Heat-insulating integrated continuous fiber prepreg tape enhanced composite pipe and processing method

A technology of reinforced composite and continuous fiber, which is applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, which can solve the problems of thermal insulation failure of composite pipes, achieve the effect of improving rigidity and water resistance, reducing labor and cost, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

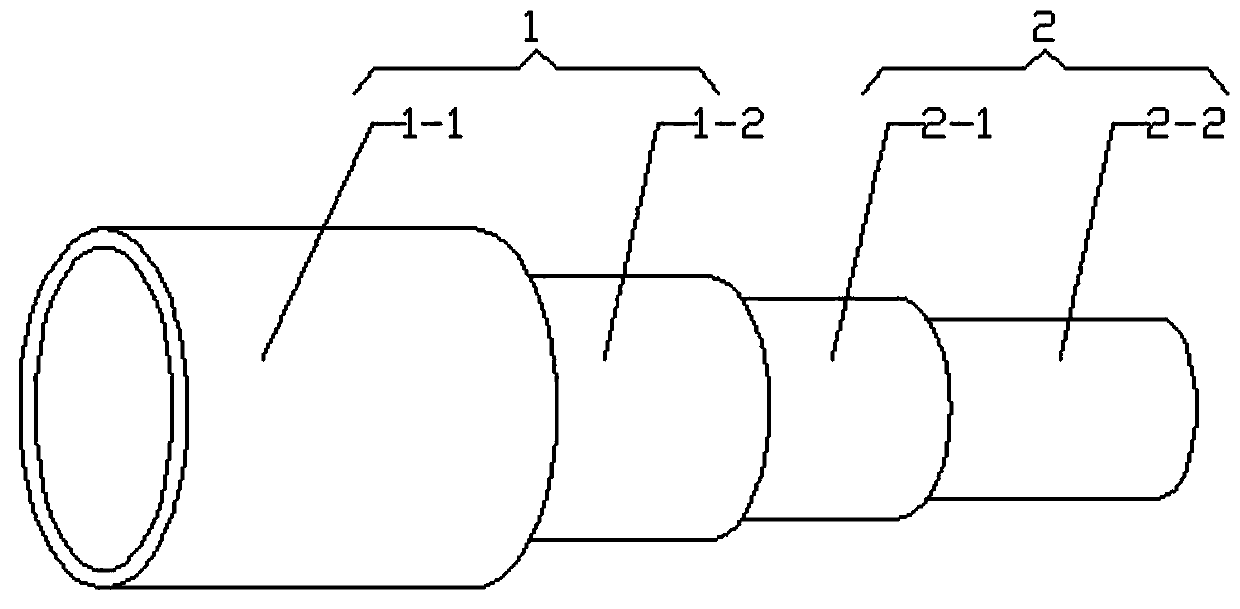

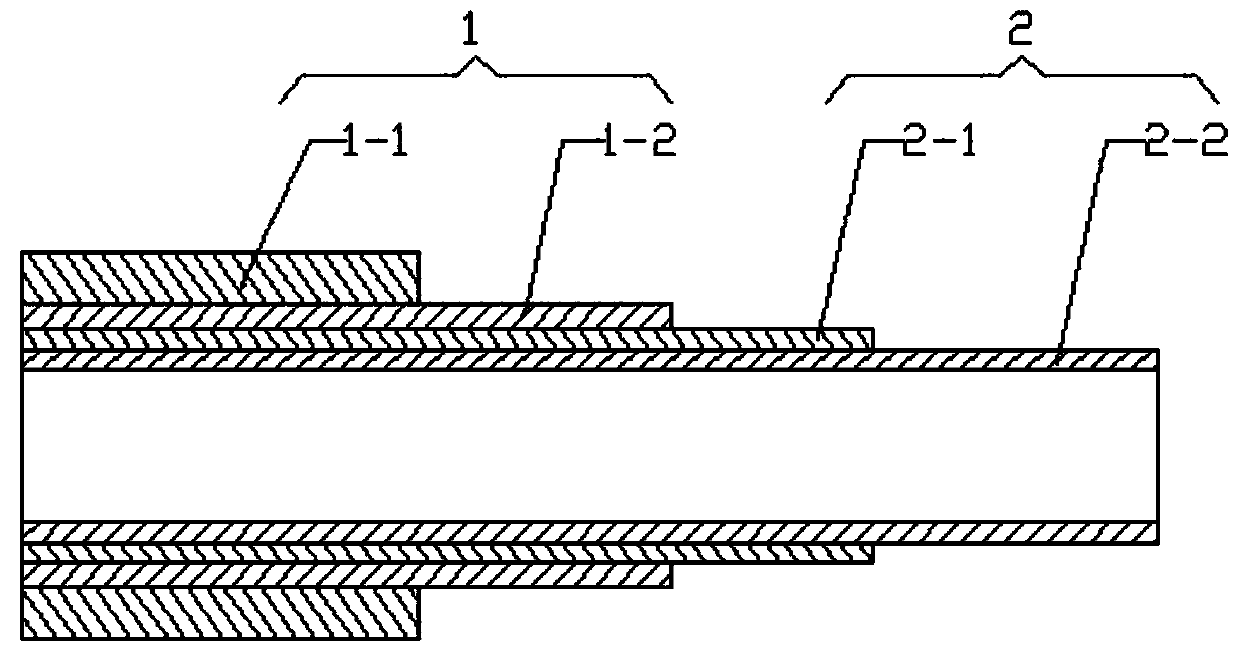

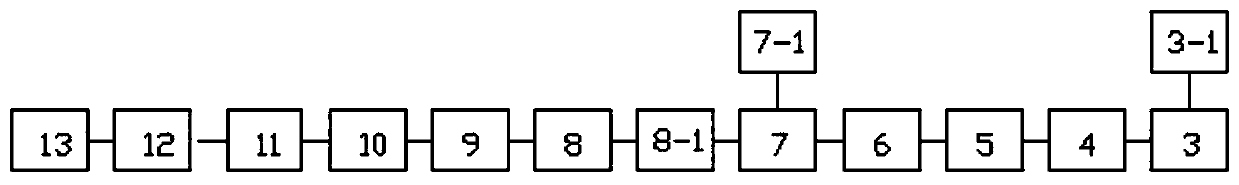

[0047] Such as Figure 1-4As shown, a thermal insulation integrated continuous fiber prepreg tape reinforced composite pipe and its processing method include a foam insulation pipe 1 and a heat-resistant and pressure-resistant working pipe 2. The plastic outer protective surface layer 1-1 and the foam insulation layer 1-2 are integrally formed. The heat-resistant and pressure-resistant working pipe 2 is integrally formed by a plastic inner layer pipe 2-2 and an isomorphic structural prepreg tape reinforcing layer 2-1 that is melted and wound on the outer wall of the plastic inner layer pipe 2-2. The prepreg tape reinforcement layer 2-1 is fused with the foam insulation layer 1-2, which improves the pressure and temperature resistance and overall rigidity of the working pipeline, as well as the rigidity and waterproofness of the insulation layer.

[0048] The foam insulation layer 12 is compounded with hot melt adhesive, AC foaming agent, and mixed plastics. The mixed plastics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com