Titanium and Kovar alloy sealing glass material for thermal battery, preparation method and application

A technology for sealing glass and thermal batteries, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve problems such as micro-cracks in the sealing interface, difficulty in cleaning, complex oxide layer structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

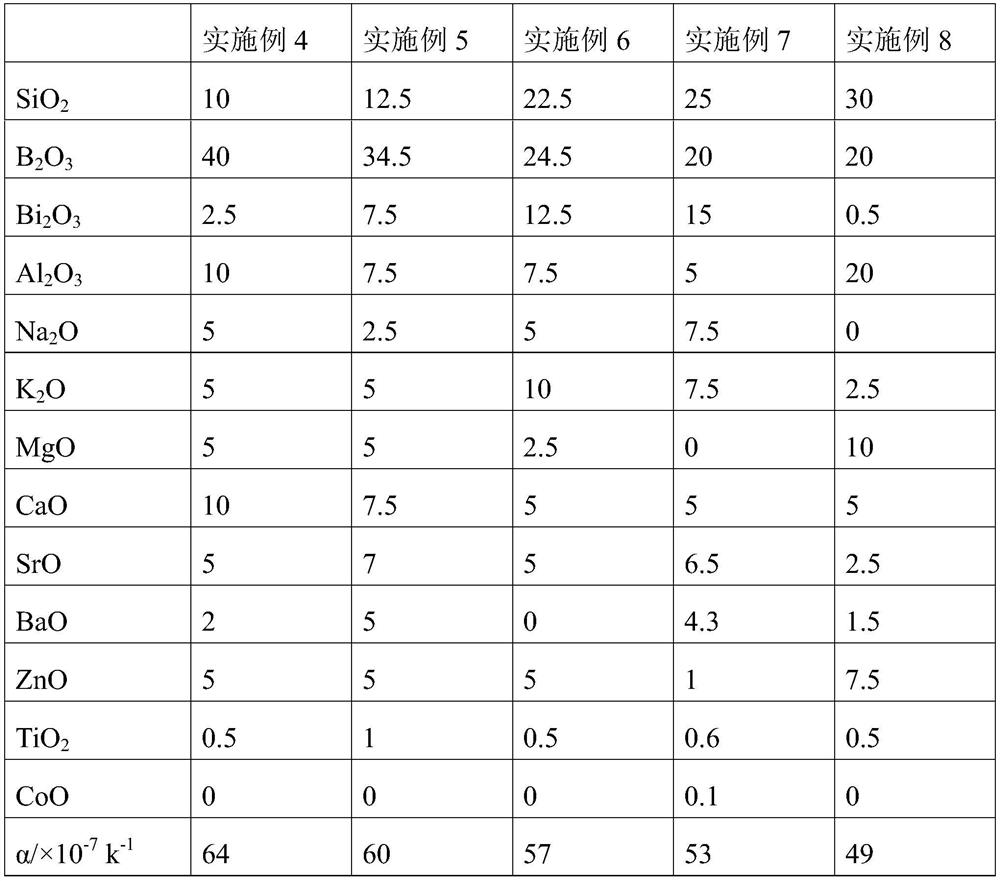

Examples

Embodiment 1

[0058] A preparation method of titanium and titanium alloy and Kovar alloy sealing glass material for thermal battery, specifically comprising the following steps:

[0059] 1), select chemical composition batching by following weight percentage:

[0060] SiO 2 15%, B 2 o 3 35%, Bi 2 o 3 5%, Al 2 o 3 17.5%, Na 2 O is 2.4%, K 2 O is 2.5%, MgO is 2.5%, CaO is 5%, SrO is 5%, ZnO is 10%, TiO 2 0.05% for CoO and 0.05% for CoO;

[0061] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0062] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 700°C at a heating rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1350°C and keep it ...

Embodiment 2

[0082] A preparation method of titanium and titanium alloy and Kovar alloy sealing glass material for thermal battery, specifically comprising the following steps:

[0083] 1), select chemical composition batching by following weight percentage:

[0084] SiO 2 20%, B 2 o 3 25%, Bi 2 o 3 10%, Al 2 o 3 10%, Na 2 O is 2%, K 2 O is 5%, MgO is 2.5%, CaO is 10%, SrO is 10%, ZnO is 5%, TiO 2 0.4% and CoO 0.1%.

[0085] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0086] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lift furnace, and raise the temperature to 775°C at a rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1400°C and keep it warm for 2 hours, stirring se...

Embodiment 3

[0102] A method for preparing a special sealing glass for primary lithium thionyl chloride battery terminals, specifically comprising the following steps:

[0103] 1), select chemical composition batching by following weight percentage:

[0104] SiO 2 18.5%, B 2 o 3 50%, Al 2 o 3 7%, Na 2 O is 5%, K 2 O is 2.5%, MgO is 3%, CaO is 6%, SrO is 2.5%, BaO is 0.36%, ZnO is 5%, TiO 2 0.1% and CoO 0.04%.

[0105] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0106] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 800°C at a heating rate of 10°C / min in an air atmosphere and keep it warm for 60min. Then increase the temperature at a rate of 10°C / min to 1500°C and keep it warm for 2 hours. During th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com