Coke oven door double-layer soft sealing structure

A soft sealing and furnace door technology, applied in the door/closure of coke oven, coke oven, heating of coke oven, etc., can solve the problems of tar penetration and removal of tar, large heat loss of burner head, coke pushing, smoke and fire, etc. , to achieve the effect of improving service life, reducing production and operation costs, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

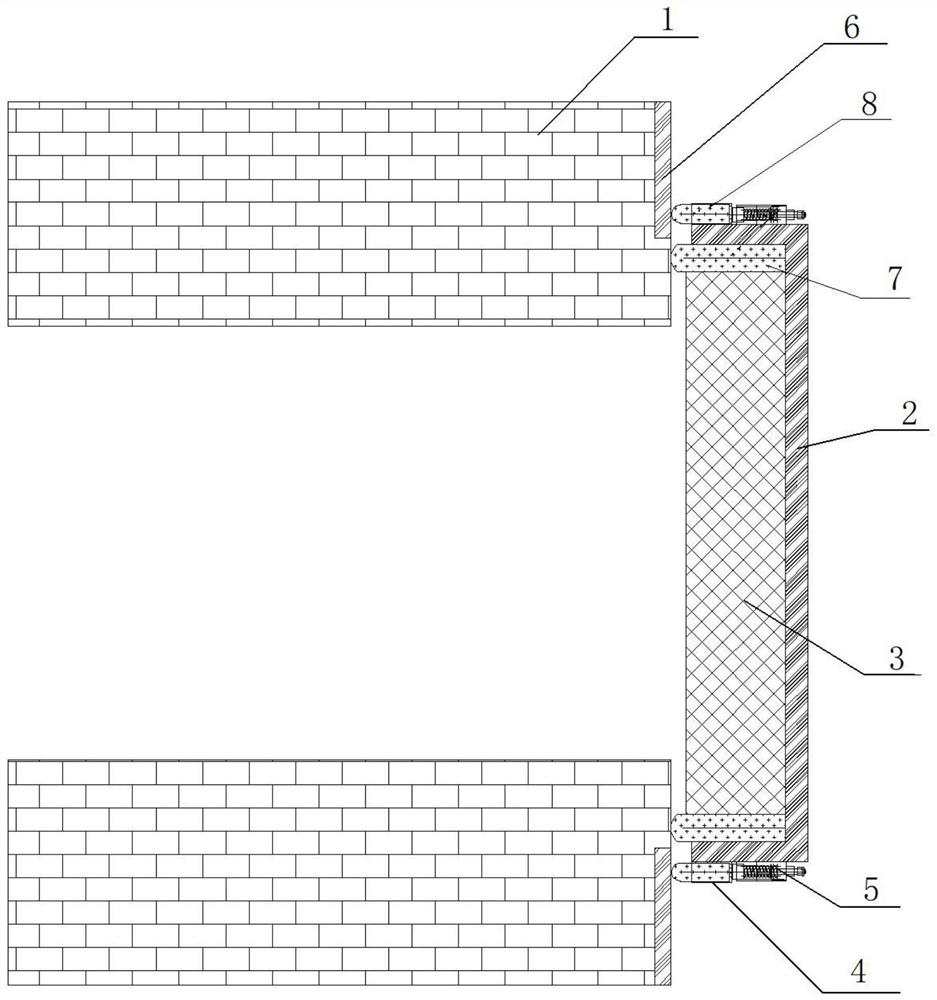

[0023] Such as figure 1 As shown, a coke oven door of the present invention has a double-layer soft seal structure. The coke oven door is arranged at the oven door frames at both ends of the coke oven carbonization chamber. The oven door body 2, the oven door lining 3 and the oven door knife The coke oven body 1 on the periphery of the furnace door frame is provided with a furnace protective iron piece 6; the inner side of the furnace door body 2 is provided with a groove, and the furnace door lining 3 is embedded in the groove; the periphery of the furnace door body 2 is provided with a furnace Door knife edge, furnace door knife edge is composed of knife edge box 4 and spring 5; The box 4 is equipped with an outer ring flexible refractory seal 8; when the coke oven door is closed, the inner ring flexible refractory seal 7 is pressed against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com