Patents

Literature

38results about How to "Spill suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

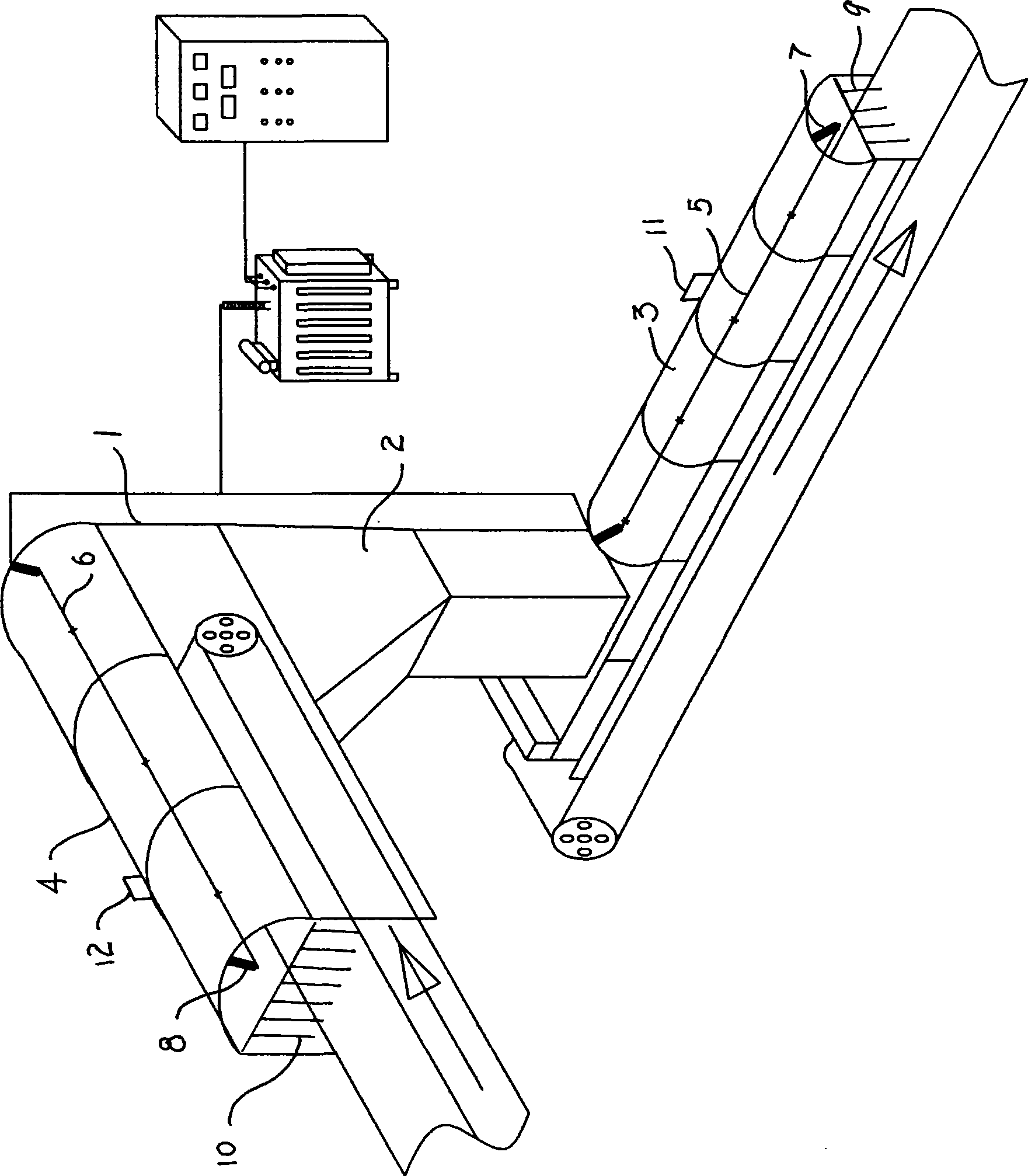

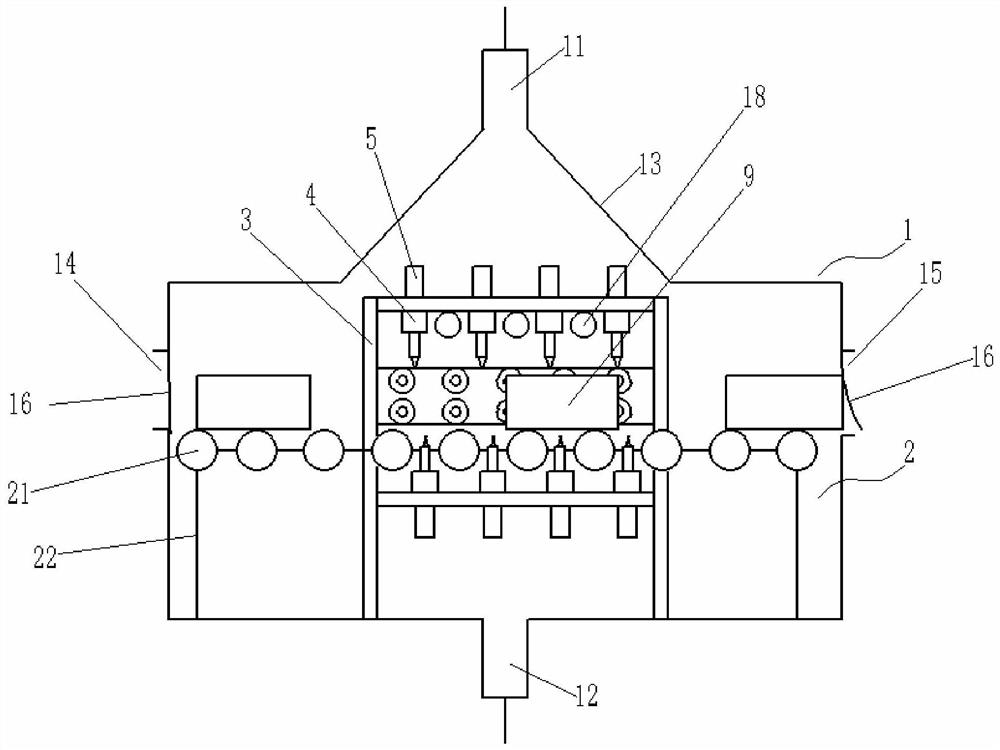

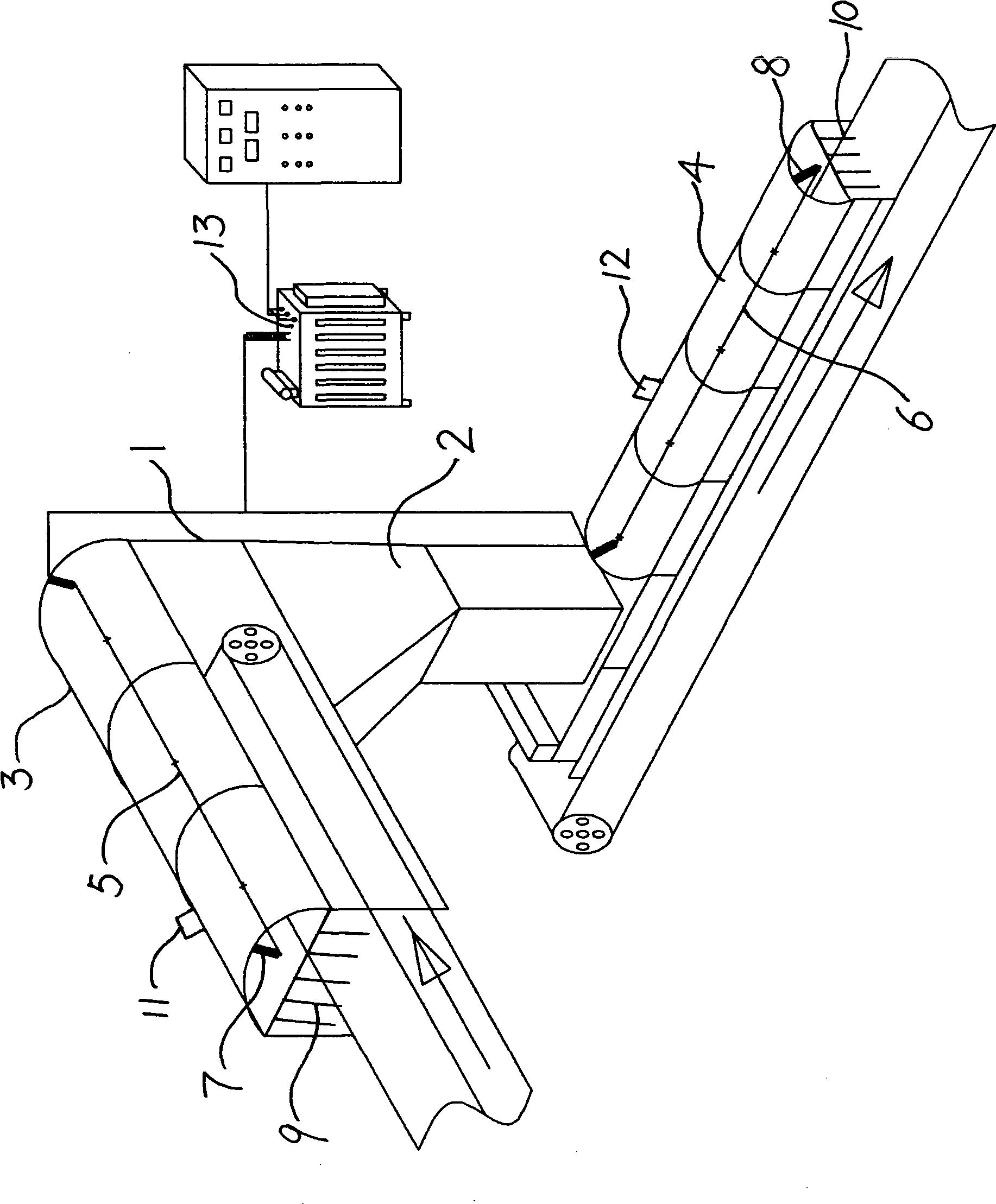

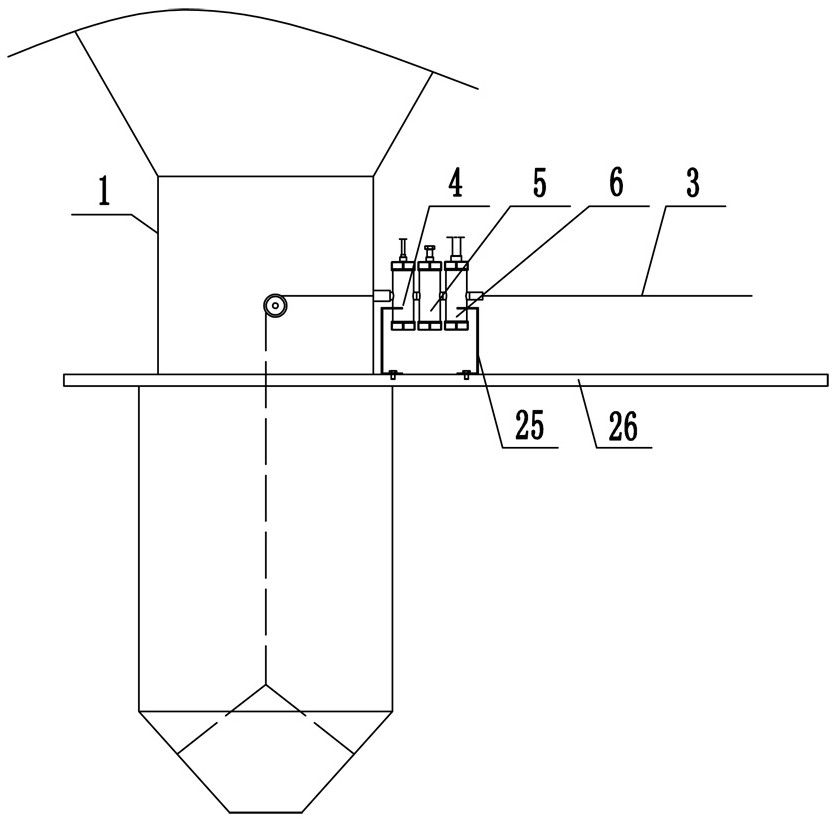

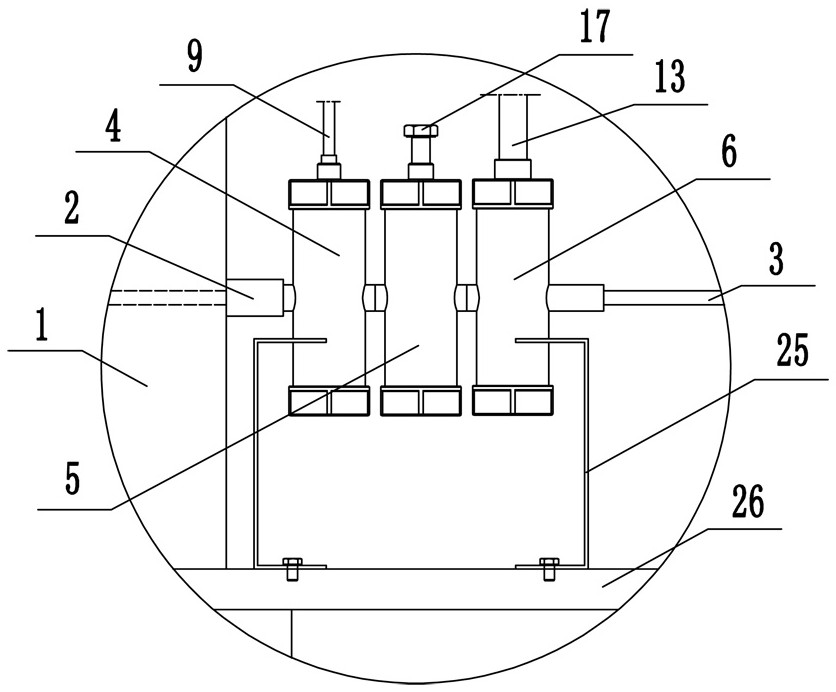

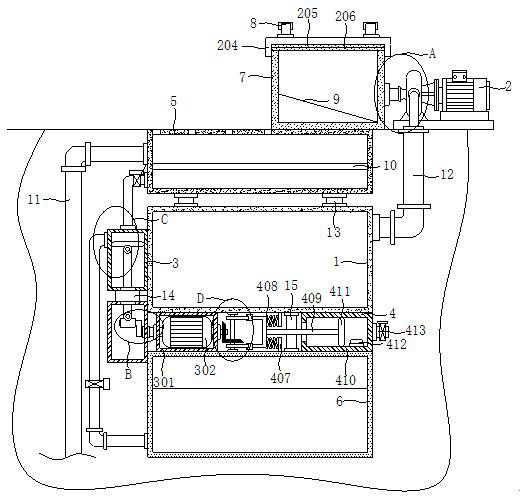

Electrostatic precipitation system of belt transfer station

InactiveCN101462650ASpill suppressionImprove purification effectExternal electric electrostatic seperatorLoading/unloadingEngineeringMechanical engineering

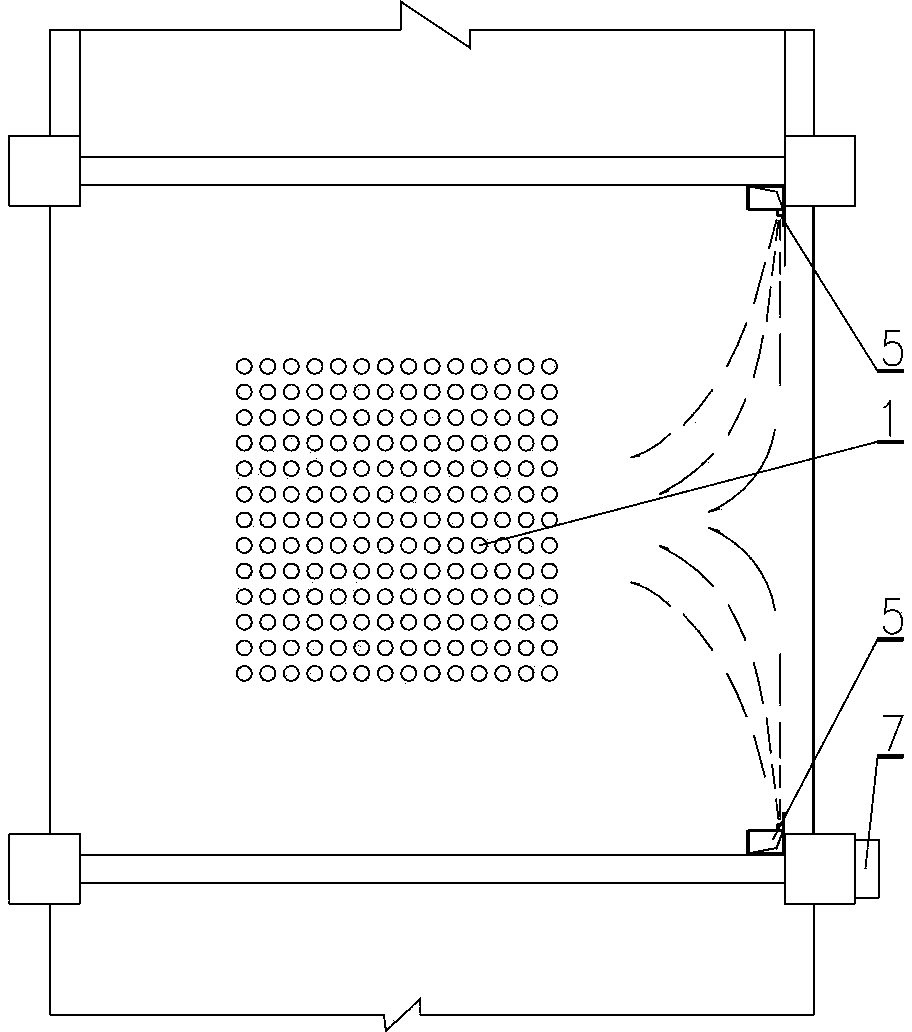

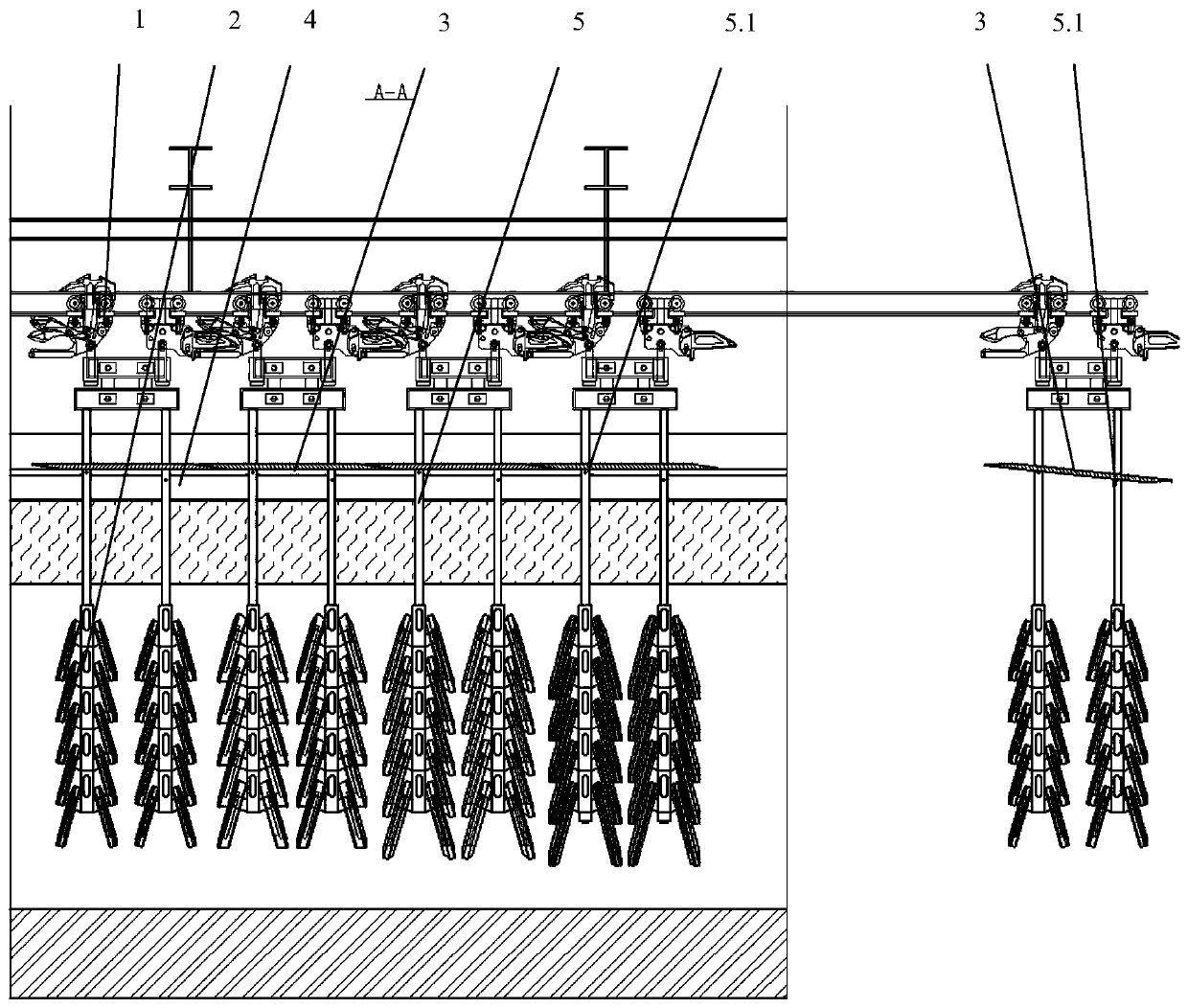

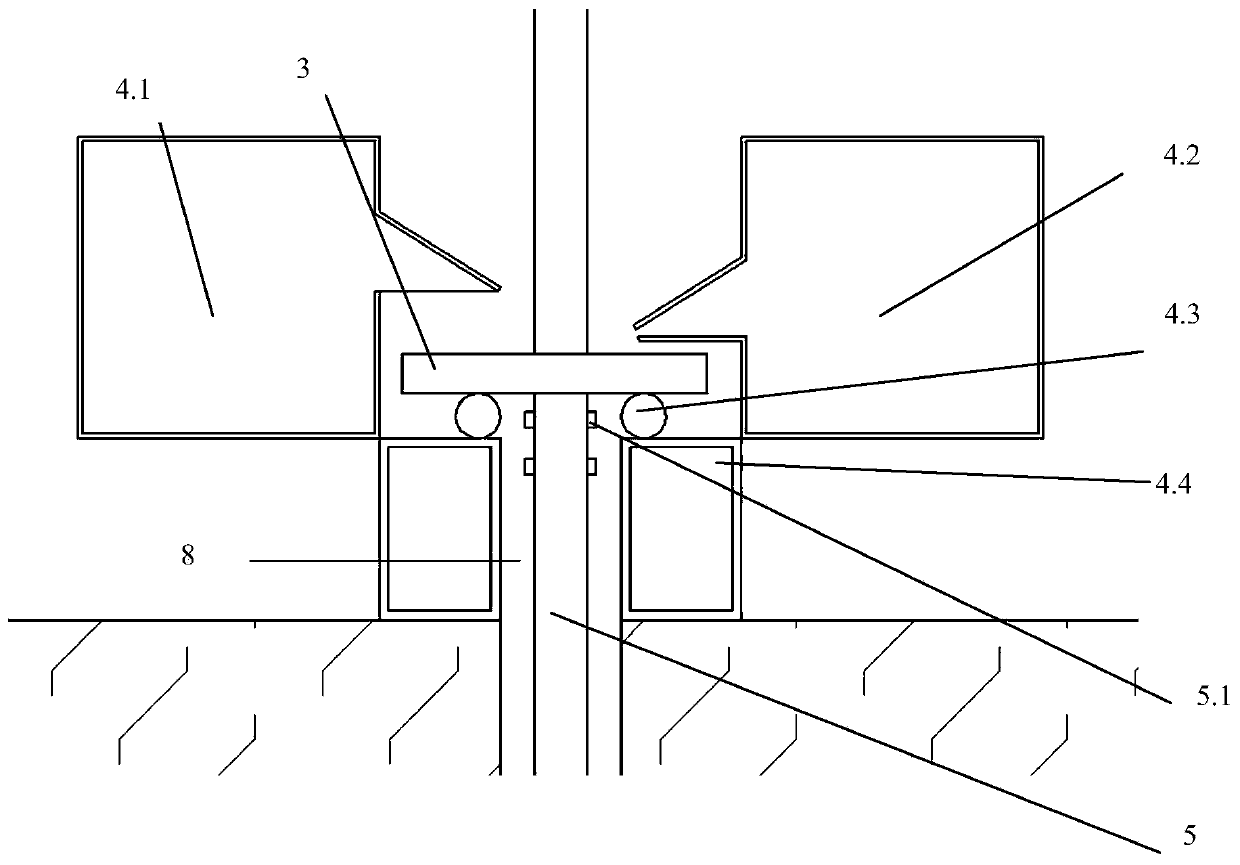

The invention belongs to the field of environment-friendly dust-removal device, and in particular relates to an electrostatic dust-removal system for a belt transfer station, which comprises a transfer station body (1) provided with a chute (2), and a power supply part, wherein a seal cover (3) and a seal cover (4) are arranged on an end region of a transmission part of the transfer station body (1); electrostatic dust-removal terminals are arranged inside the seal cover (3) and the seal cover (4); the output end of the power supply part is connected with input ends of the electrostatic dust-removal terminals; each electrostatic dust-removal terminal comprises a corona wire (5), a corona wire (6) and an insulator (7) and an insulator (8) which are fixedly matched and connected with the corona wire (5) and the corona wire (6); and a dust-removal soft curtain (9) and a dust-removal soft curtain (10) are arranged on end parts of the seal cover (3) and the seal cover (4). The electrostatic dust-removal system for the belt transfer station has the advantages of simple structure, high dust-removal efficiency, noiselessness, low energy consumption, small space occupation of equipment and low maintenance cost.

Owner:于文祥

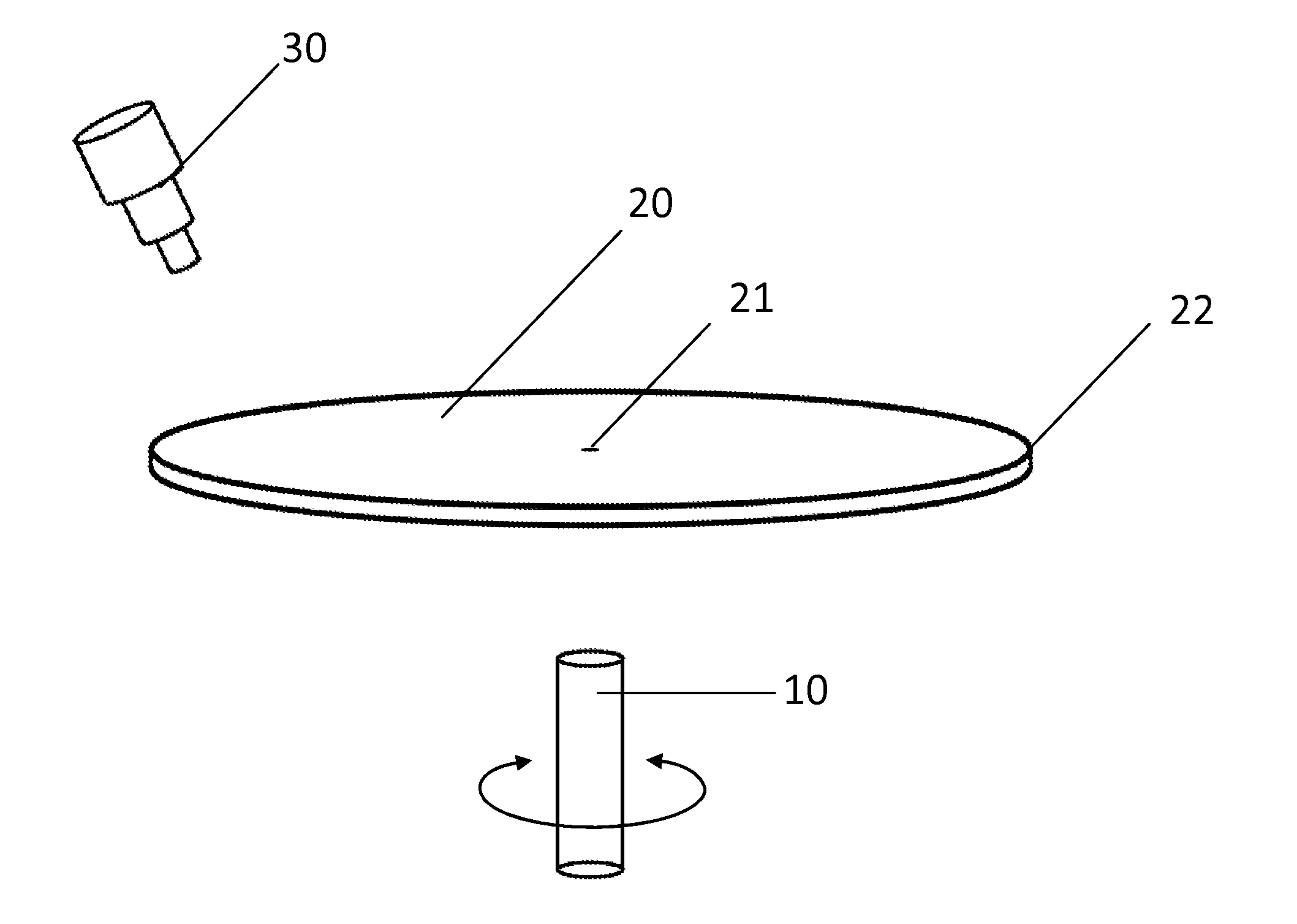

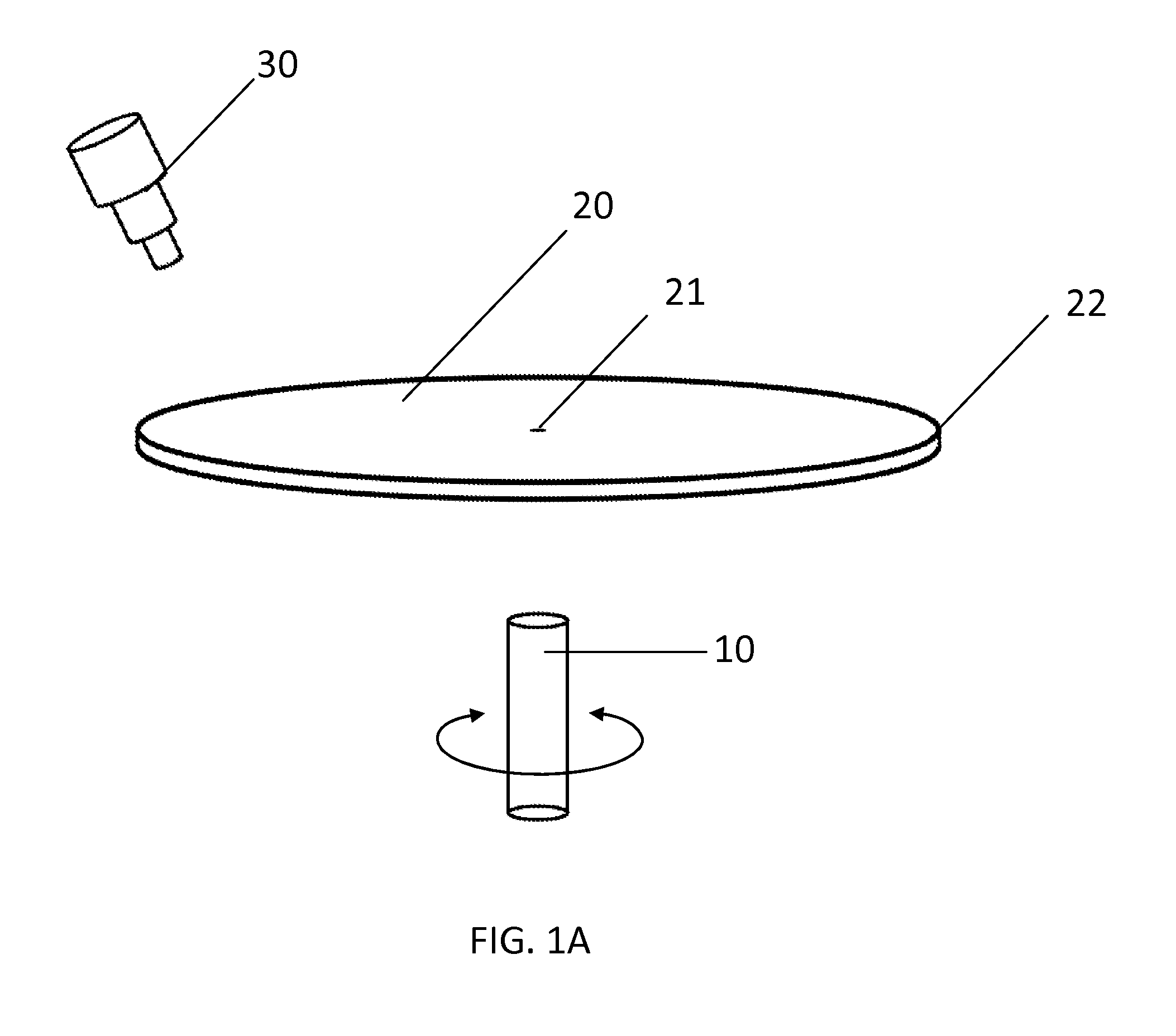

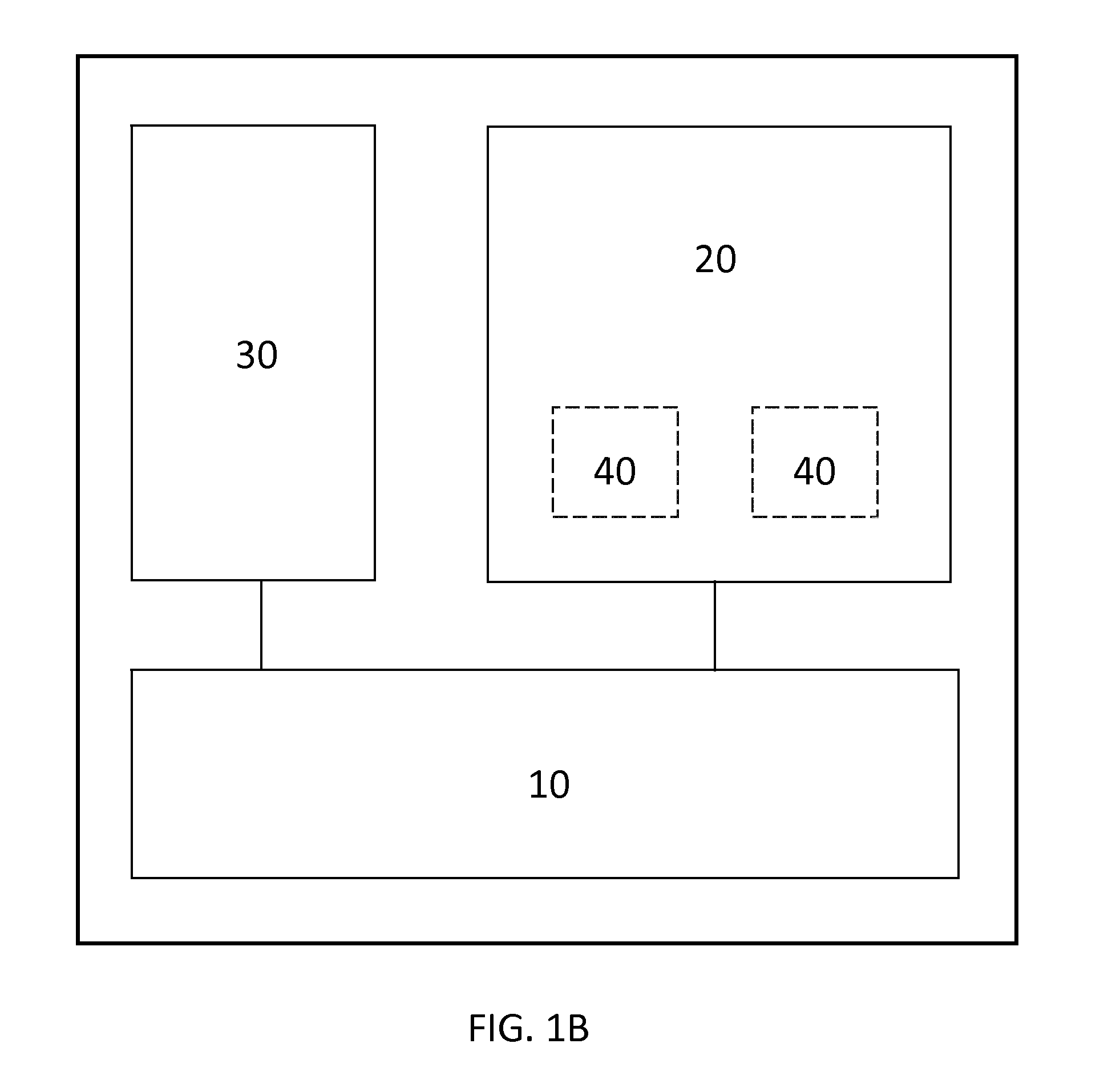

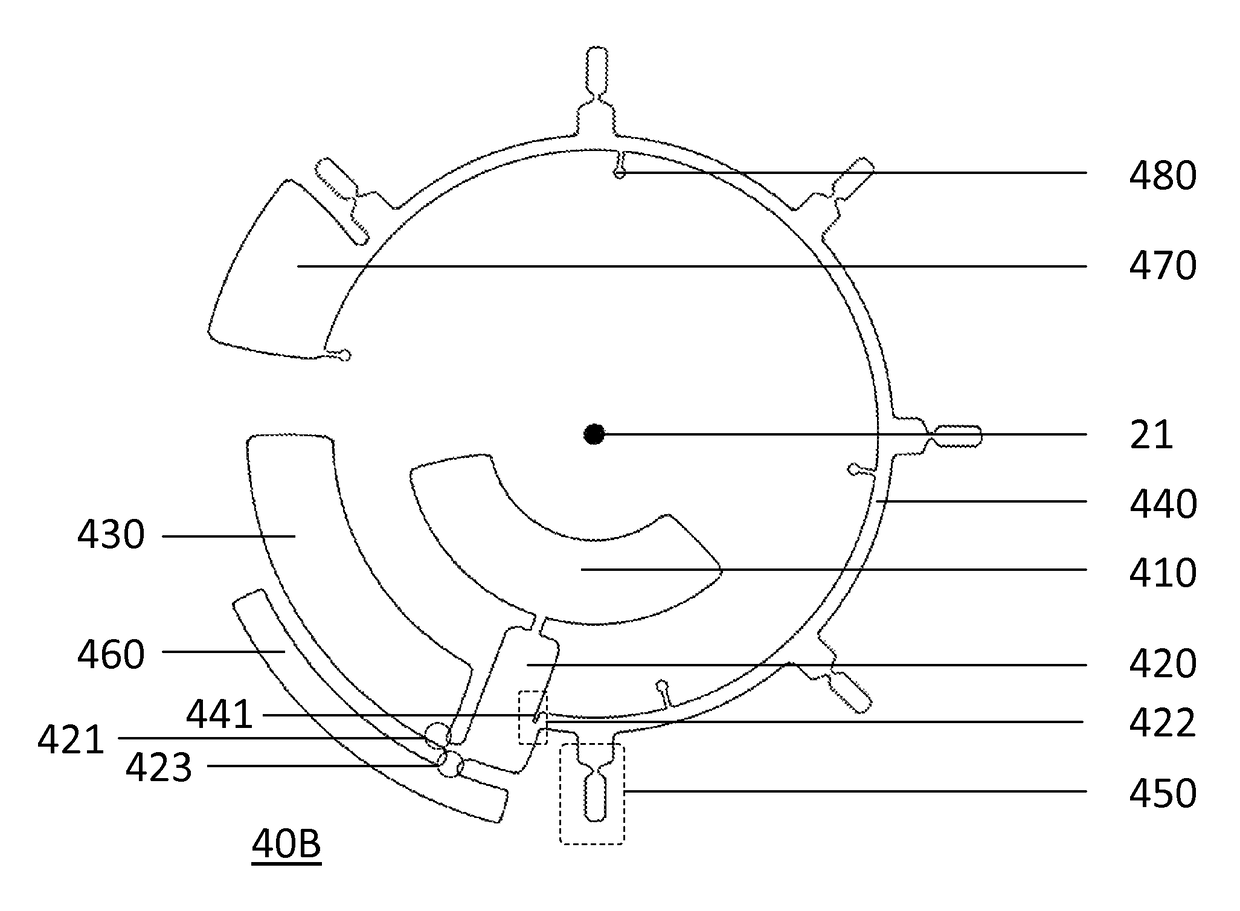

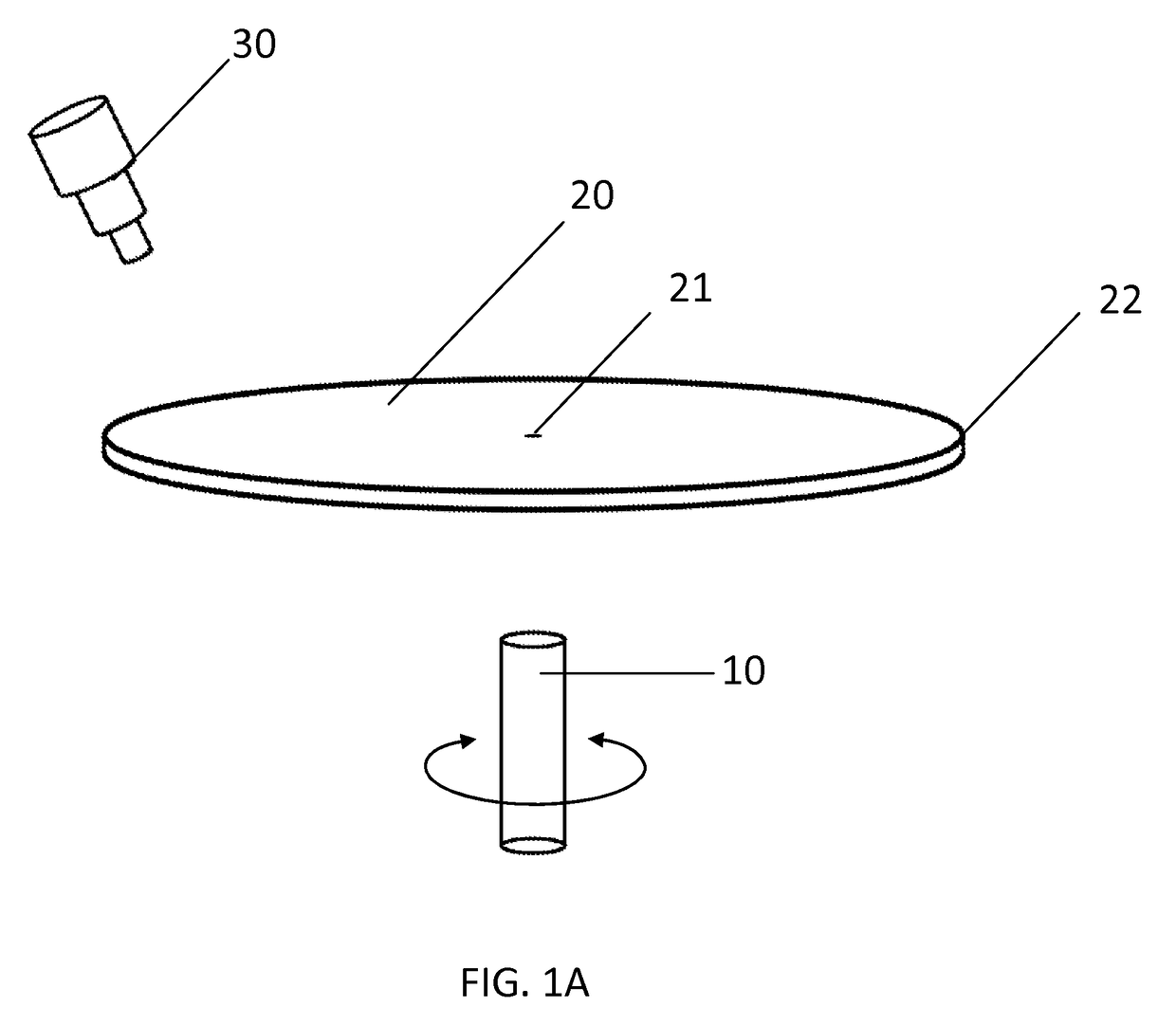

Gas-based microfluidic devices and operating methods thereof

ActiveUS20160144363A1Easy to manufactureEasy to useWithdrawing sample devicesLaboratory glasswaresEngineeringCentrifugal force

Gas-based microfluidic devices and operating methods of gas-based microfluidic devices are provided. The gas-based microfluidic devices comprise a drive module and a microfluidic platform, in which the microfluidic platform further comprises a microfluidic element having an injection chamber, a process chamber, an air chamber, an overflow channel, a barrier, and at least one detection chamber. Gases in the air chamber enable solutions to move toward the direction opposite to the centrifugal force applied by the drive module. Accordingly, the operating methods utilize the gases compressed in the air chamber to move solutions to difference components in the microfluidic element.

Owner:ZHEJIANG PUSHKANG BIOTECHNOLOGY CO LTD

Airtight concrete material and preparation method thereof

The invention discloses an airtight concrete material, wherein the preparation method comprises: stirring continuous graded limestone coarse aggregate, clean medium river sand, grinded mineral powder,II-grade fly ash, ordinary Portland cement, an efficient water reducing agent, a special air entraining agent and water, carrying out compact molding, and carrying out standard curing, and the airtight concrete material is the main concrete material of tunnel secondary lining structures in environments with overflowing of coal gas and other toxic and harmful gases. According to the invention, theairtight concrete material has the main characteristic of compactness, wherein the elastic gas bubbles exist in the capillary pores in the substructure, so that the gas permeation resistance, the impermeability, the alkali-aggregate reaction resistance, the crack resistance, the frost resistance and the like are excellent; and the raw materials excluding the special air entraining agent are widein the sources, and the preparation process is simple.

Owner:JIANGNAN UNIV

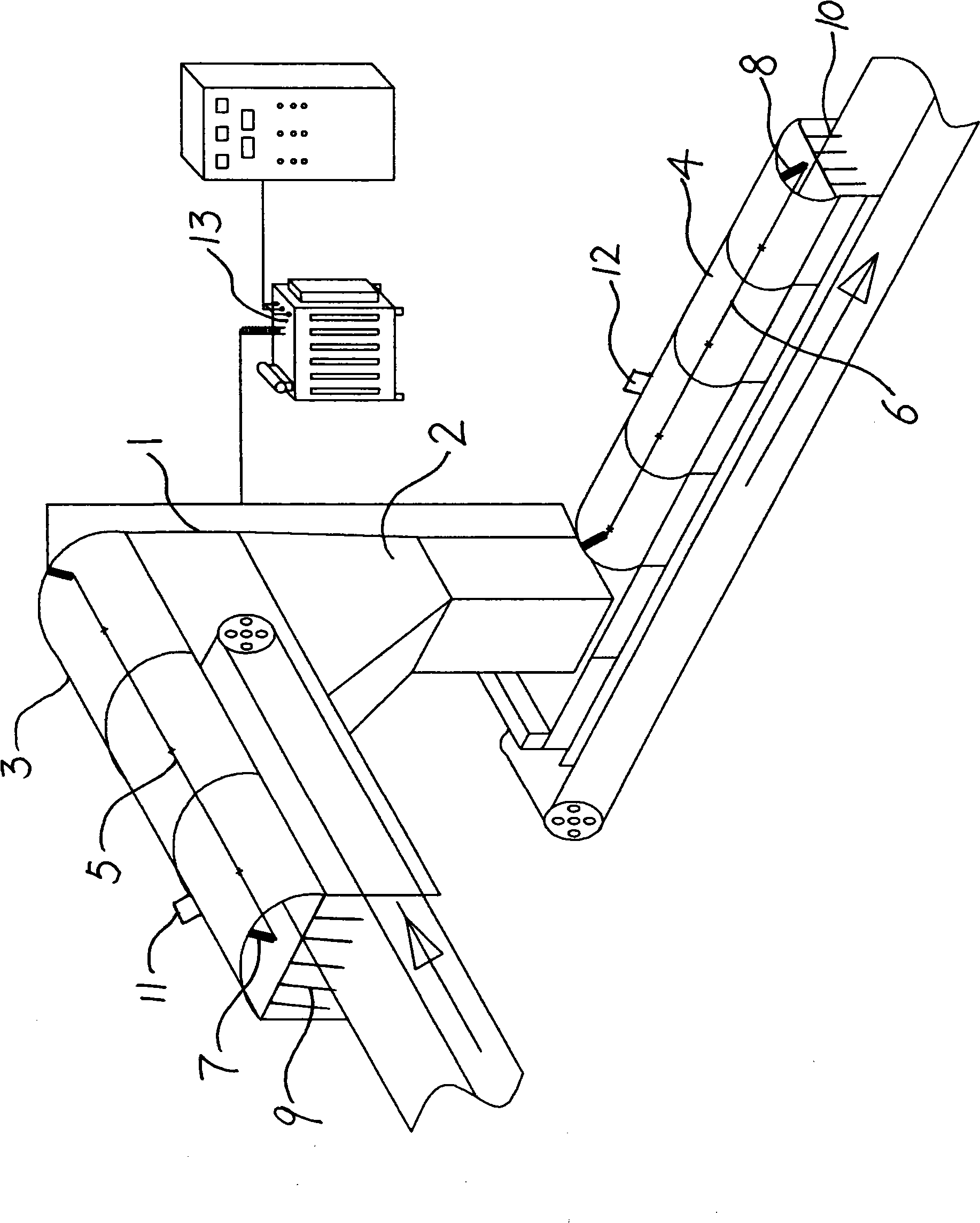

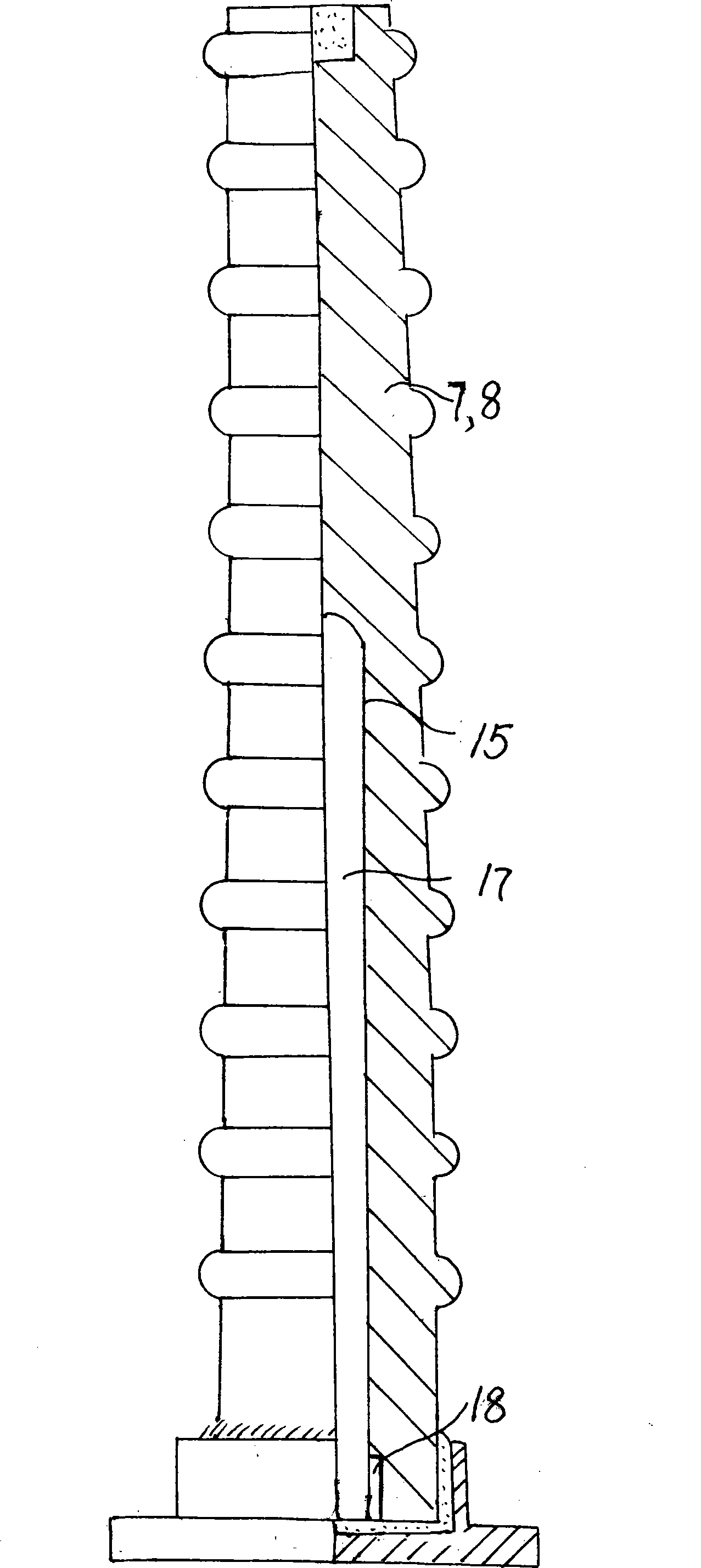

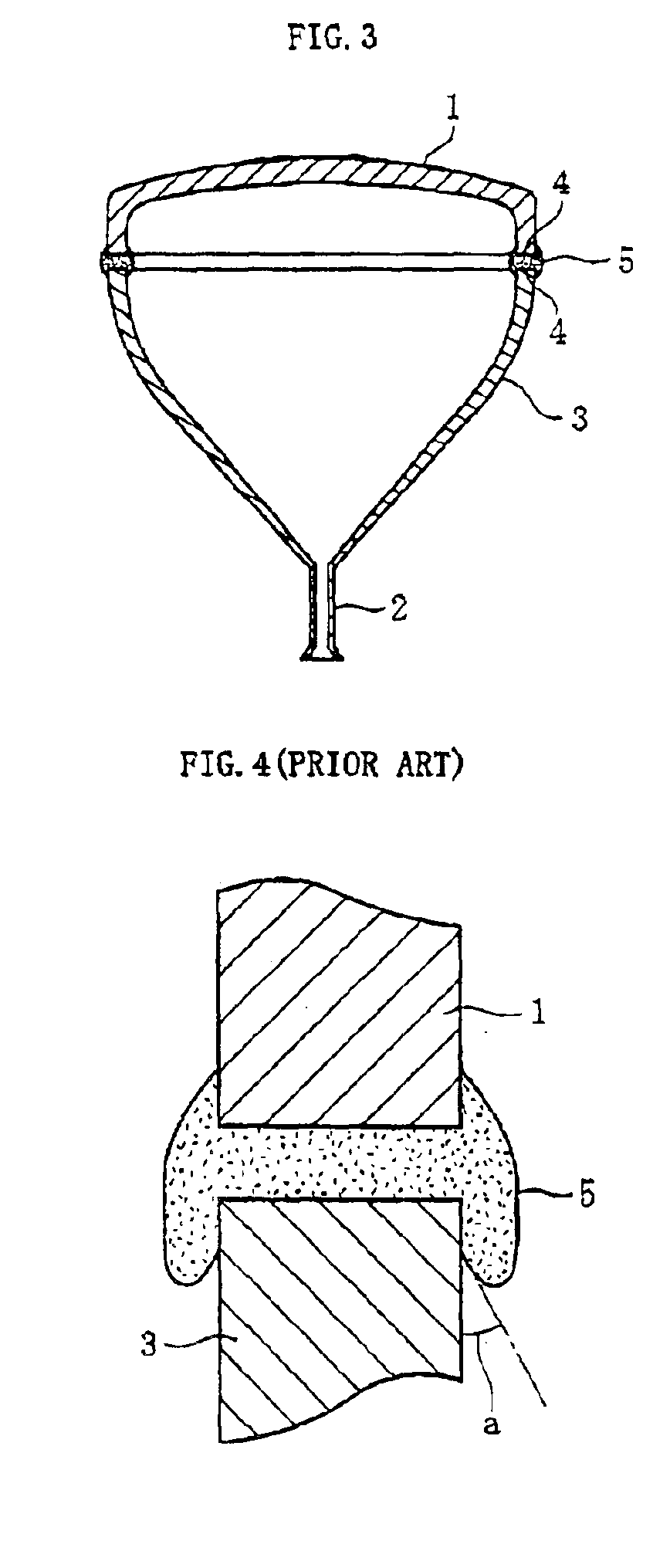

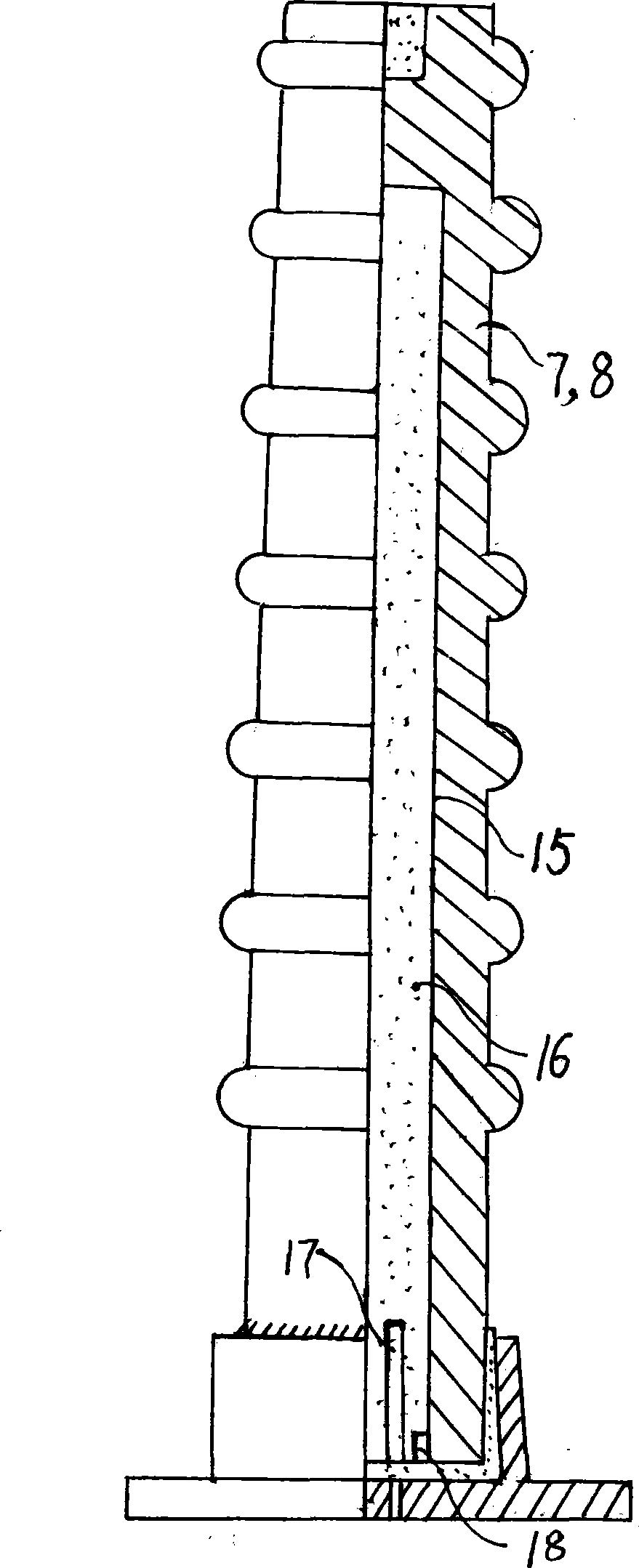

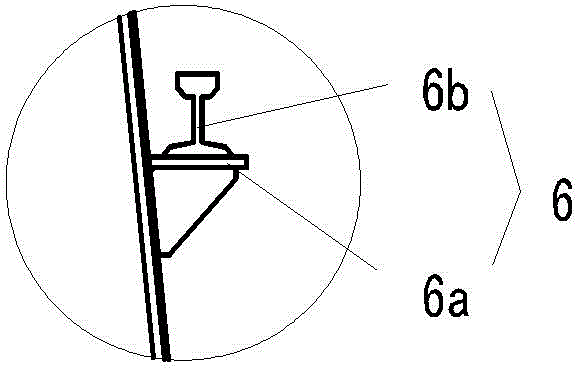

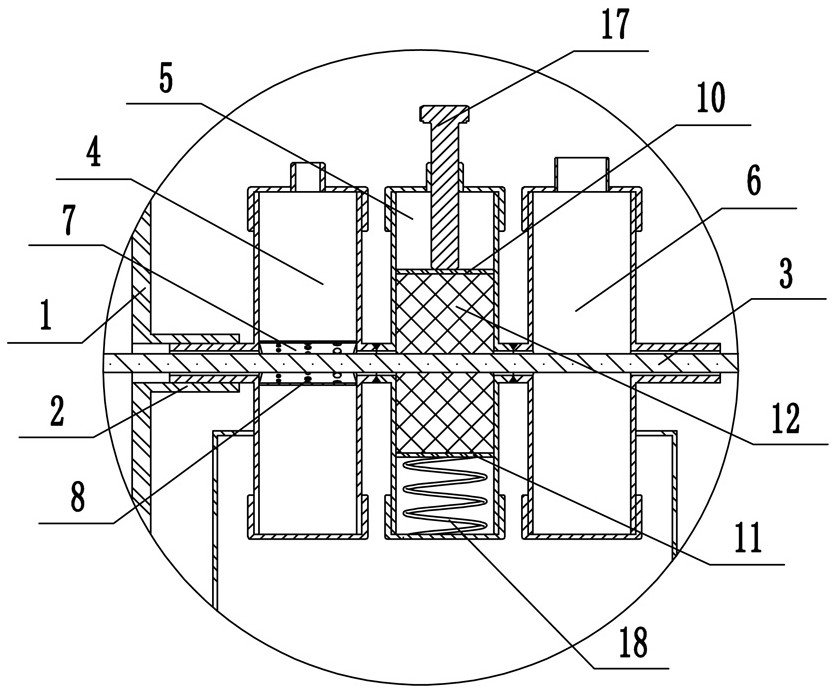

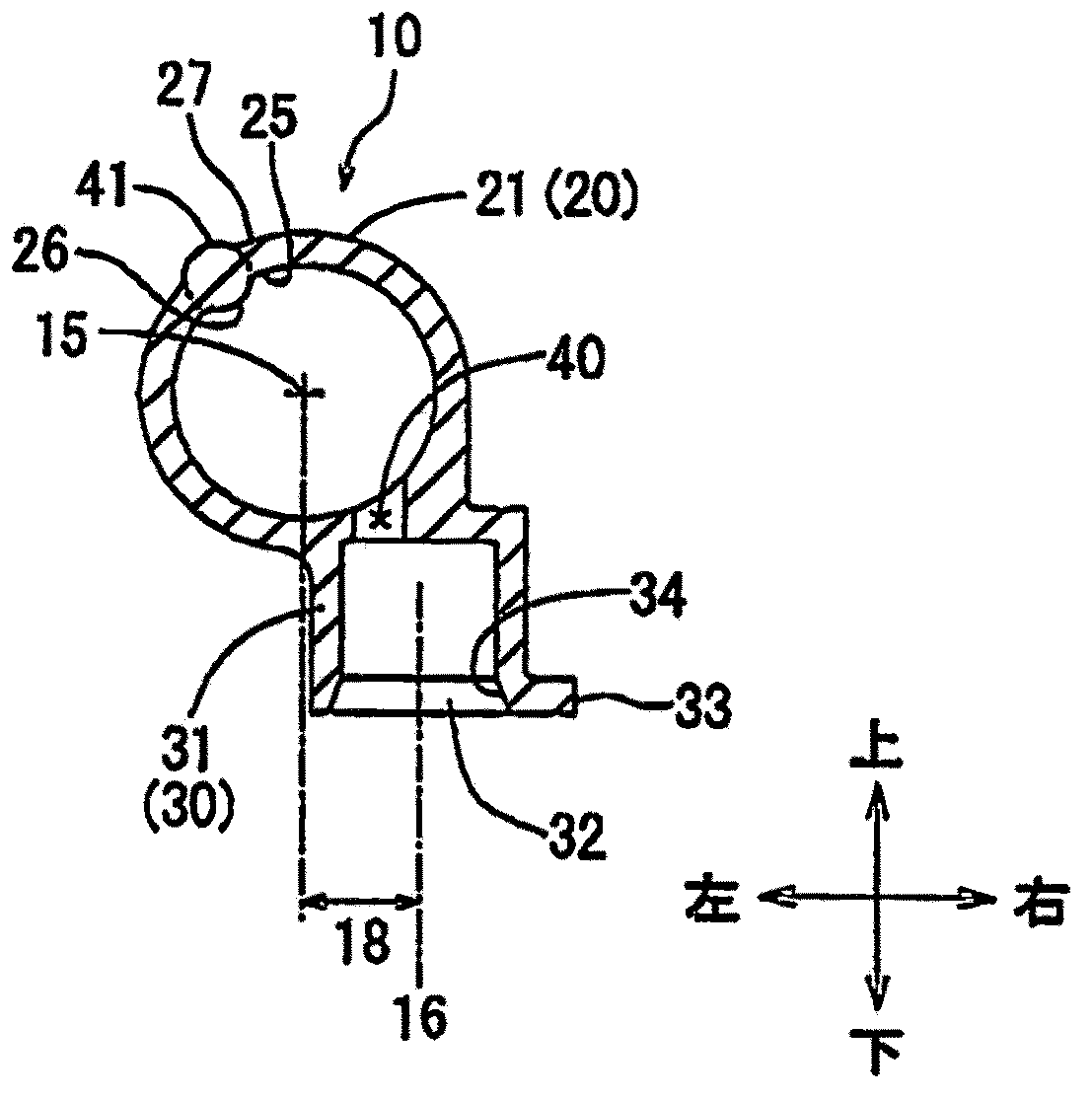

Electrostatic dust remover for belt transfer station

InactiveCN101468761ASpill suppressionGood purification effectExternal electric electrostatic seperatorLoading/unloadingElectrostatic precipitatorEngineering

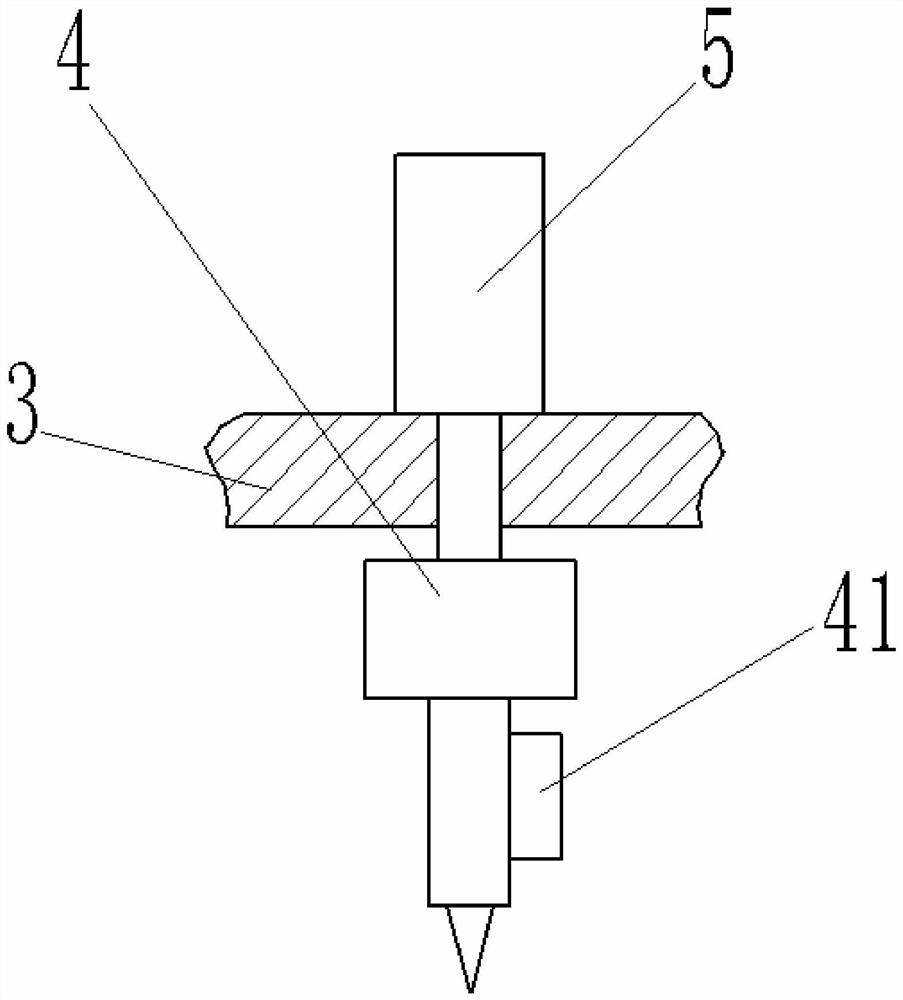

The invention belongs to the field of environmental protection dust removing equipment, in particular relates to an electrostatic dust remover for a belt transfer station, which comprises a transfer station body (1) provided with a chute (2), and a power supply part (13), wherein end parts of a transmission part of the transfer station body (1) are provided with seal covers (3, 4); the insides of the seal covers (3, 4) are provided with electrostatic dust removal terminals; the output end of the power supply part (13) is connected with the input ends of the electrostatic dust removal terminals; the electrostatic dust removal terminals comprise coronas (5, 6) and insulators (7, 8) which are fixedly connected with the coronas (5, 6); end parts of the seal covers (3, 4) are provided with dust removal soft curtains (9, 10); the insulators (7, 8) are provided with a heating device assembly bin (15) inside; and the inside of the heating device assembly bin (15) is provided with a heating device (17). The electrostatic dust remover for the belt transfer station has the advantages of simple structure, high dust removal efficiency, no noise, low energy consumption, little space occupied by the equipment, and low maintenance cost.

Owner:于文祥

Sterilization passage for cold link logistics

PendingCN112755213ASpill suppressionCreate pollutionLavatory sanitoryChemicalsCold chainThermodynamics

The invention relates to the technical field of sterilization equipment and particularly relates to a sterilization passage for cold link logistics. The sterilization passage comprises a passage body, a conveyor, a recirculating blower, an ozone generator and a plasma brush device; a plasma brush unit is arranged on the plasma brush device, the distance between the plasma brush unit and the surface of an object can be adjusted for plasma sterilization, the object can be sufficiently sterilized by ozone generated by an ultraviolet lamp tube and an ozone generator and a circulation pipeline formed on the passage body, and thus, the quality of sterilization is guaranteed; and meanwhile, pollution to environments caused by ozone overflow is avoided.

Owner:GUANGDONG AISEN MEDICAL TECH CO LTD

Automatic control circulating air curtain dustproof and dedusting device for automobile unload groove

ActiveCN103349874ALess power consumptionLow running costDispersed particle filtrationAutomatic controlElectricity

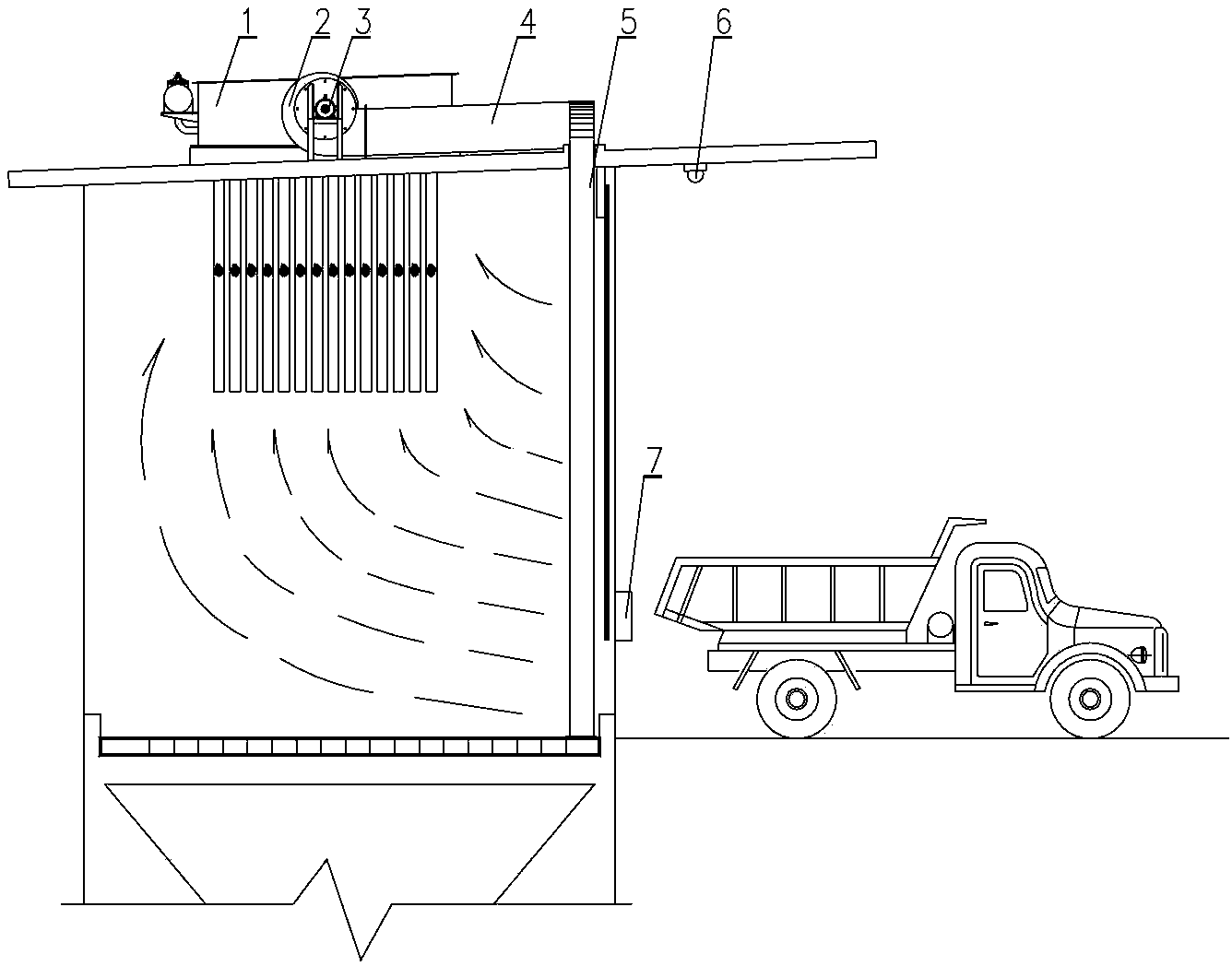

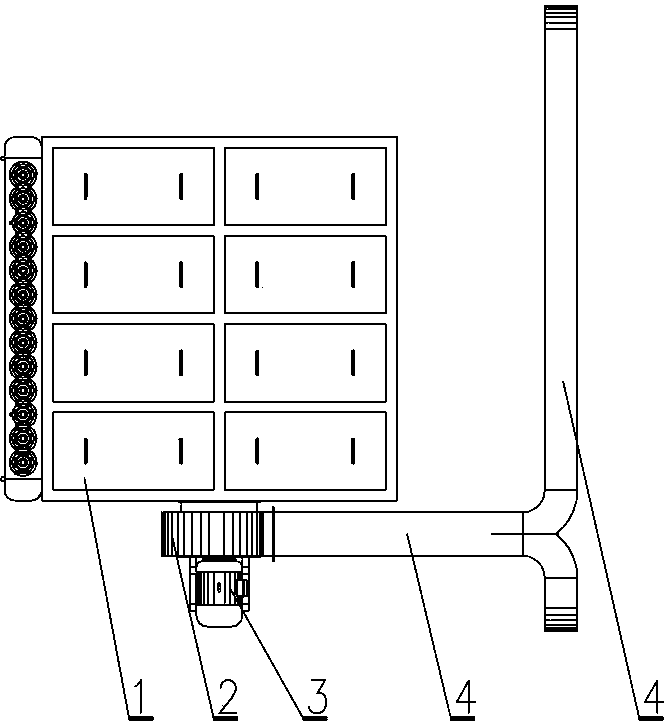

The invention discloses an automatic control circulating air curtain dustproof and dedusting device for an automobile unload groove, and mainly provides the automatic control circulating air curtain dustproof and dedusting device for the automobile unload groove, which has a simple structure, is low in cost, and has an excellent dustproof and dedusting function, and comprises a controller used for controlling various sections of the device, a dust remover arranged at the top of the automobile unload groove, a strip seam air outlet formed at the outlet of the unload groove and an electronic eye sensor arranged on the unload groove, wherein the controller, the dust remover and the electronic eye sensor are electrically connected; an air outlet of the dust remover is connected with the strip seam air outlet through an air duct. The device has a reasonable structure, and has excellent dustproof and dedusting effects on the automobile unload groove.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

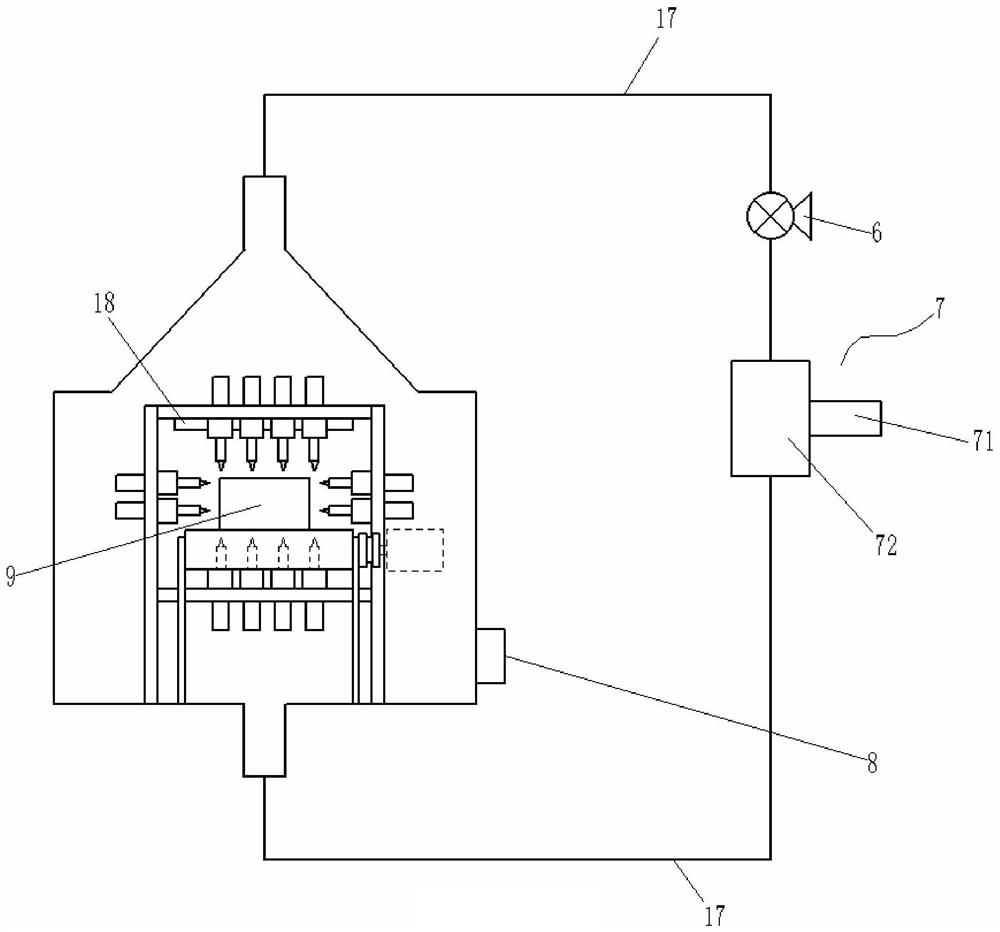

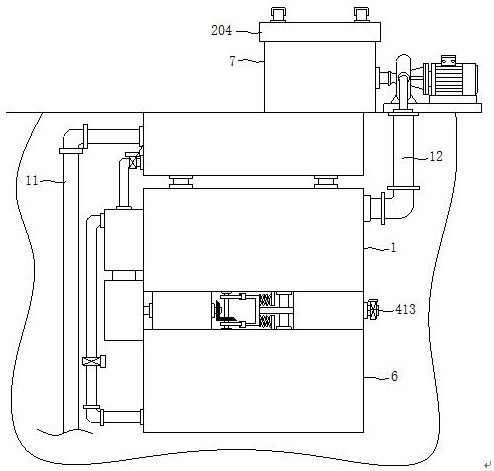

Electrostatic dust collection system of movable tripper car

InactiveCN102992053AEffective Pollution ControlAutomatic pressure adjustmentExternal electric electrostatic seperatorLoading/unloadingMultiple pointReturn channel

The invention belongs to the field of environment-friendly equipment and in particular relates to an electrostatic dust collection system of a movable tripper car. The system comprises a power supply part, a movable tripper car (1), a head dust collection hood (2), a charging conduit (3), a silo seal hood (5) and a material conveying mechanism (4), wherein the material conveying mechanism (4) is arranged on the movable tripper car (1); the head dust collection hood (2) is fixedly connected with the charging conduit (3); the discharge end of the charging conduit (3) is communicated with the silo feeding end; a dust airflow return channel (6) is arranged between the silo seal hood (5) and the charging conduit (3); the port of the dust airflow return channel (6) is communicated with a silo and the charging conduit (3) respectively; an electrostatic dust collection terminal is arranged in the silo seal hood (5); and the signal output end of the power supply part is connected with the signal input end of the electrostatic dust collection terminal. The system can be configured in multiple points, has an ideal dust collection effect, and can be automatically controlled.

Owner:LIAONING ZHONGBANG HI TECH DEV

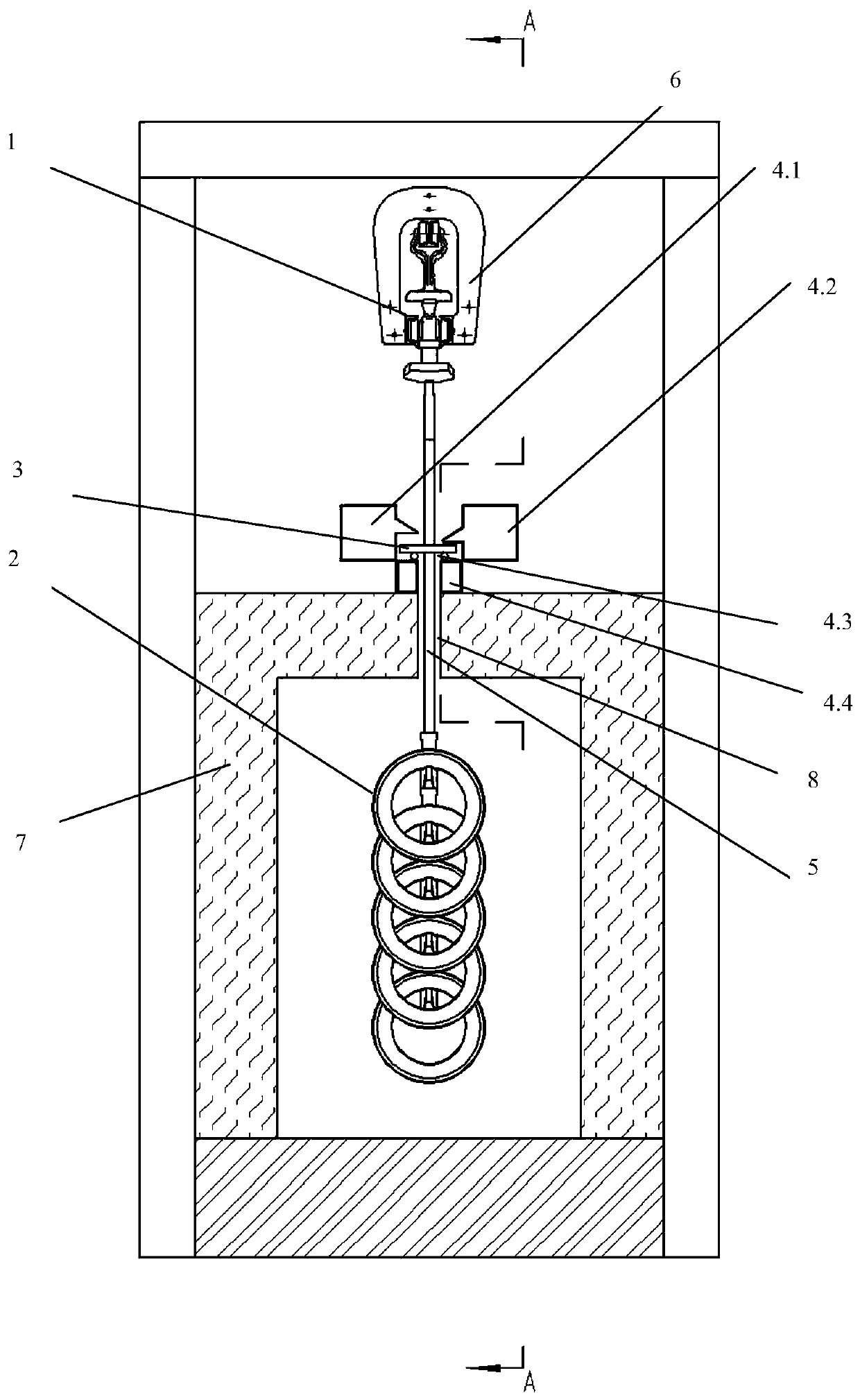

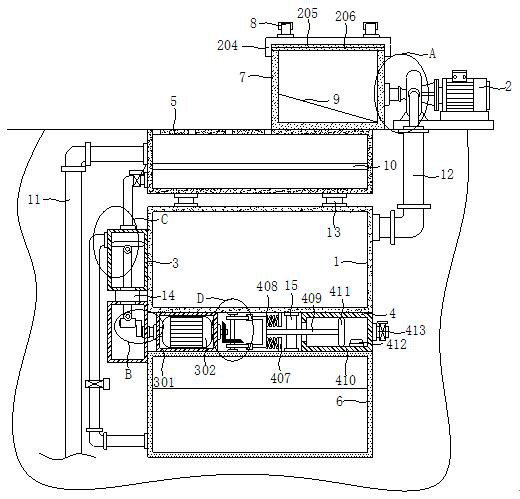

Lime dissolving tank

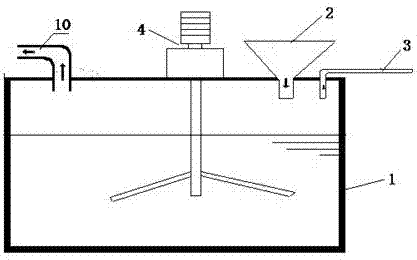

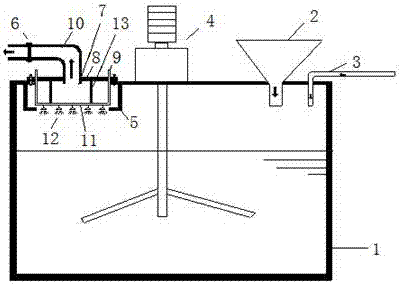

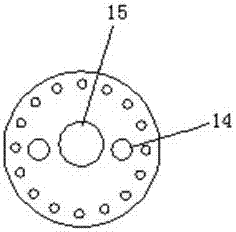

InactiveCN106984203ASpill suppressionAvoid dischargeRotary stirring mixersMixing methodsWastewaterDistribution system

The invention relates to a lime dissolving tank, particularly relates to a lime dissolving tank for a wastewater treatment system and belongs to the technical field of wastewater treatment equipment. According to the technical scheme, the lime dissolving tank comprises a tank body (1), a lime feeding system (2), a lime dissolving water distribution system (3) and a stirring device (4), wherein a dust collection device (7) and a ventilation elbow pipe (10) are arranged at the top of the tank body (1); the dust collection device (7) comprises a flange blind plate (8), a water inlet pipe (9), a fish fin tube (11) and spray heads (12); the flange blind plate (8) is fixed at the top of the tank body (1); the flange blind plate (8) is provided with the ventilation elbow pipe (10); the fish fin tube (11) is fixed at the lower part of the flange blind plate (8) and is provided with a plurality of spray heads (12); and the water inlet pipe (9) passes through the flange blind plate (8) and is connected with the fish fin tube (11). The lime dissolving tank has the beneficial effect that a lot of dust generated in the lime preparation process is effectively prevented from being discharged into atmosphere to pollute the environment.

Owner:HANGANG GRP HANBAO IRON & STEEL

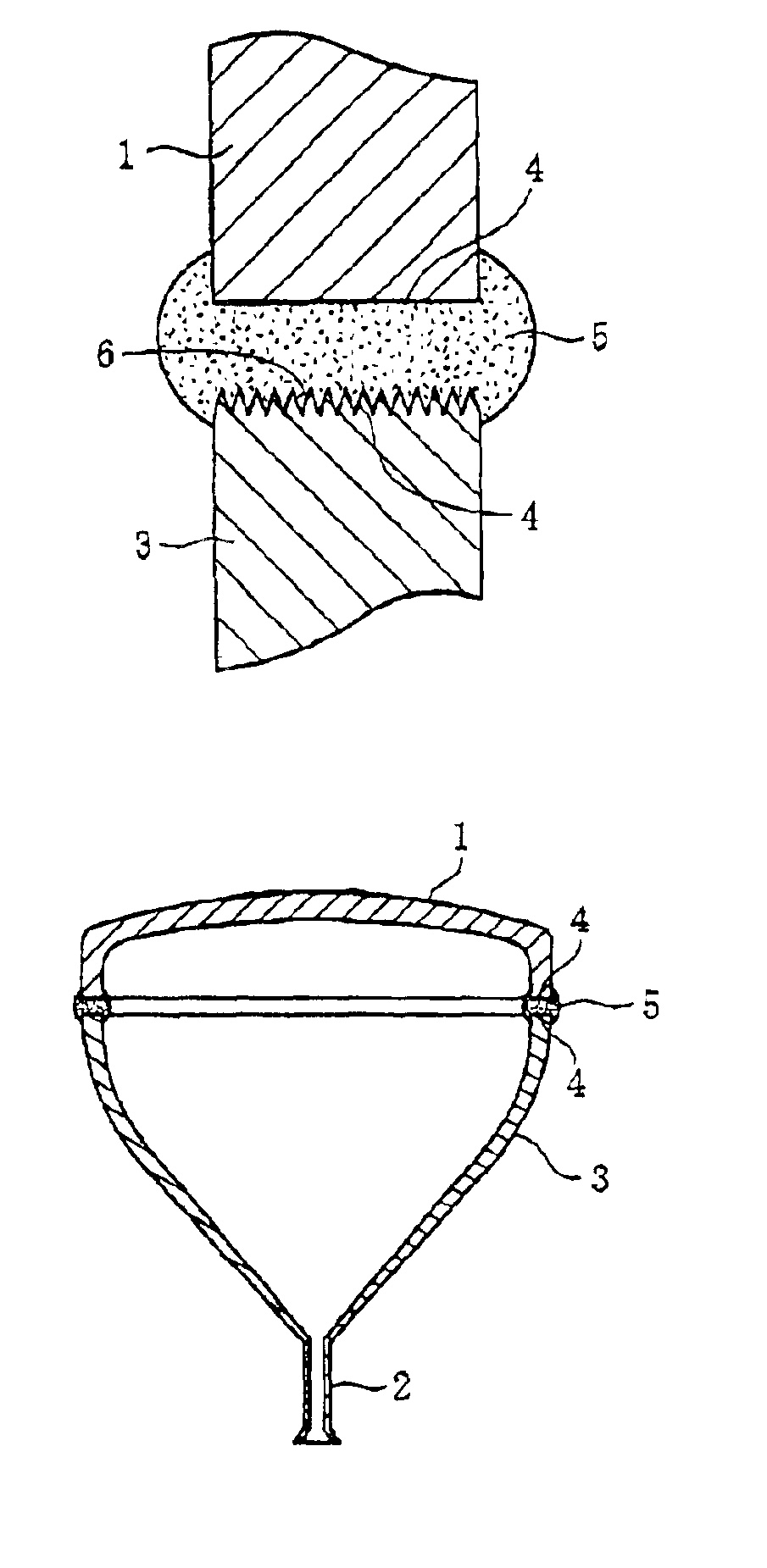

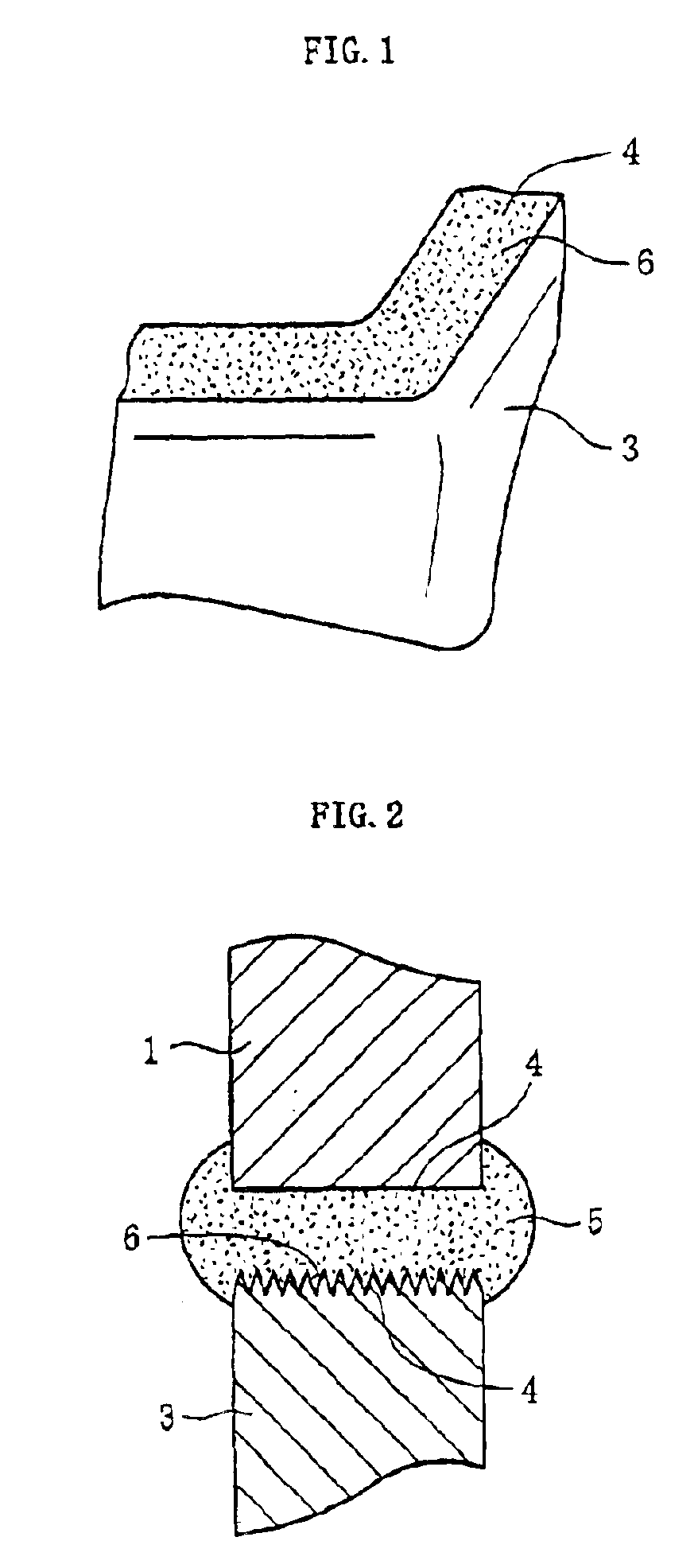

Funnel for color cathode ray tube

InactiveUS6885142B2Good sealing shapeHigh strengthCathode-ray/electron-beam tube electrical connectionTube surface sealingRough surfaceFrit

A funnel for a color cathode ray tube comprises a seal end surface to which a panel is sealed through a frit glass. An area occupying at least 50% of the seal end surface in a width direction is a rough surface. The rough surface satisfies conditions of 10<=Rz<=25 mum and 2.5<Sm / Rz<=6.0, where Rz is the ten point height of roughness profile in the width direction and Sm is the mean interval of profile peaks and profile valleys in the width direction. The rough surface comprises a plurality of dimple-like micro cavities formed by the profile peaks and the profile valleys.

Owner:NIPPON ELECTRIC GLASS CO LTD

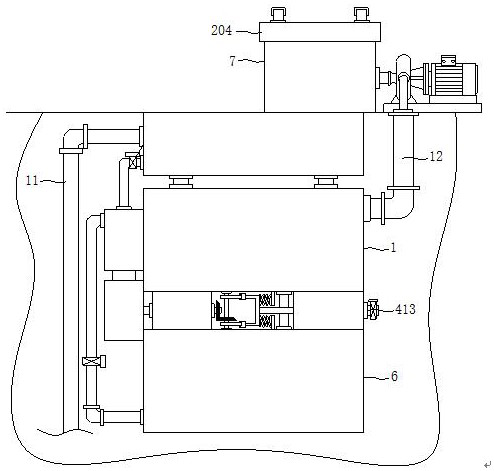

Electrostatic dust remover for belt transfer station

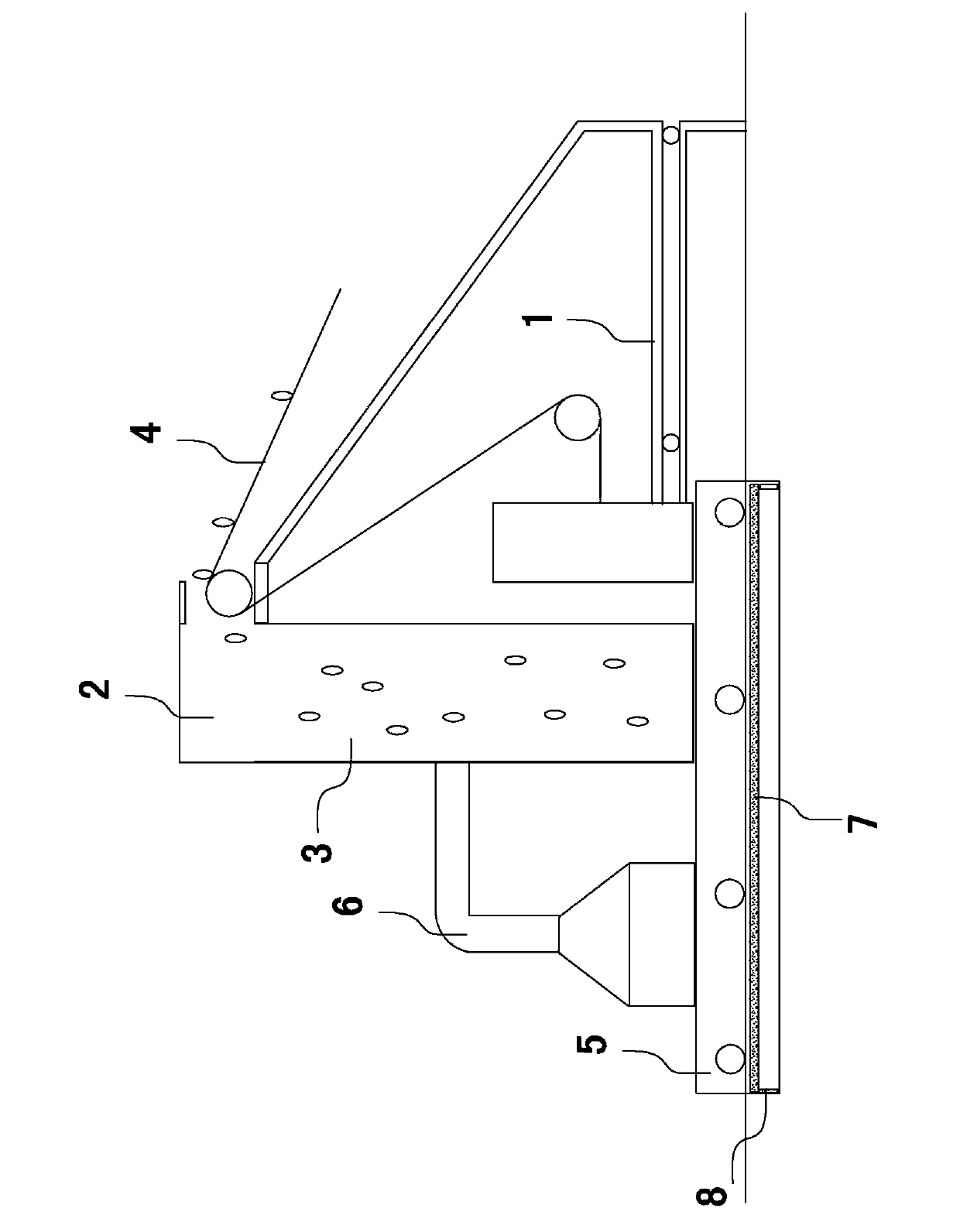

InactiveCN101468760ASpill suppressionGood purification effectExternal electric electrostatic seperatorLoading/unloadingEngineeringEnergy consumption

The invention belongs to the field of environmental protection dust removing equipment, in particular relates to an electrostatic dust remover for a belt transfer station, which comprises a transfer station body (1) provided with a chute (2), and a power supply part (13), wherein end parts of a transmission part of the transfer station body (1) are provided with seal covers (3, 4); the insides of the seal covers (3, 4) are provided with electrostatic dust removal terminals; the output end of the power supply part (13) is connected with the input ends of the electrostatic dust removal terminals; the electrostatic dust removal terminals comprise coronas (5, 6) and insulators (7, 8) which are fixedly connected with the coronas (5, 6); end parts of the seal covers (3, 4) are provided with dust removal soft curtains (9, 10); and the insides of the insulators (7, 8) are provided with electric heaters (17). The electrostatic dust remover for the belt transfer station has the advantages of simple structure, high dust removal efficiency, no noise, low energy consumption, little space occupied by the equipment, and low maintenance cost.

Owner:于文祥

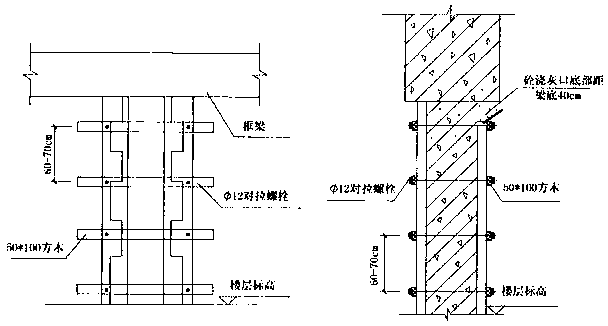

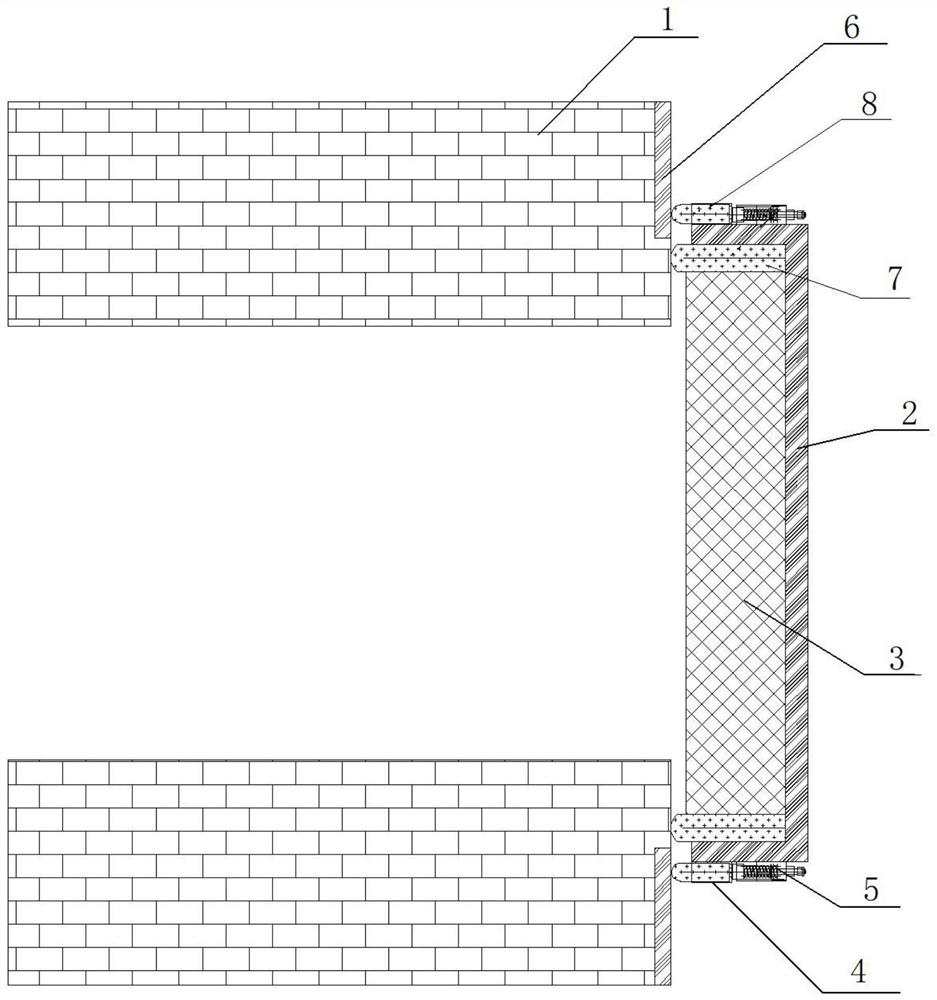

Novel construction process for preventing a constructional column from overflowing slurry

InactiveCN111042386AImprove molding qualitySpill suppressionWallsForms/shuttering/falseworksArchitectural engineeringSlurry

The invention provides a novel construction process for preventing a constructional column from overflowing slurry. The process comprises the following specific steps that 1, the constructional columnis reserved, and arranged in a retreating-before-advancing and three-retreating three-advancing mode; 2, a formwork is manufactured according to size of the constructional column; 3, double-sided sponge glue strips are used for pasting according to the shape of a joint motor of the constructional column; 4, surface layers of the sponge glue strips on one side close to the formwork are not torn away; 5, concrete filling and pouring are carried out, and concrete is vibrated to be compact; and 6, after the constructional column concrete reaches the prescribed strength, the formwork is removed, and clearing treatment is carried out. Compared with the prior art, the novel construction process has the beneficial effects that the forming quality effect of the constructional column is greatly improved, the concrete pouring quality of the constructional column is improved, the integrity of a wall body is met, and the anti-seismic requirement is achieved.

Owner:江苏永联精筑建设集团有限公司

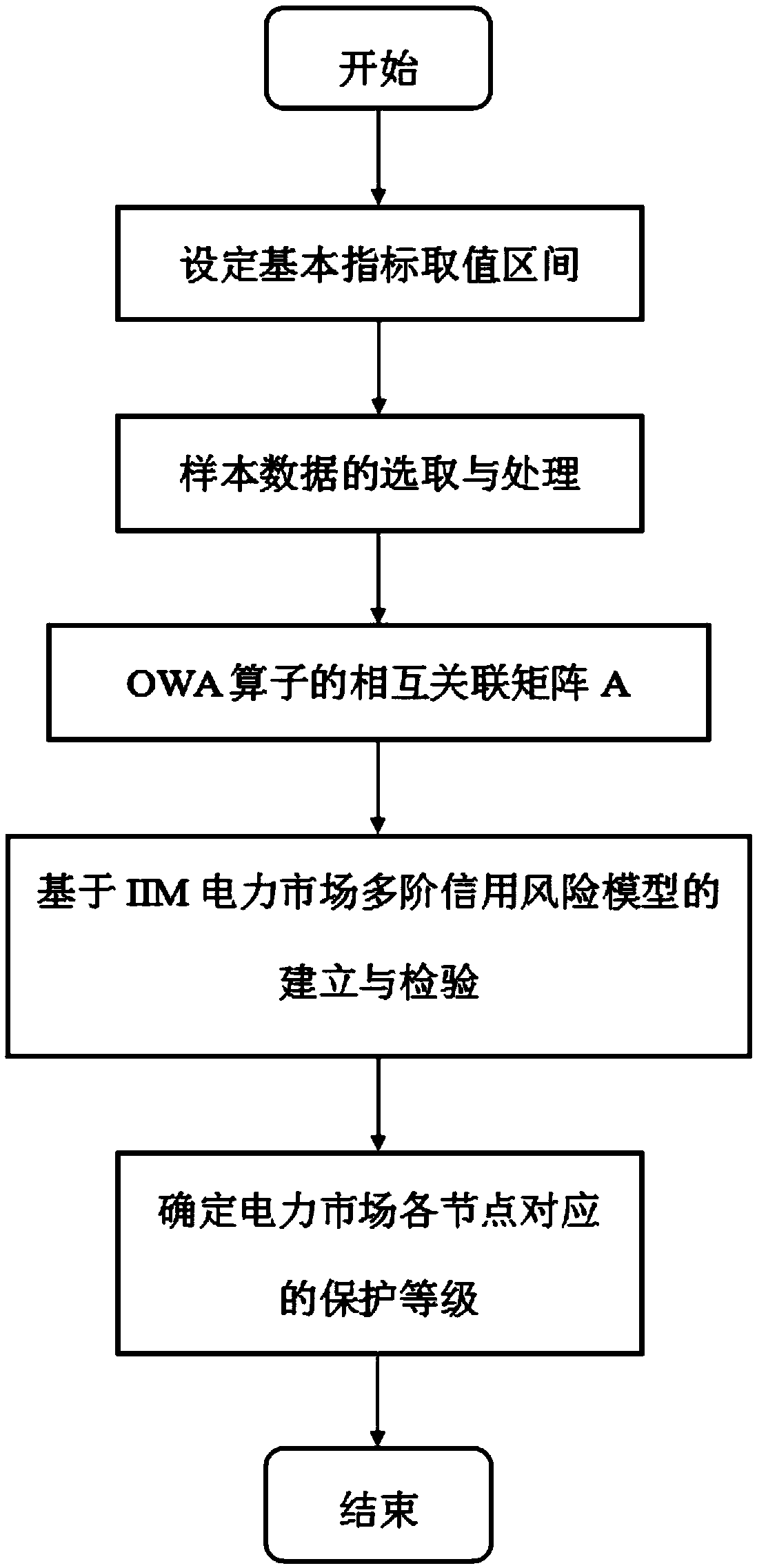

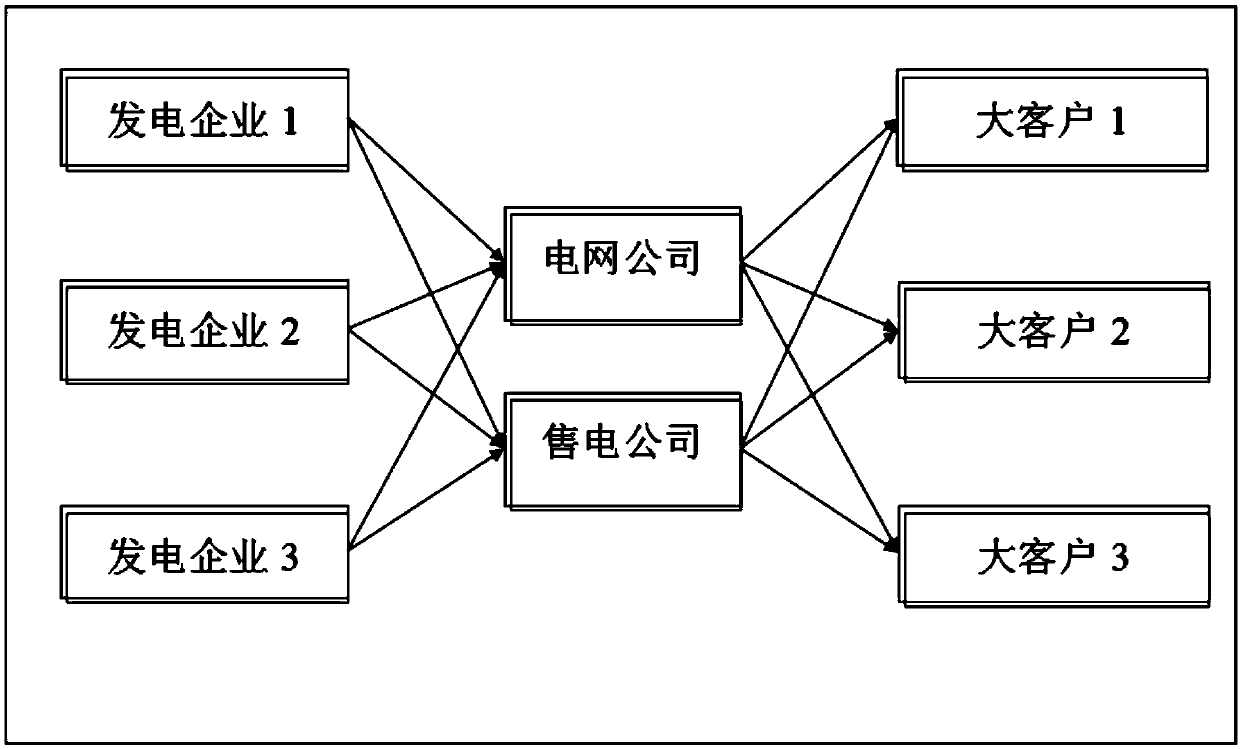

Regional power market multi-order credit risk early warning method

PendingCN111192058AMitigation of Waterfall Risk EffectsMaintain securityResourcesCommerceFinancial transactionPower market

The invention relates to a regional power market multi-order credit risk early warning method. The method comprises the steps of setting a value interval for a basic index of a decision node in a power market; selecting sample data; allocating corresponding weights to the basic indexes, and inputting the sample data into an OWA operator to obtain an incidence matrix; establishing an IIM-based power market multi-order credit risk effect model; inputting the incidence matrix and the first-order risk effect value into an IIM-based power market multi-order credit risk effect model to obtain a multi-order credit risk effect value of each node in the power market; and comparing and analyzing the multi-order credit risk effect value of each node in the power market, and distinguishing the protection level of each node. According to the invention, the waterfall risk effect of the untrusted behavior of the transaction subject on the regional power transaction market is reduced, the propagationand overflow of the credit risk of the regional power transaction market subject are inhibited, and the safety and stability of the state grid transaction market are maintained.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +2

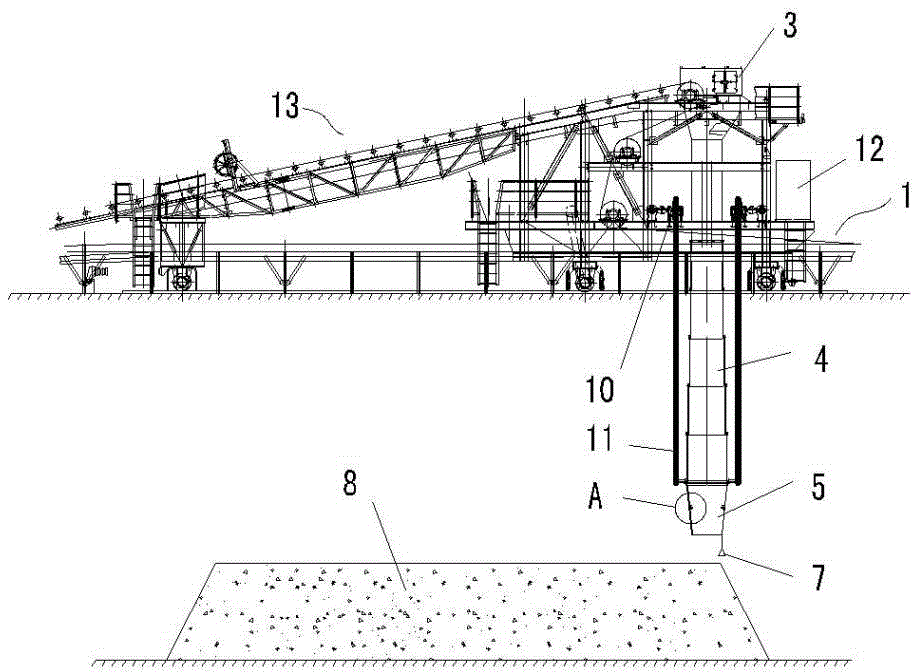

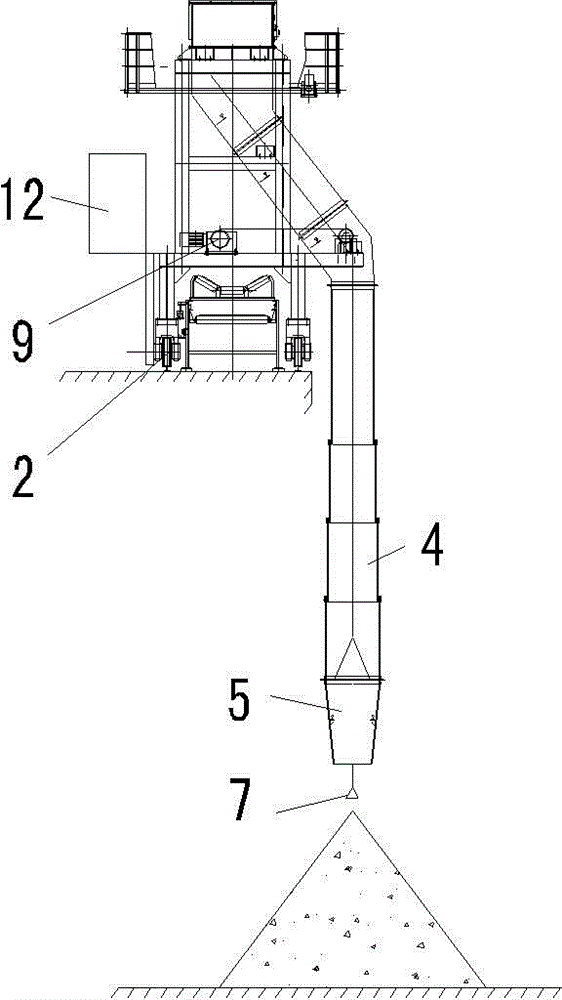

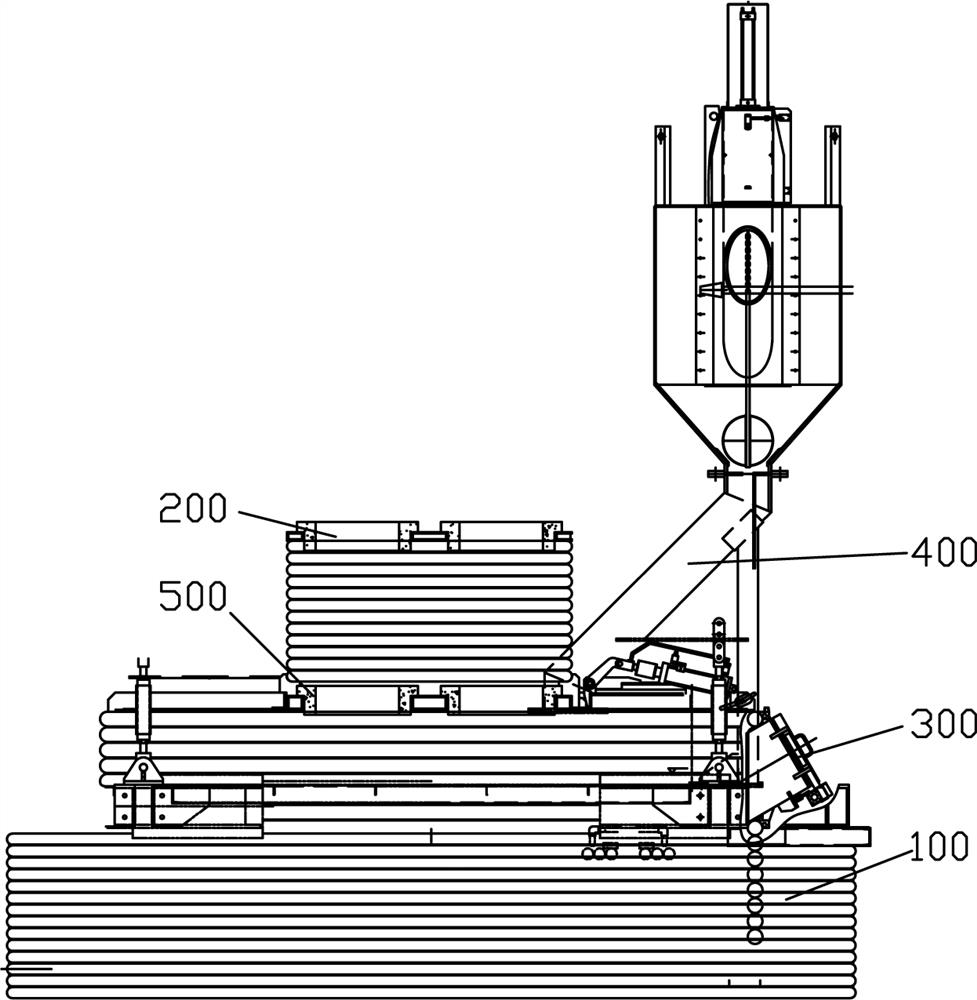

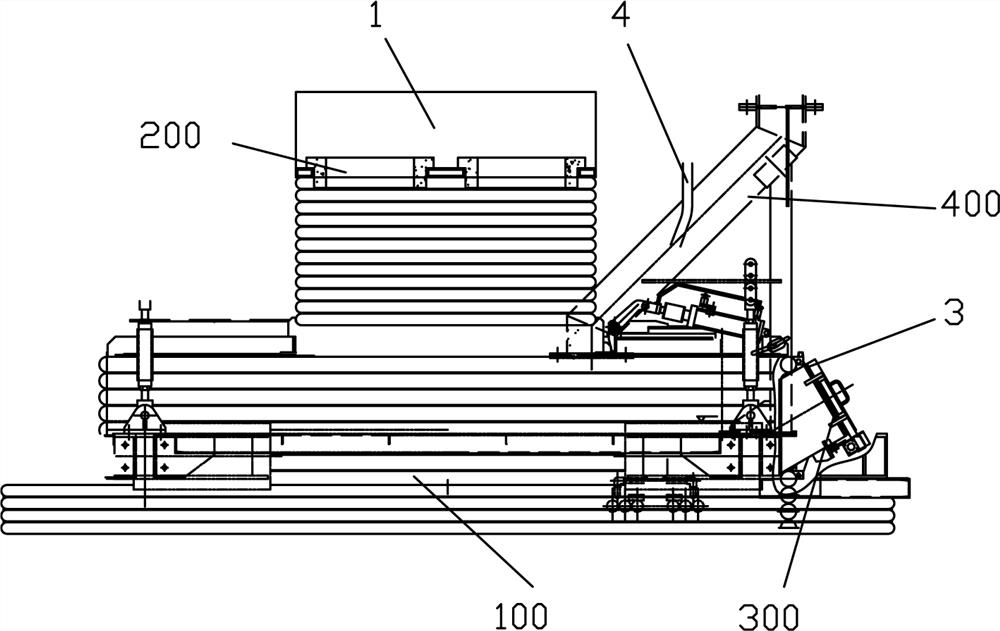

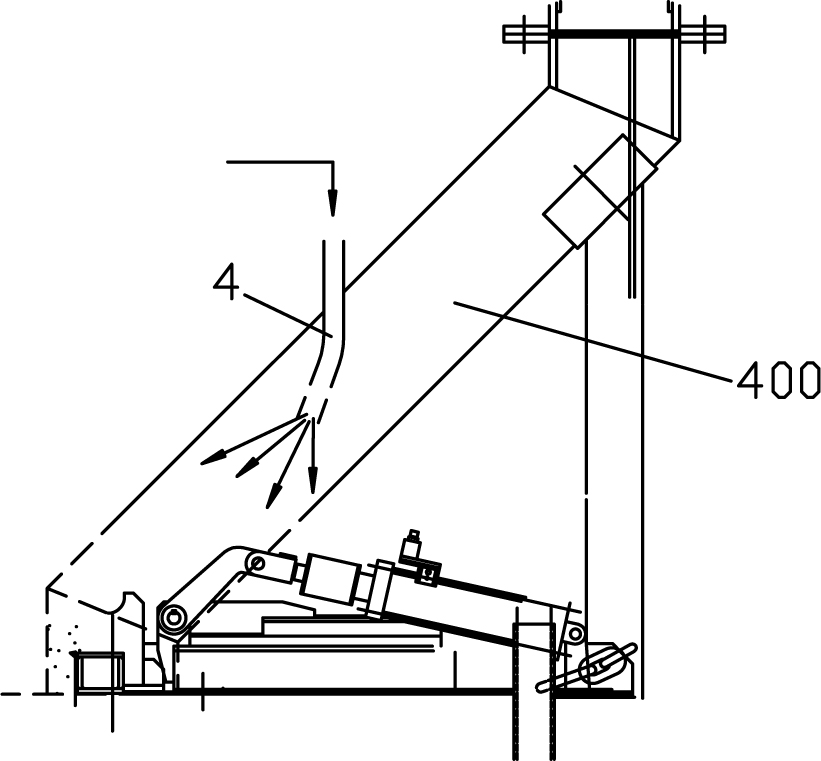

Intelligent material stacking trolley

The invention discloses an intelligent material stacking trolley, which comprises a trolley body and a driving device, wherein the trolley body is arranged on a walking rail, the driving device is used for driving the trolley body to move on the walking rail, a funnel is arranged on the trolley body, a telescopic slipping pipe and a hoisting mechanism are arranged on a material outlet of the funnel, the hoisting mechanism is used for driving the telescopic slipping pipe to be elongated or shortened, a material collecting and dust suppression hopper is arranged on a material outlet of the telescopic slipping pipe, the inner diameter of the material collecting and dust suppression hopper is gradually decreased in the vertical downward direction, a material accumulation platform used for accumulation and material buffering is arranged on the material outlet of the telescopic slipping pipe, a material level detecting device is arranged on the material outlet of the material collecting and dust suppression hopper, the intelligent material stacking trolley also comprises a control system, and the control system comprises an industrial control computer which is connected with the material level detecting device and is used for controlling the action of the driving device and the hoisting mechanism. The intelligent material stacking trolley disclosed by the invention has the advantages that the requirements of a sealed material blending field on stacking material blending equipment can be met, and in addition, the flying dust in the operation process can be effectively reduced.

Owner:CISDI SHANGHAI ENG CO LTD

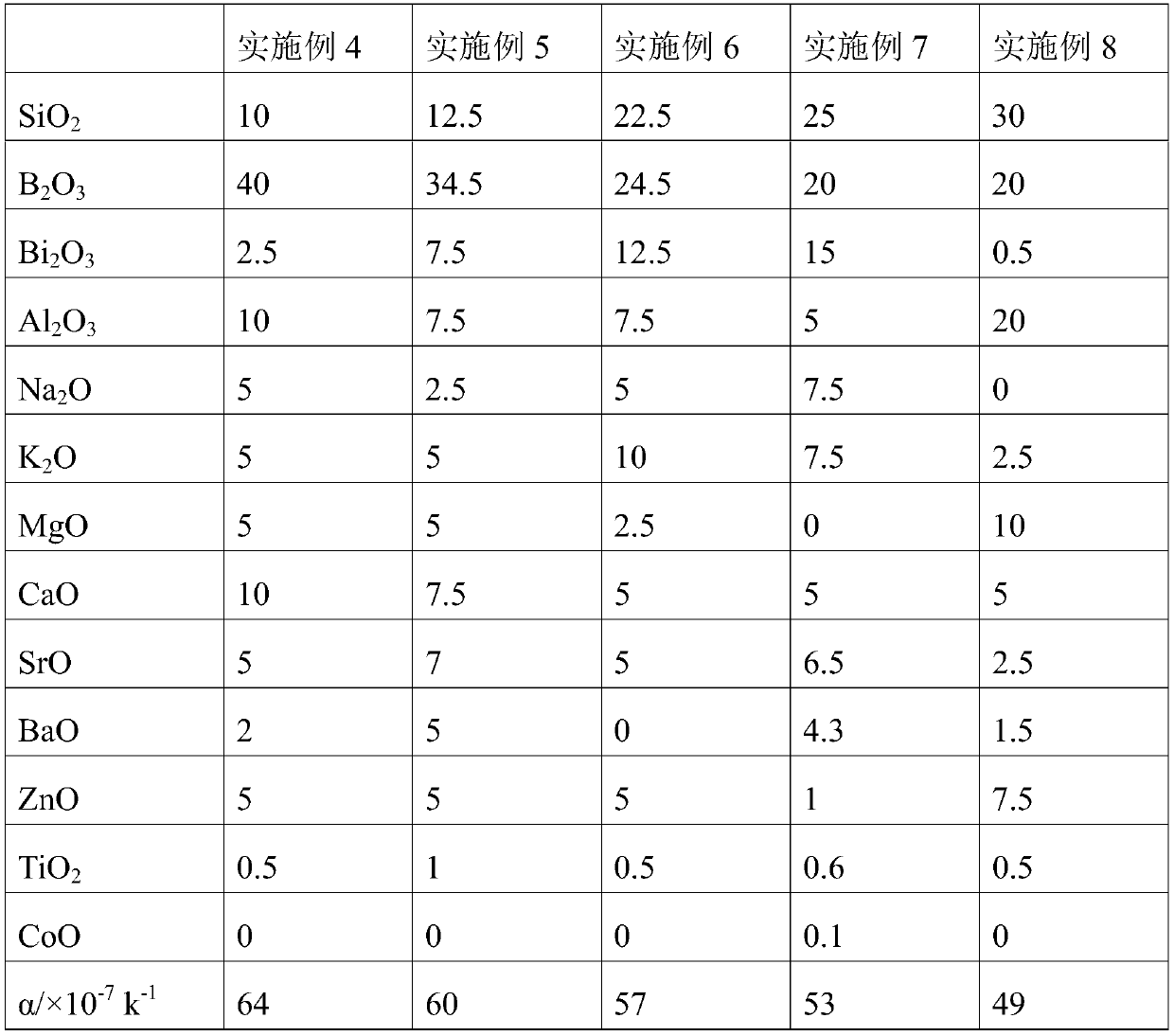

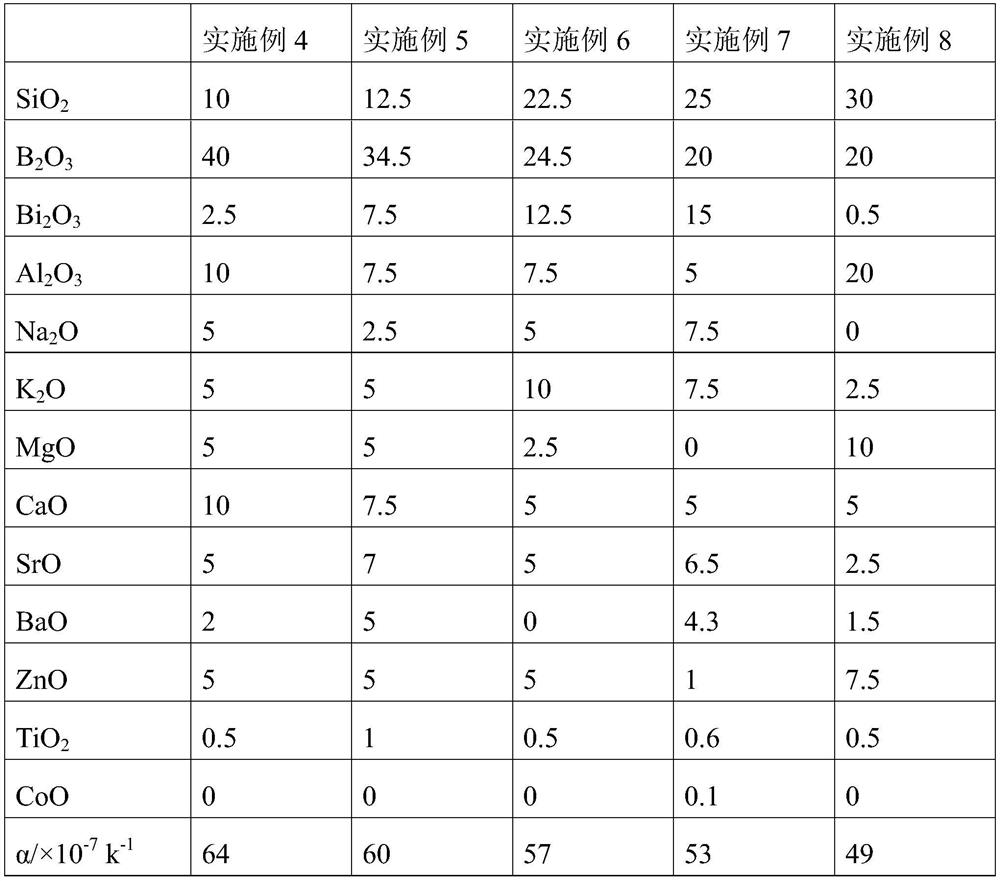

Titanium and sealing alloy sealing glass material for thermal batteries as well as preparation method and application thereof

ActiveCN111018351AStable structureImprove insulation performanceDeferred-action cellsGlass furnace apparatusOxidePhase splitting

The invention discloses a titanium and sealing alloy sealing glass material for thermal batteries and a preparation method of the titanium and sealing alloy sealing glass material. Silicon dioxide anddiboron trioxide are used as a skeleton structure, wettability and interface stability of glass, titanium and an alloy thereof are improved by adding a large proportion of diboron trioxide, glass system stability is achieved by controlling the proportion of silicon dioxide to diboron trioxide, and the problems of phase splitting, crystallization and the like are not likely to occur after annealing and other heat treatment steps. A very small amount of alkali metal elements are used for reducing the melting temperature and increasing the expansion coefficient, and the chemical stability of theglass is slightly influenced; alkaline earth metal oxides such as MgO, CaO, SrO and BaO are added, network gaps are filled with positive ions Mg < 2 + >, Ca < 2 + >, Sr < 2 + > and Ba < 2 + >, a mixed alkali effect and a pressing effect are generated, the activity of alkali metal ions is hindered, and the insulating property of the glass is improved; AlPO4 units can be formed in the glass by adding Al2O3, and a straight chain is changed into a network structure, so that the structure of the glass tends to be stable, and the chemical stability is improved.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Gas-solid dust sealing device

The invention discloses a gas-solid dust sealing device. The gas-solid dust sealing device comprises a building platform, an ash silo, a penetrating opening and a steel wire rope, wherein the ash silo is arranged above the building platform, the penetrating opening is formed in the side wall of the ash silo, and the gas-solid dust sealing device further comprises a positive pressure tank, a tightening force tank and a negative pressure tank which sequentially communicate with one another in the radial direction, and the penetrating opening is detachably connected with the positive pressure tank; one end of the steel wire rope sequentially penetrates through the negative pressure tank, the tightening force tank, the positive pressure tank and the penetrating opening and then extends into the ash silo; a sealing pipe is arranged in the positive pressure tank, a plurality of sealing holes are formed in the sealing pipe, and a pipeline I is arranged on the positive pressure tank to communicate with a positive pressure air source; an upper pressing ring and a lower pressing ring are elastically connected into the tightening tank, the space between the upper pressing ring and the lower pressing ring is filled with rock wool, and the steel wire rope is tightly wrapped with the rock wool; and a pipeline II is arranged on the negative pressure tank to communicate with a negative pressure air source. Through a three-stage sealing structure, it is effectively guaranteed that dust does not overflow, it is guaranteed that dry ash filling operation meets the environmental protection requirement, the actual production requirement of an enterprise is met, and good practicability is achieved.

Owner:HENAN JINMEI TIANQING COAL CHEMICAL CO LTD

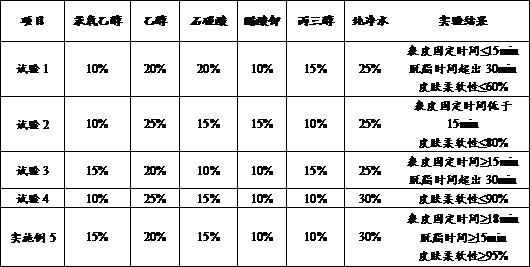

Skin repair liquid and preparation method and application thereof

InactiveCN112587427AShorten the timeImprove permeabilityCosmetic preparationsToilet preparationsSKIN SOFTNESSGlycerol

The invention is applicable to the technical field of skin repair, and provides skin repair liquid as well as a preparation method and application thereof. The skin repair liquid comprises phenoxyethanol, ethanol, carbolic acid, potassium acetate, glycerol and water, wherein the mass ratio of the phenoxyethanol to the ethanol to the carbolic acid to the potassium acetate to the glycerol to the water is (10-15): (15-20): (10-15): (5-10): (5-10): (25-30). The skin repair liquid disclosed by the invention is short in skin surface layer repairing time and takes effect quickly, and can be used forincreasing the skin permeability, inhibiting moisture volatilization and secretion overflow in the skin and dissolving skin surface layer secretions (connective tissues, lipids and the like). The skinrepair liquid can repair skin tension, relieve wrinkles and maintain skin softness, so that the effect of quickly drying the skin surface layer is achieved, the contact surface of damaged skin is naturally combined with cosmetics, and the problem that natural combination of the skin and the cosmetics is affected due to mutual repulsion of surface layer secretions of the damaged skin and the cosmetics is effectively solved.

Owner:济南市第二殡仪馆

Titanium and Kovar alloy sealing glass material for thermal battery, preparation method and application

ActiveCN111018351BStable structureImprove insulation performanceDeferred-action cellsGlass furnace apparatusBoron trioxideTitanium alloy

The invention discloses a titanium and titanium alloy and Kovar alloy sealing glass material for thermal batteries and a preparation method thereof. Silicon dioxide and diboron trioxide are used as the skeleton structure, and a relatively large proportion of diboron trioxide is added to Improve the wettability and interface stability of glass and titanium and its alloys, and achieve a stable glass system by controlling the ratio of silicon dioxide and boron trioxide. After annealing and other heat treatment steps, problems such as phase separation and crystallization are not easy to occur; A small amount of alkali metal elements can reduce the melting temperature, increase the expansion coefficient, and have a small impact on the chemical stability of the glass; add alkaline earth metal oxides such as MgO, CaO, SrO, and BaO, and its cation Mg 2+ , Ca 2+ 、Sr 2+ 、Ba 2+ Fill in the network gap and produce mixed alkali effect and suppression effect, which hinders the activity of alkali metal ions and improves the insulating performance of glass; adding Al 2 o 3 AlPO can be formed in the glass 4 The unit changes from a straight chain to a network structure, which stabilizes the structure of the glass and improves its chemical stability.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Furnace top sealing structure of suspended type heat treatment furnace

PendingCN110608612ASuppression of furnace gas escapeSmooth transitionFurnace crowns/roofsWorking temperatureMechanical engineering

Provided is a furnace top sealing structure of a suspended type heat treatment furnace. The furnace top sealing structure comprises a floating type cowl flap, a cooling beam and positioning pins. Thecooling beam comprises a wind gathering beam, a duckbill wind spraying beam, rails and hollow beams. The sufficient linearity can be kept during work at the room temperature and the high temperature.The floating type cowl flap serves as a cover plate and is pulled by the dead weight to move on the rails with the sufficient linearity, and the aim of retraining furnace gas from overflowing is realized. Meanwhile, a wind curtain is arranged at the upper portion of the floating type cowl flap, and therefore a small amount of overflowing furnace gas is isolated, and it is ensured that the workingtemperature of parts accumulated and conveyed on the upper side of the floating type cowl flap is close to the environment temperature all the time. Considering that the floating type cowl flap is notsupported by rails outside the furnace, the positioning pins are arranged on hanging rods. By setting the proper positions of the positioning pins, the front end of the floating type cowl flap is ina pitching state outside the furnace, and therefore it can be ensured that the transition action of the weight of the floating type cowl flap from the positioning pins to the rails is smooth when workpieces enter or leave the furnace.

Owner:天津鼎元热工工程有限公司

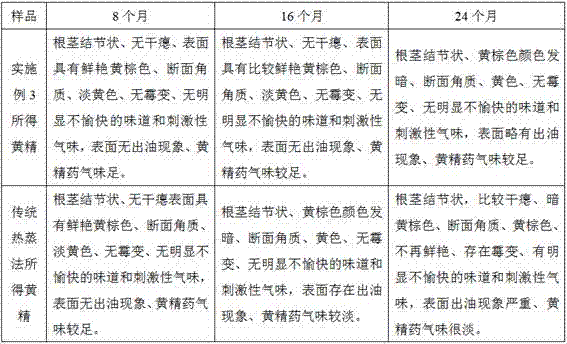

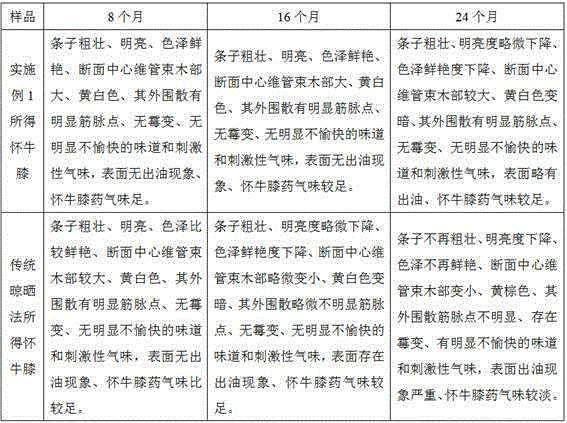

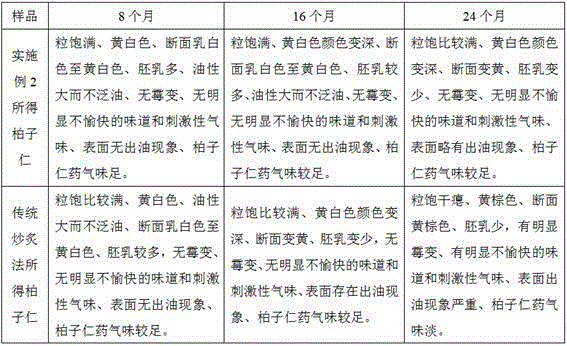

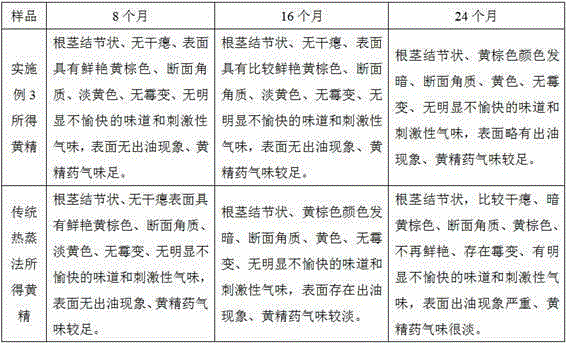

A maintenance method for oil-prone Chinese medicinal materials

ActiveCN105253356BInhibit oil bleed phenomenonQuality assurancePackage sterilisationPackaging under special atmospheric conditionsTraditional medicineFungus

Owner:北京同仁堂健康药业(福州)有限公司

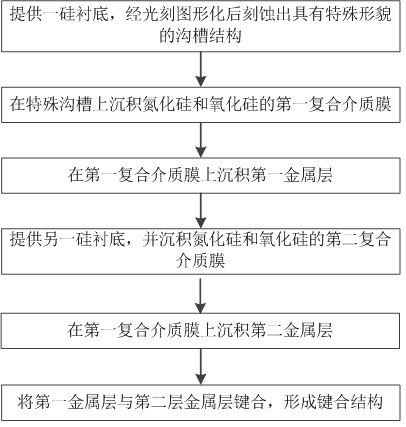

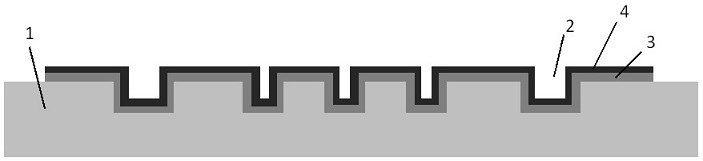

High-strength bonding structure with special groove and preparation method of high-strength bonding structure

InactiveCN113506784APrevent overflowSpill suppressionSemiconductor/solid-state device detailsSolid-state devicesUltimate tensile strengthChip stacking

The invention discloses a high-strength bonding structure with a special groove and a preparation method of the high-strength bonding structure. The preparation method comprises the following steps: manufacturing a groove type bonding structure on a silicon-based substrate by adopting a dry etching technology; and then depositing adhesion layer metal and bonding layer metal on the groove structure, and carrying out wafer-level bonding on the adhesion layer metal and the bonding layer metal on the other silicon-based substrate so as to realize high-strength bonding between wafers. According to the method, the failure risk generated in the chip stacking process due to low bonding strength is avoided, and a wafer-level stacking solution can be provided for a three-dimensional integrated microsystem.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

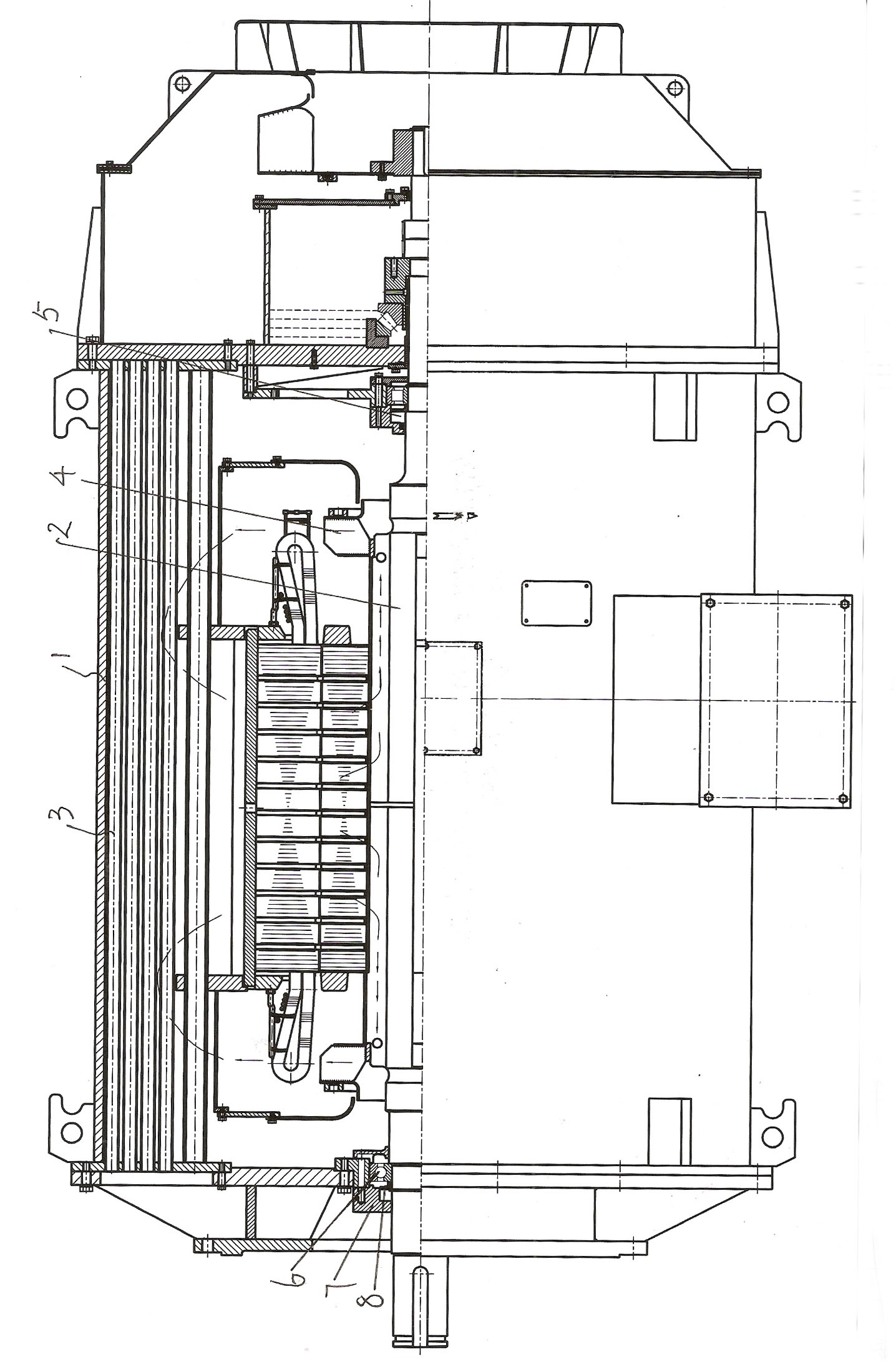

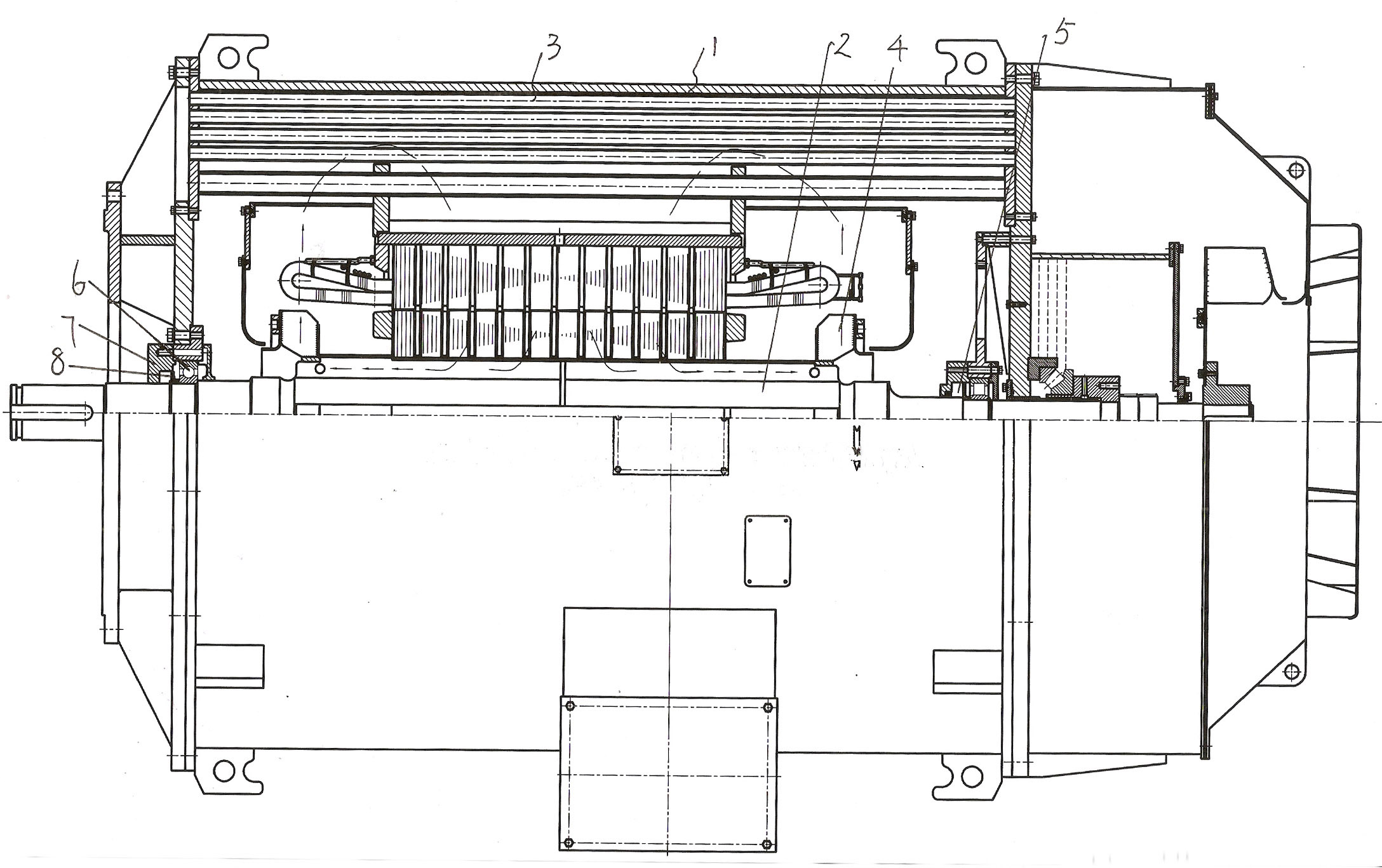

High-voltage motor bearing axial force

InactiveCN102624149ARealize heat dissipationGuaranteed uptimeCooling/ventillation arrangementSupports/enclosures/casingsCooling effectEngineering

The invention discloses a high-voltage motor bearing axial force. The high-voltage motor comprises an enclosure and a motor rotor. The high-voltage motor is characterized in that: cooling tubes are arranged on an air duct in the enclosure; a cooling centrifugal fan is arranged on the motor rotor; a front bearing is arranged on the front part of a motor shaft, and a rear bearing is arranged on the rear part of the motor shaft; a set of cylindrical roller bearing is arranged on the middle part of the motor shaft; each of the front and rear bearings comprises a bearing main body; an outer bearing cover is arranged outside each bearing main body; and an oil deflector ring for preventing oil overflowing out of the bearing main body is arranged between the bearing main body and the outer bearing cover. The high-voltage motor has the characteristics of rational and simple structure, high air speed, high air volume and remarkable cooling effects.

Owner:NANTONG WELL ELECTRIC MOTOR

A Restorative Method for Restoring Facial Injuries of Dead Body

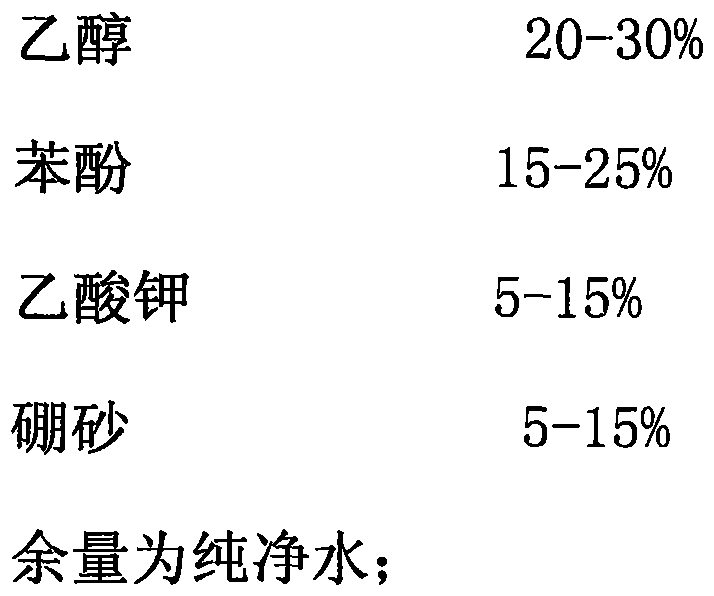

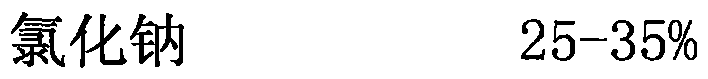

ActiveCN104997648BThe preparation method is simple and easySafe and reliableCosmetic preparationsMake-upSkin complexionSkin color

The invention discloses a repairing method for recovering the facial damage of a dead body, which comprises the following steps: S1. Use surgical tweezers to clamp absorbent cotton dipped in a fixative and apply it on the damaged part of the face, and degrease and dry the skin surface within 15-30 minutes, which is beneficial to cosmetics and skin Normal combination, wherein the raw materials of the fixative include by weight percentage: ethanol: 20-30%; phenol: 15-25%; potassium acetate: 5-15%; borax: 5-15%; the balance is pure water; S2, Use a syringe to inhale the freckle-removing solution for subcutaneous injection on the face, massage for 5-10 minutes to restore the healthy color of the cyanosis skin; S3, knead the oily material with a trowel, and apply the oily material close to the skin color on the damaged traces with a calender Wear it flat to restore the smoothness of the facial contour, and then use the makeup color to unify the facial complexion and restore the normal state of the face. The invention can restore the faces of all dead bodies damaged by accidents, so that the overall effect of the face is close to the normal state.

Owner:毕爱胜

LF (ladle furnace) dedusting and trapping system

PendingCN114322578APrevent proliferationAvoid pollutionWaste heat treatmentDust controlStructural engineering

The invention relates to an LF (ladle furnace) dedusting and trapping system, which comprises a dedusting cover, three through holes corresponding to the electrode holes are formed in the top surface of the dust removal cover, air seal rings are arranged at the through holes, the air seal rings are pipe bodies, vent holes are uniformly formed in the inner side walls of the air seal rings in the circumferential direction, and air inlet interfaces are formed in the air seal rings and are connected to a purging header pipe through pipelines; dust removal holes and corresponding dust removal pipes are symmetrically arranged on the side walls of the two sides of the dust removal cover, and the dust removal pipes are connected to the purging header pipe through pipelines; the observation door air sealing pipe is arranged at the observation door of the furnace cover and is rectangular, air outlet holes are uniformly formed in the inner side wall of the observation door air sealing pipe along the circumferential direction, and the axes of the air outlet holes are downward and form an angle with the horizontal plane; the observation door air sealing pipe is provided with an air inlet joint and is connected with a purging header pipe through a pipeline; and the lower part of the charging articulated chute purging pipe is inserted into the middle part of the charging articulated chute on one side of the furnace cover, the lower part of the charging articulated chute purging pipe positioned in the charging articulated chute is bent and forms an angle with the axis of the charging articulated chute, and the upper end of the charging articulated chute purging pipe is connected with the purging header pipe through a pipeline.

Owner:BAOSHAN IRON & STEEL CO LTD

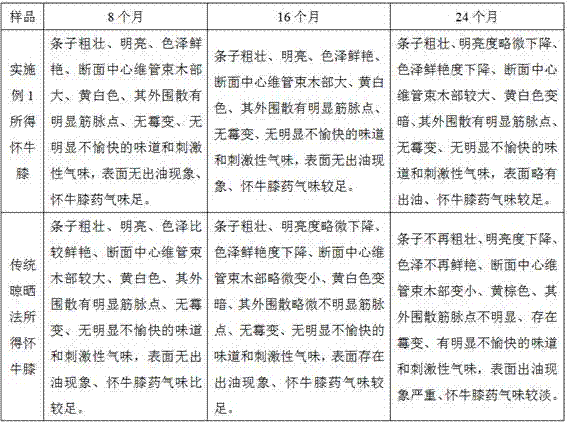

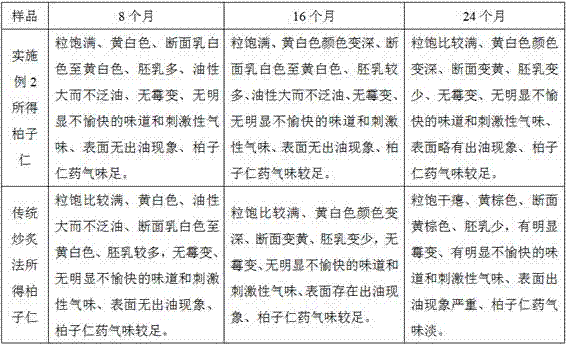

Method for conserving traditional Chinese medicinal material easy to bleed

ActiveCN105253356AInhibit oil bleed phenomenonQuality assurancePackage sterilisationPackaging under special atmospheric conditionsTraditional medicineOzone fumigation

The invention discloses a method for conserving a traditional Chinese medicinal material easy to bleed and belongs to the technical field of processing of traditional Chinese medicinal materials. The method comprises the steps of sequentially performing ultrahigh pressure treatment and ozone fumigation on processed or treated traditional Chinese medicinal material easy to bleed to effectively restrain the phenomenon that the traditional Chinese medicinal material bleeds and restrain growth of entomogenous fungi in the traditional Chinese medicinal material so as to realize the purposes of ensuring the quality of the traditional Chinese medicinal material and prolonging the storage time.

Owner:北京同仁堂健康药业(福州)有限公司

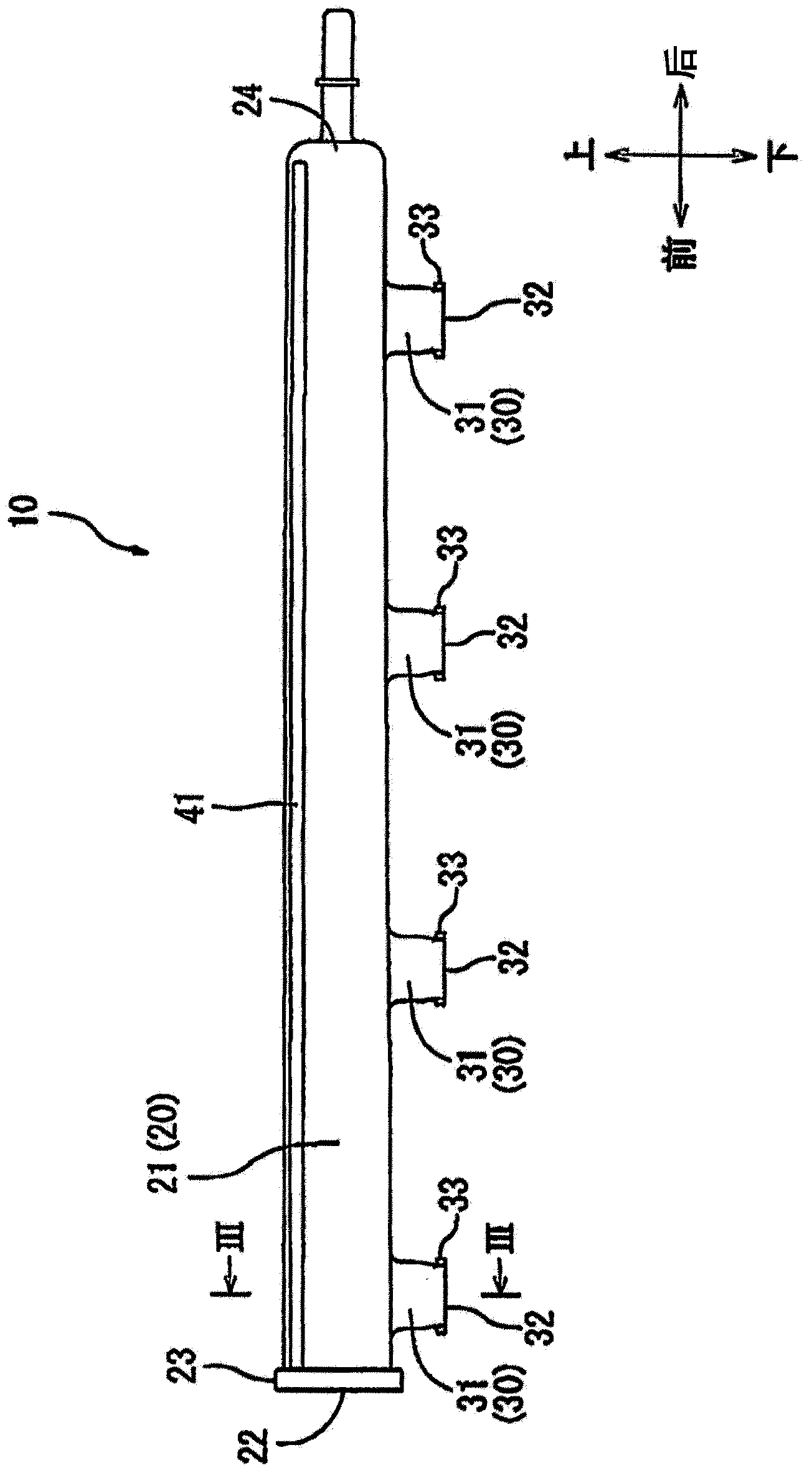

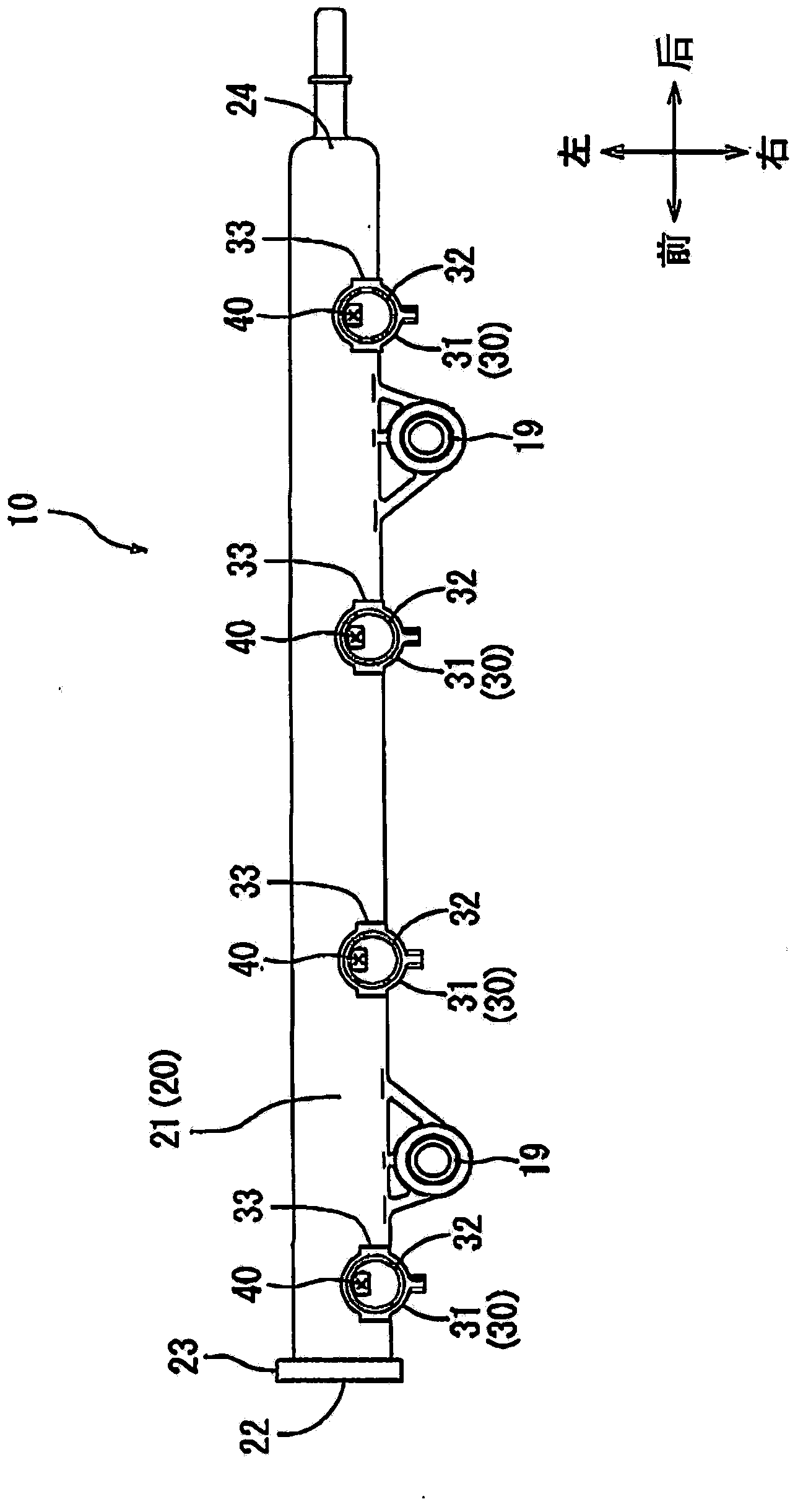

Fuel delivery pipes and methods of manufacturing the same

InactiveCN103527373ASpill suppressionHigh densityLow pressure fuel injectionMachines/enginesContact forceEngineering

The invention provides a fuel delivery pipe and a method of manufacturing the same. The fuel delivery pipe may be designed such that, during resin forming, material flash can be suppressed at a communication part which communicates a main pipe with a distribution pipe in a resin-made fuel delivery pipe which is integrally configured by the main pipe and the distribution pipe in a manner with central lines thereof alternately crossed. A flow promotion part is arranged at a point symmetrical position which is configured the commucation forming part wherein the cores for the main pipe and the distribution pipe are butted against with each other in a forming mould, relative to a first extending central axis. The flow promotion part is configured to connected the parts on the forming mould in series, thereby raising fluidity of the forming resin passing through the said parts. Preferably, the forming resin filled into the flow promotion part makes a function of pressing the main pipe to the core of the distribution pipe, thereby raising a butting force (contact force) that the pipe core and the main pipe core are butted against with each other.

Owner:AISAN IND CO LTD

A kind of airtight concrete material and preparation method thereof

The invention discloses an airtight concrete material, wherein the preparation method comprises: stirring continuous graded limestone coarse aggregate, clean medium river sand, grinded mineral powder,II-grade fly ash, ordinary Portland cement, an efficient water reducing agent, a special air entraining agent and water, carrying out compact molding, and carrying out standard curing, and the airtight concrete material is the main concrete material of tunnel secondary lining structures in environments with overflowing of coal gas and other toxic and harmful gases. According to the invention, theairtight concrete material has the main characteristic of compactness, wherein the elastic gas bubbles exist in the capillary pores in the substructure, so that the gas permeation resistance, the impermeability, the alkali-aggregate reaction resistance, the crack resistance, the frost resistance and the like are excellent; and the raw materials excluding the special air entraining agent are widein the sources, and the preparation process is simple.

Owner:JIANGNAN UNIV

A gas collection guide and drainage device for landfill regulating pool

ActiveCN113006247BEasy to landfillEasy to useSewerage structuresSolid waste disposalStormwater harvestingEnvironmental engineering

Owner:重庆三鑫环保标志有限公司

Coke oven door double-layer soft sealing structure

PendingCN113563903AImprove sealingSpill suppressionCoke oven doors/closuresCoke ovenMechanical engineering

The invention relates to a coke oven door double-layer soft sealing structure. An inner ring flexible fire-resistant sealing element is arranged between an oven door lining and an oven door body along the circumferential direction of the oven door body, and an outer ring flexible fire-resistant sealing element is arranged in a knife edge box; and when the oven door of a coke oven is closed, the inner ring flexible fire-resistant sealing element and a coke oven body are compressed to realize inner-layer sealing, and the outer ring flexible fire-resistant sealing element and an oven protection iron piece are compressed to realize outer-layer sealing. Through the double-layer soft sealing structure, the sealing performance of the oven door area of the coke oven is effectively improved, raw gas overflow is inhibited, and energy conservation and consumption reduction are realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Gas collecting, guiding and discharging device for regulating reservoir of refuse landfill

ActiveCN113006247AEasy to landfillEasy to useSewerage structuresSolid waste disposalRainwater harvestingLeachate

The invention discloses a gas collecting, guiding and discharging device for a regulating reservoir of a refuse landfill, and relates to the technical field of refuse landfill. The gas collecting, guiding and discharging device for the regulating reservoir of the refuse landfill comprises a landfill tank, a feeding mechanism is arranged above the landfill tank, a collecting mechanism and a guiding and discharging mechanism are arranged below the landfill tank, and a rainwater collecting tank is arranged above the landfill tank. According to the gas collecting, guiding and discharging device for the regulating reservoir of the refuse landfill, the landfill tank, the rainwater collecting tank, the regulating reservoir, a feeding box, a partition plate, a gas guiding pipe and a collecting pipe are used in cooperation, so that the problem that rainwater permeates into the regulating reservoir in rainy days, and consequently the water inlet concentration of a leachate treatment station is too low can be effectively solved; and the landfill tank and the regulating reservoir are deeply buried underground, so that odor pollution of the landfill and surrounding areas is not affected, the body health of workers is not affected, and popularization and use are facilitated.

Owner:重庆三鑫环保标志有限公司

Gas-based microfluidic devices and operating methods thereof

ActiveUS9675975B2Easy to manufactureEasy to useMaterial analysis by optical meansLaboratory glasswaresComputer moduleProduct gas

Gas-based microfluidic devices and operating methods of gas-based microfluidic devices are provided. The gas-based microfluidic devices comprise a drive module and a microfluidic platform, in which the microfluidic platform further comprises a microfluidic element having an injection chamber, a process chamber, an air chamber, an overflow channel, a barrier, and at least one detection chamber. Gases in the air chamber enable solutions to move toward the direction opposite to the centrifugal force applied by the drive module. Accordingly, the operating methods utilize the gases compressed in the air chamber to move solutions to difference components in the microfluidic element.

Owner:ZHEJIANG PUSHKANG BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com