Automatic ink supply system

An automatic ink filling and ink supply technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of unstable ink quality and difficulty in accurately controlling the amount of ink in the ink cartridge, and achieve the effect of improving quality and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

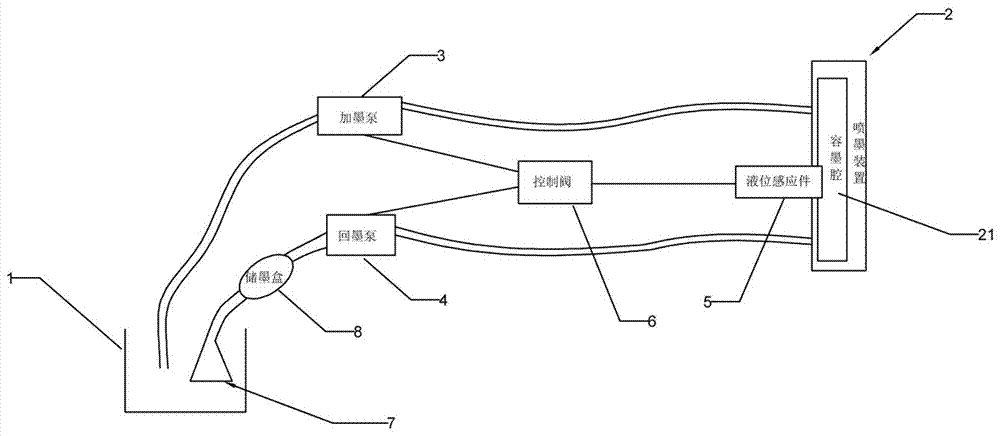

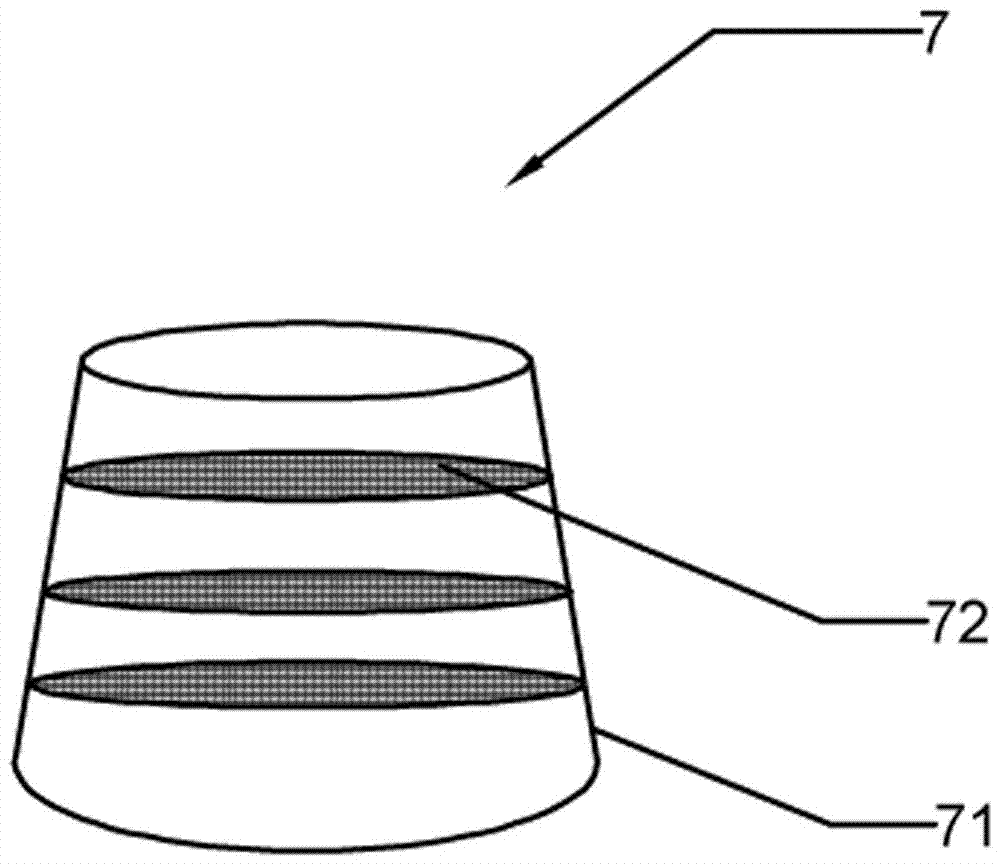

[0014] see figure 1 , figure 2 , a kind of automatic ink supply system of the present invention, is used for automatically adding ink for screen ink printing machine, comprises printing workbench and oil drum 1, and one end of described printing workbench is provided with the ink chamber 21 that holds ink Inkjet device 2; includes an ink filling pump 3, an ink return pump 4, a liquid level sensor 5 for sensing the ink level of the ink chamber 21 and an electrically connected ink filling pump 3, return ink pump The control valve 6 of the ink pump 4 and the liquid level sensor 5, the input port of the ink filling pump 3 communicates with the oil barrel 1, and the output port of the ink filling pump 3 communicates with the inkjet device 2; the ink return pump The input port of 4 is connected to the inkjet device 2, and the output port of the ink return pump 4 is connected to the oil tank 1; the control valve 6 is used to sense that the liquid level of the liquid level sensor 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com