High-voltage motor bearing axial force

A high-voltage motor, axial force technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of unsatisfactory axial force bearing effect, and achieve significant cooling effect, ensure normal operation, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

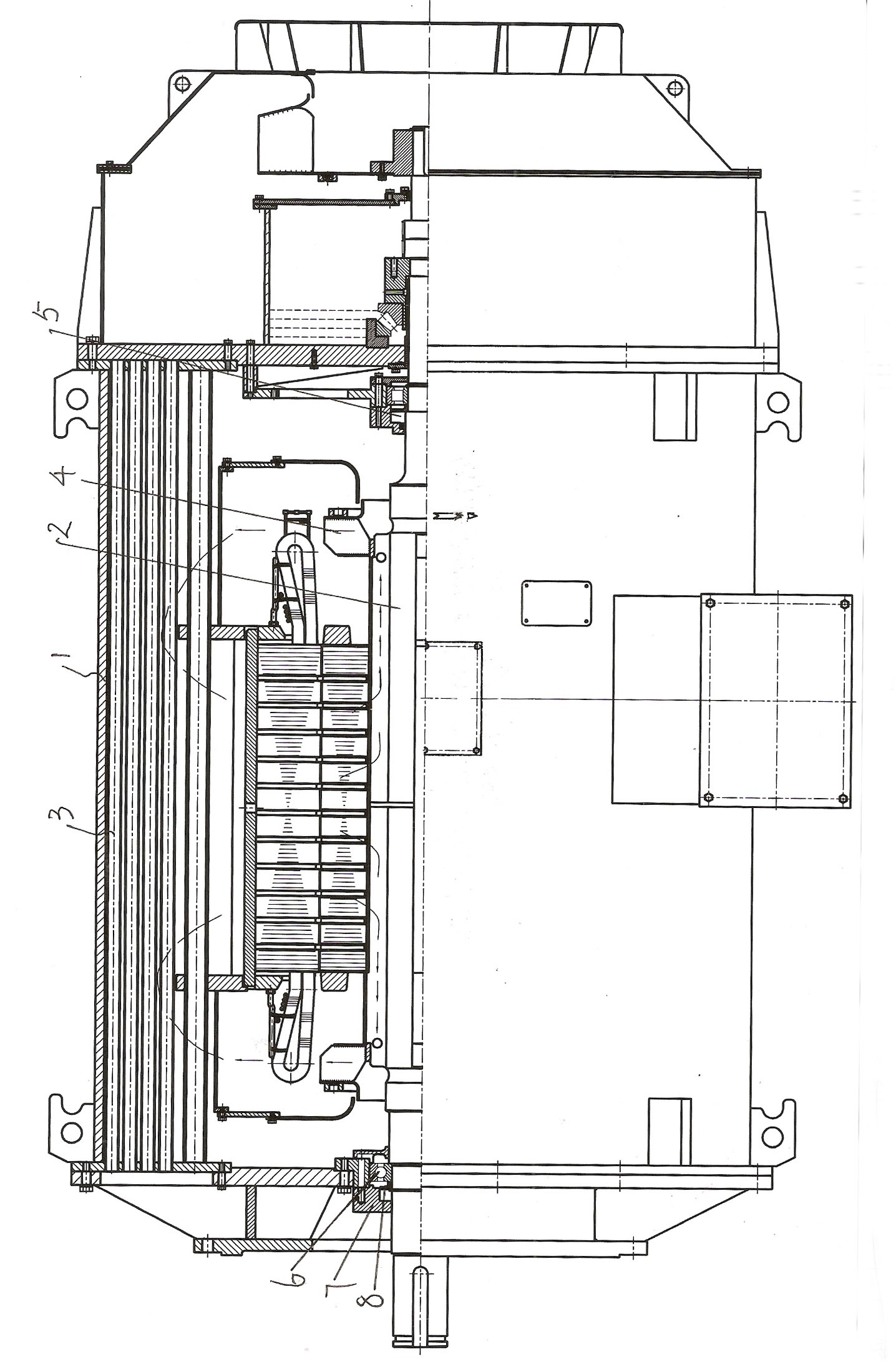

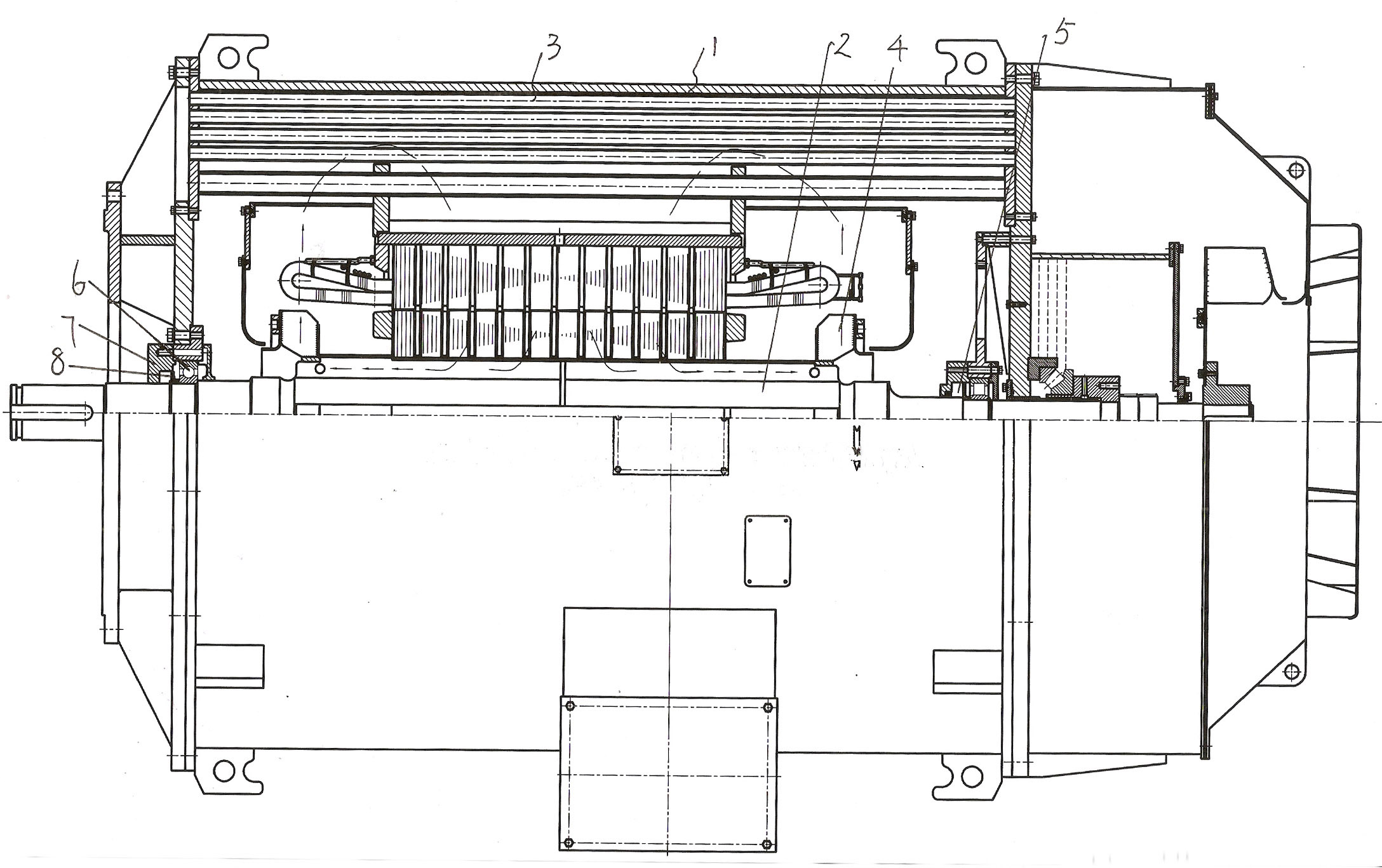

[0009] A high-voltage motor bearing axial force, comprising a casing 1, a motor rotor 2, a cooling pipe 3 is arranged on the air duct in the casing, a cooling centrifugal fan 4 is arranged on the motor rotor; front and rear bearings are respectively arranged at the front and rear parts of the motor shaft, and the motor A set of cylindrical roller bearings 5 is arranged in the middle of the shaft; the front and rear bearings include a bearing main body 6, and a bearing outer cover 7 is arranged outside the bearing main body, and an oil deflector ring is arranged between the bearing main body and the bearing outer cover to prevent grease from overflowing in the bearing main body 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com