LF (ladle furnace) dedusting and trapping system

A dust removal hood and furnace cover technology, which is applied to furnaces, furnace components, waste heat treatment, etc., can solve problems such as easy generation of eddy currents, smoke from the feeding slide pipe next to the furnace, and increased suction, so as to improve dust removal capabilities, eliminate air pollution, The effect of reduced upward resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

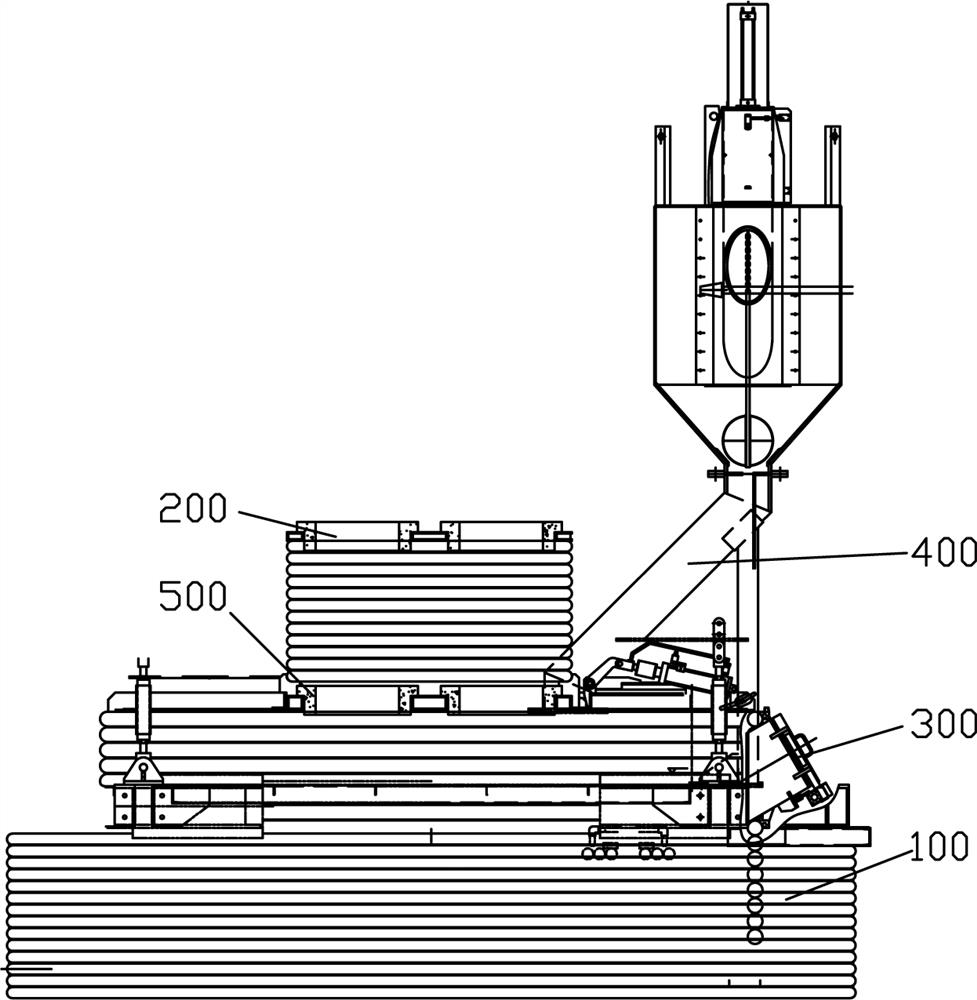

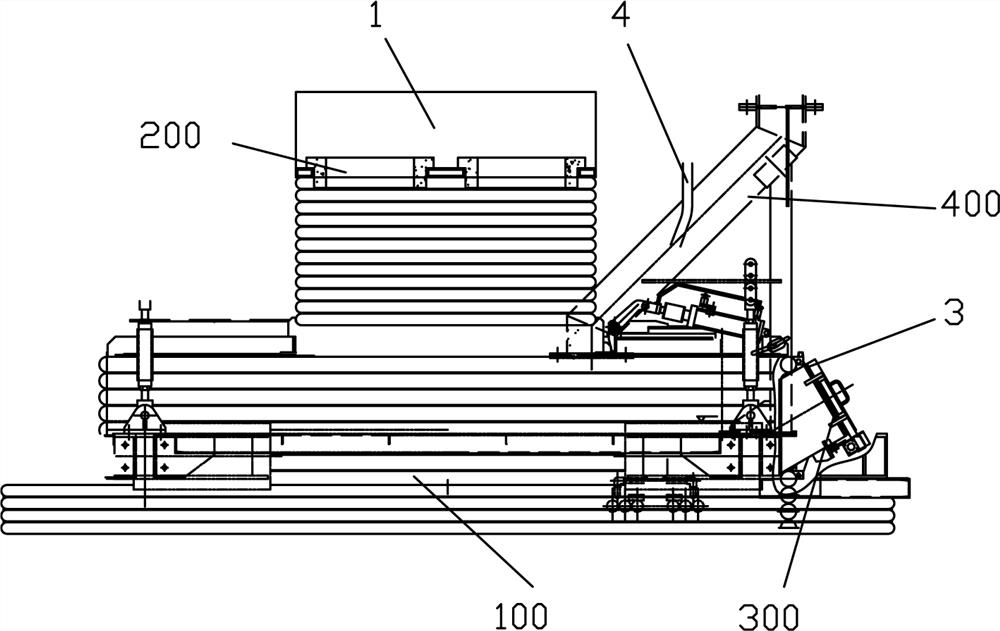

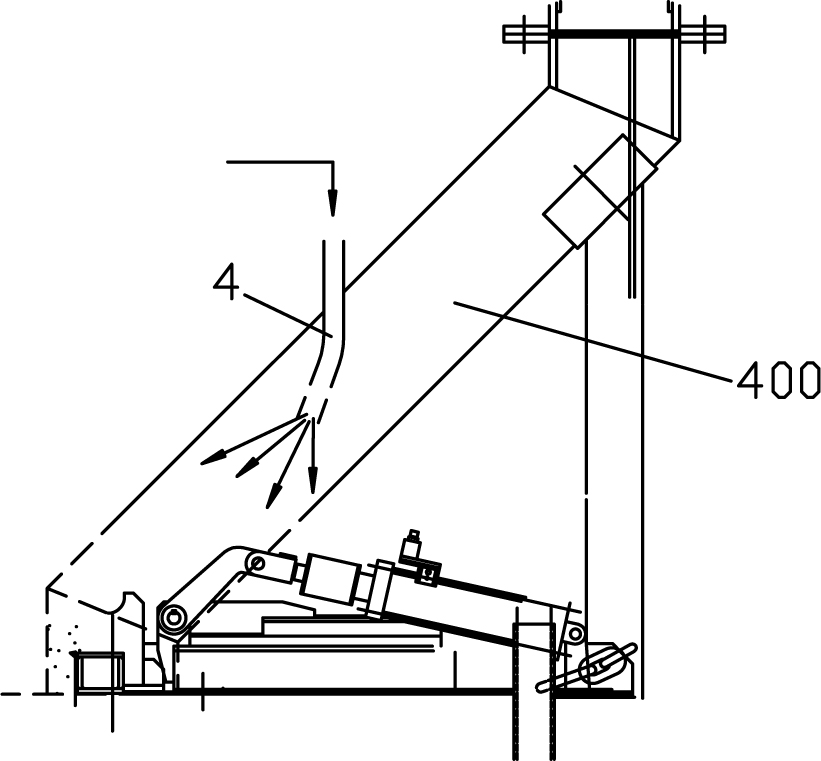

[0038] see Figure 1 to Figure 10 , the LF furnace dust collection system of the present invention is arranged on the LF furnace cover 100, which includes:

[0039] The dust removal cover 1 is a cylindrical structure; it is arranged at the electrode hole 200 of the furnace cover 100, and the top surface of the dust removal cover 1 is provided with three through holes 101 corresponding to the electrode holes. The sealing ring 2 is a pipe body, and its inner wall is evenly provided with a number of ventilation holes 21 along the circumferential direction. An air inlet port 22 is arranged on the air sealing ring 21, and is connected to the purge main pipe (not shown in the figure) through a pipeline; Dust removal holes and corresponding dust removal pipes are arranged symmetrically on both side walls of the dust removal cover 1, and the two dust removal pipes converge to the dust removal main pipe (not shown in the figure), and the dust removal pipe is connected to the main purge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com