Locomotive anti-freezing solution spraying device and spraying system thereof

A technology of spraying device and spraying system, applied in liquid spraying device, spraying device and other directions, can solve problems such as low construction efficiency, achieve the effect of improving construction efficiency, reducing aging phenomenon, and simple and convenient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-7 The application is described in further detail.

[0043] The embodiment of the present application discloses an antifreeze spraying device for a locomotive.

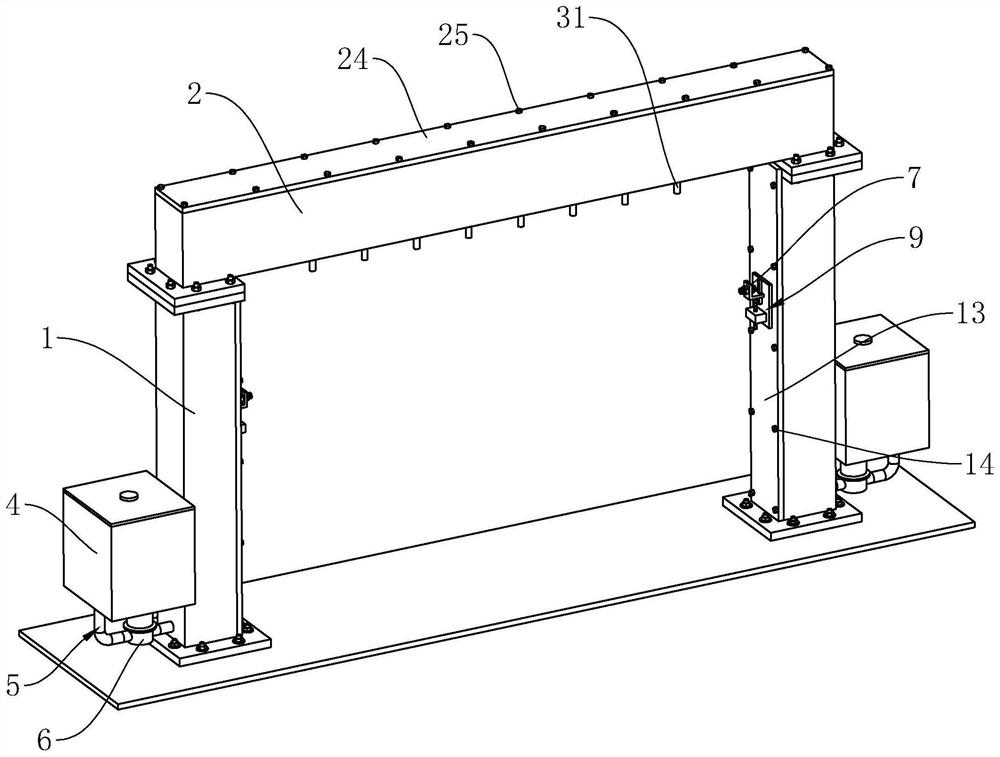

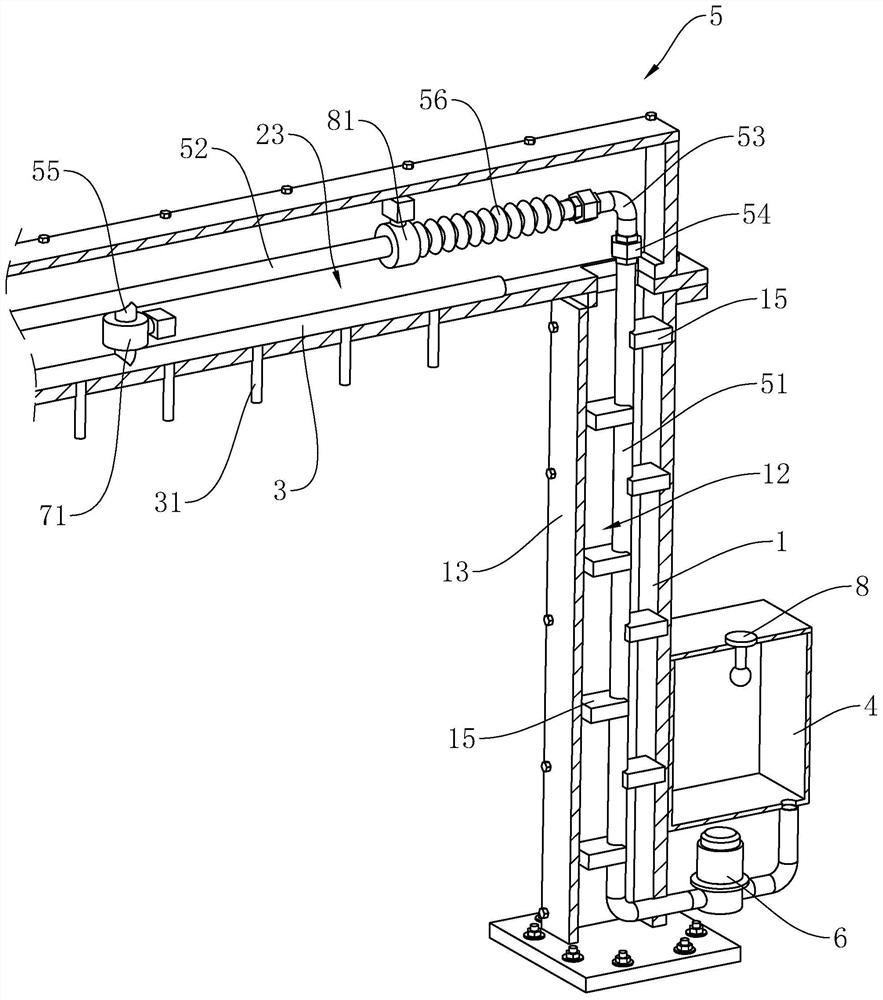

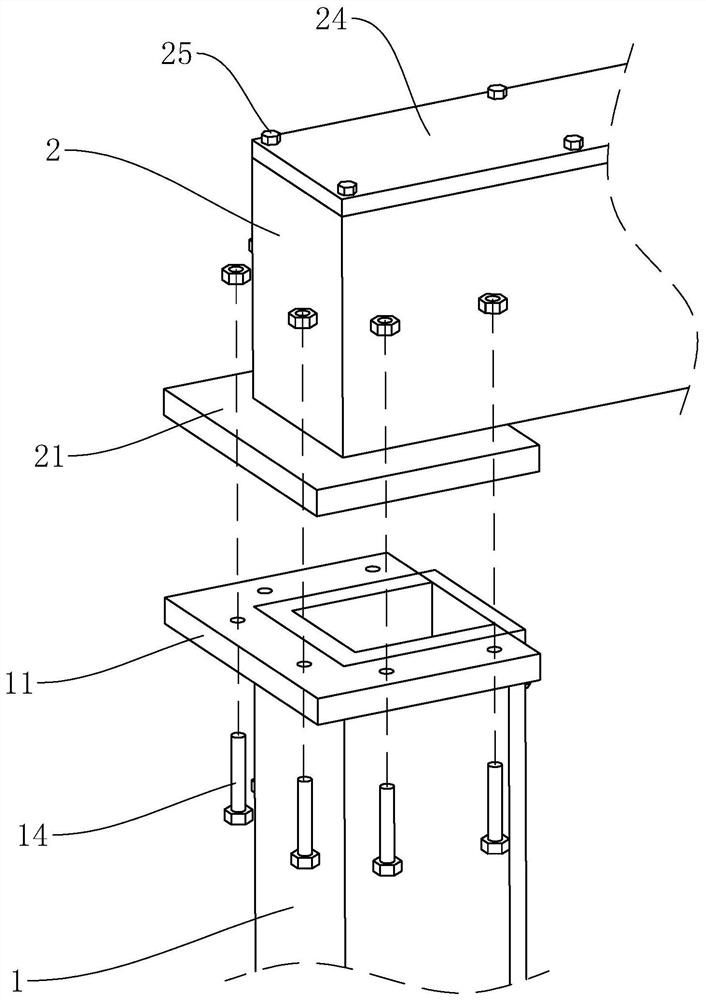

[0044] refer to figure 1 and figure 2The spraying device includes a support frame and a spray mechanism arranged on the support frame; the support frame includes two columns 1 and a beam 2 arranged between the tops of the two columns 1, and the two columns 1 are located on both sides of the track, The crossbeam 2 is supported above the track, and the two ends of the crossbeam 2 are detachably connected to the two columns 1 respectively; the spraying mechanism includes a spray pipe 3 installed on the crossbeam 2 and a plurality of spray heads 31 arranged on the spray pipe 3 , two liquid storage tanks 4 respectively arranged on the side walls of the bottom ends of the two columns 1, and the delivery pipeline 5 communicating the liquid storage tank 4 with the spray pipe 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com