Automatic dispatching method for water source well of waterworks

An automatic dispatching, waterworks technology, applied in control/regulating systems, instruments, program control in sequence/logic controllers, etc. Production and management efficiency and other issues, to achieve the effect of promoting intelligent operation management, saving time and manpower, and improving production and management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

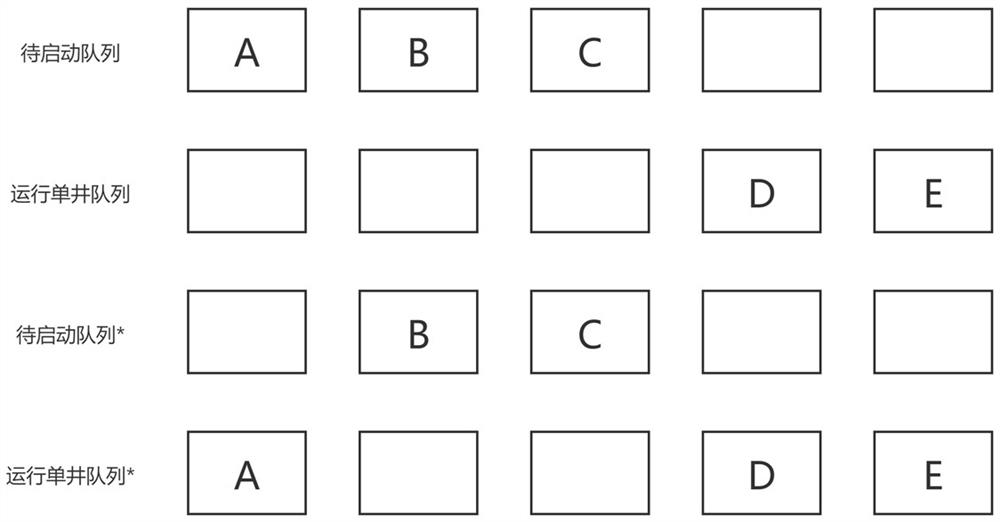

[0065] Embodiment one is to start the single well process:

[0066] 1. The running status of single wells A, B, C, D, and E is collected by the PLC module of the general control of the water plant;

[0067] 2. Among them, A, B, and C are single wells that have stopped working, and D and E are single wells that are running;

[0068] 3. Put A, B, and C into the queue to be started, and put D and E into the single-well running queue.

[0069]4. Count the power consumption per ton of water of all single wells in the queue to be started, and count the power consumption per ton of water of all single wells in the queue of running single wells;

[0070] 5. Based on the power consumption per ton of water, sort the single wells in the queue to be started and the single well in operation in order from large to small, where the queue to be started is in the order of A, B, and C , the order of running the single well queue is D, E.

[0071] 6. After the water plant master control PLC m...

Embodiment 2

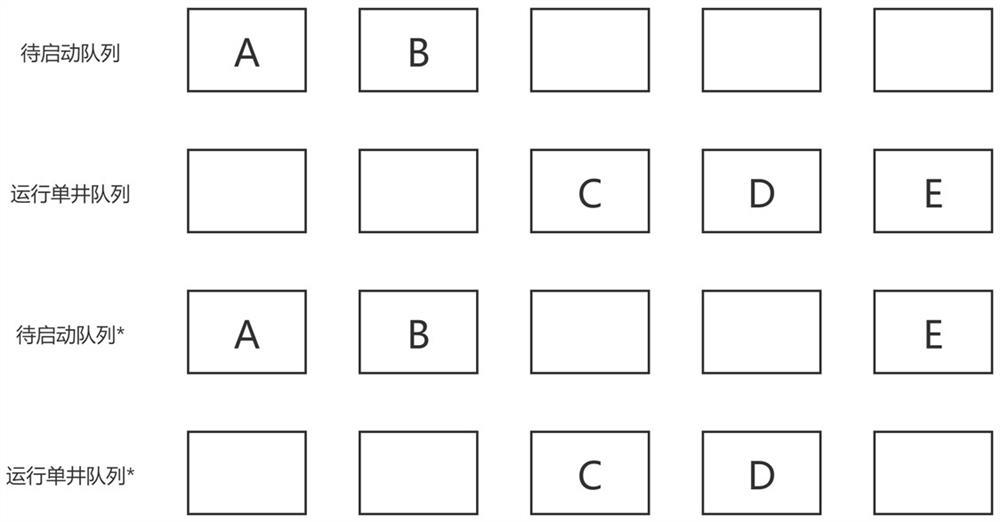

[0074] Embodiment two is to close single well process:

[0075] 1. The running status of single wells A, B, C, D, and E is collected by the PLC module of the general control of the water plant;

[0076] 2. Among them, A and B are single wells that have stopped working, and C, D, and E are single wells that are in operation;

[0077] 3. Put A and B into the queue to be started, and put C, D, and E into the running single well queue.

[0078] 4. Count the power consumption per ton of water of all single wells in the queue to be started, and count the power consumption per ton of water of all single wells in the queue of running single wells;

[0079] 5. Based on the power consumption per ton of water, sort the single wells in the queue to be started and the single well in operation in order from large to small. The sequence of the single well queue is C, D, E.

[0080] 6. After the water plant master control PLC module judges that a single well needs to be shut down, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com