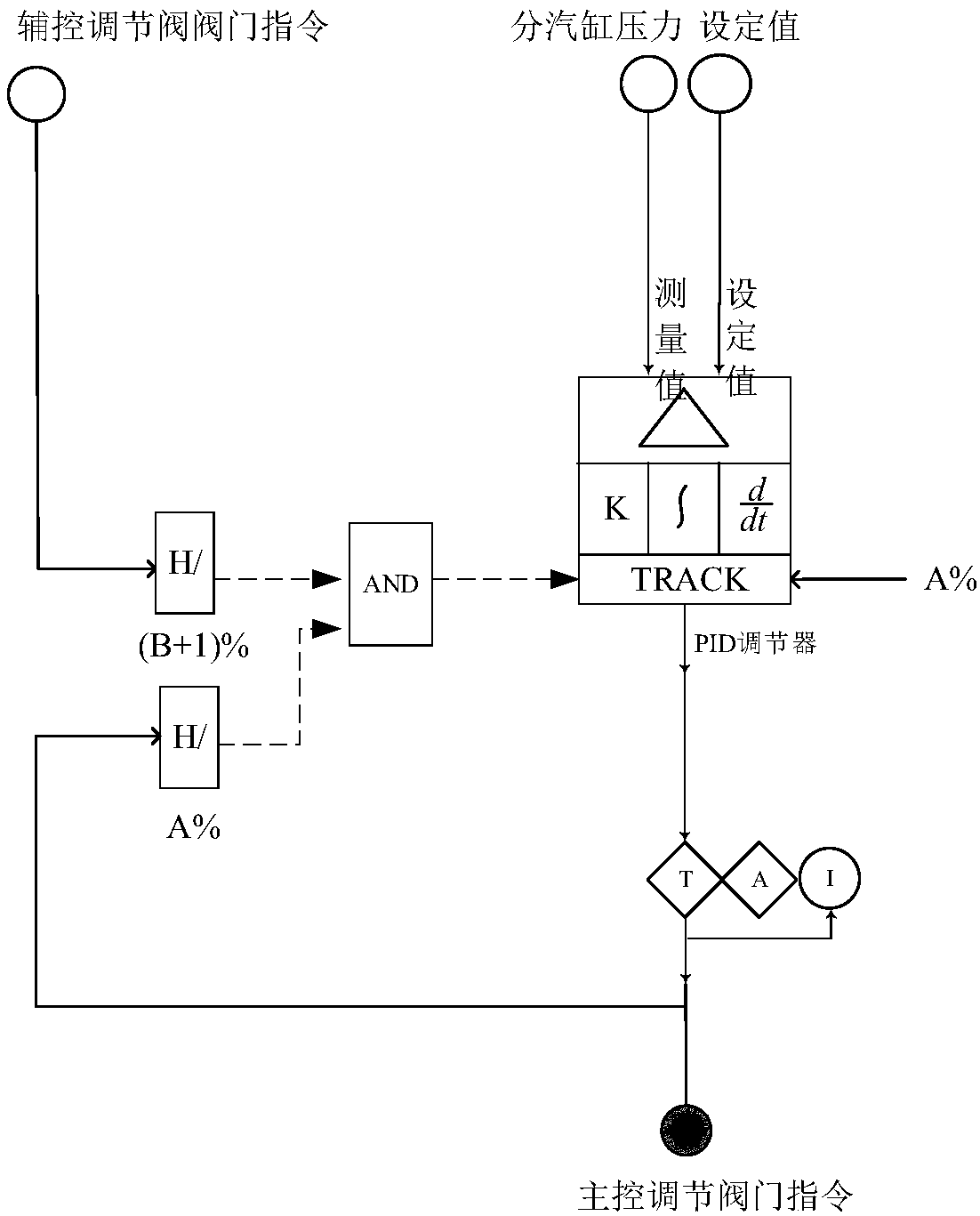

[0033] In the present invention, two heating units are set to supply steam to the heating network through two regulating valves. In order to solve the disadvantages of the prior art, the steam supply of the two units has a primary or secondary or sequence, and a main control and auxiliary control control method is proposed. .

[0034] The steam inlet regulating valve of the sub-cylinder is set as one main control automatic and one auxiliary control automatic. The main control and auxiliary control regulating valves can be set freely.

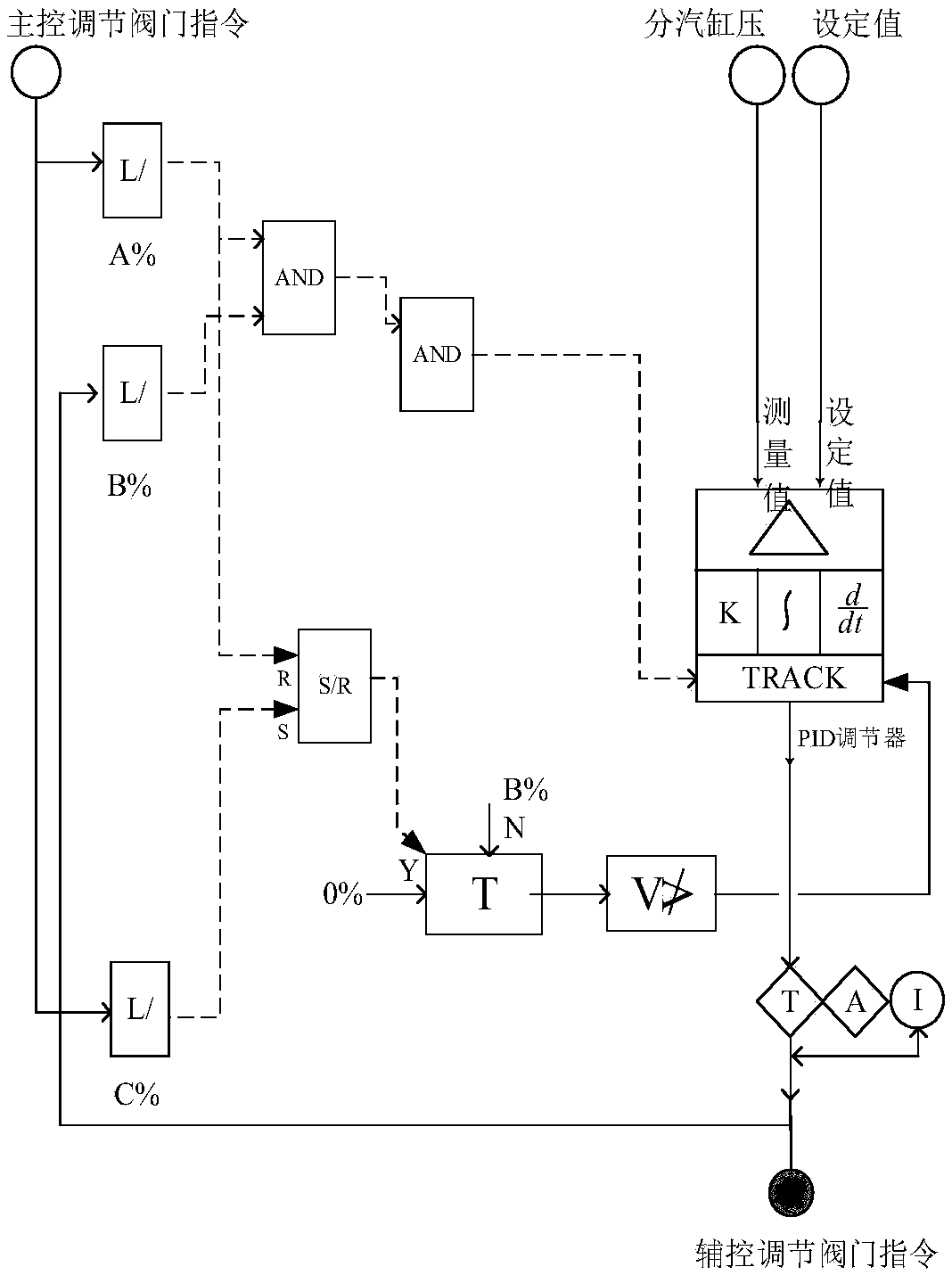

[0035] When the steam consumption on the user side is low, the steam consumption of the user can be met by adjusting the main control valve, and the pressure of the sub-cylinders can be kept stable.

[0036] When the steam consumption on the user side increases, the opening of the valve is adjusted through the main control to keep the pressure of the sub-cylinder stable. Such as figure 2 As shown, when the steam consumption on the user side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com