Titanium and sealing alloy sealing glass material for thermal batteries as well as preparation method and application thereof

A technology for sealing glass and thermal batteries, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc. It can solve the problems of poor wettability of sealing glass, complex oxide layer structure, and difficulty in cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

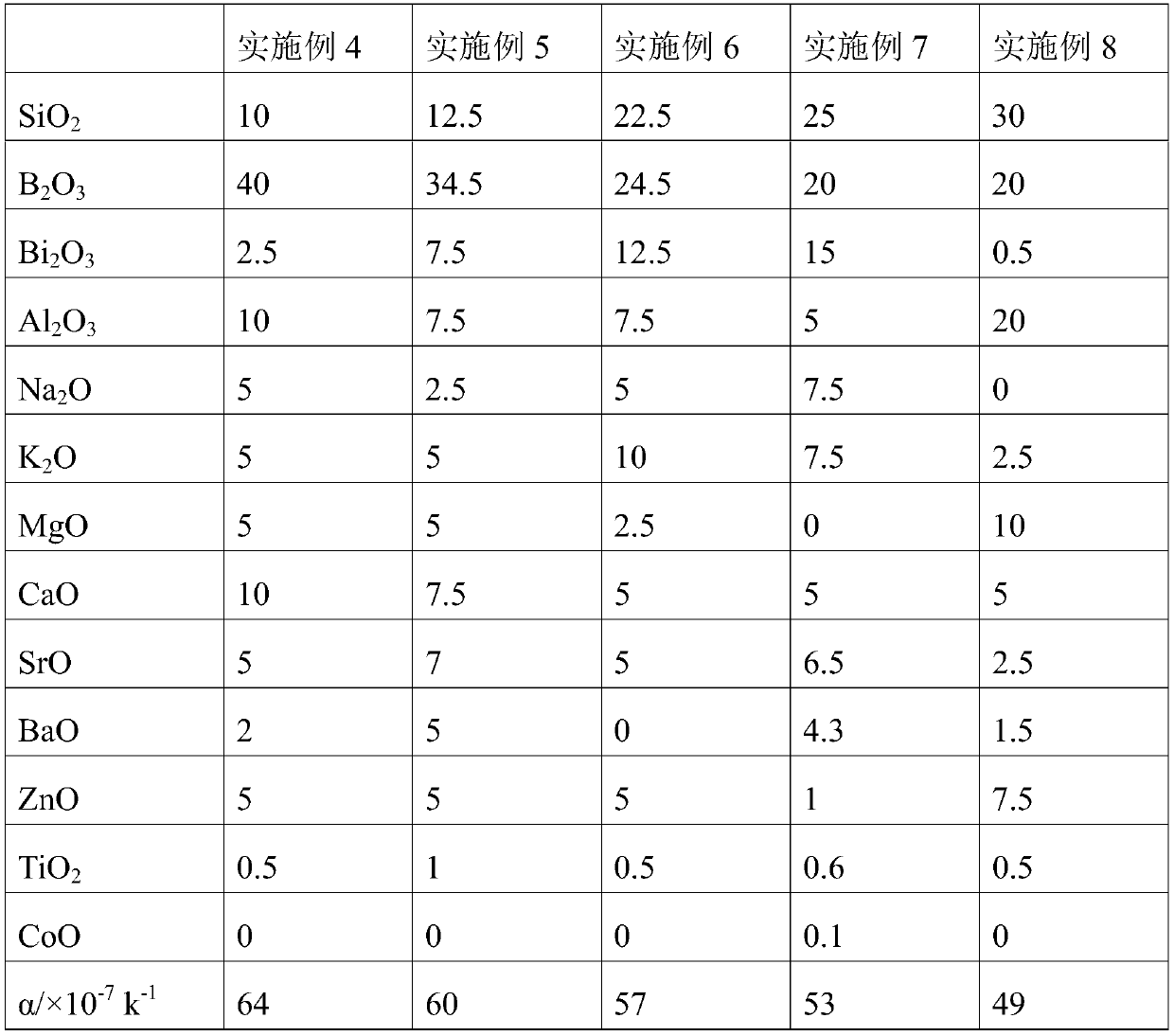

Examples

Embodiment 1

[0058] A preparation method of titanium and titanium alloy and Kovar alloy sealing glass material for thermal battery, specifically comprising the following steps:

[0059] 1), select chemical composition batching by following weight percentage:

[0060] SiO 2 15%, B 2 o 3 35%, Bi 2 o 3 5%, Al 2 o 3 17.5%, Na 2 O is 2.4%, K 2 O is 2.5%, MgO is 2.5%, CaO is 5%, SrO is 5%, ZnO is 10%, TiO 2 0.05% for CoO and 0.05% for CoO;

[0061] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0062] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 700°C at a heating rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1350°C and keep it ...

Embodiment 2

[0082] A preparation method of titanium and titanium alloy and Kovar alloy sealing glass material for thermal battery, specifically comprising the following steps:

[0083] 1), select chemical composition batching by following weight percentage:

[0084] SiO 2 20%, B 2 o 3 25%, Bi 2 o 3 10%, Al 2 o 3 10%, Na 2 O is 2%, K 2 O is 5%, MgO is 2.5%, CaO is 10%, SrO is 10%, ZnO is 5%, TiO 2 0.4% and CoO 0.1%.

[0085] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0086] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lift furnace, and raise the temperature to 775°C at a rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1400°C and keep it warm for 2 hours, stirring se...

Embodiment 3

[0102] A method for preparing a special sealing glass for primary lithium thionyl chloride battery terminals, specifically comprising the following steps:

[0103] 1), select chemical composition batching by following weight percentage:

[0104] SiO 2 18.5%, B 2 o 3 50%, Al 2 o 3 7%, Na 2 O is 5%, K 2 O is 2.5%, MgO is 3%, CaO is 6%, SrO is 2.5%, BaO is 0.36%, ZnO is 5%, TiO 2 0.1% and CoO 0.04%.

[0105] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0106] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 800°C at a heating rate of 10°C / min in an air atmosphere and keep it warm for 60min. Then increase the temperature at a rate of 10°C / min to 1500°C and keep it warm for 2 hours. During th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com