A centralized processing control method for engraving center cutting fluid

A control method and centralized processing technology, which is applied in the fields of engraving, decorative art, and processing models, etc., can solve the problems of heavy workload, high work intensity, time-consuming and laborious, etc., and achieve the effect of uniform concentration, ensuring stability, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

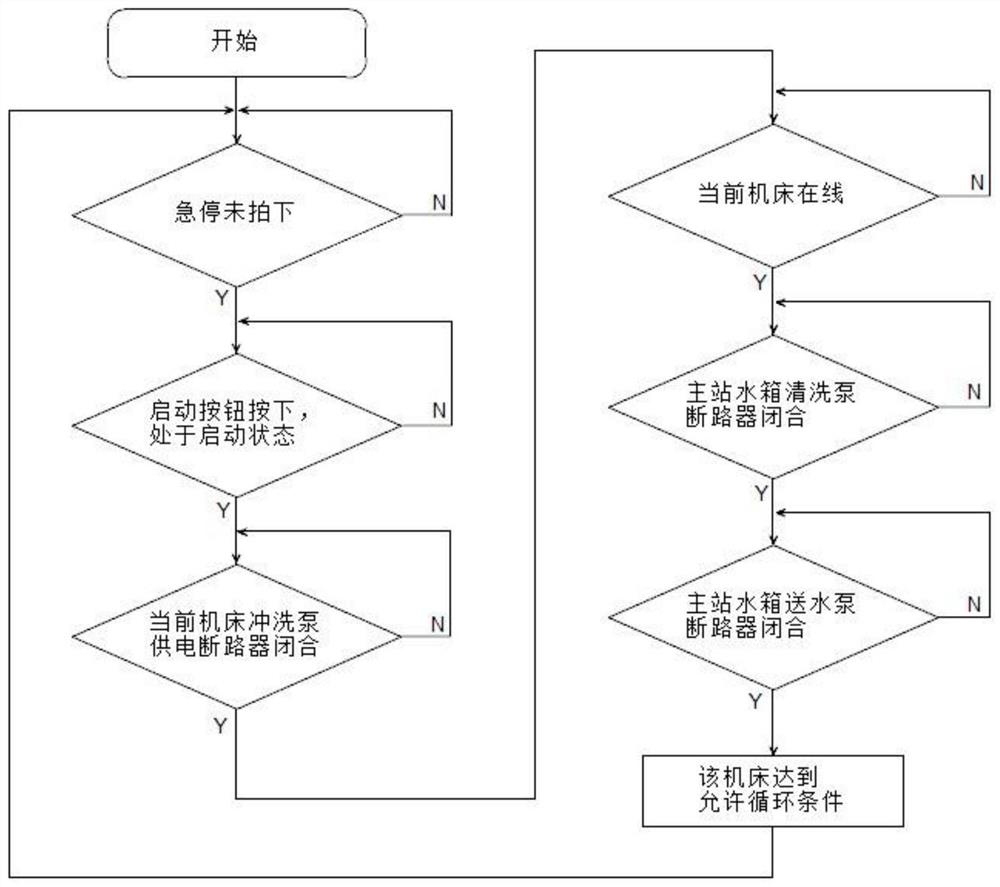

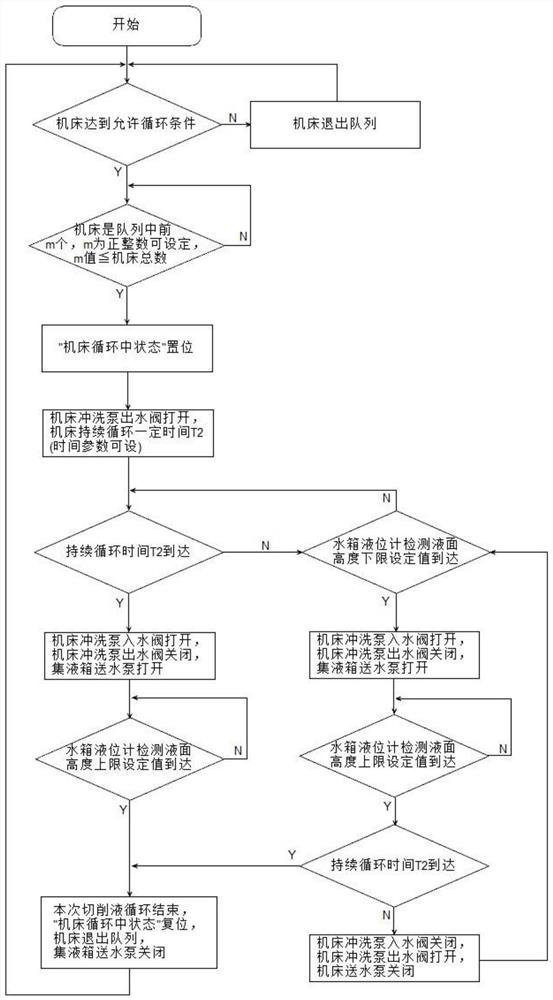

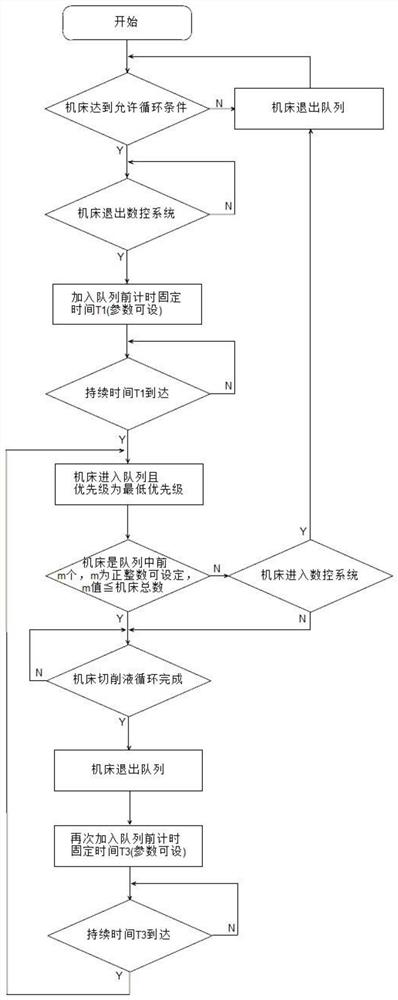

[0047] The present invention is an engraving center cutting fluid centralized processing control system, including n engraving centers and their cutting fluid water tanks, an electrical control cabinet, a liquid collection tank, a main liquid return pipeline and a main liquid delivery pipe Road, each branch cutting fluid circuit, n is a positive integer, among them, each engraving center cutting fluid water tank contains a flushing pump, 3 solenoid valves (water outlet valve, water inlet valve, machine tool flushing valve) and 1 liquid level sensor. The liquid tank includes a water delivery pump, a clean water pump and a liquid level sensor.

[0048] The electrical control cabinet is equipped with n "online / offline" knobs, n is a positive integer, and the "ON / OFF" of each knob indicates whether the cutting fluid of the engraving center water tank participates in automatic circulation.

[0049] ①Install the following components at the water tank of the single engraving center: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com