Round twist pin connector

A technology of twist pins and connectors, which is applied in the direction of fixed/insulated contact components, bases/shells, etc., can solve the problems of unstable connection, poor reliability, and large connector size, and achieve compact structure, good temperature and pressure resistance , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

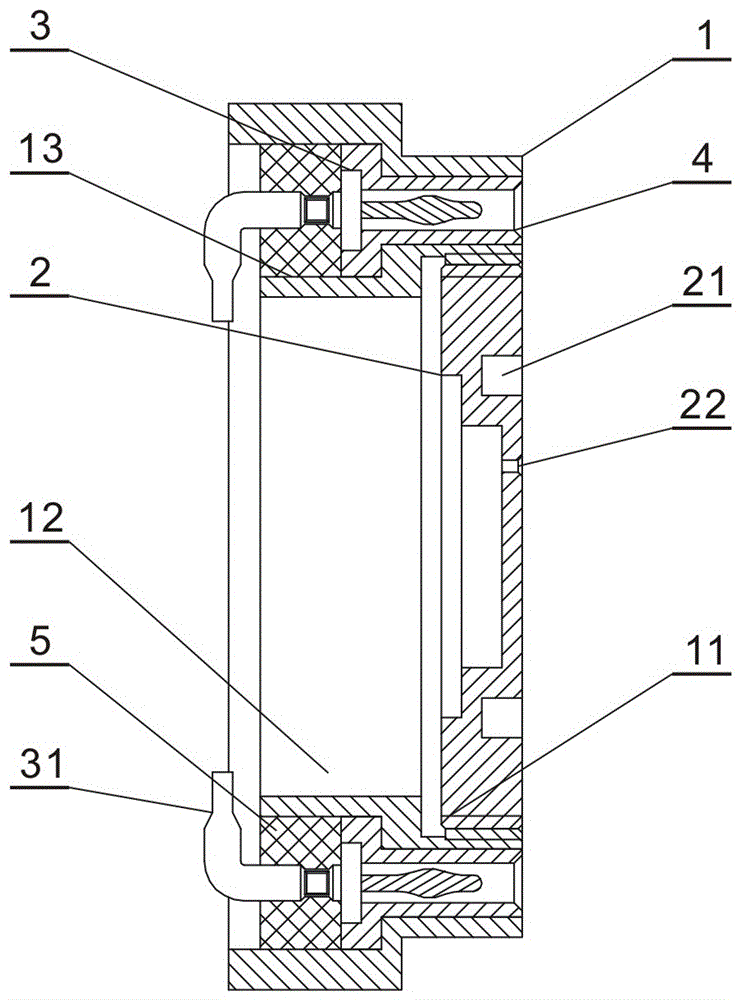

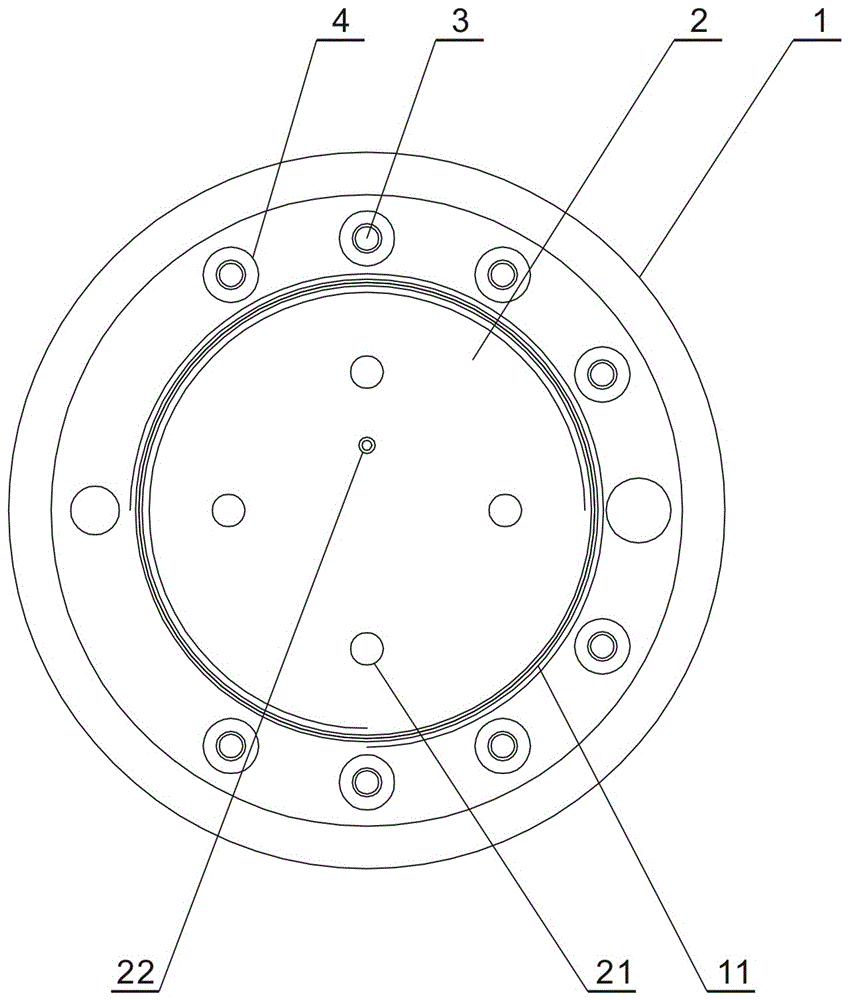

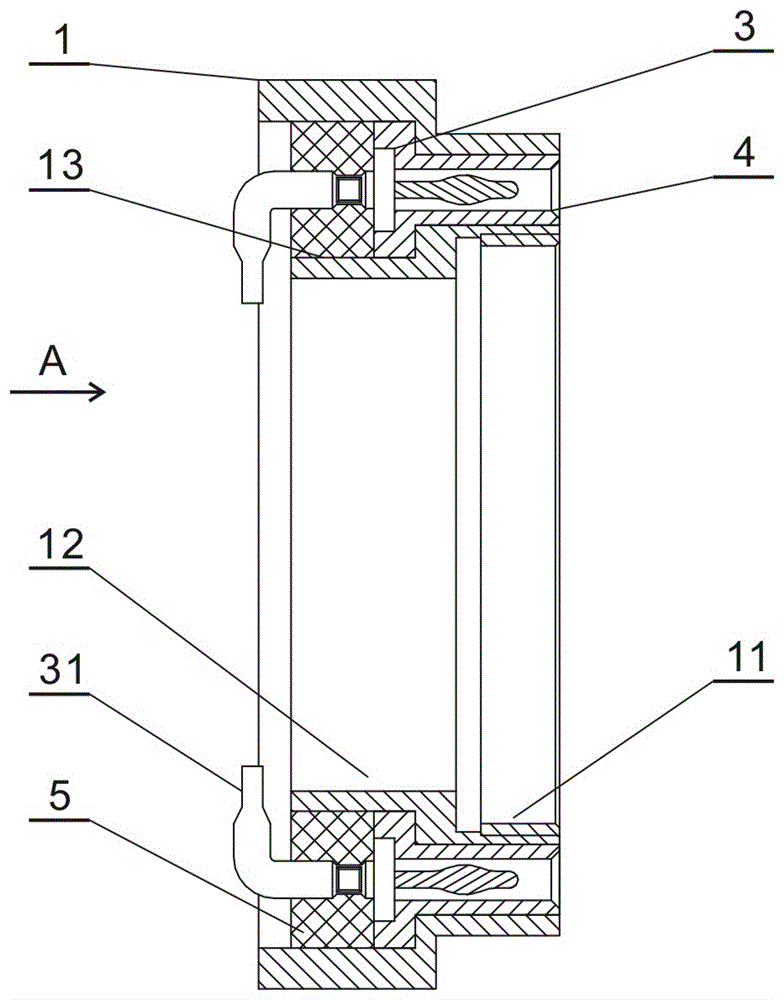

[0012] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes an upper cover 1, an end cover 2, a twist needle fitting 3, an insulating sheath 4 and a potting glue 5;

[0013] refer to figure 1 , figure 2 , image 3 , the upper cover 1 is in the shape of an annular disk, the inner circle of the annular disk is provided with an end cover seat 11 axially upward, and a microelectronic component seat 12 is provided below, and the disk surface of the annular disk is provided with several A twist needle seat 13, wherein the end cover seat 11 is provided with internal threads;

[0014] refer to figure 1 , figure 2 , the end cover 2 is a disc member with a recess in the middle and an external thread on the outer diameter. Four blind holes 21 are arranged on the disc surface along the circumference, and a vent hole 22 is provided between the middle part and the recess. ;

[0015] refer to image 3 , Figure 4 , the tail of the needle body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com