Device for quantitatively injecting wax into ceramic handicraft article

A technology for ceramic handicrafts and wax injection, which is applied to candle preparation devices and other directions, can solve the problems of high defective rate and low production efficiency, and achieve the effect of improving production efficiency and realizing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

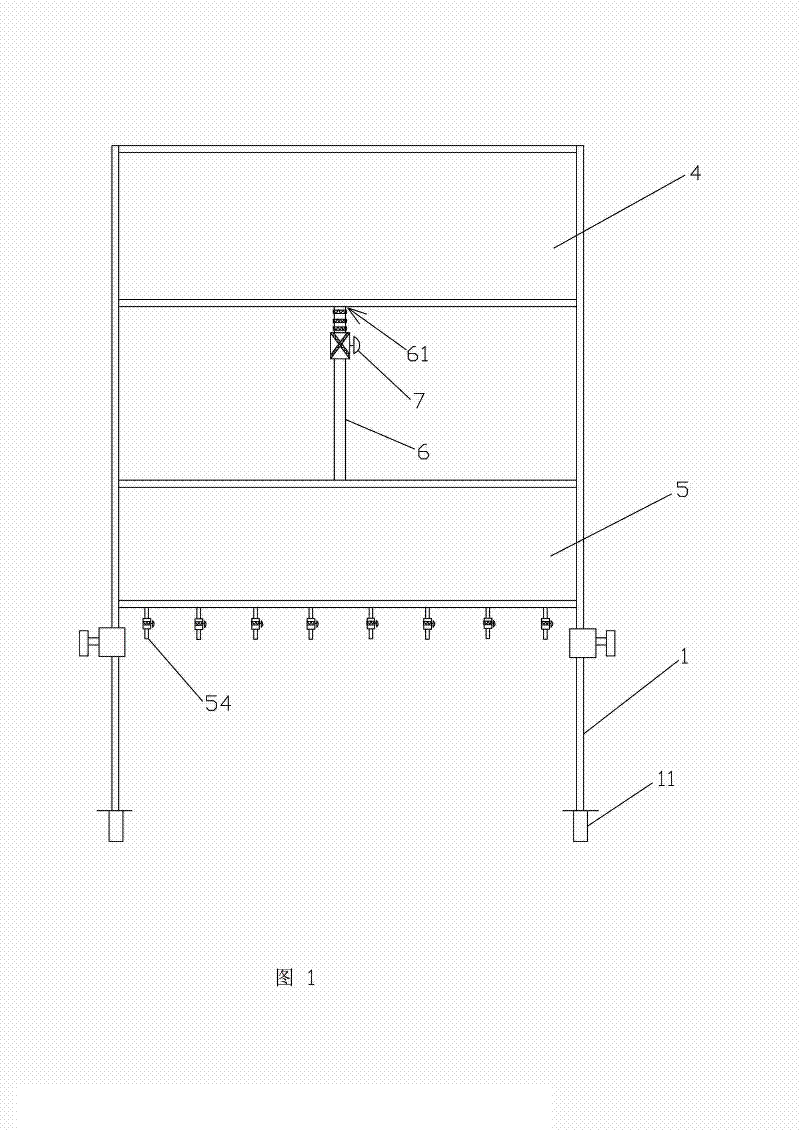

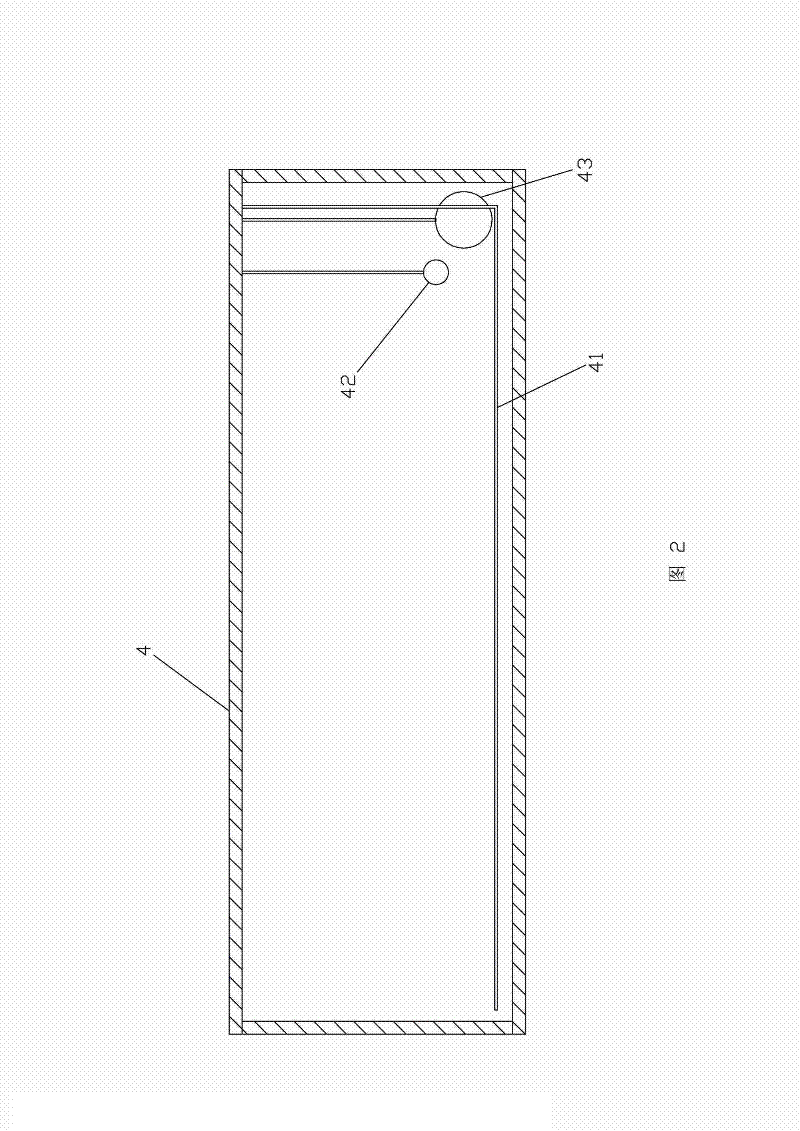

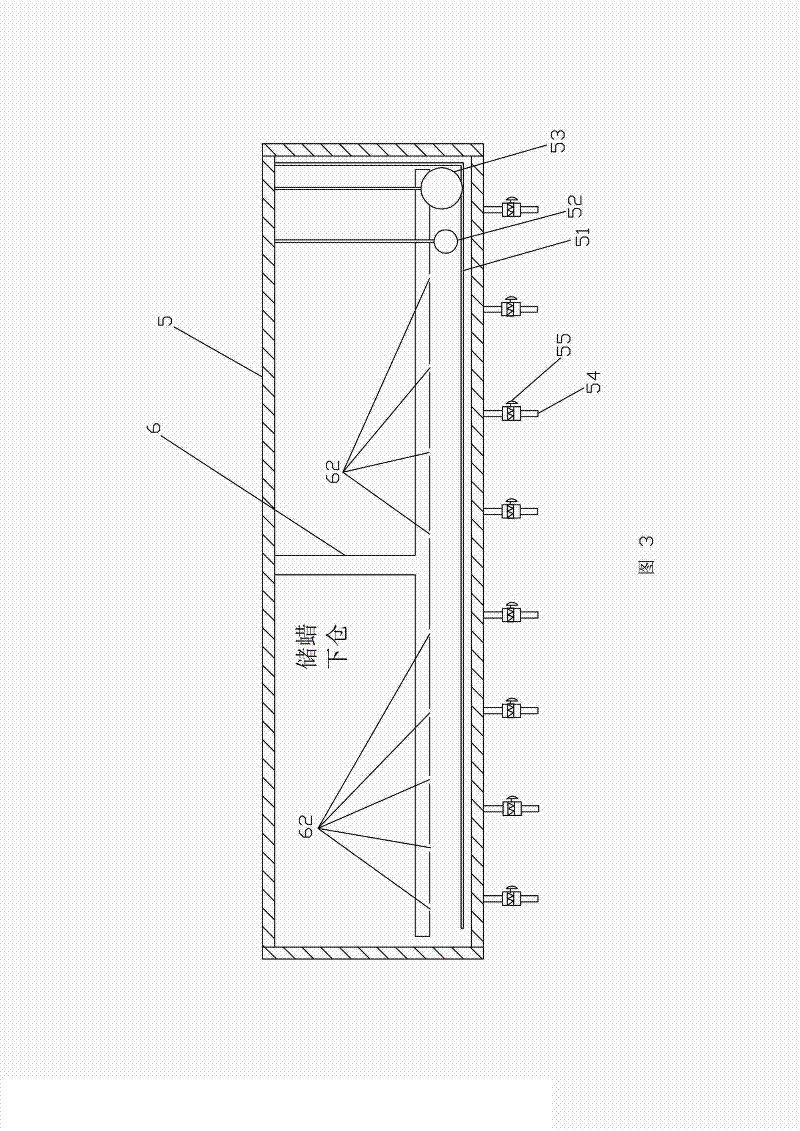

[0019] refer to Figure 1 to Figure 4 , a device for quantitatively injecting wax into ceramic handicrafts, including a liftable frame 1, a liquid wax pump 2, a control system 3, a temporary storage bin 4 and a feeding bin 5 with heat preservation functions, a liquid wax pump 2, and a control system 3 , the temporary storage bin 4 and the lower feed bin 5 are all installed on the frame 1. The bottom of frame 1 is provided with movable wheel 11, can move conveniently; Control system 3 has a control panel 31, and it can display the real-time temperature that is monitored by temperature monitoring device 42 and the real-time liquid level height that is monitored by liquid level monitoring device 43 and For corresponding adjustments, the above-mentioned temperature monitoring device 42 and liquid level monitoring device 43 are relatively common in the prior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com