Electrostatic dust collection system of movable tripper car

An electrostatic precipitator and unloading truck technology, which is used in external electrostatic separators, loading/unloading, transportation and packaging, etc., can solve the problems of polluting the production post environment, excessive dust concentration, and large dust production. The effect of environmental pollution control, ideal dust removal effect and low system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

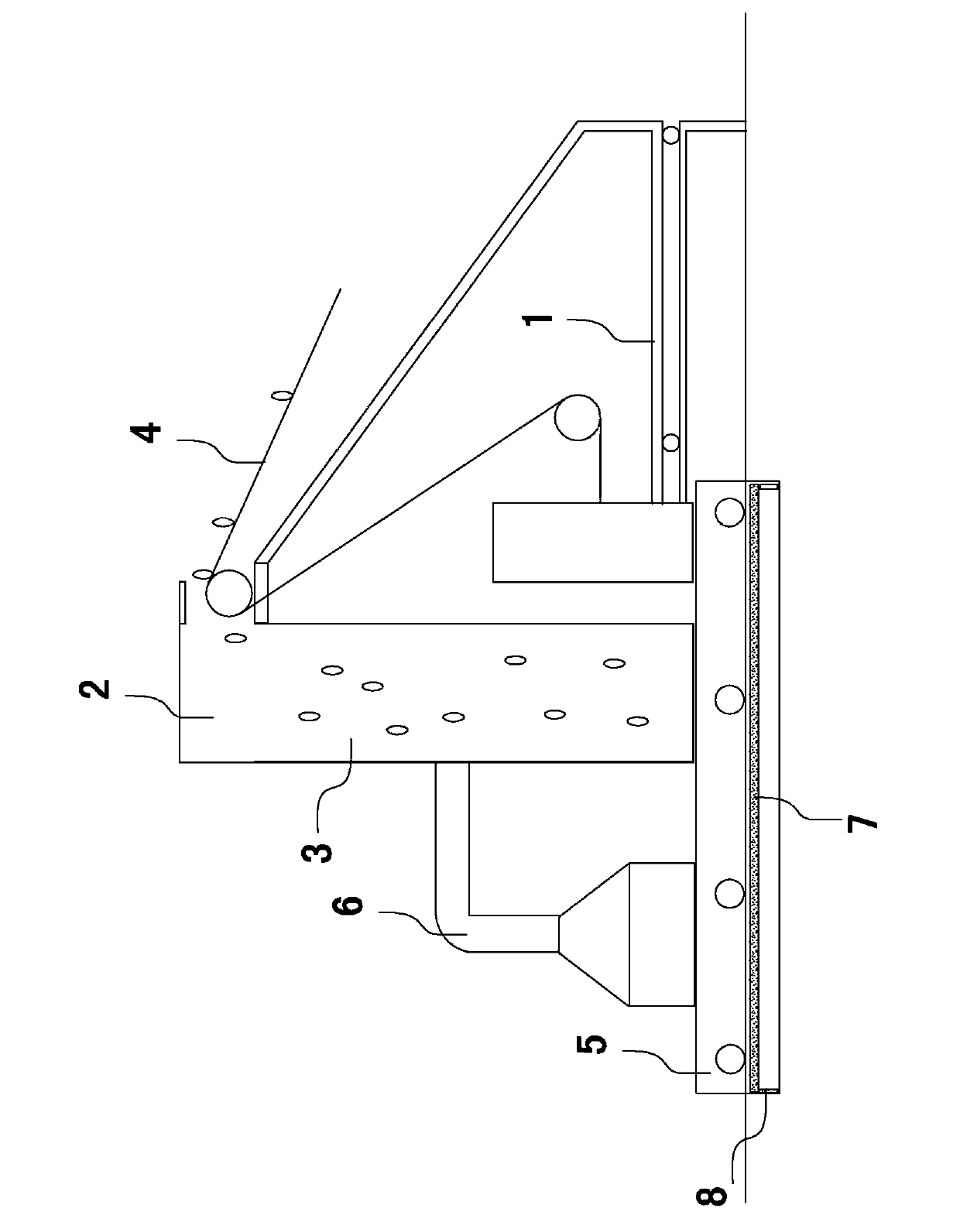

[0010] As shown in the figure, the unloading vehicle dust collection system includes a mobile unloading vehicle 1, a dust suction cover for the machine head 2, a blanking trough 3, a silo closure cover 5 and a material conveying mechanism 4; the material conveying mechanism 4 is equipped with On the mobile unloading vehicle 1; the dust suction cover 2 of the machine head is fixedly connected with the blanking trough 3; the discharge end of the blanking trough 3 communicates with the feeding end of the silo; 5 and the blanking chute 3 are provided with a dust air flow return channel 6; the ports of the dust air flow return channel 6 communicate with the silo and the blanking chute 3 respectively; an electrostatic dust removal terminal is provided in the silo closure 5 ; The signal output terminal of the power supply part is connected to the signal input terminal of the electrostatic precipitator terminal; the electrostatic precipitator terminal includes a corona wire 7 and an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com