Control device for underground layered flow rate of water injection well

A technology for control devices and water injection wells, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of difficult docking, low success rate of fishing, and inapplicability, and achieves high temperature and pressure resistance , wide flow range and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

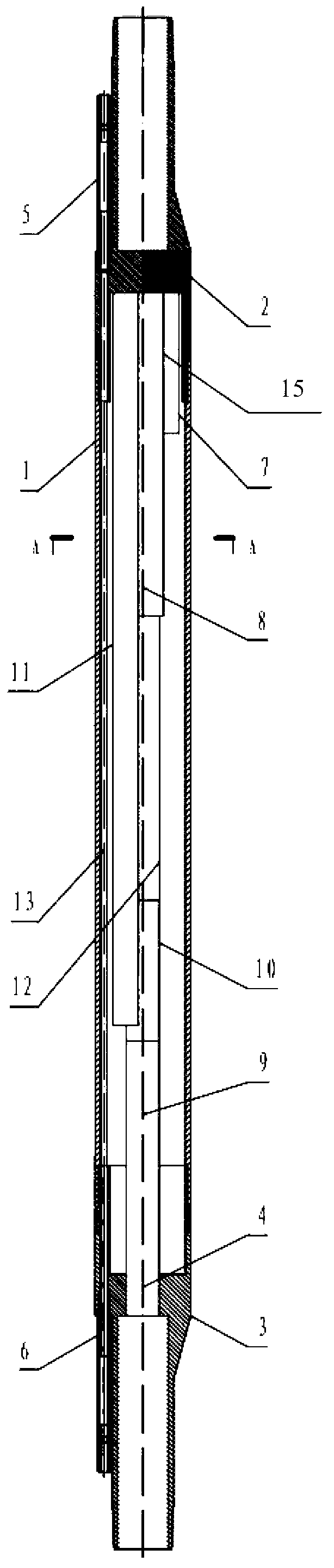

[0030] see figure 1 and figure 2 , a control device for downhole stratified flow of water injection wells comprising: a cylindrical controller main body 1,

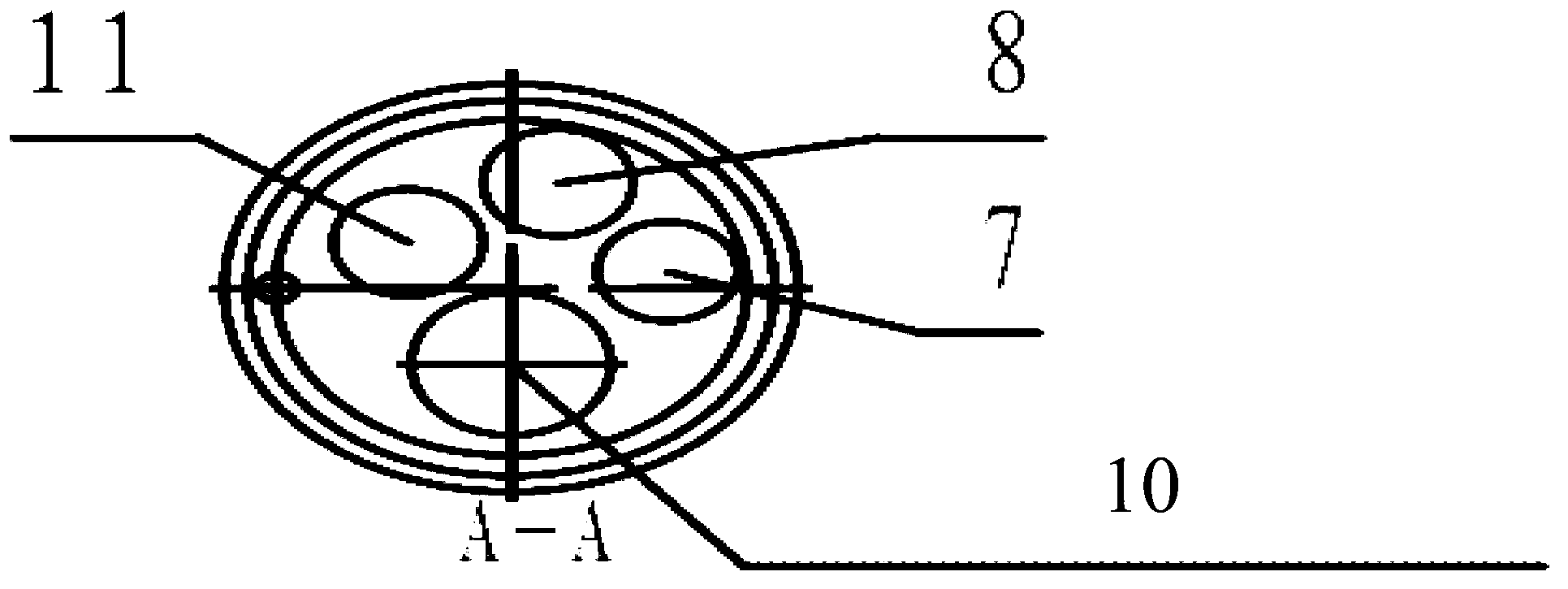

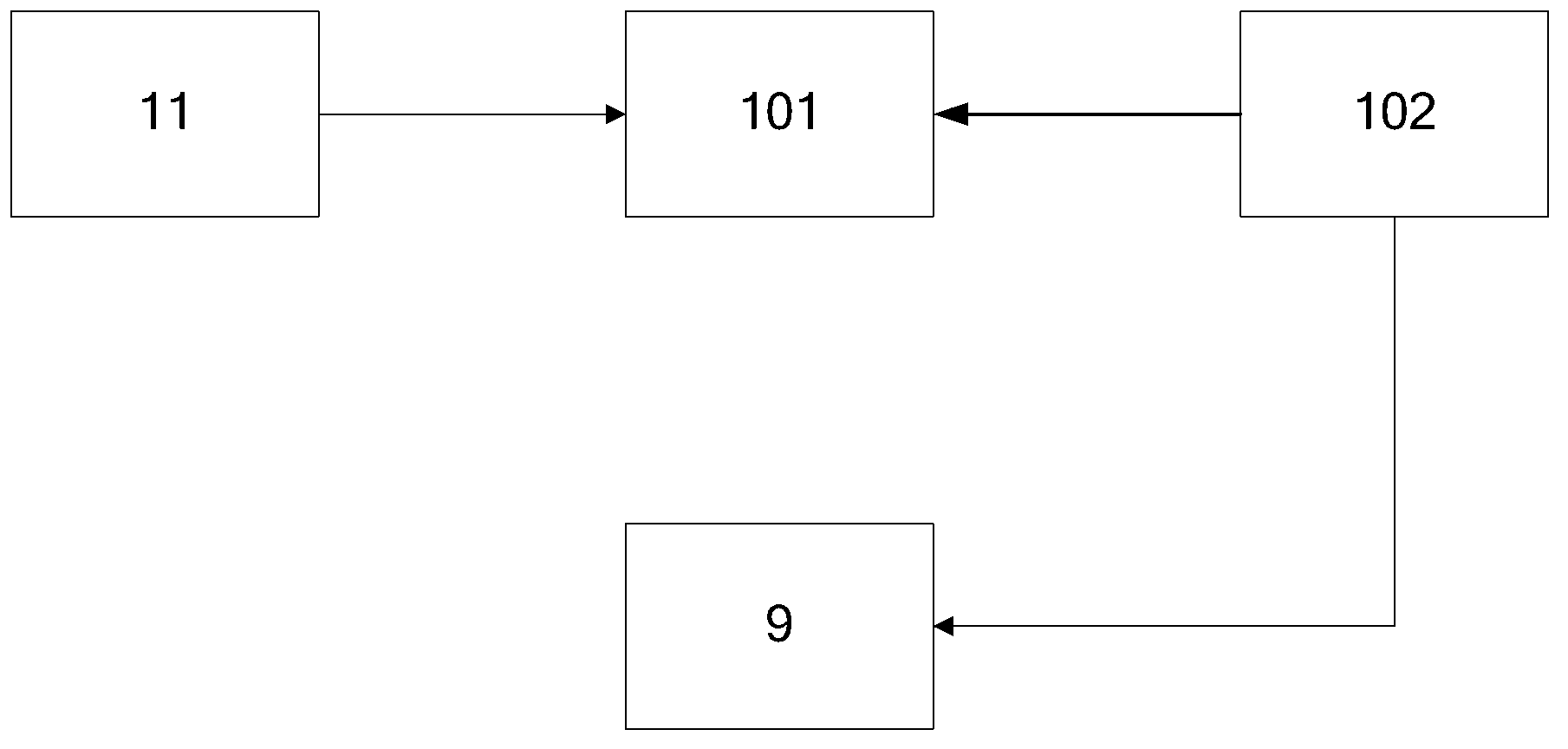

[0031] The top and bottom of the cylindrical controller body 1 are respectively provided with an upper joint 2 and a lower joint 3, and the lower end is provided with an actuator 10, and the interior runs through the flow channel 12 and the cable 13; the upper and lower ends of the cable 13 are respectively provided with cable upper joints 5 and the cable lower joint 6; the cylindrical controller main body 1 is connected with the flow meter 7 and the measurement and control unit 11; the actuator 10 is connected with the electric adjustable water nozzle 9; Liquid port 15; the main body of the cylindrical controller 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com