Intelligent pressurization device for LNG storage bottle

A pressurization device and storage bottle technology, applied in gas/liquid distribution and storage, pressure vessels, fixed-capacity gas storage tanks, etc., can solve the problem of inability to monitor the temperature of the heating element of the gas storage bottle in real time, and the complex structure of the LNG pressurization system , many booster circuits, etc., to achieve the effect of practical function, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

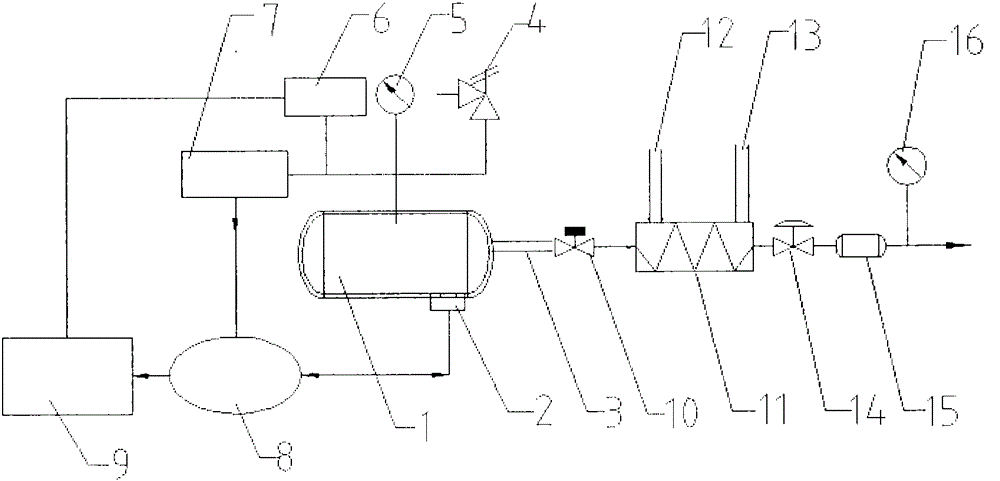

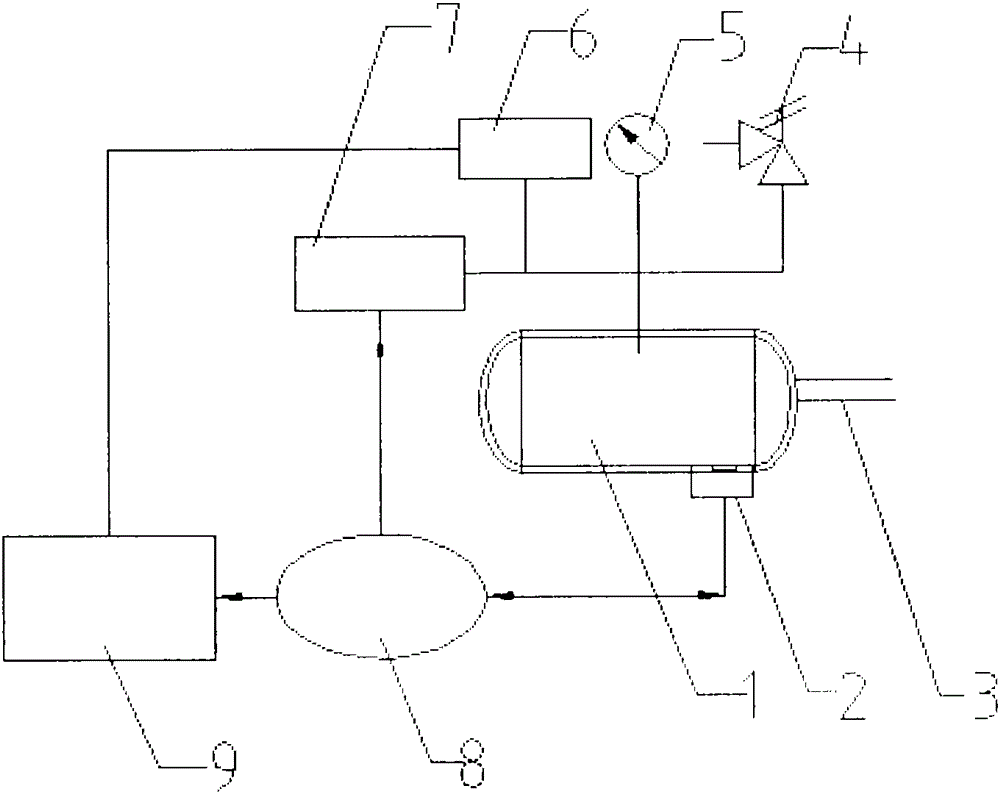

[0025] Example: as Figure 1-2 As shown in the figure, an intelligent pressurizing device for LNG storage bottles of the present invention includes an LNG storage bottle 1, a heating module 2, a pressure sensor 7, a display 9, and a PLC intelligent control system 8. The bottom of the LNG storage bottle 1 is provided with a heating module 2 , the heating module 2 is connected to the PLC intelligent control system 8, a liquid level gauge 6 and a pressure gauge 5 are installed on the top of the LNG storage bottle 1, and a safety valve 4 is installed at the mouth of the LNG storage bottle 1 , a liquid outlet pipe 3 is installed on one side of the LNG storage bottle 1, the liquid outlet pipe 3 is connected with one end of the vaporizer 11, and an overcurrent disconnector 10 is arranged between the liquid outlet pipe 3 and the vaporizer 11, The flow cut-off is composed of a manual cut-off valve and an overflow valve. The other end of the vaporizer 11 is connected with a pressure-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com