Concrete pouring height real-time monitoring method and system

A real-time monitoring system and real-time monitoring technology, applied in the direction of height/level measurement, thermometer, measuring device, etc., can solve the problems of troublesome operation, impracticality, and failure to provide pouring height, etc., to achieve multiple temperature monitoring points, real-time and accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

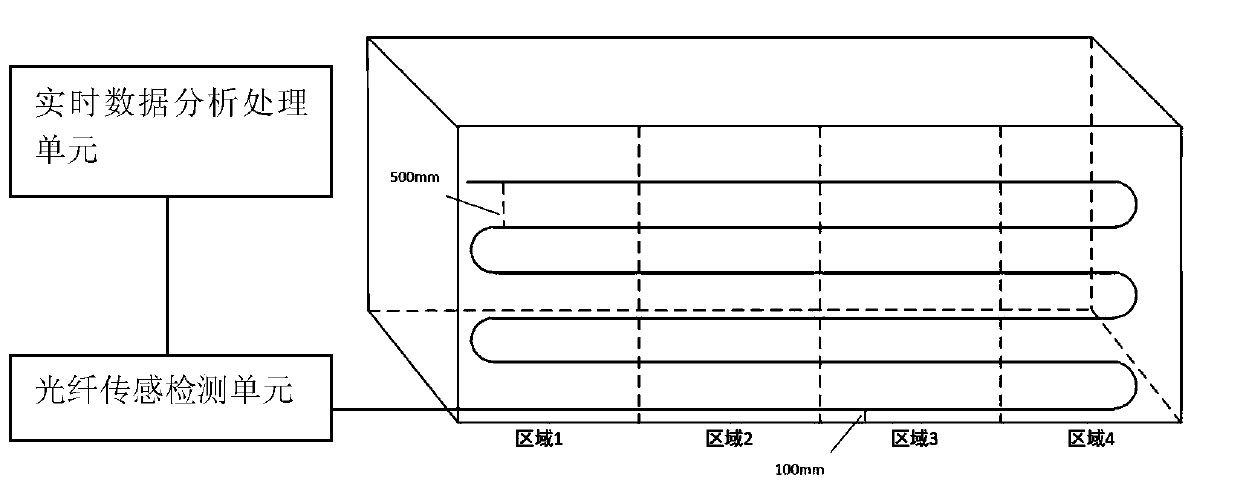

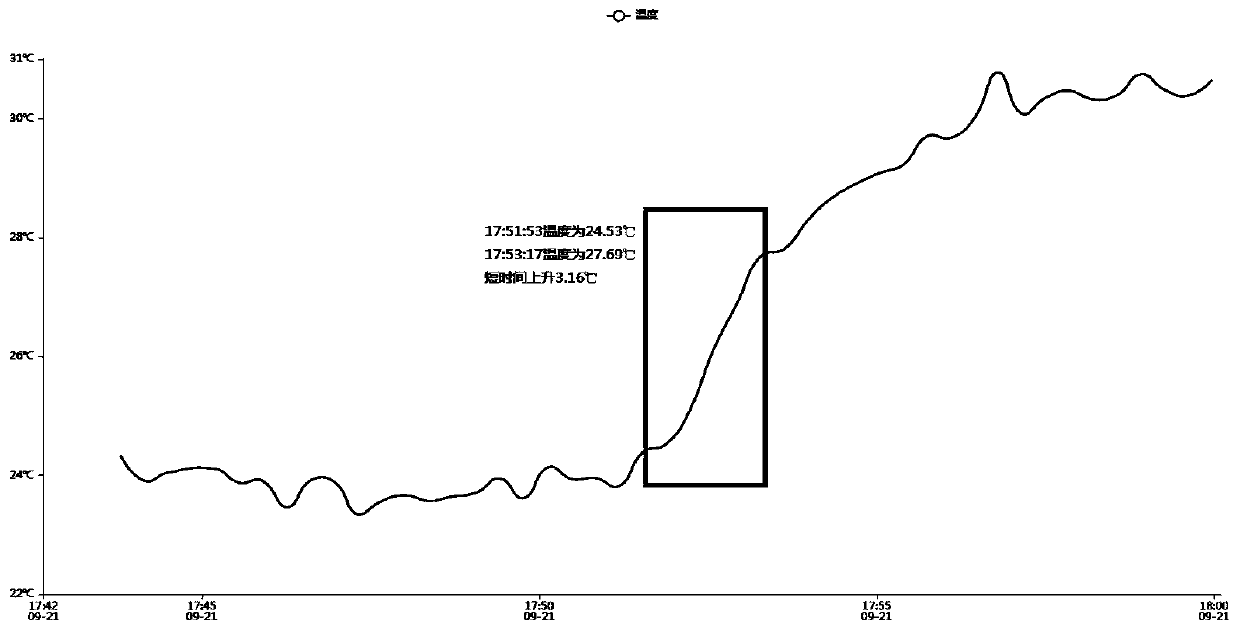

[0023] Distributed optical fiber temperature sensor (DTS) realizes temperature monitoring based on the principle of optical time domain reflectance (OTDR) and the sensitivity of Raman (Raman) scattering effect to temperature. The advantages of the environment. Before the concrete is poured, the optical fiber is laid along the steel frame, and the DTS monitors the ambient temperature. After the concrete is poured, due to the temperature difference between the concrete temperature and the ambient temperature, the fiber temperature of the covered concrete has a rapid change in a short period of time. Through this rapid temperature change phenomenon, the position where the concrete has been poured can be inferred, and thus the Concrete height and layer height.

[0024] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

[0025] As shown in the figure, the present invention provides a real-time monitoring sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com