Papermaking sewage closed circulation method and device

A closed-loop, wastewater technology, applied in chemical instruments and methods, processing wastewater treatment, water/sewage multi-stage treatment, etc., can solve problems such as poor recycling of lightweight fibers, rotten and odorous fillers, and increased recycling costs. , to reduce the pressure of membrane pollution, not easy to corrupt, and improve the water reuse rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

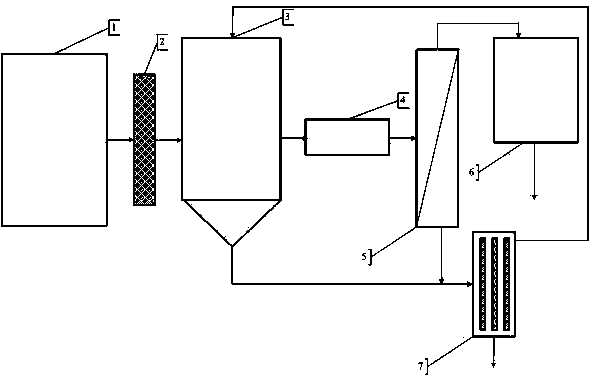

Image

Examples

example 1

[0029] Example 1: The source of sewage is concentrated white water from a paper mill, and the water quality condition is: COD Cr Content 300-600mg / L, SS 500-1200 mg / L. After the main process of papermaking wastewater closed-circuit circulation, the molecular weight cut-off of the small-pore scroll ultrafiltration membrane is 5000Da, and the final turbidity of the effluent is ≤3 NTU, SS is not detected, and COD Cr It is 50-100 mg / L, no peculiar smell after long-term storage, and reaches the first-class standard of industrial reuse water, and the permeate is used for production recycling.

example 2

[0030] Example 2: The source of sewage is white water from a paper mill in Shandong. The water quality conditions are: pH 6.5-6.8, turbidity 110-150NTU, SS 160-190 mg / L, COD Cr The content is 500-600 mg / L. After the main process of papermaking wastewater closed-circuit circulation, the molecular weight cut-off of the small-pore scroll ultrafiltration membrane is 3000Da, the final effluent turbidity is ≤1 NTU, SS is not detected, the COD content is 80-100 mg / L, and there is no peculiar smell after long-term storage , reaching the first-class standard of industrial reuse water, and the permeate is used for production recycling; the fibers in the white water can be burned after recycling and drying, realizing the reuse of water resources and the secondary utilization of waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com