Gas-solid dust sealing device

A sealing device, dust technology, applied in the direction of dust removal, loading/unloading, transportation and packaging, etc., can solve problems such as dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

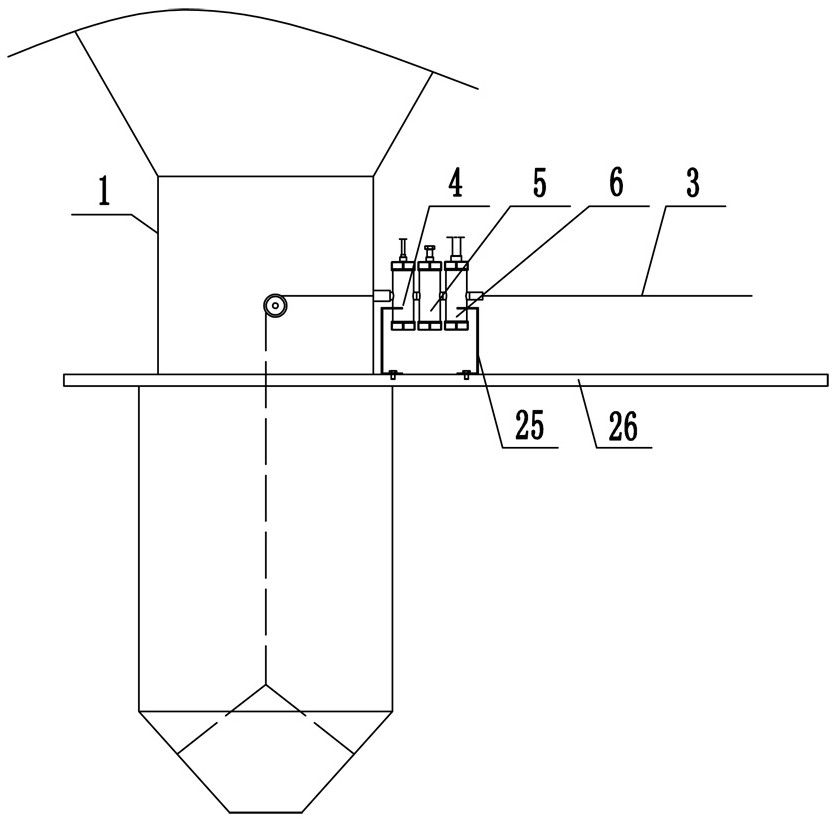

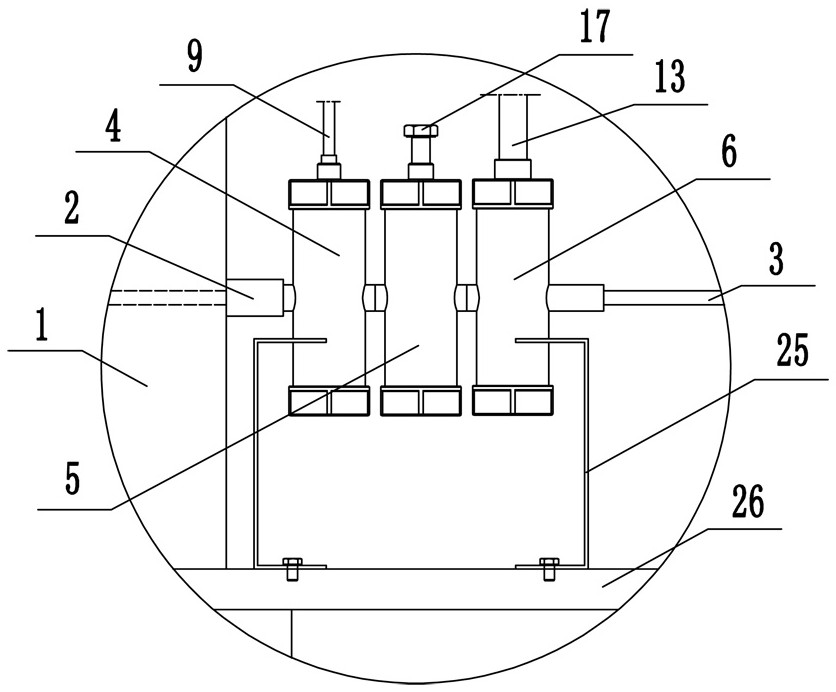

[0035] Such as Figure 1~Figure 5 As shown, a gas-solid dust sealing device includes a building platform 26, an ash storehouse 1 placed above the building platform 26, a piercing opening 2 and a steel wire rope 3 arranged on the side wall of the ash storehouse 1, and the piercing opening 2 is It is in the shape of a round tube, and the piercing opening 2 communicates with the ash storage 1, and one end of the steel wire rope 3 passes through the piercing opening 2 and is placed in the ash storage 1.

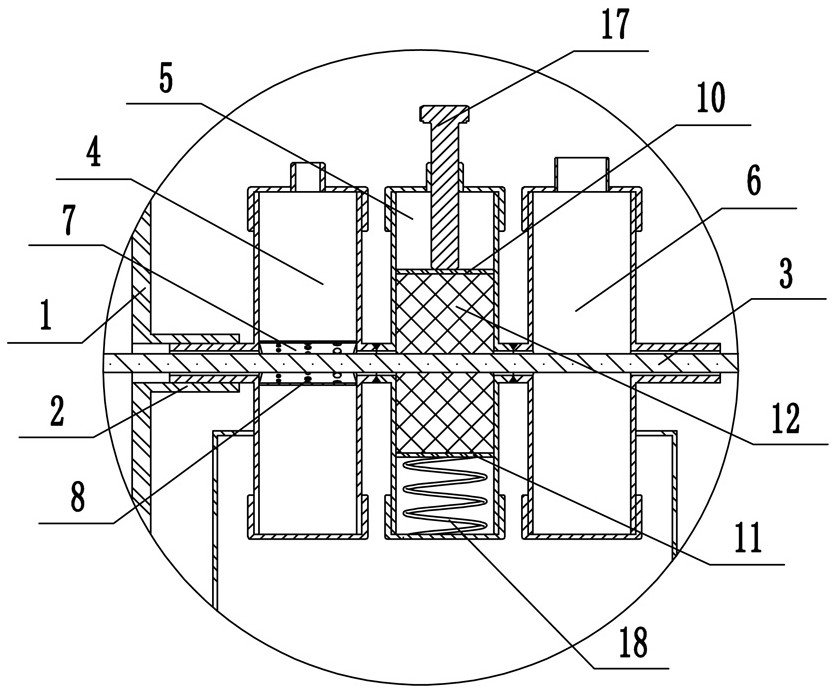

[0036] In this embodiment, it also includes a positive pressure tank 4, a tension tank 5, and a negative pressure tank 6 connected in sequence in the radial direction. The perforation opening 2 is detachably connected to the positive pressure tank 4. The cylindrical structure of the pressure tank 5 and the negative pressure tank 6 have the same structure as the positive pressure tank 4 .

[0037] Specifically, the positive pressure tank 4, the tension tank 5 and the negative pre...

Embodiment 2

[0059] Such as Figure 6 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that one end of the hollow column 15 of the positive pressure tank 4 extends inwardly into the tank body 14, and is placed in the positive pressure tank. The section of hollow column 15 in 4 is stepped.

[0060] Said sealing tube 7 comprises a left section 71 and a right section 72 which are coaxially slidably connected, said left section 71 and right section 72 are respectively provided with retaining rings 19, and a stage clip 19 is arranged between said two retaining rings 19. 20. Compression spring one 20 is tightly pressed against the retaining ring 19. Under the action of compression spring one 20, the length of the sealing tube 7 is relatively elongated, and its left section 71 and right section 72 are respectively fastened to the end of the hollow column 15. The sealing hole 8 is arranged on the segment 71 .

[0061] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com