Intelligent material stacking trolley

A technology for stacking trolleys and trolleys, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of unsatisfactory dust removal effect, waste of water source, complicated structure, etc., to suppress dust overflow, reduce secondary dust, and reduce the scope of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

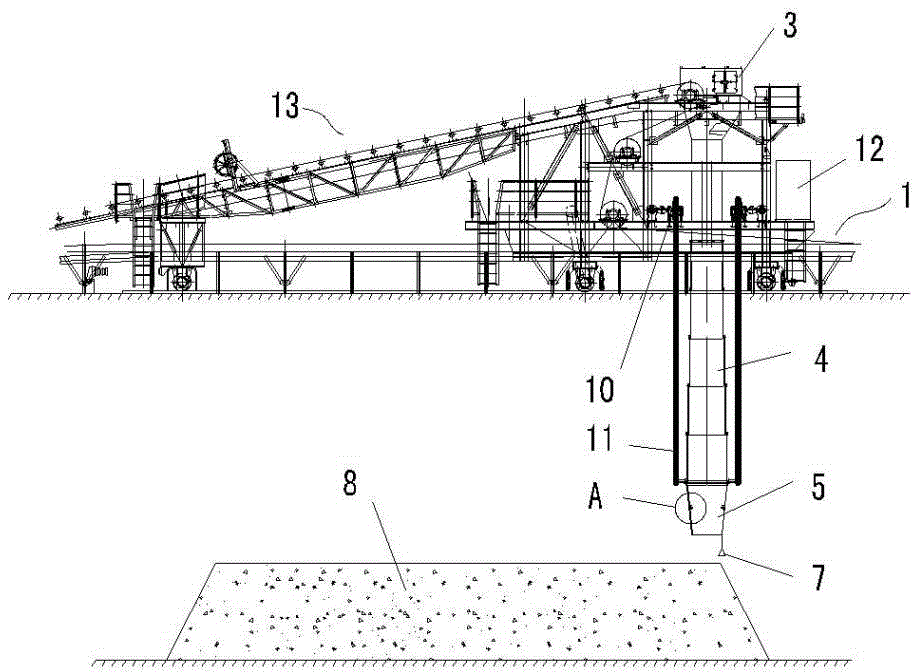

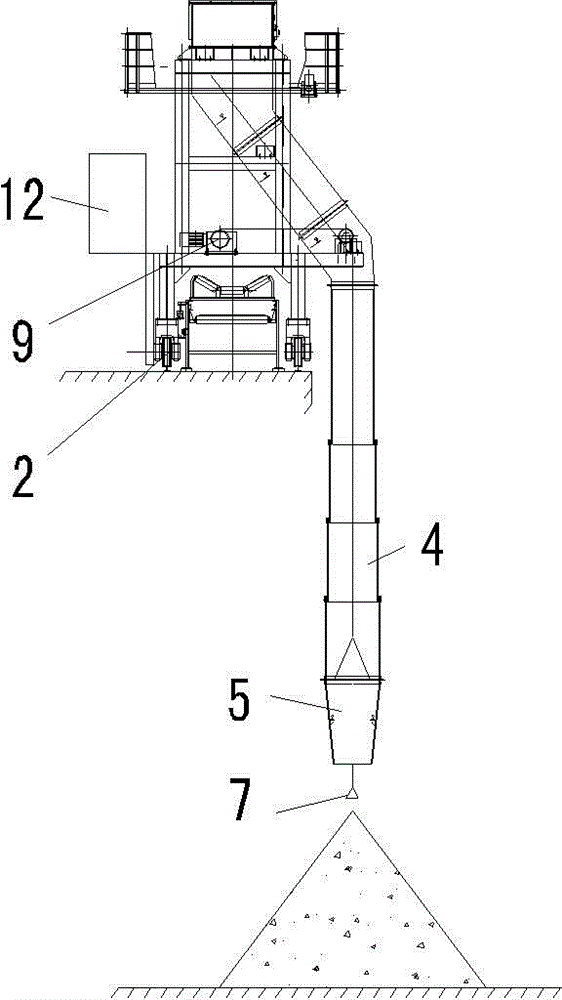

[0038] Such as figure 1 As shown, it is a schematic structural view of an embodiment of the intelligent stacking trolley of the present invention; figure 2 for figure 1 left view of . The intelligent stacking trolley of the present embodiment includes a trolley body 1 installed on the walking track 2 and a driving device for driving the trolley body 1 to move on the walking track 2. The trolley body 1 is provided with a funnel 3, and the outlet of the funnel 3 A telescopic chute 4 and a hoisting mechanism for driving the telescopic chute 4 to elongate or shorten are provided on the feed opening.

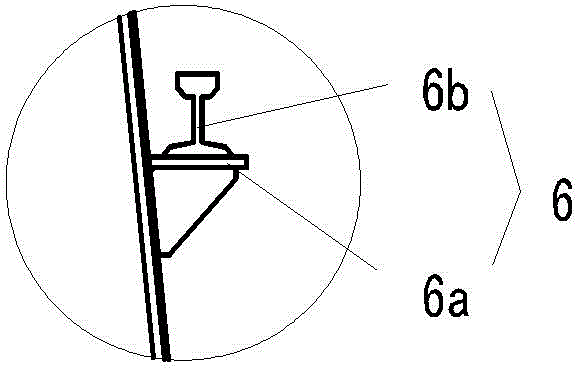

[0039] The discharge port of the telescopic chute 4 is provided with an aggregate dust suppression hopper 5, and the inner diameter of the aggregate dust suppression hopper 5 gradually decreases in the direction where the feed inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com