Recyclable steel structure filled retaining wall

A technology for steel structures and retaining walls, which is used in fillings, safety devices, mining equipment, etc., can solve the problems of harsh requirements for retaining walls, difficult equipment maintenance, high costs, etc., and achieves good slurry retaining effect and simple construction. Fast, well-stressed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

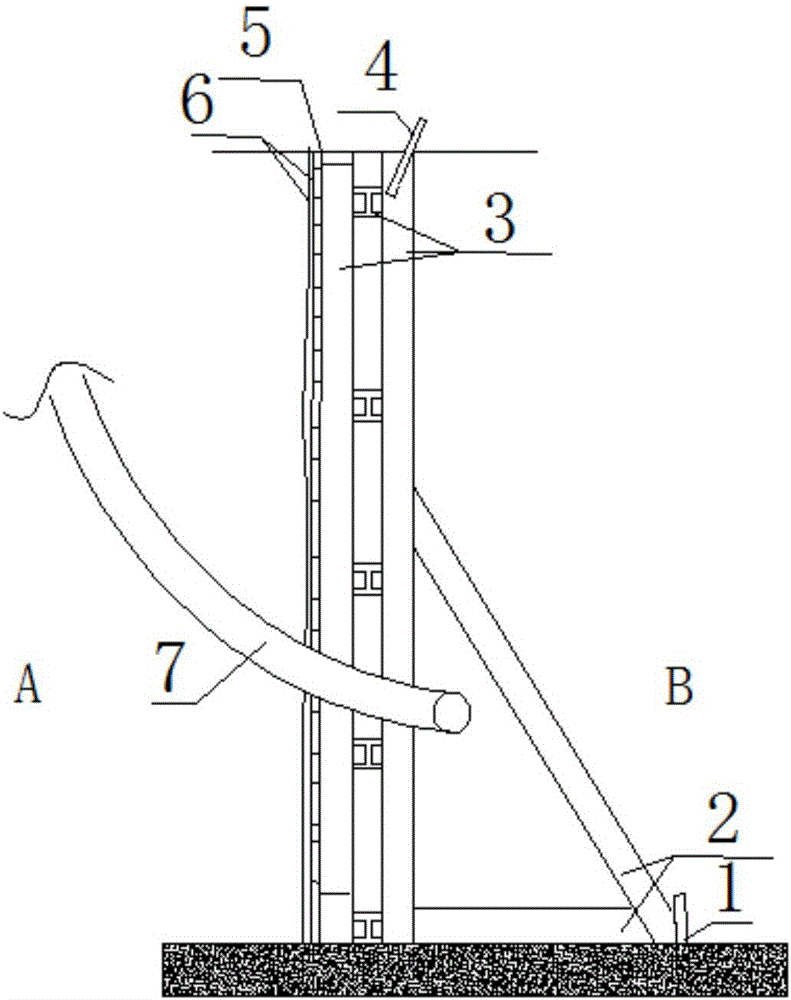

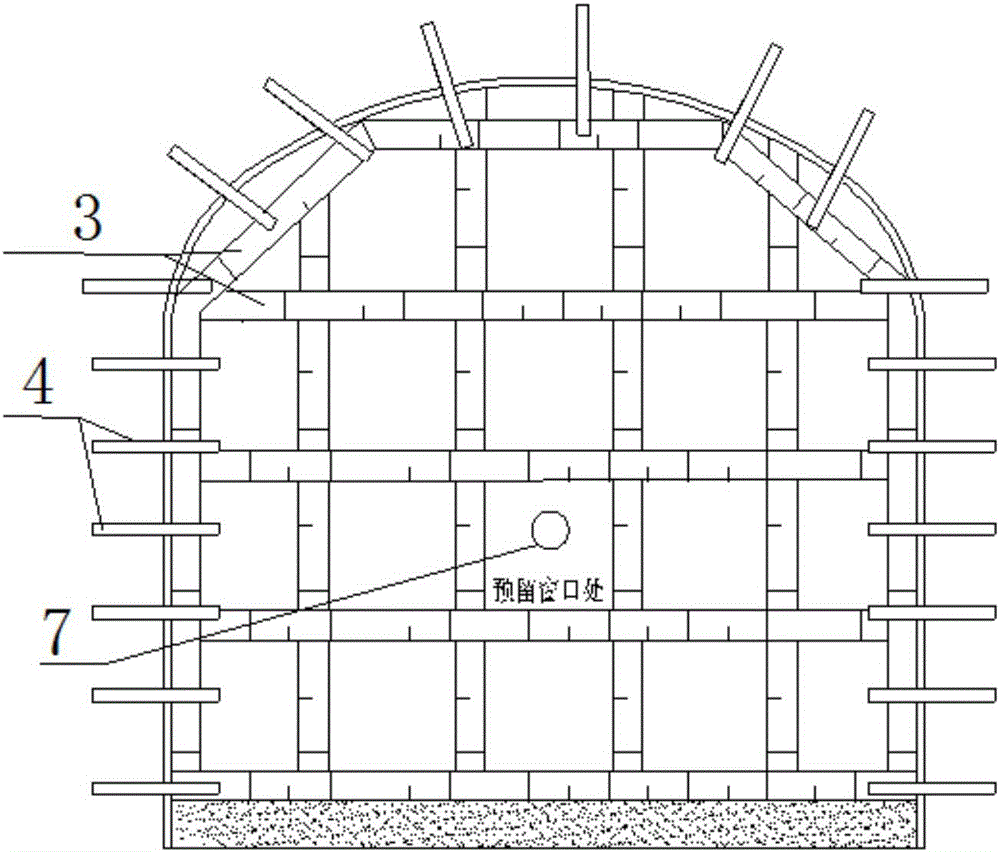

[0023] See attached picture:

[0024] The recyclable steel structure filling retaining wall includes a composite wall composed of a number of wall fixed round steel 4, I-shaped steel structure wall 3, mesh 5, and water filter cloth 6 stacked together in sequence. The composite wall is installed in mining Between the empty area A and the roadway B, the back of the composite wall is provided with I-shaped steel supports 2 and several support fixed round steels 1 for fixing, the composite wall 4 fixed round steels are arranged at intervals on the outer periphery of the composite wall, and the composite wall fixed round steels 4 The end is anchored into the surrounding rock for fixing, and the supporting and fixed round steel 1 is anchored into the bottom of roadway B, and a grouting sealing is provided between the composite wall and roadway B.

[0025] The I-beam structural wall 3 includes wall panels arranged at intervals. I-beams are arranged at intervals from top to bottom bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com